08/21/2021 67,686 VAZ Priora

Author: Ivan Baranov

Sometimes it happens that it is necessary to urgently replace the gasket or change the cylinder head. Such work at a service station costs a lot and to save money, you can try it yourself. This work is not difficult, but requires care; the main thing is to observe the sequence and tightening torque of the Priora cylinder head of 16 valves.

Here you also need to know that the tightening sequence on 16 cl and 8 cl units is different, so you need to be careful. The torque on the 16 and 8 valve power units is the same and passes in four circles.

[Hide]

In what cases is it necessary to tighten the block?

During the operation of any car, including the VAZ 2170 Priora, the engine head is exposed to long-term cyclic effects of gases located in the engine cylinders. On older power units, the tightening of the cylinder head screws could weaken under such loads and periodically needed to be brought to a normal level. Today, all VAZ Priora engines use bolts made of special steel, which are tightened once for their entire service life.

If a coolant and oil leak occurs, there is no point in further tightening and tightening these bolts, since this will not improve the tightness of the joint. The only correct way to combat a leak is to remove the head, check the evenness of the mating surfaces and replace the gasket. After performing any repair work related to removing the head from the engine, it must be tightened in compliance with all necessary conditions.

The video from the author Alex ZW shows the process of installing the cylinder head on an 8-valve engine.

crank mechanism

The correct tightening torque for the cylinder head on a VAZ-2114

This main engine unit consists mainly of the following groups:

Each part of the group has several additional elements. For example, each piston carries a set of O-rings, a connecting pin and pin retaining clips. The crankshaft has bearings and oil seals. The most interesting thing is the structure of the connecting rods.

The principle of operation of the mechanism

VAZ engines, like other cars, are based on explosive combustion of fuel. The piston creates a certain compression of the air-gasoline mixture, a spark from the spark generator ignites it, pushing the piston down, and the crank mechanism (CPM) converts translational motion into rotational motion. This occurs due to the special shape of the crankshaft. The mounting points of the connecting rods are located so that while the connecting rods pushing the pistons rise, the connecting rods pushed by the piston are lowered. And this process takes place in shifts.

Set of connecting rods "Priors"

These parts are collapsible. The main part is made of high quality metal. Only in the upper ring, where the piston locking pin fits, is an insert made of a different metal installed. In general, the connecting rod consists of the following parts:

- connecting rod;

- liner covers;

- coupling bolts 2 pcs.;

- special washers;

- connecting rod bearing.

This is due to the fact that the liners have special grooves for the passage of engine oil. Due to the high rotation speed, this unit requires uniform and abundant lubrication. The slightest discrepancy between these grooves and the oil supply holes of the crankshaft will lead to a disruption in the flow of lubricant and, as a result, jamming of the engine.

Nuances of work

At different times, Lada Priora cars were equipped with engines with a displacement of 1.6 and 1.8 liters and a different number of valves in the heads - V8 (or 8V) and V16 (or 16V). The type of unit head determines the size of the bolts, the order of their installation and the tightening torque of the cylinder head on the Priora.

If the car has an 8-valve engine, then it can use head mounting bolts of different sizes:

- on old motors 21114, M12*1.25 hex head screws are used;

- on more modern 21116, which went into production approximately in mid-2011, M10*1.25 elements with an asterisk head are installed.

When installing a removed head, it is necessary to use new screws, since the old ones will be stretched and have internal damage.

Also, the engines use gaskets of different designs - combined on the old unit and all-iron on the new one. The procedure for tightening bolts for engines with metal and combined gaskets is absolutely identical.

The main nuances when performing work are checking the length of the fasteners, observing the sequence of tightening the screws and monitoring the tightening force. Violation of these conditions leads to damage to parts and the need for additional repair work. The procedure itself is not complicated and can be done independently in any convenient place - in a garage or in an open parking lot, with the exception of the case of installing the head on the engine, which is preferably installed indoors.

It is important to remember that tightening the bolts “by eye” without a torque wrench is unacceptable, since a uniform fit of the mating surfaces of the head and block will not be ensured.

Tools and materials

Before starting the tightening procedure, you should prepare everything necessary to perform:

- wrench with built-in dynamometer up to 100 H⋅m;

- a set of sockets and regular keys;

- Togh E14 key;

- calipers for measuring the remaining length of bolts;

- plate with a marked scale up to 180 degrees;

- new bolts.

A torque wrench is an important tool for DIY repairs.

Step-by-step instruction

Sequence of operation on an 8 valve engine:

- Wipe the cylinder head surfaces and dry the bolt holes in the engine block.

- Install the gasket on the block and align it along the guides.

- Mount the head on top and insert 10 M10 or M12 mounting bolts. If the owner decides to save money and keep the old screws, then they should have a length of no more than 135.5 mm.

- Tighten the elements according to the diagram. The tightening force should not exceed 20 N⋅m.

- Then you need to re-tighten the bolts. The second tightening force should be in the range from 70 to 85 N⋅m.

- Next, you need to tighten the screws by 90 degrees in the same sequence. The rotation angle can be controlled using a special device, which is a plate with an attached scale from 0 to 180 degrees.

- In accordance with the regulations, you need to tighten the bolts again by 90 degrees.

- The attachment of the 8 valve head to the block is complete.

- After assembling the motor, you need to check the quality of operation by starting and warming up the engine. A securely tightened joint between the head and the block should not allow working fluids to leak from the crankcase of the power unit.

Let's move on to the cylinder block

We remove the pallet. Rotating the crankshaft as it is convenient for us, unscrew two bolts on each connecting rod cap. We use a TORX E10 head for this.

We take out the pistons along with the connecting rods. To do this, use the wooden handle of a hammer to press the connecting rod from below and lightly tap it to knock it up. We remove the old liners and buy new ones of the same size according to the markings on them. Here is another stone in AvtoVAZ’s garden, the owner has never climbed into the car from the interior or into the engine, but three pistons were of group “B” and one was “C”.

We buy a new piston group that does not bend the valves, connecting rods and connecting rod bearings.

It was noticed on this motor. To eliminate it, replace the thrust half-rings. Standard and repair sizes are available. We take the first repair size, if they are too tight we sand them down a little. We unscrew the middle main bearing and gently push it with a screwdriver and move the half rings. The mark on it is in the form of three serifs, shown below.

When the half ring comes out a little, turn the crankshaft, it will push it out. There are two types of half rings: white at the front and yellow at the rear; the grooves on them should point towards the crankshaft cheeks.

We install them as we removed the new half rings; if they go in with great effort, you can grind them a little on a small abrasive stone, but not from the side of the grooves. Checking the play. We tighten the main bearing with a torque of 8 kgf*m.

Assembling the piston

There is an arrow stamped on the top of the piston; it should be directed towards the front of the engine. And there are marks on the connecting rod that should look the same way. Don't get confused!

We insert one retaining ring into the groove on the piston. We insert the connecting rod into the piston and, having lubricated the connecting rod and the piston pin with oil, insert it into place. Insert the second retaining ring. Although this operation seems simple, it will take some pains. We inspect the assembled structure; all retaining rings must be clearly in their grooves, otherwise a ring that has jumped out while the engine is running can cause a lot of trouble.

After assembly, you need to break off the connecting rod bearing cap, since the connecting rod is made in one piece. It's like that on our cars. First, unscrew the bolts. We insert the connecting rod into the cleats at the level of the mark shown in the figure with the black arrow and lightly clamp it, then break it off with a slight movement of the hand. The first time is very scary. We put the cover in place and tighten the bolts so as not to mix it up in the future.

We lay out each set of rings for each cylinder. In the future we will not change their places. In turn, we insert each ring into its own cylinder and push it a little with the piston approximately to the middle.

We measure the gap with feeler gauges.

Nominal clearance: 0.25 - 0.45 mm.

The maximum clearance for all is 1 mm. But this already smacks of waste.

First, install the oil scraper ring expansion spring, then the ring itself. The oil scraper ring lock should face the opposite direction of the spring lock. Then we install the lower compression ring and finally the upper compression ring. The inscription “TOP” must be stamped on the rings; it must face up. The rings in the piston grooves must rotate easily.

Video “Installing and tightening the cylinder head on a Priora”

The assembly of the upper part of a 16 valve engine is presented in a video from the Expert R channel.

I encountered the following problem: I replaced the piston with a plugless automatic transmission. The diesel is gone. But on a hot engine, a knock appeared, which directly depends on warming up. The feeling is that the block is moving away and the piston-cylinder gap is coming out (during installation I made 3 hundred parts). So the essence of the issue is that there are two tightening methods that I came across in the literature, 1st - a torque of 20 N m (2 kgf m); 2nd - torque 69.4–85.7 N m (7.1–8.7 kgf m); 3rd - tighten the bolts 90°; 4th - finally tighten the bolts 90°. or Using a torque wrench, tighten the head mounting bolts in three steps - first with a torque of 20 N m (2 kgf m), then turn the bolts by 90° and then turn the bolts again by 90°. I pulled the first one myself. Is the question correct? If you have links to sources, please share.

Adjusting the tightening torque of bolts for a 16 valve car

Adjusting the tightening torque is a simple process, and after reading the material and video in this article, you can handle it yourself. It is enough to tighten it once and then you will be able to do it yourself and at the same time you will be able to help your friends if necessary. It is important to adhere to the diagram for cars with a 19-valve engine and observe the timing.

- a set of keys;

- a torque wrench (no need to buy it, it’s better to borrow it for a day or two);

Torque wrench - knob;

- rod compass;

Shtengel compass - socket heads.

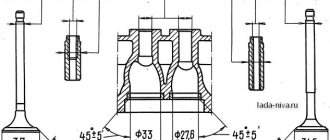

The pattern for tightening on a 16-valve engine differs from the pattern for an 8-valve engine, so we will present both one and the other so that you can compare them.

Diagram for 16 valves Diagram for 8 valves

Just don't get confused when you install. In any case, before starting work, check the instructions that came with the car. Tightening with different torques on a 16 valve unit occurs in 2 circles with different torques, and then another 2 circles with a rotation of 90 degrees. Nothing is difficult, which means you can cope on your own.

In order for self-tightening of bolts to be completed successfully and to last for a long time, a number of simple rules should be followed:

- It is better to use new bolts, since during operation they are under constant tension and lose their properties over time. There is no guarantee that the old bolt will not withstand the stress and will burst.

The length should not be more than 9.5 cm - It is not advisable to reinstall the gasket, even if it is in reasonable condition.

- Strictly observe torque when tightening.

- The sequence of tightening the bolts should be exactly the same as in the diagram for 16-valve power plants.

- Before installing the cylinder head, carefully inspect all parts for damage and deformation. If any are found, do not ignore them, but be sure to replace them. Often, small breakdowns lead to major damage, and sometimes even to the complete destruction of systems and mechanisms.

- Do not use tools of dubious quality and manufacture. This is especially true for a torque wrench.

By following these simple rules, you can guarantee the best tightening and a reliable tight connection.

Place the cylinder head on the block, first making sure that the crankshafts and camshafts are set to the top dead center (TDC) position.

Proper twisting

The tightening process itself takes place in 4 circles:

- 1st circle - moment 20 N m (2 kgf/m);

- 2nd circle - moment 69.4–85.7 N·m (7.1–8.7 kgf·m);

- 3rd circle - turn the bolts 90 degrees;

- 4th circle - another 90 degree turn.

As you can see, everything is simple. If you have any questions, watch the video. In terms of time, this work does not take more than twenty minutes, but it allows you to save a decent amount, which they will charge you at the service station.

Loading …