Signs of a malfunction: the valves “knock” When the thermal gap between the end of the valve and the lever pressing on it increases, a malfunction appears - a characteristic metallic frequent fractional knock from the side of the valve cover.

The knocking sound is especially noticeable when the car engine is not warmed up, idling and at medium loads. There may be a “knock” of one valve, several valves, or all of them at once.

Causes of valve knocking

Why do the valves in the gas distribution mechanism of a car engine “knock”?

— First of all, the valves may knock due to wear

Over time, the ends of the valves, camshaft cams, and levers wear out. Therefore, it is recommended to periodically check thermal clearances (this period is individual for each engine). Wear occurs faster and “knock” will appear earlier when the engine is operated with low-quality engine oil and under difficult conditions.

— “Knock” of valves may be a consequence of incorrect adjustment of thermal clearances

— If the spring of one of the valves breaks or settles, it will also “knock”

— A bent valve will “knock”

— When unscrewing the locknut of the adjusting bolt there will be a “knock”

How to determine that it is the valves that are “knocking”?

In addition to the valves in the engine, valve guides, the camshaft in the housing supports, or the ignition timing is set too early, and we hear detonation in the combustion chambers, can also “knock” with a similar frequent fractional knock.

Many car owners can quite accurately determine valve malfunction by ear (the knocking noise under the valve cover in most cases is quite obvious and distinct). If you have doubts that it is the valves that are “knocking,” you can check with a stethoscope. We apply it to the valve cover of an idling, not warmed-up engine. The knocking of the valves will be heard clearly. You can even determine which valve knocks more.

How to eliminate “knock” in the valve mechanism of a car engine?

checking thermal clearances in the valve mechanism of the K7j 1.4 liter Renault Logan engine

Plus the use of engine oil appropriate for this particular engine. For example, “Choosing motor oil for engines of VAZ 2108, 2109, 21099 cars.”

What happens if you continue to drive with knocking valves?

The filling of the cylinders with fuel is reduced, as well as the efficiency of removing gases from the combustion chambers. As a result, engine power and throttle response are reduced.

Notes and additions

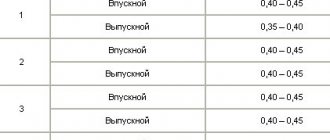

— Depending on the design of the engine gas distribution mechanism, the thermal gap can be adjusted between the camshaft cam and the lever (2101, 2103, 2105, 2106), the valve end and the rocker arm (Moskvich 2140, Logan), by selecting adjusting washers between the camshaft cam and the valve pusher (2108, 21081, 21083).

Why do engine valves knock?

The knocking of valves is frequent and metallic, and can be easily heard at idle from the engine valve cover.

The reason for the knocking is the increased thermal gap between the end of the valve stem and the pusher pressing on it. The thermal gap is necessary to compensate for the thermal expansion of the valve stem when the car engine warms up. It is adjusted using feeler gauges and has individual values for each specific engine model.

Knocking can happen from one valve, several valves, or even all of them.

Why do the valves in the gas distribution mechanism of a car engine “knock”?

— First of all, the valves may knock due to wear

Over time, the ends of the valves, camshaft cams, and levers wear out. Therefore, it is recommended to periodically check thermal clearances (this period is individual for each engine). Wear occurs faster and “knock” will appear earlier when the engine is operated with low-quality engine oil and under difficult conditions.

— “Knock” of valves may be a consequence of incorrect adjustment of thermal clearances

If the thermal clearances were recently adjusted and then a characteristic rattling noise appeared from under the valve cover, most likely something was done incorrectly during the adjustment. Check and adjust again.

— If the spring of one of the valves breaks or settles, it will also “knock”

The structural integrity of the system is violated, the valve sags, the gap increases, and a knock appears.

— A bent valve will “knock”

In this situation, the length of the valve stem also changes and the thermal gap increases.

— When unscrewing the locknut of the adjusting bolt there will be a “knock”

If valve adjustment involves the presence and rotation of adjusting bolts, then insufficient tightening will result in a knocking noise under the valve cover.

Source

Why do valves knock in a car engine?

Every self-respecting car enthusiast should know the reason for incorrect valve operation. Below we list the main ones:

- The size of the gap between the pushers and valves has changed

. When assembling the machine, this gap is precisely adjusted. If for some reason it changes, then metallic tapping will definitely appear. - Saving on fuel, that is, refueling at a cheaper price than indicated in the car’s passport

. This is fraught with engine detonation, which will certainly affect the condition of the valves. - There are situations when valve noise is heard only when accelerating or driving at high speed

. This is how low oil pressure manifests itself in the engine lubrication system. - If a knocking noise appears after replacing the timing belt, it means it was installed incorrectly

. Also, the position of the belt may become confused and thereby disrupt the operation of the valves. - One of the main causes of knocking is the normal wear of valves during engine operation

. It can only be eliminated by replacing them.

Let's look at some of the reasons in more detail.

The main reason for knocking is an increase in the gap between the cams on the camshaft and the levers. Violation of the standard value of the gap leads to knocking of the cam on the rocker. As a result, a metallic clatter is clearly heard. The gap increases, and operation in this mode leads to accelerated wear and serious engine damage. The gap size is set at the factory. Some machine models have the same gap size, while for others this parameter is unique.

At the same time, reducing the gap also has a detrimental effect on the operation of the valve. That is, in this case it is likely to be clamped, and over time, incomplete closure will become permanent. Operating the engine with clamped or poorly closing valves entails an inevitable decrease in compression, as well as overheating of the power unit. There is a possibility of complete failure of the cylinders - from one to all. To prevent such developments, it is necessary to periodically adjust the gaps. It is optimal to do this type of maintenance once every 10–15 thousand kilometers.

However, it is not only incorrect valve adjustment that can cause a metallic knock in the power unit. During detonation, the external manifestations are very similar. Detonation is a miniature explosion inside a cylinder. When this happens, the shock blast wave affects the inner surface of the cylinders and other elements of the piston system. As a result, valve knocking may occur. In addition, during detonation, black smoke comes out of the exhaust pipe, engine power drops significantly, and it quickly overheats.

Many motorists are perplexed: why valves knock only on a hot engine. In this option, a combination of factors - high speeds with insufficient oil pressure - leads to incorrect operation of the valves. Typically, low oil pressure is caused by worn parts and large gaps between them.

For what specific reason the valves knocked in your case, this list will help you find out:

- Be sure to check the engine intake and exhaust valves. Make sure the oil pressure is correct.

- Why do valves knock on a cold engine? This is a sign of a worn tappet. If the tappets are dirty or leaking, the result is that the oil is not supplied to the valves in sufficient quantities. The consequence will be overheating of the motor and metallic knocking.

- If the oil pressure is normal, check the valve clearances. This is done using a specialized tool - a probe. To measure the gap, you need to place a feeler gauge of the required thickness in the gap between the rocker arm and the rod, the cam and the pusher. The exact measurement location depends on the motor design.

Why are valves knocking?

Why does the engine knock at idle?

Why do valves knock? Smooth and uninterrupted engine operation is a sure sign of its “health” and proper maintenance. Any extraneous sounds (knocking, creaking, thuds, etc.) most often indicate problems with the engine.

One of the most common sounds that a motorist encounters is the knocking of valves; it can only be competed by an engine that is shaking.

We talked about the latter in previous articles, so this time we will talk about valves, more precisely about why they knock and how to find out the cause of valve knocking at home.

As a rule, valves knock on engines with high mileage, or on power units that are in a neglected state or are regularly subjected to enormous loads. However, there are exceptions when the knocking of engine valves appears on almost new cars that have not yet expired the warranty period.

Why are valves knocking?

The main reason for knocking is an increase in the gap between the levers and the camshaft cams. If the gap between these parts increases, the cam will begin to hit the rocker, as a result of which extraneous sounds similar to a metallic clatter will begin to appear. The larger the gap, the greater the wear and damage, which will ultimately lead to complete failure of the entire power unit. It should be taken into account that the gap is set by the manufacturer; it has a certain value that is the same for all engines of a certain brand.

A smaller gap is also not good, since in this case the valve will be pinched, and after a while it may stop closing completely. Driving with valves that are clamped or not fully closed can result in engine overheating and reduced compression. We also cannot exclude the possibility of complete failure of one or more cylinders.

To prevent such a scenario, it is recommended to adjust the valves on time, every 10-15 thousand km. mileage

In addition to incorrectly adjusted valves, engine detonation can cause knocking. Detonation in an engine is a kind of explosion, the wave of which hits the cylinder walls and other parts of the piston group. These impacts can cause the valves to knock, although sometimes the metallic clatter may not be related to the valves. Characteristic signs of detonation are: increased vibration, black exhaust (or other color uncharacteristic for the exhaust), decreased power, engine overheating.

If the valves knock “hot”, that is, on a warm engine, the reason may lie in increased speed at low oil pressure, due to increased clearances which I talked about at the beginning of the article, as well as due to high wear or damage to parts. Next we will talk about how to understand exactly why your valves are knocking.

You need to check not only the intake valve, but also the exhaust valve of the engine. First of all, it is necessary to ensure the correct oil pressure and also check its condition (viscosity and lubrication characteristics).

If the valves knock when cold, this may be due to wear on the pusher. If the tappets are dirty or leaking, they can cause limited oil flow to the valves, and as a result, you may hear a characteristic metallic clattering sound during warm-up. If you checked the oil pressure and it is normal, check the clearances; the valves may need to be adjusted. The gaps are adjusted using special feelers that establish a gap between the upper edge of the rod and the rocker arm, and if the camshaft is located at the top, between the pusher and the cam. If all your attempts to find the causes of valve knocking are unsuccessful, contact a specialist, otherwise you risk ruining the engine.

Category: Latest news, Expert advice

Why engine valves knock: top 5 reasons

Issues discussed in the material:

- How to correctly diagnose valve knocking in an engine

- Why do valves knock in a cold, hot, or accelerating engine?

- What to do if engine valves are knocking

- What do car owners think about why engine valves knock?

The engines of new cars are so quiet that they are almost inaudible. Even under intense acceleration, only a faint, noble rumble comes from under the hood. However, with mileage the situation begins to change. Sooner or later, the sound of a running engine becomes unpleasant. Such a change in engine operation is evidence of valve wear. In this article we will look at why engine valves knock and what can be done in such a situation.

How to correctly diagnose valve knocking in an engine

Inexperienced motorists have difficulty identifying the source of the noise by ear. That is, there are a lot of components and mechanisms in the car, and only an experienced driver can determine which of them is the cause of the unusual sound. However, the knocking of valves still has its own characteristic features - namely, a ringing sound, as if metal is knocking on metal. The source in this case is located near the timing mechanism. Moreover, changing engine speed does not affect the sound in any way.

Engine fingers knock when accelerating

Any extraneous noise in a car engine should alert the driver. Even if the malfunction does not in any way affect the driving characteristics of the car, its very appearance should make the car owner think about diagnostics.

One problem that is often ignored by drivers is engine knocking. It appears when the car picks up speed, and if you do not pay attention to it, over time serious problems may arise in the operation of the motor. In this case, most often the driver can determine the reason why the engine fingers knock during acceleration, as well as correct the situation, without contacting a service center.

The main reasons why engine valves knock

Every self-respecting car enthusiast should know the reason for incorrect valve operation. Below we list the main ones:

- The size of the gap between the pushers and valves has changed . When assembling the machine, this gap is precisely adjusted. If for some reason it changes, then metallic tapping will definitely appear.

- Saving on fuel, that is, refueling at a cheaper price than indicated in the car’s passport . This is fraught with engine detonation, which will certainly affect the condition of the valves.

- There are situations when valve noise is heard only when accelerating or driving at high speed . This is how low oil pressure manifests itself in the engine lubrication system.

- If a knocking noise appears after replacing the timing belt, it means it was installed incorrectly . Also, the position of the belt may become confused and thereby disrupt the operation of the valves.

- One of the main causes of knocking is the normal wear of valves during engine operation . It can only be eliminated by replacing them.

Let's look at some of the reasons in more detail.

The main reason for knocking is an increase in the gap between the cams on the camshaft and the levers. Violation of the standard value of the gap leads to knocking of the cam on the rocker. As a result, a metallic clatter is clearly heard. The gap increases, and operation in this mode leads to accelerated wear and serious engine damage. The gap size is set at the factory. Some machine models have the same gap size, while for others this parameter is unique.

At the same time, reducing the gap also has a detrimental effect on the operation of the valve. That is, in this case it is likely to be clamped, and over time, incomplete closure will become permanent. Operating the engine with clamped or poorly closing valves entails an inevitable decrease in compression, as well as overheating of the power unit. There is a possibility of complete failure of the cylinders - from one to all. To prevent such developments, it is necessary to periodically adjust the gaps. It is optimal to do this type of maintenance once every 10–15 thousand kilometers.

However, it is not only incorrect valve adjustment that can cause a metallic knock in the power unit. During detonation, the external manifestations are very similar. Detonation is a miniature explosion inside a cylinder. When this happens, the shock blast wave affects the inner surface of the cylinders and other elements of the piston system. As a result, valve knocking may occur. In addition, during detonation, black smoke comes out of the exhaust pipe, engine power drops significantly, and it quickly overheats.

Many motorists are perplexed: why valves knock only on a hot engine. In this option, a combination of factors - high speeds with insufficient oil pressure - leads to incorrect operation of the valves. Typically, low oil pressure is caused by worn parts and large gaps between them.

For what specific reason the valves knocked in your case, this list will help you find out:

- Be sure to check the engine intake and exhaust valves. Make sure the oil pressure is correct.

- Why do valves knock on a cold engine? This is a sign of a worn tappet. If the tappets are dirty or leaking, the result is that the oil is not supplied to the valves in sufficient quantities. The consequence will be overheating of the motor and metallic knocking.

- If the oil pressure is normal, check the valve clearances. This is done using a specialized tool - a probe. To measure the gap, you need to place a feeler gauge of the required thickness in the gap between the rocker arm and the rod, the cam and the pusher. The exact measurement location depends on the motor design.

Valve knocking on a hot engine, looking for the problem yourself

All internal combustion engines operate thanks to the timely intake of the next portion of the working mixture into the cylinders, therefore, when the knocking of valves on a hot engine becomes audible, this indicates the presence of malfunctions in the gas distribution mechanism.

Internal combustion engine valve - operation diagram

The main gas distribution systems have overhead valves. The main element of the gas distribution mechanism is the valve of the internal combustion engine. In addition to this, this includes pushers, rods and rocker arms, as well as a camshaft that directly regulates the operation of all valves.

The principle of operation is to rotate the shaft, when its cams alternately move the pusher and lift it together with the rod. With its upper end, the rod presses on the inner arm of the rocker arm, which, in turn, turns around its axis, alternately opens the intake or exhaust channels located in the cylinder head.

The reasons for the knocking can be very different. For example, valve knocking on a hot engine may occur due to an increase in speed and simultaneous low oil pressure, due to an increase in valve clearance, as well as the presence of worn or damaged parts. We'll look at how to determine and fix this below.

Valve knocking on a hot engine - diagnosing the causes

In such cases, not only the engine intake valve is checked, but also the exhaust valve. It is necessary to ensure sufficient oil pressure to ensure normal operation of the entire mechanism at the same time. To do this, it is necessary that the viscosity of the oil corresponds to specific weather conditions; in winter, measures must be taken to liquefy it.

Valve knocking on a cold engine may be due to a worn tappet. Dirty or leaking tappets can restrict oil flow to the valve train, resulting in a characteristic sound. Adjusting the valves on a diesel engine often helps eliminate the cause of knocking.

If the oil pressure is normal, then the valve cover is removed and the clearances are checked. Increased clearance usually causes knocking and leads to premature wear of parts. The gaps are adjusted using special plate feelers, which are inserted into the gap between the rocker arm and the upper edge of the rod, and with the upper camshaft - between the cam and the pusher.

Adjusting valves on a diesel engine and other repairs

The degree of knocking, in most cases, depends on how many engine valves a particular make of car has. The more of them are installed, the stronger the knocking in case of wear of parts. To ensure silent operation, hydraulic pushers are used to maintain the clearance in the valve mechanism at zero level.

To improve the operation of the gas distribution mechanism, the engine valves are cleaned. Over time, carbon deposits form on them, which prevents them from taking a normal position. Therefore, it is necessary to periodically clean or grind the valves. It is necessary to periodically inspect all components of the mechanism, since worn pushers, rocker arms, and rods can lead to increased clearance and cause knocking.

The same thing can happen with a bent rod or broken spring.

As the engine speed increases, a slight knocking sound with a metallic sound may occur. This very often happens due to detonation resulting from improperly set ignition, carbon deposits in the combustion chamber, or when the engine is running on low-octane fuel. To prevent such situations, it is necessary to constantly check the condition of the gas distribution mechanism. With normal and timely prevention, not only stable engine operation will be ensured, but also a significant reduction in fuel consumption.

Why do engine valves knock during acceleration?

The engine may knock while driving. If this happens, it is hardly possible to deal with it locally. The first thing to do is check the oil level in the power unit. Insufficient oil level may well be the cause of damage that causes the knocking noise. It is necessary to replenish the oil level to normal as soon as possible. It is likely that this simple action will help eliminate knocking in the power unit.

Then you need to find out whether the knocking occurs under load, that is, when the car is moving. Listen to how much it grows when the car accelerates. If both symptoms are present, then the likely culprit is the crankshaft bearings. You should not operate a car with such a defect, otherwise you can provoke a complete engine failure. Which will ultimately result in expensive repairs.

We recommend

Often, knocking in the engine occurs due to refueling with low-quality fuel. This knock will fade over time. It is unlikely to be dangerous to the engine. If the knocking does not die out, you need to listen more carefully to the sound of the engine. The most dangerous thing is when the intensity of the knocking increases - in this case, further operation of the machine can definitely result in serious damage.

What to do if engine valves are knocking

The easiest and fastest way is to have it repaired by professionals. However, not everyone can afford to pay for their services. Therefore, you have to figure it out and solve the issue yourself. There are motorists who are interested in repairing their car with their own hands. There are also people who accumulate experience in self-repair for some purpose.

If valve knocking is a problem in your car and you have to repair it yourself, be prepared to do some serious work. Seriously and carefully, because if you make a mistake, the sound will only become stronger. Therefore, it is not recommended for a novice motorist to eliminate valve knocking. The sequence of actions is of great importance in this type of repair. First of all, it is recommended to study the repair manual for a specific car brand. Next you need to follow the algorithm:

- Engine oil is drained.

- The cylinder head plug is unscrewed. This will clear the way to the valves.

- The camshaft must be rotated until the mark on the pulley and the unit match.

- Determine the gap between the rods and valves by touch. The size of the gap can be changed using an adjusting washer.

- Depending on the specific car model, you need to turn the washer the required number of revolutions.

- Reassemble everything in reverse order and then check if the valve knocking has gone away.

Each car model has its own operating characteristics. But on average, every 25 thousand kilometers you need to adjust the valve clearances. The number of valves directly affects the noise level when they knock. The more valves, the louder the noise will be in the event of a malfunction. There is an engineering solution to the problem - some cars use hydraulic pushers to accurately maintain valve clearances.

Timing valves require preventive maintenance. It consists of periodically cleaning their surface from the deposits that have formed. Carbon deposits can reach a thickness that makes it difficult for the valves to operate properly. Therefore, you should not forget about their periodic cleaning and grinding. Careful implementation of preventive maintenance will extend the life of the engine and even slightly reduce fuel consumption.

We recommend

If self-adjustment of the valves does not give a positive result, then it is better to contact a professional service station. Setting the gap yourself in this case is hardly possible. Sometimes the cause of valve knocking is completely different faults. But it is also possible that the valve clearances are set incorrectly.

What to do in such a situation

It is important to understand that there is nothing good about valve knocks on a hot engine. The simplest solution is to go to the nearest car service center, where specialists will check and fix everything.

But some people find it interesting and even useful to delve into the car themselves and gain new experience and knowledge. Someone will first have to read a lot of literature and technical documentation. Others will watch the video and easily repeat the manipulations done.

Although a similar problem occurs on many cars, it is the owners of inexpensive or quite old cars who prefer to take on knocking valves themselves, such as:

- Renault Logan;

- Chevrolet Niva;

- VAZ 2114;

- Lada Priora;

- VAZ 2106;

- Ford Focus;

- VAZ 2109;

- Opel Astra;

- Daewoo Nexia;

- Nissan Almera;

- Renault Sandero;

- Cherry Amulet, etc.

Don’t think that solving a knocking problem is very easy. If you make a mistake, you will only increase the noise and cause the situation to worsen. Therefore, beginners are not recommended to take on such work.

Before you begin disassembling, be sure to read the instruction manual specific to your car.

If we talk about the general repair scheme, it can be described approximately as follows:

- First you need to get to the valves themselves. To do this, remove the cylinder head plug and drain all the oil from the system;

- The camshaft is rotated so that the mark on the pulley coincides with the installation protrusion;

- You will probably have to check the distance between the valves and pushers by touch;

- Using the adjustment washer, the gap is changed and adjusted;

- Manipulations with the washer are carried out several times if necessary and depending on the engine itself;

- The assembly is assembled in the reverse order;

- Oil is poured;

- The presence of knocks is checked after the adjustment has been carried out.

If such actions do not produce any results, then there is no point in making further attempts at DIY repairs. It's better to send the car to a good car service center.

When the malfunction is not related to gaps, it will be extremely problematic to correct the situation on your own. But if the problem is an incorrect adjustment, you will spend a minimum of time and money restoring the engine’s performance. The valves will stop knocking when the engine is warm.

Any extraneous noise from the engine that doesn't go away and accompanies you on the road is a bad sign. It should not be ignored under any circumstances, as it may be a harbinger of much more serious problems than background noise.

Have you ever encountered valve knocking noises when the engine was warm? What was the reason and how did you eliminate it?

Thank you for being with us! Subscribe, leave comments, ask relevant questions!

(1 ratings, average: 5.00 out of 5)

Subscribe to updates and receive articles by email!

We guarantee: no spam, only new articles once a week!

The engine of a new car runs, as they say, like a clock. But nothing lasts forever, one day the car owner discovers that uncharacteristic sounds are mixed in with the usual whisper of the engine. An expert, of course, will distinguish the abnormal rustling of a belt, or the knocking of fingers, or, say, the chattering of crankshaft bearings from another sad diagnosis: knocking valves!

Let's try to figure out what the wisdom of valve diagnostics is, as well as how to treat this disease in a car. In addition, we will definitely touch on the possible reasons why the valves of internal combustion engines sometimes knock.

First, let's describe the sound by which professionals recognize the problem being described. This is a loud, distinct, metallic tapping of medium frequency in the area of the timing cover. Moreover, this particular sound does not disappear when the engine speed changes, especially if the valves knock only on a cold engine.

Secondly, only a professional who has experience can say for sure whether they are or not. However, the average car enthusiast should try two diagnostic methods. One of them is as follows: open the oil filler cap, then listen closer to the neck, if the sound increases, then they are probably to blame. Another method: rest something like a stethoscope on the work area of the suspected part; an extraneous sound will make itself felt.

Other causes of engine knocking

We can conclude that there are many reasons for engine knocking. After all, this is a complex mechanical system. As soon as one setting goes wrong, the gap is broken, the geometry of the part changes, and uncharacteristic sounds may appear. This is why it is so difficult to independently determine the cause of knocking in the power unit. For example: why do engine valves knock only under load.

Knowledge of the principles of operation of a car engine and the results of engine observations help to establish the exact cause of the malfunction. Let’s assume what the thermal state of the engine is at the time of knocking, whether there is a load, what the speed was when extraneous noise occurred. Every nuance plays a role in determining the technical condition of the engine.

The following is a description of common instructions.

· To access the valve, you must first remove the “Cylinder Block Head” plug. Be sure to drain the oil;

· Then you need to turn the camshaft so that the mark on the pulley coincides with the installation protrusion;

· The distance from the valve to the rod can be determined by feeling it yourself;

· An adjustment washer can be used to adjust the gap;

· The specific configuration of the vehicle determines how many times the puck will be operated;

· After connecting all the parts back together, check again whether there is any sound after what has been done;

If the problem recurs, take the car to a service station, for the reason that you will not be able to fix other problems not related to space. It may very well be that the adjustment was not correct.

Any extraneous noise in a car engine often makes owners feel wary. And even if these sounds do not affect driving performance in any way, their very appearance makes the driver think about diagnostics. Many cars have knocking pins when accelerating, but this problem is often ignored. The sound appears when the car picks up speed. If you do not pay attention to this in time, much more serious problems arise. At the same time, car enthusiasts cannot determine the reasons for the appearance of knocking noises, nor can they fix this problem on their own. Let's look at the reasons for these sounds that are unpleasant to the driver's ear, and also find out how to fix these problems with the engine.

Car owners about why engine valves knock

Question 1:

“This happened to me: the valves were slightly pinched, due to my carelessness. After this, a noise appeared, barely audible. I decided to fix this and loosened the gaps to the required size. As a result, on a cold engine the knocking has almost gone away. On a hot engine, the central valves knock very clearly. The gap was adjusted using a feeler gauge. The gap was set so that it was difficult to insert the probe into it.

I now suspect that when heated, the cylinder head or camshaft bed changes its size. As a result, the valve clearances also change. After all, there is no knocking on a cold engine. Random pinching of the valves helped to identify the optimal gap size for those valves that, after increasing the gap, on the contrary, rattled. Has anyone encountered anything like this?

We recommend

- “It is impossible to accurately set the gap using a feeler gauge - you need to use a micrometer (indicator) equipped with a rod.”

- “I encountered a similar problem. Adjustment with a micrometer did not produce results - the knocking remained in the region of cylinders 2 and 3. It turned out that the whole point was in the development of the ends of the valves, and the play of the valves in the guides also played a role.”

Question 2:

“I was faced with the following situation: while the engine is cold, at idle and when driving everything is quiet, no unnecessary sounds. However, as soon as the engine reaches operating temperature and there is a slight load on the motor, the knocking appears. At the same time, the frequency of knocking is different - sometimes stronger, sometimes weaker. What can be done in this situation?

- “A friend of mine faced a similar problem. It turned out that the lubrication system was to blame. Due to a clogged oil filter, oil did not have time to supply the hydraulic compensators, and they knocked. At low speeds there was still enough oil pressure, at high speeds it was no longer there. After changing the oil and filter the problem went away."

- “First, you need to measure the oil pressure. If it is low, the oil receiver should be cleaned or the oil pump replaced.”

- “If the oil pressure matches the nameplate pressure, there are two options left. The oil does not meet the viscosity requirements. Or the hydraulic compensators themselves have worn out.”

Source