The design and principle of operation of a front-wheel drive car transmission

A transmission is a complex of units and mechanisms that connect the crankshaft of a car engine (shaft with flywheel) to the driving pair of wheels of a car.

The operating principle of the transmission involves the transmission of rotation (torque) from the motor to the drive wheels. It is the transmission that allows the driver to change the torque indicator, and, if necessary, reverse movement, the direction of the torque. Passenger cars can be divided based on which wheels the transmission turns into front-wheel drive, rear-wheel drive and all-wheel drive. Let's consider the chain of torque transmission operations. First the engine, then the clutch, after it - the gearbox, then the cardan transmission (propeller shaft), the axle (rear or front), this is the main gear, including the differential and axle shafts, which are equipped with constant velocity joints (CV joints), to to which, in fact, the drive wheels are attached. It should be noted that on a car with front-wheel drive, the torque “rotates” just under the hood, because all the transmission units are located there. It is necessary to briefly dwell on CV joints - these special joints that make it possible to transmit torque to the front drive wheels, without taking into account their position (it doesn’t matter whether they are turned or not).

Let's take a closer look at the design and operating principle of the transmission of a front-wheel drive car, which includes:

· firstly, it is the clutch, which provides communication between the engine and the gearbox;

· thirdly, the drive shafts themselves.

There are two types of gearboxes in modern cars: synchronized gearboxes and non-synchronized (cam) gearboxes. And if we consider their differences according to the switching principle: simple (otherwise H-scheme) or sequential (with sequential gear selection).

Front-wheel drive cars at the racing level use non-synchronized gearboxes, which have a number of advantages:

· they are able to withstand more loads (thanks to the special shape of the gear tooth and the meshing principle);

· it takes less time to shift the gearbox, since the clutch may not be fully depressed;

· synchronizers are not destroyed.

Let's analyze such an interesting indicator as the gear ratio.

Among other things, the transmission design of a front-wheel drive car requires special tuning gear rows (they are also called commercial rows).

In addition to all of the above, experts advise installing a high-friction differential. A significant advantage of this car with this device becomes noticeable in a very unpleasant situation - if the wheel begins to slip. In such cases, due to the triggering of the locking, the axle shafts acquire a rigid connection. The wheel, which has normal grip on the surface, begins to rotate. The locking is turned off only after the torque between the axle shafts is equalized, and, of course, the differential then functions normally.

If a car has a locking system, the grip on the road surface is significantly improved, and this increases the level of car controllability.

Source

Advantages of front-wheel drive cars

Speaking about front-wheel drive models, first of all, it should be noted that today over 70% of all automakers specialize in producing models with front-wheel drive transmissions. This is no coincidence: front-wheel drive models are significantly cheaper to produce than rear-wheel drive or all-wheel drive cars.

Moreover, such a design contains fewer elements, and the fewer structural units in the mechanism, the simpler the technological process of its assembly and the higher its reliability during operation.

If we talk about the advantages of front-wheel drive cars from the point of view not of the manufacturer, but of the consumer, here the following points first of all attract attention:

- Front-wheel drive car models are usually compact and lightweight. This makes this design very attractive for small-volume solutions, which are now so in demand in urban environments.

The absence of a driveshaft in a front-wheel drive design significantly increases the size of the interior compared to a car of the same dimensions but with a rear-wheel drive transmission.

The driving front wheels greatly facilitate the parking process. This is especially true in winter, when vehicle maneuverability in small areas can be difficult.

A car with front-wheel drive usually moves more steadily. This is due to the fact that the engine and gearbox in such models are placed perpendicular to the motion vector, creating a so-called “gyroscope effect” when driving, stabilizing and leveling vibrations outside the motion vector.

The front wheels bear the main load from the weight of the engine and gearbox. This makes a car with front-wheel drive more off-road than a car with rear-wheel drive and similar other characteristics.

The efficiency of the rear-wheel drive design is due to the fact that when making a turn, the drive wheels coincide in the direction of movement, and are not located tangentially, as happens in a car with a rear-wheel drive transmission type.

- The braking process on a front-wheel drive car is faster and sharper. In some cases, this can be an essential aspect of ensuring traffic safety.

- shortage of parking spaces;

- the need to save fuel;

- the issue of the relationship between stability and maneuverability;

- traffic safety issue.

All of the above points really make a front-wheel drive car very attractive, because it solves a number of problems

, which accompany the car in a densely populated city with heavy traffic:

Car transmission

Install the internal combustion engine under the hood of the car, attach the wheel clutch to the crankshaft and you won’t be able to drive - the engine will simply stall. Why? The car engine will not have enough power to spin the wheels to operating engine speed in a split second, which is approximately 2000 rpm; the weight of the car and the friction force that occurs when the wheels adhere to the road surface will interfere. Exit? Install an intermediate mechanism that will reduce the engine torque to the required speed and transmit it to the drive wheels. This mechanism, consisting of several components, is called a transmission.

The main purpose of the transmission is transmission, step-by-step regulation, and distribution of torque from the engine flywheel over the drive wheels. Conventionally, the transmission, according to the transmission method, can be divided into:

The transmission includes several components:

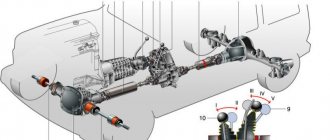

Transmission of a front-wheel drive car

Front-wheel drive and rear-wheel drive vehicles have differences in the transmission system. On cars where the front wheels are driving (front-wheel drive), the transmission with all its components is installed under the hood. As for the gearbox, it also includes a main gear with a differential. Therefore, in this case, the drive shafts to the front wheels come out of the gearbox housing. On front-wheel drive vehicles, the transmission system consists of the following components:

A distinctive feature of the front-wheel drive transmission is the placement of the main gear and differential directly in the gearbox housing. Well, the front axle in this case is a drive axle, with steering wheels.

Rear wheel drive car transmission

The rear-wheel drive transmission includes the following interconnected elements:

It is worth noting that on rear-wheel drive cars the gearbox is installed on softer supports, which reduces vibration levels and creates additional comfort. The transmission of a car with rear-wheel drive is characterized by the fact that the most common option for the location of the gearbox is its blocking together with the clutch to the rear axle via a cardan shaft. This option leads to a concentration of the center of mass in the area of the front axle. It should be noted that the rear-wheel drive version of cars is considered classic, and the transmission in this case is simpler in design and operation.

Description of the design of the front wheel drives of a car with a JH3 gearbox

Drives of the right “A” and left “B” wheels

1 – outer hinge body; 2 – large clamp for securing the outer hinge cover; 3 – cover of the outer hinge; 4 – small clamp for fastening the outer hinge cover; 5 – damper; 6 – right wheel drive shaft; 7 – small clamp for fastening the cover of the internal hinge of the right wheel drive; 8 – cover of the internal hinge of the right wheel drive; 9 – large clamp for fastening the cover of the internal hinge of the right wheel drive; 10 – housing of the internal hinge of the right wheel drive; 11 – three-pin joint of the left wheel drive; 12 – holder for the cover of the left wheel drive internal joint; 13 – cover for the internal joint of the left wheel drive; 14 – clamp for fastening the cover of the internal joint of the left wheel drive; 15 – left wheel drive shaft.

Wheel drives with constant velocity joints (CV joints) are used to transmit torque from the main gear to the drive wheels at different wheel rotation angles and suspension strokes.

When designing, they try to make drives of the same length, since this condition ensures equality of forces and moments occurring on the drive wheels. It is difficult to fulfill this condition on a car with a transverse power unit, therefore, on such cars, as a rule, the right-hand drive is much longer than the left-hand drive.

For a car with a JH3 gearbox, design solutions were used to bring the lengths of the drive wheels closer together. The lengths of the drive wheels are brought closer together due to the different design of the internal hinges. In order to increase the length of the left wheel drive, the drive inner joint housing is made inside the gearbox housing. In order to reduce the length of the right wheel drive, the inner joint housing is moved away from the gearbox housing. To do this, an additional element was introduced into the design of the gearbox - a splined shaft, which is made integral with the differential side gear. A rubber damper is installed on the right wheel drive shaft. External and internal drive joints (Tripod type) have different designs. The drive joints are covered with dirt-proof covers.

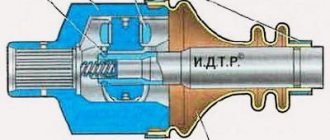

Elements of the internal hinge of the right wheel drive

1 – drive shaft; 2 – small clamp for securing the cover; 3 – hinge cover; 4 – large clamp for securing the cover; 5 – dirt deflector; 6 – hinge body; 7 – spring; 8 – three-pin retaining ring; 9 – spring thrust washer; 10 – three-spike.

The internal drive hinge allows for angular movements of the suspension and compensates for mutual movements of the suspension and power unit by changing the length of the drive shaft. The internal hinge is collapsible. At the splined end of the drive shaft, on the side of the internal hinge, there is a hub with three spikes - a three-spike, on each of the spikes (trunnion) of which there is a roller with an outer spherical surface, rotating on a needle bearing. The needle bearing is secured against displacement along the axis of the tenon by a locking ring placed on a retaining ring located in the groove of the tenon. The three-pin is fixed on the drive shaft with a retaining ring. Mutual movements of the suspension and power unit are compensated by the movement of the three-pin rollers in the longitudinal grooves of the internal joint housing.

The internal joints of the left and right wheel drives are not interchangeable.

Elements of the internal hinge of the left wheel drive

1 – clamp for securing the cover to the outer ring of the bearing; 2 – dirt-proof cover of the hinge; 3 – cover holder; 4 – three-spike retaining ring; 5 – three-spike; 6 – bearing; 7 – dirt deflector.

The tip of the housing of the internal hinge of the right wheel drive is put on the splined shaft coming out of the gearbox housing and made integral with the differential side gear (for clarity, shown on the dismantled gearbox).

A spring installed inside the housing of the internal hinge of the right wheel drive ensures that the hinge housing is pressed against the differential side gear when the suspension is operating.

The left wheel drive inner joint housing is located in the gearbox and is integral with the left differential side gear (shown with the drive removed).

Bearing (assembled with oil seal) of the left drive inner joint

A needle bearing assembly with an oil seal is installed on the left wheel drive shaft behind the three-pin of the internal joint.

The inner ring of the bearing is pressed onto the drive shaft and rotates with it. The protective cover of the inner hinge is secured to the fixed outer ring of the bearing with a clamp. The other end of the joint cover is attached to the gearbox housing through a metal flange holder.

A seal installed in the outer ring of the bearing prevents oil from leaking from the gearbox along the drive shaft. The bearing seal is protected from dirt by a plastic dirt deflector mounted on the shaft.

Note:

If the dirt-proof boot of the joint or bearing seal is damaged, oil will leak from the gearbox.

Outer drive joint

1 – fist; 2 – roller; 3 – three-spike; 4 – hinge body.

The external drive joint ensures transmission of torque at different angles of rotation of the drive wheels. The outer joints of the drives of both wheels are the same, they are non-separable and cannot be removed from the shafts.

The outer joint consists of a housing in which a three-pin joint with rollers rotating on needle bearings is rigidly fixed, and a knuckle made integral with the drive shaft. With mutual angular displacements of the body and the hinge knuckle, the three-pin rollers roll in the longitudinal grooves of the knuckle.

The outer joint housing fits into the splined hole of the wheel hub with a splined shank and is secured with a hub bearing nut.

The outer joints of both drives and the inner joint of the right drive are lubricated with MOBIL CVJ 825 BLACK STAR grease for their entire service life.

Replenishment or replacement of lubricant, as well as any other maintenance of wheel drive shafts, is not required during vehicle operation. The car owner only needs to monitor the condition of the protective covers of the hinges and their fastening clamps, as well as the condition of the bearing seal of the left-hand drive inner joint.

A damaged boot must be replaced as quickly as possible, since dirt getting into the lubricant causes rapid wear of the joint parts and its failure, and damage to the rubber boot or seal of the left drive inner joint bearing will lead to oil leakage from the gearbox and its failure. When installing a new hinge cover, its fastening clamps should also be replaced with new ones.

If the outer joint fails, the entire drive assembly must be replaced, and if the inner drive joint fails, only the joint can be replaced. The bearing (complete with oil seal) of the left wheel drive inner joint is supplied as spare parts along with a protective cover. The same bearing is used on Renault cars: Megan, Scenic, Clio, Twingo, Kangoo; Citroën Saxo; Peugeot 106; Volvo: 440, 460, 480. But the protective cover for the joint is different for these cars.

The article is missing:

- High-quality photos of repairs

Source: https://wiki.zr.ru/146-2_Largus

Tolyanych › Blog › Drive, transmission and a little physics!

Below for your consideration are a couple of articles about the difference in the drive, transmission and a little physics...

As one of my friends said, the passionate desire to perform on the track needs to be fueled by theoretical knowledge... so. we read and look for differences.)))

All information is honestly found on another site dedicated to karting by the user sokolov_drive...

My simple columns published in Automobiles magazine about the features of gearboxes and drive types.

FRONT DRIVE AND MANUAL TRANSMISSION

Front-wheel drive cars are the easiest to drive, they are the most stable and the most unambiguous in their reactions. It is not at all necessary to start your studies with a front-wheel drive car, but this is often what happens. Not least because most inexpensive mass-produced cars are front-wheel drive. This arrangement makes it possible to make the car simple, cheap and spacious, but it is difficult to talk about any advantages of front-wheel drive in relation to sports driving (only in cases of driving on dirt and snow, front-wheel drive cars often have an advantage over rear-wheel drive cars). The front wheels of such a car do the lion's share of the work - they accelerate the car and force it to turn. The load on the wheels of the front axle is enormous. At the same time, the rear tires are not busy with anything other than keeping the light rear of the car on the trajectory. Under thrust (see Kamm circle), the balance of a front-wheel drive car shifts more towards understeer the harder the driver presses on the gas.

This diagram is often used to illustrate the distribution of tire grip properties when a vehicle is moving. The circle shows the full grip potential of the tire in the contact patch. The resultant of the transverse and longitudinal components can be directed in any direction (1). So you can see that when the driver applies the gas or brake, the lateral component inevitably decreases (2), reducing the car's ability to stay on the turning arc and changing the balance of grip properties between the axles. Up to the complete loss of the ability to apply force in the transverse direction (3), if the drive wheels have turned or are blocked by the brake, that is, all the traction abilities of the tires have been used in the longitudinal direction. Thanks to this, for example, you can easily turn the car around by pulling the handbrake with drive to the rear wheels

Thus, to stabilize a front-wheel drive car, it is enough just not to give up the gas. This makes piloting easier. On the other hand, the car's ability to stay on the turning arc under traction is relatively small, especially in sharp slow turns - this limits the piloting capabilities. In order to provide a powerful exit from a corner, front-wheel drive cars have to make a deeper entry and a later apex, sacrificing speed in the corner.

sokolov-drive.com/livejournal/fwd.jpg

A front-wheel drive car has a limited ability to simultaneously accelerate and turn due to the fact that under gas the lateral grip of the front tires is small and the car tends to straighten its trajectory. To ensure a powerful exit, it makes sense to make a deep entry and a late apex to make the exit arc as shallow as possible

The disadvantages of front-wheel drive can be partially compensated by the use of self-locking differentials or systems that simulate their operation, and the maximum load of the front axle wheels. However, with each new generation of sports front-wheel drive cars, the inherent shortcomings of their layout are less and less noticeable, thanks to the work of engineers and tuners.

MECHANICS

Simple “mechanics” gives the driver maximum control over the car. He can engage any gear at any time and can use subtle manipulations of the clutch pedal to his liking. Until now, it was generally accepted that a manual transmission was the fastest when it came to driving on the track. Today this is not the case. Modern gearboxes without a third pedal often work faster than a person shifting a manual transmission. In addition, a manual transmission requires the most driver attention and the most serious skills. In fact, using manuals on the track in a powerful rear-wheel drive car is an art, not a craft. The use of a manual transmission in motorsport requires stable - brought to the level of reflexes - skills in shifting and operating with double clutch release, shifting with the side of the foot while braking and high sensitivity of the left leg, capable of handling both the clutch and the brake equally well. For those who are fluent in these - not the simplest - operations and have a good feel for the car, driving a manual transmission is a special pleasure. However, if we are talking about motorsports, then from the point of view of achieving results, any pilot will feel more comfortable if he gets rid of the need for complex leg manipulations, which complicate the precise dosing of gas and brakes. The main advantages of a mechanical transmission today are its low cost, simplicity and low weight.

How does the transmission of a front-wheel drive car work?

The transmission of a front-wheel drive car consists of the following main parts: a gearbox, which ensures the redistribution and transmission of torque and power to the wheels; clutch, due to which there is no connection or there is a connection between the gearbox and the engine itself; and drive shafts.

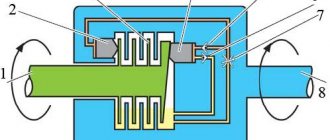

One of the most important elements of the transmission is the differential of a front-wheel drive vehicle, which is located in the gearbox along with the main gear. It is necessary in order to change, transmit and distribute torques between consumers, and also, if necessary, ensure their rotation at different angular speeds.

In addition, a distinctive feature of the device of these cars is the presence of constant velocity joints, through which torque is transmitted to the front wheels from the differential . Most often, four joints are used, two internal, attached to the differential, and two external, located on the wheels. Between these CV joints there are drive shafts.

Car transmission, circuit diagrams

Car transmission, circuit diagrams

The variable gearbox, interacting with other mechanisms and units that transmit torque from the car engine to its drive wheels, constitute one of the most important components called the car transmission.

While the car is moving, the crankshaft torque can reach 7000 rpm, despite the fact that the drive wheels at that moment rotate more than four times slower and this figure is constantly changing, depending on road conditions. In addition, operating a car involves changing both the speed of movement and the need to perform various maneuvers, reversing, and stopping. All this would be difficult to do without a transmission.

Today, cars are equipped with various transmissions in three main configurations: front-wheel drive, rear-wheel drive and all-wheel drive.

Transmission diagram of a front-wheel drive car

Transmission diagram of a front-wheel drive car

When producing cars with front-wheel drive, the following components and assemblies are installed that transmit torque from the crankshaft to the wheels:

• Clutch; • Variable gearbox; • Main gear; • Differential; • Constant velocity joint, wheel drive shaft.

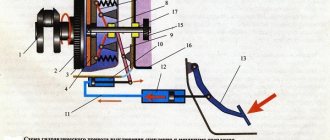

The clutch is designed to briefly disconnect the transmission from the engine and connect it smoothly when the vehicle starts moving or shifts gears.

The variable gearbox is used to change the engine torque transmitted to the driveshaft and thereby obtain traction on the drive wheels. Also, with the help of the gearbox, the direction of the drive wheels is changed and the transmission is disconnected from the engine for a long time.

In addition to the fact that the main gear transmits force from the driveshaft to the axle shafts at a right angle, it helps to reduce the speed of the drive wheels relative to the driveshaft. Thus, the traction force on the drive wheels increases by reducing the torque of the transmission mechanisms after the main gear.

The differential provides different speeds of rotation of the right and left driving wheels, taking into account road conditions (turns, bumps, etc.). Torque is transmitted to the drive wheels through the axle shafts from the differential using side gears. Such differentials are called cross-axle differentials. Another type of differential is interaxle differential, when they are stopped between different axles of the car.

Front wheel drive car

Front wheel drive car

characterized primarily by the fact that the front steered wheels are also driving wheels.

To turn the drive wheels, ball joints ( CV joints

) are located on the shafts (half shafts) of the front drive, which must allow the wheels to turn without changing their speed of rotation.

This condition is satisfied by constant velocity universal joints (synchronous ball joints). A conventional cardan joint quickly fails under these conditions, since the deviation of its driving and driven links creates an uneven angular velocity transmission of rotation to the driven link. This causes overload of the drive shafts and rapid wear of the universal joint. Modern front-wheel drive cars use axle shafts

with two synchronous ball joints to drive the front wheels: the drive wheel is of a rigid type (with an angular degree of freedom), and the power unit is of a universal type (with an angular and axial degree of freedom).

Front wheel drive used on a vehicle

compact and reliable. Its durability with proper use of the car is high. This is ensured by the perfection of the hinge design, the selection of improved materials, precision manufacturing of parts, good sealing of the hinges and the use of special lubricants.

The drives of the right 1 and left 3 wheels have the same design and differ in the shafts, which are solid for the left wheel drive, and tubular for the right one, as well as in length. The latter is explained by the shift of the gearbox to the left side of the vehicle axis.

The drive of each wheel consists of two universal joints of equal angular velocities or CV joints

and shaft.

Outer CV joint

- a joint connected to the wheel hub, consists of a housing 13, a separator 6, an inner race 4 and six balls. In the body of the CV joint (hinge) and in the cage there are radius raceways, the curvature of which has a meridian direction. These tracks contain balls that connect the housing 4 and the inner race 6. The balls are placed in the windows of the separator 7 and are held in the same plane by it. As a result, the inner race and the hinge body are centered. The working angle of rotation of the outer hinge is up to 42°.

The inner race is mounted on the splines of the shaft 8 until it stops at the ring 11. The race is held on the shaft splines by a retaining ring 5. The separator has a spherical surface and windows for the balls. It ensures synchronous rotation of the shafts connected by the hinge by installing balls in the sectorless plane of the angle of the intersecting axes of the hinge links, that is, it acts as a divider. As a result, regardless of the angle of rotation of the hinge, the balls are always kept in the plane of constant rotation speed. At the same time, torque is transmitted through the separator.

To seal the hinge cavity, a corrugated rubber cover 10 is used, which is secured to the hinge body and to the wheel drive shaft 12 with clamps 9 and 13. The tightness of the seating areas of the cover is ensured by the annular grooves on the hinge body, into which the cover is pressed when the clamp is tightened. On the other hand, grooves are made in the case itself; they create a labyrinth seal. Axial fixation of the cover on the shaft is achieved by thrust collars on the drive shaft. The tightening clamps are made of steel tape, on which three sockets and one fixing tooth are stamped. Two sockets are used for tightening the clamp with a special device; the third one receives a fixing tooth. The front wheel hub is mounted onto the splined tip of the hinge housing. It is secured with a self-locking nut.

Inner joint ( inner CV joint

) is connected to the differential side gear. It has minor design differences compared to the outer hinge. This is primarily due to the fact that the tracks in the hinge body and in the cage are made straight and not radial, which allows the hinge parts to move in the longitudinal direction. This is necessary to compensate for movements caused by vibrations of the front suspension and power unit. The longitudinal movement of the cage in the hinge body is limited on one side by a wire retainer 16, on the other by a plastic buffer 18. The retainer is installed in the groove of the hinge body, and the buffer is installed in the end of the wheel drive shaft. The shank of the hinge housing is connected using splines to the differential side gear. The side gear is held on the shaft splines by a retaining ring 23.

The protection of CV joint parts from moisture and dirt is carried out in the same way as for the outer hinge.

When assembling cardan joints, they are filled with special CV joint-4 lubricant. When operating the vehicle, the lubricant is not changed if the covers ensure the tightness of the joints.

Front wheel drives

work in the most difficult and unfavorable conditions, since they are located in the area of greatest exposure to moisture and dirt and transmit torque to the wheels under constantly changing angles and loads. High precision manufacturing of hinge parts, the use of high-quality materials and lubricants ensure reliable operation of the unit even in these conditions, but only while maintaining the tightness of the hinges. Therefore, it is necessary to periodically check the condition of protective covers and clamps in order to promptly detect cracks, deformations or traces of contact with the road surface and take measures to replace them. This prevents premature wear of the hinges.

Front wheel drive of a front wheel drive vehicle

1. Right front wheel drive; 2. Gearbox; 3. Left front wheel drive; 4. External joint housing; 5. Retaining ring of the hinge cage; 6. 18. Hinge cage; 7. 19.Hinge separator; 8. 17. Hinge ball; 9. Outer clamp of the cover; 10. 15.Hinge protective cover; 11. Thrust ring; 12. 14.Left wheel drive shaft; 13. Inner clamp of the cover; 14. Internal hinge lock; 15. Retaining ring of the inner joint cage; 16. Shaft buffer; 17. Inner joint housing; 18. Axle gear retaining ring.

Transmission diagram of a rear-wheel drive car

Transmission diagram of a rear-wheel drive car

The components of this transmission (also called classic) are:

• Clutch; • Variable gearbox; • Cardan transmission; • Main gear; • Differential; • Half shafts.

As you can see, the components of the rear-wheel drive transmission include a cardan transmission, which is an intermediate unit between the output shaft of the gearbox and the rear axle, and serves to transmit torque, regardless of the angle between the axes of the gearbox shaft and the final drive.

Front-wheel drive cars do not need a cardan transmission, since all components and assemblies of the transmission are combined into one common unit under the hood of the car. Due to the fact that the gearbox housing contains a differential with the main gear, the drive shafts of the front drive wheels come out of the gearbox housing itself.

All-wheel drive transmission diagram

All-wheel drive transmission diagram

Transmission schemes for all-wheel drive vehicles are full of great variety and are conventionally divided into three groups:

Basic Concepts

Front wheel drive car.

What is a transmission? This is a set of mechanisms that have the following functions:

- change of direction, as well as the magnitude of the torque;

- redistribution of torque from the motor to the wheels;

- distribution of torque to the drive wheels.

The operating principle of the unit is based on energy conversion. Based on this criterion, the following types of transmissions are distinguished:

- Mechanical. There is a transformation and transfer of mechanical energy. These are classic planetary gearboxes.

- Electric. Mechanical energy is converted into electrical energy, then after the energy is transferred to the wheels, it is converted in the reverse order from electrical energy to mechanical energy.

- Hydrovolumetric. Mechanical energy is converted into the energy of fluid flow, then, after it arrives at the main wheels, the energy is converted in the reverse order.

- Combined. There are electromechanical or hydromechanical types of devices. Such designs combine several methods of energy conversion.

Structurally, cars are divided by type of drive:

- Front-wheel drive. The main wheels are the front wheels of the car.

- Rear drive. The rear wheels of the car become the main ones.

- All-wheel drive. Such vehicles have drive on all axle axles (front and rear).

For vehicles with different types of engines, different transmissions are used that have certain design features. The components of the transmission of a rear-wheel drive car are the following main components: gearbox, clutch, main and cardan drives, axle shafts, differential.

All main transmission components for front-wheel drive vehicles are located under the hood of the vehicle. The following types of transmissions are typical for all-wheel drive vehicles:

- All-wheel drive design, activated by the driver. A prerequisite for the functioning of such a system is the presence of a transfer case, through which the torque is distributed between the front and rear axles.

- Design equipped with automatic switching. Often the front pair serves as the main wheels. Instead of a differential, there is an electrically controlled clutch.

- Permanent all-wheel drive system. The main feature of such a system is the presence of a center differential. The vehicle's cross-country ability increases, as does its acceleration performance. Such results are achieved due to the redistribution of traction force.

Recommend: Diesel Engine High Pressure Fuel Pump

We recommend watching a video about the purpose and operating principle of the transmission: