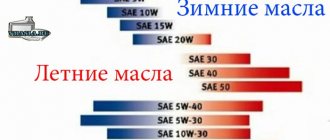

Lubricant poured into the crankcase of a car engine reduces friction and cools the parts of the crank mechanism. The engine oil temperature reaches +130…+140 °C, which leads to an increase in fluidity and a deterioration in the performance characteristics of the fluid. When selecting a lubricant, it is necessary to take into account the design features of the internal combustion engine and follow the manufacturer’s recommendations.

Functions of motor oil

The main functionality of motor oil is:

- reducing friction between rotating parts and elements performing reciprocating movements;

- reducing the volume of gases penetrating from the working chamber of the cylinders into the crankcase;

- removing carbon deposits and deposits from working surfaces and oil channels;

- neutralization of aggressive substances formed during fuel combustion (for example, acids).

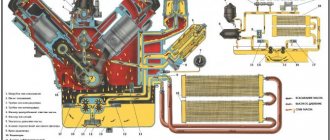

Motor oil is responsible for cooling engine structural elements. In power plants with a liquid heat removal principle, the lubricant removes up to 30% of excess heat. In air-cooled engines, the lubricant accounts for up to 80% of the excess heat.

Compression ratio

The first condition that will determine whether the engine reaches the desired temperature is the compression ratio. This term is discussed in detail here . In short, it depends on how strongly the air in the cylinder is compressed whether the diesel fuel in the chamber will ignite or not. In a working unit, this parameter can reach 6-7 hundred degrees.

Unlike a gasoline unit, a diesel engine ensures fuel combustion by injecting a portion into hot air. The more the volume in the cylinder is compressed, the higher its temperature will be.

For this reason, the engine is tuned so that its compression ratio promotes uniform combustion of fuel, and not its sudden explosion as soon as it begins to atomize. If the permissible air compression is exceeded, the fuel-air mixture will not have time to form. This will lead to uncontrolled combustion of diesel fuel, negatively affecting the dynamic characteristics of the internal combustion engine.

Engines in which the working process is associated with the formation of an increased compression ratio are called hot. If this indicator exceeds the permissible standards, the unit will experience local thermal overloads. Plus, its operation may be accompanied by detonation.

Increased thermal and mechanical load leads to a reduction in the working life of the motor or some of its elements, for example, the crank mechanism. For the same reasons, the nozzle may fail.