A little about the camshaft

Fortunately for many, the camshaft is not one of the components that are positioned as capricious, often and quickly failing. The resource largely depends on the quality of the part and operating conditions.

The camshaft has a life limit. Uninterrupted operation can last from 50 to 150 thousand kilometers. These are fairly average indicators, since each situation is still individual. Active work is already underway to remove this element from the engine design. Moreover, experts say that in the future the camshaft may completely cease to be part of the engine. It will be replaced by electromagnetic actuators.

It is difficult to say how effective and realistic this will be in the near future. Plus, some skeptics doubt the correctness of the transition from a mechanical part to a computer-controlled actuator.

What is engine knocking?

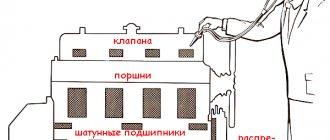

The appearance of engine knocking in most cases indicates that in the area of mating of certain parts there has been a critical increase in the gaps between the elements. If the engine lubrication and cooling systems are functioning normally, then noise and knocking begin to appear at clearances that, on average, are double or more times the permissible parameters. The strength of the knock directly depends on how much the gap has increased. It turns out that knocking in the engine is the impact of parts against each other, the load at the point of contact increases significantly. In this case, wear of parts occurs much faster.

The rate at which further wear increases will depend on the size of the gap, materials of manufacture, load, lubrication efficiency and a number of other factors. For this reason, some components can go through tens of thousands of kilometers with a knock without serious consequences (the timing belt), while others (CVM and CPG) can fail after just a few kilometers. In some cases, the engine may knock even if the clearances are normal and there is no serious wear on the parts. This knocking noise can be caused by:

- detonation and heavy loads on the internal combustion engine;

- distortions of parts inside the engine;

- jamming of individual elements;

- loss of protective and other properties by motor oil;

Eliminate camshaft knock (axial runout) with your own hands

Many people already know that the VAZ 2111 injection engines have the following disease: “Axial runout of the camshaft.” This disease does not progress and does not cause damage to other timing components, but it manifests itself in the form of an unpleasant camshaft knock. It just so happened that the developers of the 2111 engine missed this point.

Where carburetor engines used to have a fuel pump and distributor, injection engines have a regular plug into which the camshaft rests. The camshaft axial play set by the manufacturer should not exceed 0.15-0.20mm. Over time, as the camshaft pastel wears out, the axial play increases, and a distinct knock begins to be heard from under the valve cover. Of course, you can continue to drive with this knock and not worry, but not every car enthusiast will be pleased.

Check time alignment

If the crankshaft and camshaft marks do not match, the engine will not run correctly. Installing time stamps on a VAZ 2107 injector is no different from the same procedure on carburetor engines. The mark on the crankshaft pulley must match the mark on the front engine cover. And the point on the rim of the camshaft sprocket should be opposite the beacon on the bed.

Align the sign on the star with the ledge

When putting on the sprocket, block the camshaft so that it is stationary. Do not tighten the nut completely. Align the marks on the camshaft by turning the sprocket. The chain should remain in its original position, so throw links until you reach the alignment of the mark and casting on the bed. Then move the crankshaft with a wrench a quarter turn counterclockwise. Turn the crankshaft in the opposite position so that the marks on it match. When the marks are aligned on the crankshaft and camshaft, tighten the nut on the camshaft sprocket using a wrench. Tightening torque - 5 kgf. Adjust the chain tension using the tensioner.

READ Towbar for VAZ 2110 Do It Yourself

Why do my fingers knock in the engine?

So, let's begin.

| Index |

| I. Blue smoke comes out of the exhaust pipe |

| II. My engine won't idle |

| III. My engine is making shots from the exhaust system |

| I can hear the crash |

| V. I hear a rumbling noise |

| VI. I hear a knock |

| VII. My engine has no power |

| VIII. Preventing problems |

Problems with the valves can lead to exhaust pipe smoke.

Can the camshaft make a knocking noise?

Many people have encountered crankshaft knocking in their lifetime. But not all drivers know how and when exactly the camshaft knocks.

It's all about the sounds. They are really very similar to each other. This appears the same on different cars:

- for VAZ 2106;

- Niva has 8 valves;

- VAZ 2107;

- VAZ 2109;

- on Priora;

- VAZ 2110;

- VAZ 2114;

- for Daewoo Nexia;

- for Subaru Forester, etc.

But what should a car owner do when he hears a sound, but cannot understand what exactly is knocking? Is it the crankshaft or the camshaft?!

Here you just need to listen and observe the behavior of the car and specifically the engine. Sometimes this makes it quickly clear where the source of extraneous sound is, and which unit needs to be prepared for repair.

The key role is played by the fact whether you hear sounds when it is cold or when it is hot.

You will be able to hear sounds from the camshaft only when the internal combustion engine is cold, when the engine starts and the lubricant has had time to leave the rubbing elements. After starting, the oil will gradually lubricate them, causing the knocking noise to disappear.

- The camshaft makes so-called dull sounds;

- Noises appear precisely when the engine is cold, when the engine starts;

- Initially the crankshaft sounds similar;

- As it gains speed, the faulty crankshaft acquires a louder sound;

- In fact, the camshaft is dull and the crankshaft is sonorous;

- An increase in speed will help to accurately determine;

- If you still can’t identify it by sound, you will have to carry out diagnostics.

Based on these points, you will be able to independently diagnose the nature and source of the malfunction without any problems, and then begin the appropriate actions to eliminate them.

The connecting rods or crankshaft are knocking in the diesel engine

Knocking connecting rods is a sign of serious damage, which means the need for a major overhaul of the diesel engine. This “crank knock” of a diesel engine differs from a similar malfunction of a gasoline engine.

Pistons in diesel units come almost close to the cylinder head during reciprocating motion. The appearance of a knock means that the gap in the connecting rod journal of the crankshaft has increased, as a result of which the top of the piston slightly “sticks” into the cylinder head. The second cause of knocking may be a loose connecting rod nut. By its nature, the sound resembles dull metallic knocks, which also occur when the timing belt is incorrectly aligned and has slipped by one “tooth.”

It will not be possible to diagnose a malfunction by turning off the power to each cylinder one by one (used when diagnosing similar malfunctions on gasoline units). The crankshaft will still rotate and the piston will continue to touch the cylinder head. Driving a diesel engine with a knocking rod is strictly prohibited. The car must be delivered to the service by tow or tow truck for boring the crankshaft, replacing bearings, etc.

The knocking noise of a diesel crankshaft is most pronounced when it is cold, when the engine oil has not yet had time to fully reach the bearings through the oil channels. As the engine warms up, the problem is masked a little; the crankshaft may knock less intensely at certain speeds. On a cold engine, the sound is metallic, rhythmic and muffled at idle. As the speed increases, the rhythm increases and the knock becomes louder.

The crankshaft may knock due to too large gaps that appear in the main or connecting rod bearings. The crankshaft begins to knock as a result of worn journals and/or bearings.

An increase in gaps and wear is caused by operating the engine on dirty oil or low-quality lubricant, or by untimely replacement of engine oil in a diesel engine. The crankshaft can knock if excess fuel gets into the oil as a result of damage to the cylinder head, as well as working fluid from the engine cooling system.

Another common cause of diesel knocking is a clogged oil filter, as metal particles and debris, along with the oil, enter the camshaft bearings. A working filter element cleans the oil well, but when the throughput decreases, the valve opens and dirty oil freely flows into the engine without filtration.

Knocking noise from a diesel engine crankshaft can occur as a result of a drop in oil pressure and a lack of lubricant supplied to the bearings. Such a malfunction can be caused by improper operation of the oil pump of the engine lubrication system, or a clogged oil filter, which structurally does not have a valve for direct oil supply, bypassing the filter element.

Occasionally the oil channel becomes clogged. The crankshaft can knock even after a short drive with a critically low oil level in the engine crankcase. In such cases, the knocking of the crankshaft is accompanied by the lighting of the oil pressure warning light on the instrument panel (provided that the oil pressure sensor and the indicator on the dashboard are in good working order)

The presence of scratches or a rough surface in the area of the shaft journal after repair work can also be the cause of diesel knocking after assembly. If the necks of the shaft or the bed of the liners have become oval beyond the norm, then the knob will knock.

Before installing a new shaft (or after restoring an old one), it is imperative to measure each journal with a micrometer. This is done in order to check that the ovality indicator is within acceptable limits to a maximum of 0.005 mm.

What to do

Drivers had to deal with the fact that occasionally after the start an incomprehensible knocking sound began to appear, but when accelerating and warming up the engine it disappeared. As we have already figured out, most likely the camshaft on the engine has failed.

Now another question. What to do in such a situation? If it is the camshaft that starts knocking, you should be prepared to spend a considerable amount of money. But this is not a 100% probability, since sometimes hydraulic compensators begin to knock, or knocking noises are made by worn gears and bearings. Not all situations solve the problem by replacing the entire camshaft. If you suspect a knocking noise from this unit, it is better to immediately go for diagnostics. Due diligence can help you find out where the source of the problem is and what needs to be done about it.

It’s definitely not worth delaying diagnostics. If the compensators fail, and the problem was in them, then the chain reaction will lead to the breakdown of the shaft itself. And these are completely different expenses. So it would definitely be a good idea to check the hydraulic compensators.

You can drive a car without hydraulic compensators with a knock from the camshaft for more than 50 thousand km, but then you will probably have to completely change the engine or carry out major repairs.

As you can see, delaying the check is definitely not in your interests.

Why does the engine knock?

Noise in the operation of the motor signals the presence of a deviation in the operation of a particular unit. In this case, you should not immediately condemn the internal combustion engine and prepare for its capitalization or replacement.

First of all, it is necessary to find out what exactly in the engine is responsible for the appearance of this symptom. You need to pay attention to which part of the engine compartment the noise is most intense.

In addition, it is also important to take into account the conditions under which this phenomenon manifests itself most clearly. Let's consider a number of reasons for knocking during engine operation, which are included in the list of the most common.

- detonation phenomena in the operation of internal combustion engines;

- increased wear of components;

- mechanical damage to elements.

The first reason most often occurs when low-quality fuel is used. The fact is that in the vast expanses of our vast Motherland there are many charlotans who, under the guise of 92 or 95 gasoline, “sell” cheap low-octane fuel, which is less resistant to detonation.

This phenomenon often occurs when the car is operated for a long time at low speeds. Such “careful” driving can play a bad joke on the car enthusiast. The fact is that in this case, carbon deposits form on the walls of the pistons and combustion chamber, which can cause detonation processes.

The second, no less common reason for the appearance of noise in the internal combustion engine area is directly related to the wear of key components and elements. In most cases we are talking about motor bearings.

Thus, the occurrence of increased gaps in the contact areas of the rubbing surfaces of the crankshaft and camshaft has a negative impact on the uniform operation of the entire power unit.

It is worth noting that the presence of an oil pressure warning lamp in this case can serve a good purpose. If there is increased wear of the crankshaft liners, as a rule, this leads to a decrease in pressure in the oil line, which is indicated by the indicated lamp.

Among other things, a characteristic noise can also be produced by an elongated timing chain. To solve the problem, it will be enough to tighten it in strict accordance with the manual.

Is it correct to independently determine the source of the knock?

Even an experienced driver can misinterpret knocking noises coming from the engine, since not every car enthusiast has encountered repairs to this unit. Any bearing, bearing or other element can produce sounds that will be interpreted in different ways. If the oil has been changed a long time ago, and fuel is used only from trusted brands, then the only thing you need to pay attention to is the intensity. Increasing knocking sounds indicate not the most pleasant reasons, which only professionals can eliminate.

However, looking for a source yourself is still the right decision, since in most car services workers are not in the habit of doing cheap and long work. The easiest way to answer the client is that only an expensive “capital” will help, but this is not always true, because sometimes it’s enough just to change the oil.

Why do engine valves knock?

But problems with the valve train can occur even if you regularly maintain your engine and make the necessary repairs, especially if it has a high mileage.

Whatever the cause, this guide will help you diagnose the most common valve train problems and their potential sources. Diagnose the problem sooner rather than later to avoid costly repairs.

To make this easier, the following sections are divided into symptoms that can be caused by different types of valve problems. Look at the index below. If one or more of these symptoms are similar to what you are dealing with, go to this section. Reading the additional sections will give you more ideas about the types of problems that may arise and will help you with your renovation project.

Before you begin, however, keep in mind that while we're focusing on valve train problems here, none of these symptoms are exclusive to the cylinder head. Therefore, try to get as many clues as possible during the diagnostic phase and, if necessary, troubleshoot suspected components. You will find some troubleshooting tips in the relevant sections.

The main causes of knocking

See also

The key elements of the assembly are the neck and cams. Malfunction of the camshaft elements leads to the formation of extraneous knocks during engine operation.

If you hear this knocking noise, the problem lies in one of the following reasons:

see also

- Play in the shaft bed. It is unlikely that you will be able to solve the problem on your own. This requires boring or honing of the bed itself, or a complete replacement of the unit;

- Problems in the lubrication system. Even with a slight disruption of its operation, sound may appear. Moreover, the reason is not only in the quantity, but also in the quality of the lubricant;

- Deformation and mechanical damage. Most often, the supports burst and the neck breaks;

- Violations in the regulation of fuel supply processes;

- Development of the resource of cams. If the problem is definitely in the camshaft, and the knocking noise appears even when it’s hot, then the problem is in the cams.

It is almost impossible to give an accurate forecast as to what exactly was the source of the knocking noises without conducting comprehensive diagnostics. Masters often talk about this in various videos where the problem under consideration is described.

In any case, the knock should alert you. Whether you have hydraulic compensators or not, it does not matter. The sooner you send your car for diagnostics, the higher the chances of getting by with little damage and spending a minimum of effort and money to fix the problem. All in your hands.

Subscribe to our website, leave comments, ask relevant questions and tell your friends about our project!

DVS64 › Blog › Ringing in the engine when hot on a Lada Priora.

Yesterday I was at a meeting with the guys from the Lada Priora club in Saratov. We did a diagnosis on one of the club members. So he complained about a hot ringing in his car, apparently a piston ringing in one of the cylinders; by the way, the wear on the cylinder liners turned out to be really quite large. I would like to say this: This is the piston skirt knocking, everything can end sadly, with the cylinder breaking. Here is an attempt to describe the physics of the process of the piston knocking when it’s hot (if the piston knocks when it’s cold, then “the matter is already taking a fatal turn”). My personal experience in this is as follows: “Apparently, the reason for the knocking is the poor quality of the material of the original pistons; during winter operation, scuff marks appear on the skirts, which in turn, when heated, expand along with the piston, the skirt of which is no longer ideally evenly loaded at idle side on the cylinder walls, and the oil becomes more fluid when heated, which does not contribute to reliable lubrication of the defective area, the process further develops and soon moves to the surface of the cylinder, where after approximately 20-30 thousand kilometers scuff marks or aluminum inclusions of particles of the defective piston skirt appear - after which - the logical conclusion of the epic - oil consumption, reduction in traction and further destruction, rings, etc... Is the car owner ready for this?

I think no. PS1 In this situation, replacing the oil with a more viscous one does not help to avoid piston knock.

PS2 When cold, the piston skirt knocks when there is already a fairly large thermal gap between the piston skirt and the cylinder wall.

Does anyone have any other opinions on this issue?

Source

How to choose quality spare parts

Buy a camshaft from a reliable and time-tested company such as PJSC AvtoVAZ. There is a hologram print on the packaging. It flickers in the light and depicts the company logo. There is also a barcode sticker on the box. The product is packaged in blue translucent film. There is a seal from the quality control department inside the package. Buy rockers with adjusting bolts. There are levers of the new and old model. The holes in them vary in diameter and number of cuts. If you buy the arms and bolts separately, they most likely won't fit together.

READ How to Find out the Size of VAZ Piston Rings

Engine knocking when cold

A knock when starting a cold engine, which disappears after it warms up, is associated with the natural wear of its parts, which after warming up take on standard sizes, clearances, etc. A knock in a cold engine differs from a knock in a hot engine in that it goes away after the engine warms up.

Any spare parts that may be required when repairing an engine, including those from leading manufacturers MAHLE and ADDAX-Q, can be found in IXORA stores. Managers will always help you when choosing a product.

* Please check the applicability of parts specifically for your car with our managers by phone (calls within Russia are free).

| Manufacturer | Detail number* | Part name |

| ADDAXQ | CZB003 | Inlet valve |

| ADDAXQ | CZC004E | Exhaust valve |

| MAHLE | 029FX31174000 | Valve guide |

| ADDAXQ | CJC045S | Connecting rod bearing STD |

| MAHLE | 03319N0 | Piston rings |

| MAHLE | 02202N0 | Piston rings |

| ADDAXQ | CJC044A | Main liner 0.25 |

| MAHLE | 08316N0 | Piston ring set |

| MAHLE | 029FX31173000 | Valve guide |

| MAHLE | 0116902 | Piston |

| MAHLE | 0122100 | Piston with pin and rings |

| ADDAXQ | CJA026B | Connecting rod bearings |

| ADDAXQ | CJA034S | Connecting rod bearing STD |

| MAHLE | 001AS18750000 | Axial displacement semi-ring |

| MAHLE | 00249N0 | Piston rings |

| MAHLE | 0045900 | Engine piston |

| MAHLE | 01195N1 | Piston ring set |

| MAHLE | 011VE30337000 | Inlet valve |

| MAHLE | 01317N0 | Piston rings |

| MAHLE | 01337N2 | Piston rings |