What does the cylinder head consist of?

In almost all engines, the cylinder head design is the same.

It includes:

- The body of the product, which is made by precision casting. It provides channels for supplying coolant and engine lubrication to rubbing parts.

- Valves in the intake and exhaust ports.

- Camshaft (in some designs there are two).

The main element of the cylinder head is the housing. It, together with the gasket, ensures sealing of the combustion chamber. Valve guides are pressed into the body; their number depends on the design features of the cylinder head. The valves move in bushings, ensuring the supply of fuel and the removal of exhaust gases. Aluminum is used to make the head housing; it is attached to the block with bolts made from high-quality steel.

Cylinder head

The coefficient of thermal expansion of these metals is different, so it is possible to ensure high tightness of the combustion chamber only if the head is tightened evenly over the entire plane of the cylinder block. If this condition is not met, the power unit may fail.

About the forces acting on the cylinder head during engine operation

It is impossible to ensure uniform thermal impact on the head while the engine is running. The areas in the housing located above the combustion chamber are subject to the most intense heating, which causes metal stress in these areas. The pressure force of the aluminum housing on the gasket between the cylinder head and the cylinder block increases greatly, which can damage it. To avoid this, periodically tighten the cylinder head bolts.

Forces acting on the cylinder head while tightening screws

It is not possible to ensure high tightness of the combustion chamber only by installing the head on the cylinder block, so there is a gasket between them. It has lower rigidity; when the bolts are tightened, the gasket is compressed, thereby sealing the gaps. If the fastening screws are screwed in in a random order and the tightening torque of the cylinder head bolts on the key is not controlled, the head housing may be deformed or the gasket will burn out.

It should be recalled what the tightening torque of bolts is. This means the amount of force on the wrench that will ensure a tight connection between the head and the cylinder block. The tightening torque of the bolts and the sequence of work are indicated in the repair and operating instructions for the vehicle. These recommendations should be followed strictly.

How to tighten cylinder head bolts

From studying. It is by studying the Repair Manual for your car, preferably the original one. It is there that the manufacturer indicates everything that is necessary to tighten the cylinder head. And you need to know:

- the procedure (diagram) for tightening the cylinder head bolts;

- what tightening torque is required;

- what bolts are used to tighten the cylinder head.

Bolts for tightening the cylinder head are a special matter. The fact is that in modern engines, bolts with special characteristics are used for the cylinder head. So-called “spring” bolts, which, due to their properties, do not require additional tightening after initial tightening at the factory.

Moreover, when trying to tighten the cylinder head bolts, due to the “fluidity” of the metal, they will be pulled out. As a result, you may end up with a broken bolt.

When repairing the cylinder head, it is necessary to install gaskets that do not shrink. This eliminates the need to tighten the cylinder head bolts.

But, if you have already decided that you absolutely need to tighten the cylinder head bolts, then you should do it with the “manual” from the manufacturer and using a torque wrench. Movement to movement, number to number. Amateur performance based on reserve is not needed here.

When is it necessary to tighten the cylinder head?

The design of engines is constantly being improved, service life is increasing, and the amount of work on servicing power units is decreasing. Motors manufactured after 2010 no longer require periodic tightening of the head bolts. For earlier engines, it is recommended to carry out such an operation at each regular maintenance. When the machine is used for a long time, traces of engine oil or coolant leaks sometimes appear. In this case, it is necessary to immediately tighten the cylinder head fasteners, otherwise serious engine repairs may be required. The causes of leaks may be overheating of the power unit and non-compliance with the bolt tightening order.

Errors when installing the head

If you do not use a torque wrench when installing the cylinder head, you may make a mistake with the force, which will lead to uneven torque. In such cases, there will be excessive or insufficient force, which will result in either deformation of the head surface or allow the breakthrough of gases, oil or coolant. In both cases, this is fraught with serious consequences for the engine.

If you follow the rules for tightening the fastening bolts, as well as the required torque, you can always count on reliable and durable operation of the installed parts. The gas distribution mechanism in the engine plays a major role, so you should not neglect the rules for installing the component elements.

Source: autochainik.ru

Basic recommendations

First of all, it should be noted that such a procedure can be carried out after repairing the power unit or in order to check the tightening torque of the bolts during engine operation. If the cylinder head has been dismantled, you should carefully inspect the bolts, as well as the holes in the cylinder block for their installation. Screws must not have elongation or deformation of the threaded part. The holes in the block for the bolts are cleaned of any remaining engine oil, liquid, or other foreign particles. If this is not done, the cylinder block may be damaged, and the cylinder head will not be able to be tightened with the required force.

Work should begin only after reading the vehicle manufacturers' recommendations for operation and repair. There the driver will find all the necessary information to complete the job, including the forces and sequence of tightening the bolts.

Important! For engines with TTY bolts, there is a prohibition on reuse, as they may break.

Another feature of using such bolts is their installation at a certain angle. To do this, you will need a special key with an indicator that will show the degree of inclination.

User Igor Ivanov shows in the video the installation and tightening of the cylinder head.

What errors may occur

Unfortunately, drivers who independently restore the power unit make annoying mistakes that can harm the cylinder block and the working tool.

These include the following:

- leaving motor grease or other foreign particles in places where fasteners are installed;

- overestimation of the bolt tightening force;

- using a tool not intended for this operation;

- non-compliance with the sequence of tightening the cylinder head;

- use of bolts of inappropriate length.

If the moment of tightening the motor mounting screws is determined “by eye,” most often overtightening occurs, which leads to the bolts breaking. Worn edges of the key can damage the head of the fastener, after which it will be impossible to screw it in or out. Changing the order of installing the bolts yourself will lead to overstresses in the head housing, and this can lead to the appearance of cracks. They can be through, which contributes to the appearance of lubricant or coolant leaks. A gas breakthrough will appear in the intake or exhaust manifold. Interruptions in the operation of the motor will begin and its power will be lost.

If engine cooling fluid enters the lubrication system through cracks or burnouts, the engine oil will dilute. After this, the lubricant pressure will decrease, and its supply to the friction points will be insufficient, and the crankshaft liners may turn. Many documents allow the reuse of fasteners, but it is better to use new products. The cylinder head should be attached to the cylinder block only with high-quality screws.

General recommendations for broaching the cylinder head

Finally, let's highlight the main tips that are important to consider when doing this kind of work:

1. Strictly follow the manufacturer's recommendations regarding the order of tightening the bolts, as well as the required torque. All these issues are discussed in detail in the manual.

There is no point in listing them, since they may differ for each model.

2. When tightening bolts, use only a working torque wrench. Don’t rely on your “eye” and the “good old” wrench.

3. If you suspect a low quality bolt, replace it. Here the “yes, it will do” principle can lead to many problems in the future.

Before tightening the bolts, be sure to check the cleanliness of the threads and their condition.

Please note that the secondary use of spring bolts is prohibited - you still will not achieve normal broaching.

As a result, after a few hundred kilometers the oil will begin to squeeze out from under the gasket.

4. Pay special attention to the choice of gasket - it should indicate the permissible moment of force (it is not advisable to exceed it).

At the same time, make sure that the numbers on the product at least approximately correspond to the manufacturer’s recommendations.

5. If there is a “blind” mounting bolt, carefully fill in the oil. Otherwise, it can be “overdone” and the bolt simply will not be tightened to the required moment.

If there is a through hole, it is advisable to treat the threads with a special sealant.

Remember that stretching the cylinder head is not difficult. The main thing is to strictly follow the manufacturer’s requirements and take into account the recommendations in the article. Good luck on the roads and of course no breakdowns.

Source: remontavtovaz.ru

Procedure and control of cylinder head tightening

When tightening, you should do it evenly, without unnecessary effort or haste.

Before you begin, you need to prepare the following tools and consumables:

- a torque wrench with a socket that will fit the bolt head;

- a small amount of motor or any other oil;

- rags.

Regardless of the design of the power unit, be it a 402, 406 engine or even a G4EE, 4B12, the cylinder head will always be tightened the same way. The mounting screws will be located parallel to the combustion chambers. The operating instructions will tell you how hard to tighten the cylinder head.

Is it necessary to broach the cylinder head?

Welcome, friends, to the DIY auto repair website. The cylinder head (cylinder head) is an important element of the power unit, which only at first glance seems simple.

Cylinder head broaching

The mechanism contains spark plugs, gas distribution valves, combustion chamber blocks, and so on.

In this case, the cylinder block itself and its head are separated by a special gasket made of a special material (usually steel asbestos).

Purpose and structure of the cylinder head

Modern cars overwhelmingly use various types of fuel to perform work due to its combustion. Ignition of the air-fuel mixture occurs in an internal combustion engine.

When fuel detonates in the combustion chamber, the mixture “explodes” and gases are released, which push the piston to bottom dead center. In order for the engine to operate correctly, all exhaust gases are discharged into the atmosphere through the exhaust manifold. For this purpose, the engine design includes a gas distribution system. The most important component of this mechanism is the cylinder head.

The cylinder head of the timing mechanism is designed to provide a seal between the piston and the surface of the engine combustion chamber.

Depending on the design of the car engine, cylinder heads may be made of cast iron or lighter aluminum. The cylinder head is usually shaped by casting. Design features may vary, but basically the head contains parts such as:

- combustion chambers;

- valves (there are intake and exhaust valves, depending on their purpose - the intake valves allow access to the working mixture of fuel and air into the cylinder, the exhaust valves ventilate the cylinder by pushing the exhaust gases into the exhaust manifold with a piston);

- section of the gas distribution mechanism;

- cooling jacket;

- casting for injectors or spark plugs;

- oil channels.

A gasket is usually installed between the cylinder block and the head, which prevents the breakthrough of gases from under the combustion chamber, as well as oil and coolant from the channels connecting the cylinder head and the block itself.

Important! If the cylinder head mounting bolts are tightened incorrectly and unevenly, the tightness of the combustion chamber will be compromised, and this will lead to loss of power, burnout of the gasket and failure of the head itself (deformation or cracking of the housing is possible).

About the forces acting on the cylinder head during engine operation

When a car engine is running, the head is exposed to high pressure (due to the compression stroke in the combustion chamber, the pressure can reach up to 15 atmospheres), high combustion temperature of the mixture (about 550-600 ºC), and vibration from the crank mechanism.

A gasket of a certain thickness is installed between the cylinder block and the head - when the head bolts are tightened, this thickness decreases (shrinks) and the cylinder head fits tightly to the engine body. But during tightening, the head tends to deform by thousandths of a millimeter, so the bolts are always tightened in a certain order.

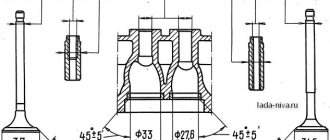

Forces acting on the cylinder head during bolt tightening

In the process of tightening the bolts at their fastening points, the pressure on the surface increases significantly, which in turn leads to a V-shaped deformation of the “sole”. If the tightening order is not followed, as well as with an unregulated torque (force), installation of the head can lead to burnout of the gasket due to gas breakthrough, which will lead to more serious consequences.

How is the tightening torque of VAZ 2109 bolts adjusted?

If it is necessary to tighten the cylinder head of a Nine engine, it is important to observe not only the strength and degree of tightening of the bolts, but also other conditions. Below we will look at how to correctly stretch the cylinder head on a VAZ 2109.

What will you need?

The procedure for tightening fasteners after removal and repair, as well as when installing the cylinder head, is carried out exclusively with a torque wrench.

A dynamometer is a tool designed to tighten the cylinder head screws of various engines.

In addition to the key, you will also need a caliper or a regular ruler.

User Marat Ibatullin made a video in which he clearly showed how the task of tightening the screws is performed.

Scheme of work

The order of tightening the bolts on cars with an injector or carburetor engine is determined by the manufacturer and is indicated in the service book for the car. According to the diagram, the pulling procedure begins with the central two cylinder head bolts.

The cylinder head bolts must be tightened as follows:

- First, you need to twist the screws with a force in Newtons of 2.0 kg/cm.

- Then the bolts are tightened to a torque of 7.5-8.5 kg/cm.

- After this, all screws must be tightened 90 degrees.

- At the end, each bolt is rotated 90 degrees again.

How to tighten the head screws of a VAZ 2109 block with your own hands:

- The torque wrench holder is placed in the zero position. This indicates that the instrument data corresponds to the moment of the initial position.

- Evaluate the indicators on the key before starting the tightening procedure.

- The tool holder can now be rotated. Monitor the readings as you complete the task.

- If it happens that the torque does not change during tightening, then the head mount may be stretched. This is quite normal, as it should be. First, use a wrench to tighten the screws to 2 kg/cm. Follow the tension sequence shown in the diagram.

- At the next stage, the covering is performed again in the same sequence. Only now the bolts need to be pulled to approximately 8 kg/cm.

- At the end of the procedure, the screws must be tightened once 90 degrees in a circle, and then again 90 degrees.

Channel RUS13 in its video showed how to install the cylinder head on a VAZ 2109 engine and tighten the bolts.

Tightening rules

What nuances should be taken into account when carrying out this procedure:

- Observe the appropriate tightening torque for the VAZ 2109 cylinder head.

- The use of wrenches and other tools is not allowed, since the degree of tension can only be determined using a dynamometer.

- To perform tensioning, only working screws are allowed. The bolts must meet the requirements of the power unit installed on the machine.

- Before completing the task, make sure that the holders are in good working order.

- If the cylinder head has been replaced or repaired, then the old bolts cannot be used for tension; new ones must be purchased. On sixteen-valve power units, it is allowed to re-use screws to fix the block head, but only if the length of the parts is no more than 9.5 cm. It is necessary to measure the length of the screw only with a washer. If the bolts are larger than 9.5 cm, they must be replaced.

- If the vehicle is equipped with an aluminum head, then the cylinder head is fixed with TTU type screws. They cannot be tightened because they are screwed into a thread with a certain degree.

- When purchasing a cylinder head gasket, you need to pay attention to the manufacturer's specifications. They often prescribe a certain tightening ratio required for specific gaskets. Please note that the specified moment of force should not diverge much from the one applied during the work process.

- In power units equipped with aluminum cylinder heads, the tightening procedure is carried out on a cold engine. As for cast iron engines, in such internal combustion engines it is necessary to perform the tightening while it is hot.

Any internal combustion engine has several main components. This is the pallet, the main block, the head, as well as attachments. It is imperative to strictly observe the tightening torque of the cylinder head bolts, as this affects the operation of the entire engine as a whole and the gas distribution mechanism.

During engine operation, a very large amount of heat is released, so the block design has a jacket through which cooling liquid flows. Lubrication, which is also necessary for the engine, is supplied through channels to the motor elements. To prevent coolant and lubricant from mixing, the design provides for a gasket between the head and the main block.

When is it necessary to tighten the cylinder head?

On modern cars, it is no longer necessary to re-tighten the cylinder head bolts - this work was previously carried out on old cars of the VAZ, UAZ, MOSKVICH family - this operation was the main one when passing the TO-1 car.

When replacing a gasket, you need to have the right equipment, favorable weather conditions (or take into account existing ones), straight arms and a clear head. It must be taken into account that the ambient temperature can quite strongly affect the cylinder head installation process.

When is cylinder head broaching necessary?

Maybe not all car enthusiasts know, but modern cars do not require preventative cylinder head broaching.

Previously, pulling the cylinder head was a mandatory item during the first maintenance, but then the situation changed. Even relatively modern VAZ engines. Broaching the cylinder head is mainly required today for older models of VAZ, UAZ, Moskvich, etc. engines.

The main reason that prompts a car owner to think about the need to tighten the cylinder head is “wet” at the junction of the head and the block. This indicates an existing oil leak.

There may be several reasons. The most traditional: failure of the cylinder head gasket, warping of the cylinder head as a result of unnoticed engine overheating, or initially incorrectly tightened cylinder head bolts. If you had a capital repair done at a car service center.

In fact, many experts recommend after repairing the cylinder head, after a thousand km. adjust the tightening torque.

Tools used

The equipment you need is a torque wrench with force calibration for a specific car (on different cars, the tightening torque of fasteners can differ significantly), a socket head of the required size, which is suitable for a specific type of fastener.

So, torque wrenches come in several types:

- clicky;

- switch;

- digital;

- other devices.

Snap key

A click (also limit or spring) wrench is used to quickly tighten threaded connections with a given torque. When the required force is reached, a spring mechanism inside the key is activated, resulting in a click being heard, indicating the need to stop tightening with the current torque (force). The error of such a key does not exceed 4% (subject to correct storage and use).

Arrow key

An arrow (torsion) wrench is a lever with an arrow and a force scale (or a dial indicator), which makes it the easiest to use. When using such a wrench, the arrow indicates the current tightening torque when turning the lever. Among the disadvantages of such keys, it is worth noting a rather large error (from 5 to 20%), and over time the steel loses its elasticity, which makes it impossible to adjust it.

Digital key

The digital key (or digital adapter) is the most accurate tool in its category - its accuracy is only 1%. Therefore, such wrenches are often used when installing “critical” threaded connections.

Other devices

Homemade torque wrenches are used when there are no other devices at hand - usually these are homemade mechanisms consisting of a ratchet and old spring scales or modern digital ones. But the error of such devices is much higher than factory keys - this is due to incorrect force calibration.

Assembly of the unit

It is extremely important to observe the tightening torque of the cylinder head bolts. Be sure to use a torque wrench during installation. Only with its help will you be able to evenly tighten all the bolts on the block head. The tightening pattern is to the edges from the middle of the block head. It is necessary to tighten in two steps:

- During the first pass, it is necessary that the force be equal to 4.1 kgf/m (or 40 N*m).

- During the second pass, the force increases to 11.45 kgf/m (95..117 N*m).

- The small bolt, which is installed on the ebb, must be tightened with a force of 3.8 kgf/m.

Assembling the camshaft and adjusting the gas distribution mechanism is carried out only after the cylinder head has been installed. The tightening torque of the remaining threaded connections does not matter; they do not affect the operation of the mechanism.

Correct tightening order

There is a certain order for tightening the bolts; it is the same on almost all cars - from the center of the head to its edges, cross to cross. So, for example, the two central bolts of the right and left rows are tightened first, then the two bolts located to the left of the central ones, then the two to the right of the central ones, then the two bolts located on the left in both rows, and the bolts located on the right in both rows complete the order.

It is important to remember that fastening is always performed in three to four approaches:

- The first approach is a force of 3-4 kgf.

- The second approach is a force of 7 kgf.

- The third approach is a force of 9 kgf.

- The last approach is a force of 11.5 - 12 kgf.

Instructions for tightening cylinder head bolts

As mentioned above, we use exclusively a torque wrench to tighten the cylinder head. It is impossible to tighten the cylinder head with the required force with open-end or ring wrenches, even if you use additional tools, a crowbar or a pipe.

The dynamometer located near the handle shows how much force was applied when tightening, and this requirement must be met accurately. A slight deviation from the requirements is allowed, about 0.5 kg/m.

After you take the torque wrench, remember the second requirement - the order in which the cylinder head bolts (nuts) are tightened. The order is a certain scheme that must be strictly followed.

The central nuts (bolts) are tightened first, and then we gradually move to the edge of the cylinder head.

There are several head tightening patterns, and all of them are correct. The main thing is to follow the “iron” rule: tighten the bolts (nuts) in pairs from the center to the edges. And don’t try to tighten it completely right away, as this can warp the head. Tighten in three stages: first tighten the bolts (nuts) slightly, then tighten them strongly, and then finally tighten them firmly. For the first tightening, set the key dynamometer to 3 kg/m, then more. The intermediate puff should be “sounded” by a characteristic crackling sound. This sound means that the nut (bolt) is tightened correctly. Experienced mechanics recommend tightening bolts (nuts diagonally).