Welcome, friends, to the DIY auto repair website. Crankcase protection is an invariable attribute of modern cars. Many manufacturers install protection at the factory.

Engine crankcase protection

But more often than not, the new owner himself makes the decision whether to install such “armor” on his car or not. At the same time, the variety of materials, shapes and designs is often confusing.

A person does not know how to choose crankcase protection and what parameters to pay special attention to. In this article we will look at the main points that will allow you to clearly and accurately determine the appropriate design.

Engine crankcase protection: how to choose and where to buy

Every car enthusiast, of course, wants his car’s engine to last as long as possible. But, alas, not everyone cares about protecting such a vulnerable element as the engine crankcase. Given the state of our roads, such protection is a necessity. It will protect the crankcase from damage due to road defects, dirt and foreign bodies. It will also be an additional anti-theft agent, as it will limit access to the engine compartment.

- Crankcase protection requirements

- What is the crankcase protection made of?

- Basic material selection criteria

- How to install it yourself

First, let's understand what crankcase protection is in a car. This is a body part located underneath the engine and designed to protect it. The crankcase guard looks like a plate with functional holes.

Interesting fact! The word “crankcase” comes from the name of engineer-inventor Harrison Carter, who invented the housing that lubricated and protected the chain of the Sunbeam motorcycle back in 1889.

In this article we will look at various aspects of choosing and installing crankcase protection.

Crankcase protection requirements

Since crankcase protection plays such an important role, you should choose it responsibly. Let's start by determining what requirements it must meet.

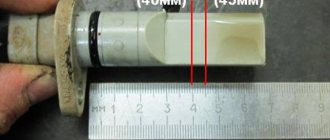

Firstly, the protection must have optimal rigidity (deformation within 20-30 mm), weight (within 7-15 kg) and sufficient strength.

Secondly, it must have a minimum number of technological holes that will provide access to the crankcase plugs, but will not impair the strength of the protection.

Thirdly, the protection profile must guarantee a gap of 2-3 cm from the crankcase to ensure unimpeded heat transfer. Fourthly, noiselessness is important, that is, contact with the subframe should not be heard in the cabin when driving.

And fifthly, safety comes first, and therefore crankcase protection should in no case affect the designed deformation pattern of the body in an accident.

Important! It is better to buy original factory protection. It will be equipped with all the necessary holes that will match the car underbody parts.

What is the crankcase protection made of?

When choosing engine crater pan protection, the material from which it is made plays an important role. There are many factors to consider here. After all, it often performs not only a protective function, but also some specific ones. Let's take a closer look at what types of protection there are.

Crankcase protection is made either from metals or from composite materials (plastic). In turn, they can be divided into the following types.

Made of steel 2 mm and 3 mm (reinforced)

- Aluminum

- Stainless steel

- Titanium

- Made from fiberglass

- Carbon fiber

- Kevlar

Interesting! High-tech carbon fiber is used in the space industry and in the production of Formula 1 cars.

Basic material selection criteria

Each material has its own characteristics, advantages and disadvantages. To make it easier for you to make your choice, below are the main properties of each type.

Steel protection. They have proven themselves positively. The advantages include comparative cheapness, ease of repair and rigidity. The downside is corrosion. For standard vehicle use, this is a good value for money option. Protections made of 2 and 3 mm steel have the same characteristics, only those made of 3 mm steel are slightly more expensive, heavier and less repairable. They are better suited for SUVs.

Did you know? Original crankcase protection offered by global car manufacturers (Audi, VW, BMW) are made only of steel.

Made of aluminum. More suitable for sports cars. They are several times more expensive than steel ones, are more difficult to repair and do not have stiffeners, which we classify as disadvantages. They are more durable than steel ones and are not inferior to them in strength.

Made from stainless steel. Due to the high cost of the material, they are mainly produced individually. Excellent for SUVs due to their high corrosion resistance, durability and appearance.

Titanium crankcase protection. Cost-effective only for expensive, luxury cars. Without taking into account the cost, this is an ideal option, since it is very durable, but lightweight and practically does not oxidize.

Plastic. In the manufacture of such protection, several layers of reinforcing material (fiberglass, carbon fiber or Kevlar) are used, which are connected with resin. Thanks to production technology, it is possible to obtain protection of any form. Resistant to corrosion. They are characterized by high strength, but also high cost. They function also as anthers, very hard. Expensive to repair.

Note! Any of the above protections is not a 100% guarantee of engine crankcase safety, but only reduces the risk of damage to it.

How to install it yourself

Having decided on the choice of protection for the engine and purchased one, proceed with installation. You can do it yourself, following simple instructions.

- Use a lift or place the car on an overpass/pit.

- Remove the boot, if your car has one.

- Install the required cage nuts/bolts/brackets (depending on vehicle make and model).

- Connect the mounting holes on the bottom and on the crankcase guard.

- Tighten the mounting bolts, but do not over-tighten or over-tighten.

Sheriff protection, advantages and disadvantages

The Sheriff crankcase protection is made of aluminum and steel, 2-3 millimeters thick, depending on the vehicle. There are several main characteristics that correspond to the Sheriff engine crankcase protection:

- Durable material - steel engine protection is the best choice for a car, as it withstands impact and can be straightened in case of deformation.

- Reliable fastenings - the development of crankcase protection is carried out taking into account the specific design features of the car, so installation is carried out only on the standard holes of the power components of the body using high-quality fasteners.

- Boot Option - The crankcase guard design features metal or plastic fenders that help keep moisture and dirt from getting under the vehicle's hood.

- Resistant to corrosion - a special powder coating, which is applied using an individual technology, is highly resistant to damage and prevents corrosion.

- Minimizes noise during operation (vibration) - rubber shock absorbers are provided at the junction of the protection with the body.

- Stable temperature conditions - the crankcase protection design has holes for cooling the motor.

- It is convenient to maintain the vehicle - depending on the design of the vehicle, the protection has holes for changing the oil filter and oil.

Owner reviews

If you have not yet decided which protection is better, perhaps reviews from car owners will help you make the right choice.

Composite protection

| Positive reviews | Negative reviews |

| Very light | High price |

| Easy to install | The holes were slightly shifted |

| Withstands hitting rocks |

Steel protection

| Positive reviews | Negative reviews |

| Low price | Started to rust |

| Takes hits well | Noise appeared after installation |

| Quick installation | Very heavy |

Aluminum engine protection

Aluminum crankcase protection is very good; firstly, it is much lighter than metal protection and does not rust, which is also important. You can also purchase ready-made car oil pan protection or make it yourself.

If you make it yourself, you can purchase a fairly thick sheet of aluminum, which will provide reliability no worse than metal, because store-bought versions of aluminum protection are often thin and, when hitting a good obstacle, they are often simply deformed or even tear spots appear in them

Stainless steel

This is a material that is difficult to process, so parts made from it are not cheap. It is often used by SUVs, for example, Rav 4, X-trail, Kia Sportage, Qashqai. It does not show external signs of corrosion, and also has high strength, so it is used to protect the engine. Moreover, when using this particular material, we tick several boxes at once: we get a beautiful look and good quality, forking out a small amount.

What is protection made of?

The question of which crankcase protection to choose haunts many car owners. It is made from a variety of materials - steel, stainless steel, titanium, aluminum and composite materials such as carbon fiber or fiberglass. They all have different properties, and car owners often wonder which crankcase protection is better. Common people are more familiar with metal crankcase protection, while composite ones are just beginning to gain a place on the market, and therefore many drivers distrust them.

Steel

Steel engine crankcase protection is most widespread. First of all, this is due to its low cost; it costs less than any other. At the same time, the steel protection copes well with its main task: thanks to its high strength, it reliably protects the crankcase from impacts. As a rule, its thickness is 2 mm. In the vast majority of cases, this is quite enough, and even if it becomes deformed after an impact, it can always be removed and relatively easily straightened with a sledgehammer.

Reinforced steel protection is also found in stores; its thickness reaches 3 mm. It is used on SUVs that are constantly used in particularly difficult conditions. It weighs more and can easily withstand strong impacts, but restoring a deformed sheet with your own hands is much more difficult. The main enemy of steel protection is corrosion, which primarily affects the attachment points.

Stainless steel

Stainless steel protection is no different in its characteristics from ordinary steel. Its only advantage is corrosion resistance and a more presentable appearance. True, it costs much more. As an alternative, many drivers install conventional steel protection and attach a decorative stainless steel trim to the front, thus achieving an attractive appearance of the car without extra costs.

Aluminum

Aluminum protection is much more expensive than steel protection due to the high cost of the metal itself. Its advantages include high rigidity, due to which it does not deform, and a long service life. It is also important that aluminum does not spark when hitting an obstacle, so the likelihood of an accidental fire in the engine compartment is practically reduced to zero. In addition, the weight of such protection is less than that of steel.

Aluminum protective sheets also have disadvantages. First of all - the price, second - the lack of stiffeners, the third disadvantage is that aluminum oxidizes in air, and after a while such protection does not look very nice. The fastening bolts at the points of contact with the aluminum may also become sour, which may cause problems in removing the protection.

Article on the topic: Anti-corrosion treatment of the body: is it worth doing the maintenance yourself?

Composite

Composite oil pan protection is made from composite materials such as fiberglass or carbon fiber. Its undoubted advantage is its light weight, as well as the fact that it is not subject to corrosion and quite reliably protects the crankcase from impacts.

It has many more disadvantages, and together they outweigh its advantages. After strong pinpoint impacts, chips or even cracks appear on the sheet, which cannot be repaired, i.e. it is purchased for one time, and then, most likely, will require replacement. In addition, composite protection (carbon, plastic, Kevlar) conducts heat poorly and can cause engine overheating, and its cost is very high, especially for products made of Kevlar.

Titanium

Perhaps the best material for protecting the engine oil pan is titanium. It combines all the advantages of other materials:

- high strength;

- resistance to corrosion and oxidation;

- light weight.

Titanium protection has the only drawback compared to its other competitors - it is very expensive.

Where can I buy

Today there is enough of this goodness on the auto parts market. For common budget and middle-class car models, protection can be purchased on the auto parts market; there are many of them in every city. For foreign cars, more expensive ones can be bought or ordered from catalogs at an auto parts store. Many of them are divided into European, Asian, and American manufacturers.

Don’t forget about official representatives of car factories, who also offer additional equipment. You can also use their installation services, but keep in mind that their prices are usually inflated.

If you have any difficulties with choosing and installing engine crankcase protection, you can always contact the specialists of our auto center for professional assistance. We will always be happy to help you and your iron horse. Call: 8-917-338-80-12 or leave a request for a call back below.

We hope you now know how to properly protect the “brain of your car.” Each option is attractive in its own way, but differs in price, quality and time that will last. Another important factor is appearance. Don't forget to tell your friends about our article.

See below for an example video on installing protection. Choose an option to suit your taste and budget and ride with pleasure!

With or without protection? It's up to the owner to decide

Usually, before deciding to install crankcase protection , car owners hesitate a little, however, given the quality of domestic public roads, such hesitation is completely unnecessary. After all, the standard protection is an ordinary thin plastic boot, which at best protects against sand/dust, but not against possible road ledges or stones. Such a boot is especially useless in winter, when the road is dotted with numerous ice growths that strive to pierce such a vulnerable engine crankcase, or in relatively off-road conditions, where you can run into, including a wooden snag.

Here is what is important in choosing the main consumer qualities:

- structural rigidity;

- its weight, the lower it is without compromising the main function - protection, the better;

- high degree of safety in the event of a collision;

- no extraneous noise after installation.

In a word, the decision to use crankcase protection is made exclusively by the owner of the vehicle, which he strives to protect as much as possible from possible damage.

Which crankcase protection is better to install or choose?

We are constantly asked which crankcase protection is best to install on a Polo sedan? Or which crankcase protection to choose for Solaris?

The answer is simple - you need to choose protection with the characteristics that you want to see!

What is crankcase protection?

This product is made of some kind of impact-resistant material. Anther is one thing. Defense is different. For sports, the weight of the part is important, but for others, the price is important. Some people want a hole for draining the oil, while others want a tightly closed sheet... So many people, so many opinions. Correction: characteristics can sometimes overlap, for example, a steel crankcase protection (although it can protect the underbody, gearbox, something else) performs the same functions as a plastic boot, i.e. protects components and assemblies from water and dirt + has its own characteristics, this is the safety of the car (you can say “takes a hit”). But it doesn’t work the other way around; the plastic boot will crack the first time it hits an obstacle. Now the market is diverse, there are many options, different configurations and materials: plastic, metal, aluminum, fiberglass. All materials have their pros and cons! Read customer reviews or the history of the manufacturer and find yours!

Crankcase protection, why is it needed?

The engine is the heart of every vehicle, so it requires regular maintenance. Damage to the engine crankcase is the main danger for transport. As a rule, the causes of crankcase damage are careless driving and poor-quality road surfaces.

It is worth noting that on many domestic and foreign cars there is no engine protection, although the engine is actually mounted at the bottom of the vehicle and is the lowest point to the road surface. To protect the engine from dust, a special boot is mounted on the car, but it is not able to protect the engine compartment of the vehicle from water, dirt and stone impacts, which often fly off poor-quality road surfaces when driving. All these factors are quite capable of leading to serious damage. That is why many car enthusiasts install protection on the crankcase.