If the front suspension of your car is knocking, you have to go to a service center and look for the problem. But the issue is not always resolved during diagnosis. Firstly, the qualifications of the technicians may not be enough to detect the problem. Secondly, some elements of the chassis cannot be checked without disassembly. So you need to learn to look for problems based on the nature of the sound. A knock in the front suspension may occur when hitting bumps. We have already talked about such cases; they are not difficult to find. This type of problem can be found quite simply if you drive into a pit and ask an assistant to shake the car. At this time, it is enough to hold on to various suspension parts or release the silent blocks. This will help you find exactly the part that knocks when hitting obstacles.

If the knocking noise in the forward drive occurs on a flat road, the problem is more subtle. Finding it will not be easy, especially without experience and knowledge in this matter. It should be remembered that knocking can occur in different ways. It is by the nature of the sound that you can often understand what is knocking in your car. However, the concept of a smooth road in Russia is quite relative. So we will consider the issues of knocking of various parts, including sounds on small irregularities and smooth holes on the road. Knocks are also possible on a perfectly flat road. In this case, any rotation element may become unscrewed, which causes a knocking sound simply when turning the wheel. But it’s worth sorting everything out in order. There are a number of reasons that are worth checking if your car exhibits a clunking sound on relatively smooth roads in the suspension area.

CV joints are the main instigators of knocking noises during rotation

Often problems are solved by replacing CV joints. This is a rotary mechanism in the external version and an object of independent transmission of torque in the internal version. If before the mystical knocking sound appeared when turning, you did not hear crunching sounds, then the internal CV joint may be to blame. The outer one fails more often, but before failure it begins to crunch when turning. You can check the part as follows:

- put the car in the pit, turn off the speed and turn on the handbrake for easy access to the axle shafts and other suspension elements in the front of the car;

- check for play on the axle shafts by loosening them from top to bottom or in different directions, then check the play by pushing the axle shaft inside the CV joint and back;

- if there is play, the parts have fallen apart, they need to be replaced, you should buy only high-quality spare parts to carry out the necessary repair processes;

- Before replacing, do not forget to drain the oil from the gearbox, since otherwise it will simply flow out through the holes that appear at the site where the CV joints are installed.

The process of replacing internal CV joints is quite complicated. Interestingly, the main reason for parts failure is a torn boot. A part that costs a hundred rubles damages an expensive mechanism that is very difficult to replace. So it is worth monitoring the condition of the anthers and always changing them if necessary.

Ball joint - knocking in the suspension of different characters

There is a part in the car suspension that is difficult to check. If it knocks, it happens precisely on small and unnoticeable irregularities. The ball loses its lubricant and begins to move very difficultly inside the seat. This causes sounds like creaking, light knocking, and annoying rattling. An element fails for the following reasons:

- just natural wear of the part, which occurs every 100,000 kilometers; during operation, the mechanism wears out, lubricant comes out, and efficiency decreases;

- the support begins to knock quite unexpectedly, the intensity of the sounds quickly increases, so it is better to promptly replace the element;

- when installing a low-quality support, a not very pleasant process occurs - after a few thousand kilometers, extraneous sounds appear that are unpleasant to listen to;

- Also, a torn boot is one of the main causes of problems in this part of the car, so you should constantly look at the rubber bands and their integrity.

The ball joint is very difficult to diagnose. To check it, it must be removed, which cannot be done without the help of a professional service. That is why they often do not sin on it when going through other suspension parts. It may well happen that you change half of the suspension until you get to the knock directly in the ball joint.

Struts and strut supports are a problem for every car

Even high-quality and reliable racks begin to struggle with unevenness and knock after prolonged use. For a Chinese spare part, a long service life of 1000 kilometers is considered, for an original Japanese or European one - 15-20 thousand. Struts and upper supports regularly fail on cars in Russia, and the reasons for this can be very different:

- the strut itself rarely fails completely; when the car is rocking, creaking and extraneous sounds will be heard, and the knock will be heard throughout the entire suspension at once;

- the support in most cases fails at the moment when the support bearing breaks, this happens in the event of a sudden collision with large uneven roads;

- Perhaps a simple tightening of the support or shock absorber fastening at the top point will help you; you need to check all fastening elements;

- If the struts break down, they may leak, which will be visible on the body, but this is not a prerequisite, but simply a recommendation for additional diagnostics of the suspension element.

The steering rack is a quiet separate element with sophisticated diagnostics

It often happens that after reassembling the entire chassis, it is time to check the steering rack. By moving the steering wheel left and right, you will hear small knocks if the rack has already begun to wear out. But this does not mean at all that it knocks during operation. It is difficult to give general recommendations here; there are different recommendations for owners of different cars:

- It’s worth visiting specialized forums and reading information about how and when the steering rack fails, how you can check and fix it;

- tightening the steering rack is a solution for a few days; soon it will start knocking again if a problem is identified with this particular element of the car;

- the knock of the rack is often a distinct feedback on the steering wheel, as well as on the body in the area where the control pedals are attached, so diagnosis will not be difficult;

- Sometimes steering tips or rods knock, which is more difficult to check, but you can perform a full diagnosis in a pit without any problems or inaccuracies.

The steering system likes to knock in domestic cars, as well as in cars older than 10 years. Changing the steering rack is very difficult due to the high cost of spare parts and the rather inconvenient location in many cars. Therefore, they prefer to perform this process on a service. Professionals will complete all tasks quite simply and quickly.

CV joint

If you can clearly hear a knock when starting and braking, then the first step is to diagnose the CV joints. Pay attention to the sounds when turning the wheels for the first time. If you hear knocking noises, then the problem is in the car's chassis. Also among the reasons are a broken constant velocity joint, a failed steering rod, and a worn rack. By the way, the latter can leak if there is a malfunction - you should pay attention to the anthers. They may have malfunctioned. Vibrations may also indicate that ball joints and shock absorber struts need to be replaced soon.

Silent blocks in the front of the car - replacement check

A very important element of the front suspension, which can knock in the most unusual way, is a set of silent blocks. The most common knocking sounds are the rear silent blocks of the front suspension arms, as well as the support silent blocks of the stabilizer, which are attached to the body. The whole problem is solved by replacement, there is no point in diagnosing for a long time - it is better to change the part. Failure occurs for the following reasons:

- the rubber simply breaks due to increased loads, it does not withstand too much pressure and is deformed under the influence of the connections of the suspension arms;

- The silent block stops turning freely in the right place, there is no flexibility in the suspension, and the levers knock due to the lack of the required maneuver;

- the rubber has worn through, worn out and decreased in size, so metallic sounds are heard from the chassis, which are difficult to diagnose;

- It is necessary to pay attention to the fastenings of silent blocks; often replacing them turns out to be difficult due to preliminary unskilled work with suspension parts.

You can check while driving whether the rear silent blocks of the front control arms are knocking. You need to place your foot directly on the floor and listen to whether there is a knock on your foot. The same procedure should be done on the passenger seat. The stabilizer support bushings are checked by placing your foot or hand on the part of the body behind the pedals. However, if you have suspicions, you can simply change this element. We invite you to watch a short video with self-diagnosis of the Hyundai Solaris suspension:

Let's sum it up

It is worth using various methods to test equipment before replacing. Otherwise, because of one knock, you can change half of the suspension without eliminating the cause of the problem. Therefore, you should always approach diagnostics from different angles and use the services of testing suspension parts at several service stations. You can change parts only if you are sure that certain mechanisms are faulty. You should approach the issue of repair with full understanding so as not to spend too much money on this process. Many novice drivers simply buy every part that they are guilty of, and as a result, repairs are very expensive.

There are certain difficulties in diagnosing the chassis of a modern car. It is not at all clear which element may be causing the knocking. There are a number of possible options, they are all interconnected, and even analysis does not answer the question. Therefore, it is very difficult to use the full picture of the breakdown to purchase the spare parts necessary for repair. Sometimes you have to change parts just at random, not getting the result on the first try. There are various repair options available, but to do so you need to pinpoint the problem. How do you usually diagnose and repair the chassis of your car?

A knock in the front suspension on small bumps is one of the signs that some of the chassis parts are damaged or almost completely worn out. Novice motorists, without much hesitation, take their car to a service station for diagnostics and shell out considerable sums for repairs. However, there is no guarantee that the knocking will disappear and its source will be found. You can not only identify but also eliminate most of the causes that cause knocking on your own.

About the difficulties of diagnosis

In addition to the braking system, it is worth checking for faults in the wheel drives - this is indicated by a knock in the front suspension when braking. This is a fairly common phenomenon that motorists encounter. Experts say that often the culprits of suspicious sounds can even be the steering system and engine mounts. This is why fault diagnosis is a very complex process. One of the typical features of the occurrence of sounds when braking is that knocking appears only in the pedal, which is depressed halfway. If you press it to the floor during intense braking, then the extraneous sounds will disappear. Car owners often write on forums that this sound can be heard when driving at low speeds, and also at medium speeds. At high levels - less often. In most cases, it is impossible to hear anything as long as the brake mechanism is cold.

Another point that complicates diagnosis is the frequency with which knocking occurs when braking in the front or rear wheel. It can be heard for some time, then disappear completely and appear again after a while. Nowadays, many cars are equipped with ABS - sometimes the malfunction may lie in it. But this is far from a fact. Even self-diagnosis systems are not able to detect errors in the operation of the anti-lock braking system.

List of the most common reasons

Knocking in the suspension when driving over uneven surfaces is an extremely common problem. In most cases, the sound that appears when the body vibrates when a wheel hits an uneven surface is associated with partial performance of the chassis, but occasionally there are other reasons. The most common reasons are:

- faulty shock absorber strut mounts;

- damage to shock absorbers or their individual elements;

- wear of ball joints, silent blocks, support bearings;

- damage to the steering rack.

These are the most common causes of metallic knocking noises coming from under the car body. Defective suspensions are much less common. Sometimes the engine support components are to blame. Each individual problem is solved in its own way, but most often you simply have to replace the damaged part. The most common cause of the problem is wear of components due to poor quality roads. Since most foreign cars simply do not have any additional chassis protection systems, silent blocks, supports and other elements suffer, which bear the brunt. While reducing damage to the body and other parts of the car, these elements themselves wear out, and very intensively.

First of all, it is worth checking them and replacing them if a malfunction is detected.

You should definitely not repair damaged parts yourself; they must be replaced with factory equivalents. You shouldn’t ignore the problem either, because the longer the knocking continues, the more extensive the damage will be in the end. Try to quickly check all possible causes, and this should be done in this order.

Common front suspension problems

A clearly audible knocking sound in the front area of the vehicle while driving on rough roads indicates the need for urgent diagnostic and repair measures. Please note that it is not possible to operate a vehicle with damaged chassis parts. If it is not possible to diagnose the suspensions in a car service center, you can search for the fault yourself. It is best to carry out the inspection on an overpass, or by lifting the vehicle with a special lift.

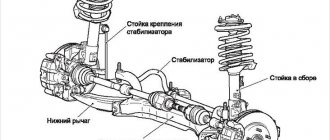

Knocks in the suspension when starting or driving are a consequence of a malfunction of the following elements:

- ball joints;

- stabilizer bar mounts;

- CV joints;

- support bearings;

- hubs;

- silent blocks;

- brake system parts;

- shock absorbers.

Replacing silent blocks

A dull knock in the front suspension usually occurs due to problems with silent blocks and springs. If the reason is silent, then the car's handling will noticeably deteriorate. The only option is to replace the entire set. There is only one way to check whether this is true - carefully examine the front suspension arms. To do this you will need a mount. Using a pry bar as a counterweight arm, bend each front suspension arm. You need to bend in different directions. If there is a malfunction, you will find play, which is why the knocking occurs.

If you can disassemble the structure, then all that remains is to replace the silent blocks in the following sequence:

- Remove all levers.

- Next you need to pull the silents out of their seat. Using a special mandrel they can be easily pressed out.

- Clean the seat from any remaining oil and dirt.

- New silent blocks must be lubricated with machine oil before installation.

This, in fact, is all that is required of you.

The rear suspension suffers less from this problem, since the main load falls on the front suspension due to the motor assembly. Nevertheless, it is worth checking the condition of the silent blocks in both parts of the chassis.

Malfunction in the lever system

Very often the problem is wear of the silent blocks of the levers. As a result of their wear, the system begins to “play” and knock. At the same time, the car’s controllability deteriorates, and accordingly, traffic safety is greatly reduced. To troubleshoot silent blocks, you will need a jack and a pry bar.

First of all, you need to jack up the wheel to hang it completely. Then use the pry bar as a lever, applying load to the suspension arms in different directions, i.e. shaking them from side to side. If play with a dull tapping sound is detected, then your diagnosis is correct. In the same way, you need to check the levers of the second wheel.

As a rule, parts wear out evenly. Therefore, if you find problems on one side, there are probably problems on the other side to a greater or lesser extent. To fix the problem, you just need to replace the silent blocks (rubber-metal hinges). The diagram above shows a front suspension arm with silent blocks on a Lada Vesta.

We recommend: Cold welding for metal: instructions and application features

You can even replace the hinges yourself. To do this, first of all it is necessary to dismantle the levers. To remove the old joints from the arms and install new ones, you will need a special tool designed specifically for your make and model of car.

Steering rack

A knock in the suspension when turning can occur due to problems with the steering rack. Typically, it is the turning of the steering wheel that causes the sound, which occurs due to play inside the structure. A characteristic feature is that the sound comes from one side and is also accompanied by a noticeable vibration of the steering wheel. The malfunction is especially pronounced on a gravel placer, then vibration is very frequent, although there should not be any at all.

The sound occurs when the steering gear and the rack itself rub against each other.

Occasionally, a similar defect is observed immediately after replacing the bearing in the hubs of VAZ 2109. As a result of the defect, the backlash will increase, which will lead to damage to the elements of the steering structure. To verify the reason, you will need a jack to raise the car:

- Raise the car.

- Take a pry bar and carefully move the tie rods from side to side.

- If significant play occurs (it should be visible to the naked eye), then the problem is worn out bushings that will need to be replaced.

- It is also necessary to tighten the rack nuts to seat it on the gear.

It is rare, but it still happens that the steering wheel and its components are in order, but vibration and knocking are still present. In such cases, attention should be paid to inspecting the steering joints.

Racks, supports, springs

A strong knock in the front suspension occurs due to impacts on the car body. This happens when the shock absorption system wears out. In rare cases, the shock absorber spring can also be the culprit of the knocking, but this happens extremely rarely, since the springs are the strongest part of the assembly.

The sound occurs on small bumps when the shock absorbers take a sharp blow. The vibration damping system copes very poorly with such an active load, so rapid wear of the elements during frequent driving on uneven roads leads to such consequences. The result is wear of the rubber layer of the support.

To detect a malfunction, you will have to go through the entire rack, remove it along with the support, and for this you need to dismantle the wheel and partially disassemble the chassis. There will be a lot of work. To make sure it is the strut support that is the problem, you need to measure the distance from the support to the rubber stopper. Ideally, there should be no discrepancies, maximum 1–2 mm.

If the reading is higher, you will have to replace the rubber layer of the strut.

If you don’t want to do this yourself, then the service station will do this work much faster, albeit for a fee. Vibration and knocking should disappear immediately after replacement.

It is extremely rare that the cause of a knock is the rack itself, which has become severely worn out due to constant loads. The sound will be very loud, and the car will shake considerably on bumps.

Checking the strut is quite simple: press harder on the hood. If the rack is faulty, the car will sharply return to its original position with a characteristic loud knock, while the body will sway a little.

The source of the sound may be a loose nut inside the mechanism that can be tightened.

Well, the latest option is a complete malfunction of the shock absorber mechanism. This happens as a result of accidents and collisions. At first, no attention is paid to the knocking, but the problem is discovered much later.

Troubleshooting in the rack

Basically, the strut can make a knock and transmit impacts from uneven roads only when the entire structure is severely worn. Moreover, this element of the car suffers the most when the front pair of wheels falls into a deep hole - the rebound strut does not work, but the spring undergoes a sharp straightening. As a result, the wheel will go sharply down, stretching the spring to the maximum possible length. Thus, it turns out to be 2 hits - the racks against the support and the racks with the bottom of the pit.

Checking the functionality of the support pillar is carried out in a standard way - the vehicle is swung vertically or a partner presses forcefully on the central part of the hood. If the rack is in good condition, the body of the machine should return to its original state once without sharp straightening.

If the case falls sharply, you will hear a dull thud. This indicates a malfunction of the element due to a loose lock nut, which makes noise inside the support post itself. Repair of the rack should only be carried out at a car service center, since special equipment will be used to secure all elements in a high-quality manner.

If a knock occurs on small bumps due to the strut, the car sways strongly when moving and loses control. This may result in an accident on uneven roads.

Also, problems may lie not in the strut itself, but in the shock absorbers. A malfunction of the shock absorber system is primarily due to improper treatment with oil. Drivers often pour an oil solution with incorrect viscosity characteristics inside. This value is affected not only by the purchased oil, but also by the ambient temperature at which the solution is poured. Too low a temperature does not allow the oil fluidity to increase to the required value.

We recommend: Car diagnostics and repair

Other reasons

In addition to all the options described above, the suspension also knocks for other reasons. One of these is brake pads that produce a metallic knock. In such cases, the sound disappears as soon as the brake pedal is pressed. Often this problem occurs after installing new elements or severe wear of old pads.

Any knocking noise in the rear suspension can repeat the problems described above, but this happens extremely rarely due to the fact that most modern car models are front-engined. Since the engine is one of the heaviest parts of the car, the front part of the body bears much more load, and even shock absorbers do not protect against this. The rear of the car is unloaded, and therefore is not subject to such problems.

By the way, knocking noises in the front end may be the result of a worn engine mount.

The rubber inserts of the unit wear out over time, this happens after about 100–120 thousand kilometers of a new car. As a result, when the rubber parts are worn out, any trip on an uneven road will be accompanied by a metallic knock. Additional sound can be produced by the motor itself, the unit of which will be slightly displaced. If the reason is in the support, then you will find carbon deposits on the spark plugs, and when you inspect the support itself, you will find tears.

Knock in rear suspension

Diagnosis of the rear suspension is faster because its design is simpler. There can be several reasons for the knocking sound - worn torque rod bushings (if any), loose wheel bolts, loose or broken exhaust pipe fastening, broken suspension spring coil, loosening of the short torque rod mounting bracket, recoil valve in the shock absorber, rear shock absorber bushings, released axle shaft, pad spacer bar. Also, unknown sounds may be caused by reasons not directly related to the suspension. For example, objects in the trunk, an unscrewed spare tire, and so on.

It is also recommended to check the exhaust pipe mounting and its general condition. After all, a burnt-out muffler produces extraneous sounds that a car enthusiast may mistake for a knock in the rear suspension. In addition, it is necessary to check all pipe fastening elements. If it is not securely fastened, then on uneven roads it can produce a small and dull knock, which the driver may mistake for problems with the suspension.

When diagnosing yourself, you need to check the following components (some of them may be absent on some car models):

Suspension check

- rear suspension guide structure;

- levers (transverse, longitudinal);

- anti-roll bar;

- rear shock absorbers;

- shock-absorbing springs;

- shock absorber cups and brackets;

- rubber bushings;

- rear axle beam;

- compression buffer;

- bearings.

Diagnostics of the guide structure

During the diagnostic process, you must perform the following steps:

- Check the force and condition of the beam, as well as the levers (if any). Make sure there is no deformation on these parts.

- Check the hinges. They may develop cracks due to wear and tear. This also leads to deformation.

It is worth checking the threaded connections of the flanges at their attachment points. Depending on the make and model of the car, they can be repaired or you will have to buy and install new ones. The above work must be performed in a car service center or in a garage with an inspection pit.

Diagnostics of suspension springs

Despite the fact that the steel from which the springs are made is strong, they can fail over time. Their individual coils break, so the spring stops working normally. To diagnose the spring, it is enough to carry out a visual inspection. In this case, it is worth paying attention to the absence of defects on the spring coils, as well as the integrity of the rubber inserts that are located in the places where they are installed. If a spring fails, it must be replaced; it cannot be repaired.

Rear shock absorbers

Used shock absorber boots

As with the front shock absorbers, it is necessary to diagnose the anthers . Replace them if necessary. When inspecting the shock absorbers, you should also pay attention to the absence of oil leakage from its housing. If the shock absorber is collapsible, it makes sense to dismantle it and disassemble it to ensure that the internal elements are in good working order. In this case, it is worth checking the rubber bushings inside, which often fail.

You will need an assistant to complete the check. You need to rock the rear part of the body and see if there is any play in the bushings and a characteristic up-down stroke of the shock absorber. If there is play, then most likely the bushings have already been made into an oval shape - they need to be replaced.

Additional reasons

If you have checked the parts listed above, but the rear knock still persists, you should pay attention to the following things:

- Stopping support. Here they proceed as in the case of the front suspension. When it is skewed, the caliper will make a loud sound, so diagnosing this malfunction is not difficult.

- Wheel bearing. You need to jack up the car completely or just the wheel you want to check. When rotating freely, the bearing should not make noise, knocking or creaking noises. When checking, the brake pad may rub against the disc, the sound of which is very similar to a squeak. Therefore, be careful when diagnosing.

The table below shows the main causes of noise in the rear suspension:

| Character of the knock | Cause of malfunction | Remedy |

| A dull knock when hitting holes or bumps | Rear shock absorbers have failed | Repair the shock absorbers; if they cannot be restored, replace them with new ones. |

| Constant thud when driving in a straight line | The shock absorber fastening is loose, the bushings in the eyes of the rear shock absorbers are worn out | Tighten the bolt and nut of the shock absorber, replace the bushings in which wear has already appeared |

| A dull knock when the body rocks while driving on a rough road | Damaged bushings in the rear suspension arms | All rubber bushings need to be replaced |

| Metallic knocks and sagging of one side of the body | The spring has collapsed or broken | Replace the spring with a new one |

| Dull, strong knock (breakdown) in the rear part of the suspension | The buffer has collapsed, the breakdown of the rear suspension has increased | A torn or worn buffer needs to be replaced |

Causes of extraneous noise and knocking

There can be plenty of reasons for extraneous noise and knocking in the front suspension. When parts wear out, the brakes, steering system, and engine can rattle. However, the greatest amount of noise in the presence of defects occurs in the suspension and shock-absorbing units; read more about the Renault Logan front suspension design here.

In order to carry out an independent inspection, and, if necessary, repairs, you will need a lift or inspection hole.

Support stand

For comparison: old and new support strut on Logan

Before you begin inspecting the suspension under the car, first assess the condition of the front strut supports. To do this, you need to open the hood and evaluate the gap on the spring stop cup.

If the gap exceeds 1 cm or it differs relative to the opposite side, this indicates that the supports have sagged and they do not absorb impacts on small bumps, therefore, they need to be replaced.

Shock absorber struts

The presence of a dull knock in parts of the front suspension may indicate defects in one of the shock absorber struts. The easiest way to diagnose is to alternately rock the car on the left and right sides. If there are working shock absorbers, the car will smoothly return to its original position, already on the first or second free play.

The presence of smudges and unsatisfactory condition of the bumpers will also indicate that the rack should be replaced.

Anti-roll bar link

This chassis element is checked when the vehicle is under load. By rocking the car, you should pay attention to the movement of the cup relative to the lever itself. If this element malfunctions, it will jump and make a characteristic knock, which in turn, undoubtedly, is observed when driving on an uneven road.

Inspection and replacement of the stabilizer bar link

The same goes for the anti-roll bar bushings. When they wear out, play and free movement will be felt in the places of contact with the rod itself. Diagnostics and replacement of stabilizer bushings can be carried out both on the ground and with the car suspended.

Silent blocks

The arrow marks the silent block

After the car has been raised, you should check the silent blocks in the suspension arms. In order to determine the degree of their wear, you will need a mount, with the help of which, by moving the lever on the subframe in the longitudinal and transverse directions, you can determine their play, as well as identify rubber defects.

On Renault Logan, the silent blocks are attached to the front suspension arm, so their replacement should be carried out on a removed element.

Spherical bearing

Diagnostics of a ball joint is diagnosed in the same way as silent blocks. By turning and pushing movements (left - right) you should influence the front suspension lever, and if the ball joint is faulty (there is play), moving it will not be difficult.

Ball boot diagnostics

The support on the Renault Logan is pressed into the front suspension arm. Therefore, before dismantling it, the lever must first be removed, and the replacement itself must be carried out using a press. Read more in the material: replacing and diagnosing a ball joint on a Renault Logan.

If the ball joint is sentenced to replacement, then it is important to know which ball joints are better!

What does the suspension make noise, or the sounds of a car malfunction?

Often, when driving a car, you can hear extraneous sounds - noise, knocking, grinding. As a rule, this is a sign of problems with some node or system. Also, do not forget about the noise produced by loosely secured interior elements . While operating the car, you must constantly listen to extraneous sounds so as not to start a problem and diagnose possible faults in a timely manner.

Common sources of abnormal sounds include the suspension, steering, brake system, transmission and exhaust system.

Suspension malfunction sounds

The most difficult component to determine a malfunction “by ear” is the suspension. Let's talk about “auditory” suspension diagnostics using the example of the popular McPherson today. A knock may indicate wear on the silent blocks of the levers, ball joints or tie rod ends. If these malfunctions occur, they disrupt the suspension geometry and affect the stability and safety of the vehicle.

Often the cause of a knock can be wear on the struts and bushings of the anti-roll bar. This also worsens the car's handling.

Less often, the shock absorber or its upper support may knock. Usually paired with a suspension of this type, rack and pinion steering is installed. It may also make a knocking noise. The reason is wear of the bushings. It’s worth noting that you can drive with this (and for quite a long time), but it’s still better to fix the problem.

If the car has a worm steering mechanism, the source of the knock may be the bearings of the pendulum arm and bipod shafts. But in this case, this leads to an increase in play in the steering mechanism, and this is more dangerous than with a rack.

If the car's suspension is multi-link, it accordingly has many silent blocks, which, when worn, produce extraneous sounds. Ball joints may also make noise.

Almost rare, torsion bar suspensions “sound” like faulty torsion bar bearings. The sound is similar to the noise from worn silent blocks. The rear suspension is no different in its “sound” from the front. Silent blocks, shock absorbers or their bushings may also knock there. Also sometimes there is a knocking noise due to wear of the rear beam bushing.

Sounds of faulty brakes

In this case, the noise may be annoying the handbrake adjustment mechanism installed in the rear brake mechanisms. This indicates the need to replace the pads or at least adjust them.

Sometimes it happens that extraneous sounds are produced by pads or calipers of disc mechanisms. This is a sign of the resulting mobility of the pads due to the weakening of their springs.

A torn brake pad lining can also make a sound. To identify this malfunction, we advise you to drive through a garage pit with the wheels slightly braked. The pad pressed to the disc will not make noise.

Please note that some suspicious sounds may only occur under special driving conditions :

— Worn shock absorber rod bushings can knock only when starting to move or turning to one side, but in other conditions they work quite normally. — Only when driving over uneven corners can the ball joints make noise. Note that the upper ball joints are most often noisy in small holes, and the lower ones - in large ones. — When descending, if there are holes along the way, the front springs may remind you of themselves. Their coils touch each other and make a characteristic sound. — In front-wheel drive cars, the outer CV joint makes noise when the wheels are turned, and the inner one makes noise when the wheels are turned. — At the beginning of movement, rear-wheel drive cars can “crunch” with ball and universal joints of transmission shafts, as well as thud with faulty engine and gearbox mounts. However, the latter is typical for all cars.

Finally, we note that if you decide to identify the cause of extraneous noise in the car, you need to remove all things that can rattle from the glove compartment, shelves, trunk and other places. This primarily applies to tools, CDs, fire extinguishers, spray cans and other household items that are not packed in a box. Note that it is not necessary to remove all things from the car; you can line the trunk and glove compartment with soft, thick material (foam rubber or porous rubber) to eliminate the noise of their contents.

Most often, used cars, whose service life has been significantly exhausted, suffer from extraneous sounds of malfunctions.

Still, you shouldn’t rely entirely on your own hearing. The “diagnosis” must be confirmed by visiting a service station.

- To make your car shine like new, we suggest visiting St. Petersburg car washes - you won’t regret it!

Read with this article:

We adjust car headlights with our own hands

CVT, CVT, continuously variable transmission - what is it?

Chip tuning is a special type of car tuning

Insulating a car hood, a step-by-step guide using the example of Toyota Corolla Spacio

Additional noise sources

Let's consider additional sources of extraneous noise!

Steering rack

Failure of the steering rack (especially on the left side) is not a rare occurrence for Renault Logan.

The price for a new steering rack for Renault Logan is very steep

It is necessary to check the serviceability of this element by rocking the lever itself. When it is faulty, a slight play will be felt.

Engine mount

In order to find out the condition of the engine mount, you just need to visually look at it; with a high degree of wear, tears will be visible.

On the left is the old mount, on the right is the new engine mount. The service life of rubber seals is about 100,000 km

In order to conduct such a full, detailed inspection and find a fault on the Renault Logan front suspension, it may require a lot of effort and time. However, when the problem is found and solved, noise when driving on any, even the worst roads, will no longer bother and cause a lot of discomfort to its owner.

Remember that timely repair of even small faults guarantees the durability of the entire suspension as a whole.