20.09.2019

| (Votes: 2, Rating: 5) |

Issues discussed in the material:

- How to correctly diagnose valve knocking in an engine

- Why do valves knock in a cold, hot, or accelerating engine?

- What to do if engine valves are knocking

- What do car owners think about why engine valves knock?

The engines of new cars are so quiet that they are almost inaudible. Even under intense acceleration, only a faint, noble rumble comes from under the hood. However, with mileage the situation begins to change. Sooner or later, the sound of a running engine becomes unpleasant. Such a change in engine operation is evidence of valve wear. In this article we will look at why engine valves knock and what can be done in such a situation.

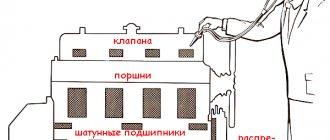

How to correctly diagnose valve knocking in an engine

Inexperienced motorists have difficulty identifying the source of the noise by ear. That is, there are a lot of components and mechanisms in the car, and only an experienced driver can determine which of them is the cause of the unusual sound. However, the knocking of valves still has its own characteristic features - namely, a ringing sound, as if metal is knocking on metal. The source in this case is located near the timing mechanism. Moreover, changing engine speed does not affect the sound in any way.

But even if it is possible to determine that the knocking comes specifically from the valves, then only very experienced car owners can accurately identify the cause of the malfunction. However, there is a certain diagnostic algorithm with which you can more accurately determine the cause of the problems that have arisen. You need to do the following:

- Open the hood and unscrew the engine oil filler cap.

- Listen carefully to the running engine. An increase in the volume of the sound without the cap is a clear indication that the valves are the source of the problem.

- A stethoscope, which should be placed closer to the suspected faulty part, will help determine the source of the noise even more accurately.

Engine valves knocking - I hear a rumbling noise

Like worn guides, rods and springs, worn rocker arms are rare unless they have been used for quite some time, the lubrication system has problems, or the system has been neglected.

While a worn rocker likely won't affect engine performance, it can cause system noise. You may hear light tapping or rattling sounds coming from one or more of the affected rocker arms.

To diagnose the problem:

- Check the condition of the engine oil.

- Check for proper oil circulation around the valve system.

- Identify the noisy rocker arm using a mechanic's stethoscope or rubber hose as described in the previous section.

- Remove the rocker arm and check for dents or roughness where it contacts the valve or, if applicable, the pushrod.

Any of these problems can shorten the life of the rocker arm if they cause insufficient lubrication or increased clearance between the rocker arm and the rod.

Too much clearance can cause noise and accelerate valve stem and rocker arm wear.

The main reasons why engine valves knock

Every self-respecting car enthusiast should know the reason for incorrect valve operation. Below we list the main ones:

- The size of the gap between the pushers and valves has changed . When assembling the machine, this gap is precisely adjusted. If for some reason it changes, then metallic tapping will definitely appear.

- Saving on fuel, that is, refueling at a cheaper price than indicated in the car’s passport . This is fraught with engine detonation, which will certainly affect the condition of the valves.

- There are situations when valve noise is heard only when accelerating or driving at high speed . This is how low oil pressure manifests itself in the engine lubrication system.

- If a knocking noise appears after replacing the timing belt, it means it was installed incorrectly . Also, the position of the belt may become confused and thereby disrupt the operation of the valves.

- One of the main causes of knocking is the normal wear of valves during engine operation . It can only be eliminated by replacing them.

Let's look at some of the reasons in more detail.

The main reason for knocking is an increase in the gap between the cams on the camshaft and the levers. Violation of the standard value of the gap leads to knocking of the cam on the rocker. As a result, a metallic clatter is clearly heard. The gap increases, and operation in this mode leads to accelerated wear and serious engine damage. The gap size is set at the factory. Some machine models have the same gap size, while for others this parameter is unique.

At the same time, reducing the gap also has a detrimental effect on the operation of the valve. That is, in this case it is likely to be clamped, and over time, incomplete closure will become permanent. Operating the engine with clamped or poorly closing valves entails an inevitable decrease in compression, as well as overheating of the power unit. There is a possibility of complete failure of the cylinders - from one to all. To prevent such developments, it is necessary to periodically adjust the gaps. It is optimal to do this type of maintenance once every 10–15 thousand kilometers.

However, it is not only incorrect valve adjustment that can cause a metallic knock in the power unit. During detonation, the external manifestations are very similar. Detonation is a miniature explosion inside a cylinder. When this happens, the shock blast wave affects the inner surface of the cylinders and other elements of the piston system. As a result, valve knocking may occur. In addition, during detonation, black smoke comes out of the exhaust pipe, engine power drops significantly, and it quickly overheats.

Many motorists are perplexed: why valves knock only on a hot engine. In this option, a combination of factors - high speeds with insufficient oil pressure - leads to incorrect operation of the valves. Typically, low oil pressure is caused by worn parts and large gaps between them.

For what specific reason the valves knocked in your case, this list will help you find out:

- Be sure to check the engine intake and exhaust valves. Make sure the oil pressure is correct.

- Why do valves knock on a cold engine? This is a sign of a worn tappet. If the tappets are dirty or leaking, the result is that the oil is not supplied to the valves in sufficient quantities. The consequence will be overheating of the motor and metallic knocking.

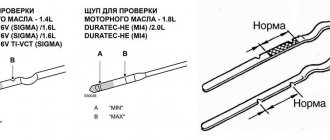

- If the oil pressure is normal, check the valve clearances. This is done using a specialized tool - a probe. To measure the gap, you need to place a feeler gauge of the required thickness in the gap between the rocker arm and the rod, the cam and the pusher. The exact measurement location depends on the motor design.

Valves are knocking - why not come visit the engine

Owners of modern cars sometimes notice some kind of unnatural ringing knock coming from under the hood. It's the valves knocking. Many people are surprised by this fact. According to the general opinion, valve knocking is typical only for old cars, where the thermal gap is adjusted using a bolt or selecting washers. Mechanical wear of the working parts of the camshaft cams and other parts contribute to an increase in clearances. This is all clear.

How to explain the origin of the knocking if the thermal gap is adjusted automatically by such newfangled devices as hydraulic compensators? It turns out that in this case, valve knocking can occur very often. The reasons for the appearance of such an unpleasant sound are much greater than those of other types of valve thermal clearance regulation.

A little theory about valves

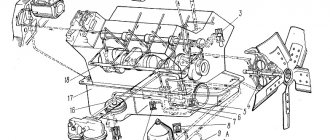

It is believed that the hydraulic compensator is the most reliable system for regulating valve thermal clearances. In fact, if all engine systems are in full working order, the driver should not worry at all about adjusting the gaps. A hydraulic compensator, consisting of a housing and a plunger, is installed between the camshaft cam and the valve. The clearance is adjusted automatically each time the cam is pressed due to the oil pressure in the lubrication system.

The operating principle of the hydraulic compensator is as follows:

- in the initial stage of pressing the cam, when the hydraulic compensator body begins to move down, its oil channel coincides with the channel in the head block. Oil under pressure enters the plunger and pushes it out of the body, occupying all the empty space between the cam and the end of the valve stem. Oil under pressure is sealed inside with a ball valve. The thermal gap is eliminated and with further movement of the cam the valve moves down (opens);

- returning to its original position, the oil pressure is equalized, the ball valve opens and excess oil is discharged, which allows the gap to appear again.

This cyclical action is repeated each time the cam is pressed and the hydraulic compensator moves down. Motor oil, having a low compression ratio, allows you to cope with the task as efficiently as possible. In this case, all parts of the cylinder head are lubricated.

Why valves knock - troubleshooting methods

Even the most advanced systems have their drawbacks. Hydraulic compensators are the best that mechanical engineering offers, but their proper operation depends on many factors. Let's look at the most typical types of problems that cause unpleasant valve ringing.

Typical reasons why valves ring:

- mechanical wear. You should not be surprised at the appearance of a knock if, after the last replacement of the hydraulic compensators, the car has driven over 150-200 thousand km. Even the highest quality products are not immune to wear and tear. The breakdown is eliminated by replacing the hydraulic compensators. It should be remembered that hydraulic compensators are replaced as a complete set, and in case of repair, hydraulic compensators cannot be swapped if old ones are installed during assembly;

- poor quality or old oil. A lot depends on the quality of the oil. Bad oil has a lower viscosity and compresses more, which leads to knocking. The oil should be changed promptly;

- clogging of the oil channels of the plunger or head. Long-term operation without replacing the filter leads to gradual clogging of the channels, which significantly reduces oil pressure or completely prevents its flow. There are situations when the plunger gets jammed in the hydraulic compensator body and the mechanism stops working altogether. The breakdown is eliminated by washing, replacing the filter and oil;

- drop in oil pressure due to a clogged filter or worn oil pump. When oil pressure drops, the hydraulic compensator does not receive the necessary amount of oil to completely eliminate the gap. Regular replacement of the filter and oil, as well as prevention and timely repair of the oil pump will help avoid breakdowns;

- The oil level is too low or the vehicle is at an angle, which leads to air being sucked into the lubrication system. Enriching the oil with air leads to a significant reduction in the compression ratio. The specified breakdown is “treated” by flushing the system, changing the oil and constantly monitoring its level.

Considering that hydraulic compensators are an indispensable component of the lubrication system, a strong connection is obvious between the technical condition of the pump, the filtration system, the quality of the oil and the operation of the gas distribution system. In most cases, valves knock due to a malfunction of the engine lubrication system. If a car owner promptly changes the oil and filter and monitors the condition of the oil pump, the hydraulic compensators will serve properly for the entire period allotted to them.

Source

Why do engine valves knock during acceleration?

The engine may knock while driving. If this happens, it is hardly possible to deal with it locally. The first thing to do is check the oil level in the power unit. Insufficient oil level may well be the cause of damage that causes the knocking noise. It is necessary to replenish the oil level to normal as soon as possible. It is likely that this simple action will help eliminate knocking in the power unit.

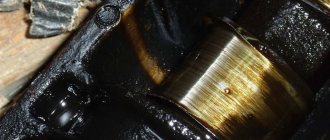

Then you need to find out whether the knocking occurs under load, that is, when the car is moving. Listen to how much it grows when the car accelerates. If both symptoms are present, then the likely culprit is the crankshaft bearings. You should not operate a car with such a defect, otherwise you can provoke a complete engine failure. Which will ultimately result in expensive repairs.

We recommend

“How to properly turn off a car engine: some useful tips” Read more

Often, knocking in the engine occurs due to refueling with low-quality fuel. This knock will fade over time. It is unlikely to be dangerous to the engine. If the knocking does not die out, you need to listen more carefully to the sound of the engine. The most dangerous thing is when the intensity of the knocking increases - in this case, further operation of the machine can definitely result in serious damage.

Causes of extraneous noise

As stated above, if the engine knocks, it means that car enthusiasts must carry out diagnostics to identify the reasons for such operation of the power unit, and eliminate them before major problems arise, up to the engine jamming.

Noises when starting the power unit

Engine knocking when cold (when starting it) can only occur in a few cases (we are considering the option when the noise appears during startup and then disappears):

- the crankshaft is faulty, in this case, if the car owner listens carefully to his engine, he will hear a characteristic dull noise in the lower part of the power unit, such a problem appears when the crankshaft bearings are worn out (for example, the oil did not meet the required level), or for other reasons, but such a knock disappears after the engine warms up;

- the camshaft is faulty, this unit also has bearings that can wear out over time for the same reason as the crankshaft, but this noise appears in the upper part of the power unit;

- valves knock on a cold engine, this problem can be caused by several factors, which will be discussed below.

It is interesting to know that in some cases the cause of the characteristic knocking of the engine may be the hydraulic shock of the engine.

Knock of the power unit when idling

Now let’s figure out the situation, how to determine the reasons why knocking occurs on a hot engine (in this case, when it has warmed up, but there is no load on the power unit). There may be several problems here.

- Malfunction of the crankshaft or camshaft. As described above, if the play on the rubbing parts of the camshaft or crankshaft bearings is not large, then after they are heated, the knocking will disappear. But in cases where the bearings already have significant wear, no amount of warming up will help, and the noise in the engine due to the crankshaft or camshaft will be constant.

- Fuel detonation. For example, if a Polo sedan car needs to be filled with A-95 gasoline, and the car enthusiast has filled it with A-92, then characteristic sharp knocks can be heard when the engine is running. This is the so-called fuel detonation. It occurs when the fuel mixture is not ignited by a spark from a spark plug, but by the action of a hot piston on it. This may also be due to oversaturation of the mixture with air, or it does not ignite at top dead center.

- Faulty valves. The valves may also make characteristic sounds. This is caused by several reasons, which will be discussed in more detail below.

- High pressure fuel pump malfunction. These reasons can only occur on diesel power units. If the fuel pump is not working well, then the car owner may hear a dull sound after the diesel engine starts and starts idling.

Some experts believe that such engine operation may be caused by the fact that the piston rings or cylinder walls are worn out, and therefore, at the moment of the explosion, part of the energy enters the bowels of the engine, which is why the characteristic sounds of sharp pops appear (detonation).

You should also pay attention to the phrase “tickling fingers.” This is a description of the characteristic ringing signal emitted by valves that are not working properly

For some car brands, a characteristic clattering noise under heavy loads is the norm and indicates that the ignition angle is correctly set.

What to do if engine valves are knocking

The easiest and fastest way is to have it repaired by professionals. However, not everyone can afford to pay for their services. Therefore, you have to figure it out and solve the issue yourself. There are motorists who are interested in repairing their car with their own hands. There are also people who accumulate experience in self-repair for some purpose.

If valve knocking is a problem in your car and you have to repair it yourself, be prepared to do some serious work. Seriously and carefully, because if you make a mistake, the sound will only become stronger. Therefore, it is not recommended for a novice motorist to eliminate valve knocking. The sequence of actions is of great importance in this type of repair. First of all, it is recommended to study the repair manual for a specific car brand. Next you need to follow the algorithm:

- Engine oil is drained.

- The cylinder head plug is unscrewed. This will clear the way to the valves.

- The camshaft must be rotated until the mark on the pulley and the unit match.

- Determine the gap between the rods and valves by touch. The size of the gap can be changed using an adjusting washer.

- Depending on the specific car model, you need to turn the washer the required number of revolutions.

- Reassemble everything in reverse order and then check if the valve knocking has gone away.

Each car model has its own operating characteristics. But on average, every 25 thousand kilometers you need to adjust the valve clearances. The number of valves directly affects the noise level when they knock. The more valves, the louder the noise will be in the event of a malfunction. There is an engineering solution to the problem - some cars use hydraulic pushers to accurately maintain valve clearances.

Timing valves require preventive maintenance. It consists of periodically cleaning their surface from the deposits that have formed. Carbon deposits can reach a thickness that makes it difficult for the valves to operate properly. Therefore, you should not forget about their periodic cleaning and grinding. Careful implementation of preventive maintenance will extend the life of the engine and even slightly reduce fuel consumption.

We recommend

“Cleaning fuel system injectors: choosing products for gasoline and diesel” More details

If self-adjustment of the valves does not give a positive result, then it is better to contact a professional service station. Setting the gap yourself in this case is hardly possible. Sometimes the cause of valve knocking is completely different faults. But it is also possible that the valve clearances are set incorrectly.

The following is a description of common instructions.

· To access the valve, you must first remove the “Cylinder Block Head” plug. Be sure to drain the oil;

· Then you need to turn the camshaft so that the mark on the pulley coincides with the installation protrusion;

· The distance from the valve to the rod can be determined by feeling it yourself;

· An adjustment washer can be used to adjust the gap;

· The specific configuration of the vehicle determines how many times the puck will be operated;

· After connecting all the parts back together, check again whether there is any sound after what has been done;

If the problem recurs, take the car to a service station, for the reason that you will not be able to fix other problems not related to space. It may very well be that the adjustment was not correct.

Other causes of engine knocking

- The gasoline pump drive may make a loud metallic noise . It can easily be mistaken for the sound of faulty valves.

- Diesel engines have a fuel pump that creates high fuel pressure . Its knock is also loud, but half as often as one engine revolution.

- Connecting rods can also knock due to worn bearings . Each car model will sound unique. You can accurately determine a faulty connecting rod by turning off the cylinders one by one. If the sound disappears when one of the cylinders is turned off, the problem is in the connecting rod. Often, the knocking of connecting rods only appears when the engine speed decreases. This malfunction can only be eliminated by overhauling the engine.

- Subaru and Toyota cars are characterized by weakening of the crankshaft pulley . The reason for this is the loosening of the fastening nut. This defect is almost always manifested by oil leakage.

- After engine repair, a knocking sound may also appear.. This is often due to a poorly fitting cylinder block gasket. Its protruding edges prevent the piston from making its stroke. Naturally, this knock does not depend on the speed. It is barely visible against the background of the engine.

- There is another reason for knocking with a frequency that is half the engine speed . These are hydraulic compensators. When the lubrication system is clogged, the oil is dirty or does not meet the required characteristics, a knocking noise appears on a cold engine. As the power unit warms up, it disappears.

- Diesel units have another source of knocking - plunger pairs . However, this type of knock is not dangerous; the car can be operated with it.

We can conclude that there are many reasons for engine knocking. After all, this is a complex mechanical system. As soon as one setting goes wrong, the gap is broken, the geometry of the part changes, and uncharacteristic sounds may appear. This is why it is so difficult to independently determine the cause of knocking in the power unit. For example: why do engine valves knock only under load.

Knowledge of the principles of operation of a car engine and the results of engine observations help to establish the exact cause of the malfunction. Let’s assume what the thermal state of the engine is at the time of knocking, whether there is a load, what the speed was when extraneous noise occurred. Every nuance plays a role in determining the technical condition of the engine.

Determining the causes of sound

Modern cars are equipped with engines in which the clearance is adjusted automatically. When looking for an answer to the question why a valve is knocking on a foreign car, the answer is most likely not in adjusting the clearance. All modern internal combustion engines are equipped with hydraulic compensators. But with domestic cars and other foreign cars that do not have a similar system, the issue of adjusting the gap is relevant. On many foreign cars, the procedure for adjusting or checking the clearance is a complex topic. As a rule, the engine should be checked for violations of the gap by specialists. On an old engine or domestic units, you can check why the valves are knocking as follows:

- check the condition of the pusher.

If they are dirty or leaking, then they should be replaced, as the valve is knocking due to oil supply restriction. After checking the oil pressure, measure the gap itself. The correctness of the set gap is checked using a feeler gauge, which is placed between the rocker arm and the upper edge of the rod or between the pusher and the cam if the camshaft is located at the top in the engine.

Other causes can only be identified through a professional inspection of the engine, or in some cases, during its disassembly.

Car owners about why engine valves knock

Question 1:

“This happened to me: the valves were slightly pinched, due to my carelessness. After this, a noise appeared, barely audible. I decided to fix this and loosened the gaps to the required size. As a result, on a cold engine the knocking has almost gone away. On a hot engine, the central valves knock very clearly. The gap was adjusted using a feeler gauge. The gap was set so that it was difficult to insert the probe into it.

I now suspect that when heated, the cylinder head or camshaft bed changes its size. As a result, the valve clearances also change. After all, there is no knocking on a cold engine. Random pinching of the valves helped to identify the optimal gap size for those valves that, after increasing the gap, on the contrary, rattled. Has anyone encountered anything like this?

Valves knocking on a cold engine

When diagnosing, special attention should be paid to such a thing as engine temperature. Depending on whether the valves are knocking on a hungry or hot engine, some other nuances may “pop up”.

If noise occurs only when the engine is cold, then the reasons may be:

- narrowing of the valves. At high temperatures, metal tends to expand, and at low temperatures, on the contrary, it tends to shrink. As a result, the space between the pushers and valves was small, and after warming up the engine it was restored to the factory value.

- wear and tear of the engine itself.

Thus, the gap between the rods and valves may not correspond to the norm, but when the engine is hot, this will not “pop up” yet.

The engine knocked on the road

If the engine suddenly starts making a clattering noise while driving, the first thing you need to do is check the oil level. If it is insufficient, even with a working pump, normal lubrication of all elements will not be ensured. The level should always be at least halfway.

It is necessary to find out whether valve knocking increases under load and as speed increases. If this is the case, the crankshaft bearings in the engine are most likely worn out. Another knocking noise may occur immediately after refueling. This indicates low-quality fuel. Usually such knocks are of a subsiding nature; they are not fatal to the engine. But in the future it is better to change the gas station. How to fix valve knocking? Depending on the design of the timing mechanism, each cylinder in the engine may have two or four valves. Some launch the combustible mixture, others remove gases. Since the elements operate at high temperatures, they can expand. Therefore, the gap will change. If the valves are adjusted incorrectly, this leads to rapid wear of the timing elements and a loss of engine performance as a whole. With an increased gap, the valves will not open completely. If not enough, they will burn along with the saddles.

If the internal combustion engine does not have hydraulic compensators, experts recommend adjusting the valve clearances every 25 thousand kilometers. Also, for proper operation, such elements should be cleaned. During operation, the valves become overgrown with carbon deposits. It prevents them from working in normal positions. If the clearance is optimal and the valves are clean, the car will operate stably and not overuse fuel.

Why are they knocking?

Common causes of knocking

To determine that it is the valves that are knocking, it is necessary to determine the causes of this defect. The first cause of knocking may be a manufacturing defect. This option is typical for new cars that were assembled in bad faith. The next option is excessive wear of the cylinder head parts due to prolonged operation. Also, do not forget about the unscrupulous “unowner” attitude towards the car, which leads to many breakdowns in the engine.

Causes of knocking noise due to wear

One of the reasons why valve knocking can be detected is a change (increase) in the gap between the camshaft cam and the lever. Due to the change in the gap between the parts in the cylinder head, the camshaft begins to hit the rocker with inertia, and as a result, a metallic knock occurs in the engine compartment. This unpleasant moment is fraught with engine failure and costly repairs in the near future.

Important! The clearance between the camshaft cam and the lever is the same for each engine model.

Another point leading to valve ringing is an underestimated gap between the above parts. In this case, the valve is constantly in a clamped state and soon stops closing completely. This leads to a decrease in compression and failure of one or a group of cylinders. But this is quite difficult to determine. A common cause of valve ringing is detonation in the cylinders, which creates a kickback in all elements of the piston group. Due to the increased recoil on the parts, they begin to make a metallic ringing sound.

Attention! However, valve knocking can often not be immediately detected and can be confused with a metallic knocking sound from a chain or crankshaft bearings.

The main causes of valve knocking

Smooth engine operation without extraneous sounds often indicates timely and high-quality maintenance, in other words, its serviceability. The appearance of uncharacteristic sounds is the first signal of a malfunction. Unfortunately, the malfunction does not always manifest itself in this way. Valve knocking can be attributed to a problem that can always be determined by ear. A problem like this can signal many future problems.

Risk area

As a rule, problems of this kind occur on an engine with high mileage or a serious problem. In addition, engines that are operated under heavy loads fall into the risk zone; for example, a semi-truck is equipped with an engine that is not designed to transport a load of a certain weight. In addition, valve knocking is a common occurrence on domestically produced cars. However, there are known cases when knocking appears on a cold engine in new foreign cars. What problems can lead to such a phenomenon?

What is the problem?

No matter how far progress has gone in the field of automobile construction, the operating principle of the internal combustion engine has remained virtually unchanged, only improved. Why does valve knocking occur?

Such problems can be prevented if you determine in time whether the valves are knocking or the sound comes from other elements of the internal combustion engine.