Suspension device

Since ancient times, front suspension began to be used, which was also used in the design of the car. The first cars rode on almost the same suspension that was used on horse-drawn carriages. Since the speed of the first cars was no higher than thirty kilometers per hour, such a suspension was designed for light loads. But in modern cars it has undergone many changes; moreover, many new designs have appeared.

The first elements of cars were aimed at making the movement more comfortable, while individual parts of the wheel control began to be formed in the thirties to make it easier to drive the car. The stabilizer, which is used in the structure of an independent front wheel system, helps with this; later a system appeared for the rear wheels. But in this article we will focus on the front suspension.

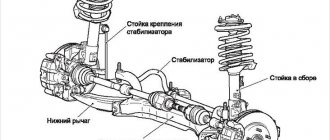

The front suspension device is represented by an independent system, which aims to fix the movement of the front wheels so that they have, on the one hand, good grip on the road surface, which would give them easy controllability, and on the other hand, would help them easily take turns, which is something no one can do without. road. Although there are many schemes for the formation of parts, the principle of the content of the elements is the same. Consider this diagram:

- The presence of guide elements that would maintain the desired trajectory of the wheels in comparison with the body,

- The presence of elastic elements that provide the necessary force to help the wheels move,

- You also need to have elements that dampen vibrations.

The most reliable type for Russia and the CIS

Every motorist in Russia complains about the poor condition of the roads. There is an opinion that all types of suspensions quickly wear out their service life when driving on Russian roads.

But this largely depends on the driving style of the car enthusiast. To extend the life of your entire vehicle, remember to slow down for or avoid bumps and potholes.

Drivers argue on forums which type is better. But it all depends on personal preferences - some people like a hard suspension, while others like a soft one. If we talk about reliability, spring and torsion types are considered durable. Manufacturers listen to the opinions of car owners and produce combined types, for example, torsion-spring ones.

We recommend: Description and principle of operation of the ESC stability control system

Characteristics of elements

Each pendant has guide elements. We are talking about levers, struts, ball joints, and hinges made of rubber-metal materials. It also has elastic elements, here we are talking about springs, leaf springs, pneumatic chambers, and torsion bars. Damping elements are all types of shock absorbers.

But in fact, such a classification is a purely conditional characteristic. For example, this may concern a part such as a front suspension cross member. It has been used since the days of carriage construction.

We can also talk about the spring, which was still used in horse-drawn carriages; it has been preserved in modern cars. Such a part can replace three, which, like a spring, softens the movement of the car. The spring is widespread, it allows the car to move without much shaking, which cannot be said about the device that acts as a cross member of the front suspension.

Classification of pendants

In the modern automotive industry, the following types of suspensions are most often used:

1. McPherson. Developed in 1960 by an engineer who gave the design his last name. Consists of the following parts:

- Anti-roll bar, or “swinging plug”. It is attached to the body with a hinge and tends to swing when the wheel moves vertically.

- Block (spring element and telescopic shock absorber);

- Lever.

The advantage of the suspension is its low price, simplicity and reliability. The disadvantage is a noticeable change in the camber angle on the wheels.

2. Double lever. It consists of two levers of different lengths - the upper short and the lower long. This scheme is one of the most advanced, since the car on it has excellent lateral stability and low tire wear due to minimal lateral movement of the wheels.

3. Multi-link. It has a similar structure to the double-lever, but is much more advanced and complex. In it, all the hinges, levers and silent blocks are attached to a special subframe. A variety of ball joints and rubberized bushings perfectly absorb shock when hitting a bump and reduce noise in the cabin. This suspension scheme provides the best tire grip, smooth ride and handling. The advantages of a multi-link suspension are as follows:

- Optimal wheel turning;

- Isolated longitudinal and transverse adjustments;

- Small unsprung masses;

- Independence of wheels from each other;

- Excellent potential with all-wheel drive.

We recommend: Checking the engine oil level correctly: how often to check?

But the main disadvantage of the suspension is its high cost, although recently not only executive cars, but also golf-class cars have been equipped with such a unit.

4. Adaptive. It contains fundamental differences from other types of mechanisms, being a logical and improved continuation of the hydropneumatic suspension first implemented by Citroen and Mercedes. Its advantages are as follows:

- Low sway at high speed and minimal body roll;

- Forced variable damping;

- Automatic adaptation to any road surface;

- Excellent stability when driving straight;

- Adaptation for the driver;

- High degree of security.

When manufacturing the unit, different companies develop their own original design, but in general the design consists of the following components:

- Adjustable anti-roll bars;

- Chassis control unit;

- Active shock absorber struts;

- Various sensors (ground clearance, roughness, etc.).

The main disadvantage of the device is its complexity.

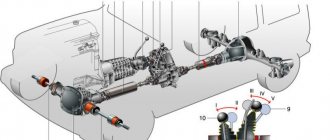

5. Like "De Dion". The invention of the French engineer has the main goal - to relieve the rear axle of the vehicle as much as possible by separating the main gear housing, while it is attached directly to the body. Torque is transmitted through axle shafts and CV joints, which allows the suspension to be either dependent or independent. The main disadvantages of the design are “squatting” on the rear wheels during a sharp start and “dive” when braking.

6. Rear dependent. The device can be seen on classic VAZ models, where the distinctive feature is cylindrical coil springs as elastic elements. The rear axle beam “hangs” on them and is attached to the body by four longitudinal arms. Transverse jet thrust dampens roll and improves handling. The design does not provide good comfort and smoothness due to the unsprung masses and the massive rear axle, but it is relevant when attaching the main gear housing, gearbox and other massive parts to the beam.

7. Semi-independent rear. Widely used in many four-wheel drive vehicles, it consists of a pair of trailing arms attached in the center to the cross member. This suspension has the following advantages:

- Compact size and relatively light weight;

- Ease of repair and maintenance;

- Noticeable reduction in unsprung masses;

- The best wheel kinematics.

The main disadvantage of the suspension is the impossibility of installing it on rear-wheel drive vehicles.

8. Pickups and SUVs. Depending on the purpose and weight of the car, there are three types of suspension:

- Independent front and dependent rear;

- Completely independent;

- Completely dependent.

In most cases, a spring or spring suspension is installed on the rear axle, interacting with rigid one-piece axles. Springs are used in heavy jeeps and pickups due to their ability to withstand impressive loads, unpretentiousness and reliability. Such a suspension is inexpensive, which has influenced the equipping of certain budget cars with it.

The spring design is long-stroke, soft, and not complex in structure, which is why it is most often installed on light jeeps. Spring and torsion bar circuits are installed on the front axles.

9. Trucks. Trucks are equipped with dependent suspensions with longitudinal and transverse springs, and hydraulic shock absorbers. This scheme is as simple and cheap to produce as possible. But at high speeds, the driver is faced with poor controllability, since the springs do not perform well as guide elements.

Common front suspension designs

Let's pay attention to the types of suspensions that make up the main part of the car. The main device is a multi-link suspension. It makes it easy to drive the car even on the most difficult roads. For example, this is a scheme such as McPherson.

In this case, you need to pay attention to such a part as the front suspension subframe. It works great when the car needs to be given stability, which cannot be said when the front suspension frame does not have a subframe.

Suspensions of the type under consideration allow the use of a multi-link type, where there is a rigid spring, and a vertical strut is also necessarily present. It turns out that the stabilizer absorbs all vibrations, helping the driver to control the car more easily.

The stabilizer also performs the function of stability. Thanks to it, it is possible to control the trajectory of the wheels, which is very convenient, since the front suspension frame is higher than the lower arm. In addition, the stabilizer helps the car move more smoothly. Let’s also not forget to mention the multi-link unit, which helps to avoid vibrations when the car is moving.

Elastic suspension element

The following elastic elements are used in car suspensions (Fig. 7.2): metal (springs, springs, torsion bars), pneumatic, hydropneumatic combined (for example, spring-pneumatic). Diagrams of elastic elements are shown in Fig. 7.6.

Rice. 7.6. Types of elastic suspension elements: a – spring; b – spring; c – torsion bar; d – air cylinder; 1 – root leaf; 2, 5 – bolts; 3 – clamp; 4 - gasket; 6, 7 – rings; 8 - shell

7.4. Suspension design

The design of the suspension depends on the type and layout of the vehicle. On front-wheel drive passenger cars, the lever-telescopic suspension shown in Fig. 7.7. This suspension includes a telescopic strut 1, fixed in the upper part to the car body using an upper support 13 on a bearing 12. To protect the strut from breakdowns under dynamic loads, there is a compression limiter 10. The shock absorber rod is protected from dirt by a casing 9. In the lower part the stand is connected to the rotary lever 6. A spring 8, which is an elastic element of the suspension, is fixed between the upper support cup 11 and the lower support cup 7.

Rice. 7.7. Lever-telescopic suspension of a front-wheel drive VAZ car: 1 - telescopic strut; 2 – steering knuckle; 3 - lower lever; 4 — ball joint; 5 – hub; 6 – rotary lever; 7 — lower support cup; 8 – spring; 9 – protective casing; 10 – compression buffer; 11 – upper support cup; 12 – upper support bearing; 13 – upper support of the rack

The hub 5 of the front drive steered wheel is fixed to the splines of the steering knuckle 2. In the lower part, a trailing arm of the suspension guide is connected to the steering knuckle using a ball joint 4. The advantages of such a suspension are described above.

Rice. 7.8. Front pivot independent double wishbone suspension with levers of different lengths of a GAZ passenger car: 1 – steering knuckle; 2 – kingpin; 3 – vertical stand; 4 – compression limiter; 5 – rebound limiter

On passenger cars with a classic layout, independent suspension with wishbones of different lengths is most often used (Fig. 7.8). In the suspension shown in the figure, the steering knuckle 1 is connected to the vertical post 3 using a pin 2. The upper arm has a shorter length compared to the lower one. To protect the suspension from breakdowns and interturn shocks of the spring, compression limiters 5 and rebound limiters 4 are provided. The elastic element is in the form of a spiral cylindrical spring, inside of which a shock absorber is installed.

Rice. 7.9. Rear spring suspension of a passenger car: 1 – bracket; 2 – clamp; 3, 5 – compression limiters; 4 – shock absorber; 6 – bridge; 7 stepladder; 8 – spring; 9 – overlay; 10 – bolt; 11 earring; 12 – finger; 13 — bushing; 14 – hinge; 15 – pillow

In Fig. 7.9 shows the dependent spring suspension of a GAZ passenger car. A semi-elliptical spring 8, the leaves of which are tightened with a center bolt 10 and fixed with clamps 2, is secured from the bottom of the drive axle 6 with stepladders 7. Polyethylene gaskets are laid between the long leaves of the spring, reducing interleaf friction. The front end of the spring is fixed in bracket 1 in rubber bushings 13 with pin 12. The rear end of the spring is connected with pin 12 and bushings 13 to shackle 11, which in turn is connected to the car frame with bushings and a pin. To protect the spring from destruction, compression limiters 3 and 5 are used. The shock absorber 4 is installed at an angle and, using a hinge 14, is connected to the pad 9 at the bottom and the cushion 15 to the car frame. In such suspensions, the spring simultaneously performs the functions of an elastic element and a guiding device.

In Fig. Figure 7.10 shows the design of the front (a) and rear (b) suspensions of the GAZ truck. Front suspension (a) dependent, leaf spring, with shock absorbers. The semi-elliptical leaf spring 7 is attached to the frame by two stepladders 8 with brackets 1 and 4 through rubber supports 2, 11, 12. The rubber supports are covered with covers 6, which makes it easier to remove the springs from the car. All spring leaves are tightened with a center bolt. The two main sheets have ends bent in different directions, which creates a supporting surface. The front end of such a spring is motionless, because rests on the end pore 12; the rear end is movable, because clamped between two rubber supports and moves due to their elasticity. The maximum upward deflection of the spring is limited by the rubber stop 9. The shock absorber 8 dampens vibrations of the front part of the vehicle, including the cab, and the front wheels.

The rear suspension (b) is dependent, spring, without a shock absorber and consists of a main spring 16 and a suspension 15. The main spring and suspension are attached by the same stepladders 14 to the bridge beam in the upper part with linings 13 and in the lower part with linings 17. Front and rear the ends of the main spring are fixed in rubber supports, similar to the front suspension. When the vehicle is loaded, the suspension comes into contact with the rubber supports (section B-B), providing additional rigidity to the rear suspension. Damping of vibrations of the rear part of the car occurs due to the forces of interleaf friction of the main spring and the suspension. The use of spring supports with elastic rubber bushings reduces impacts transmitted from road unevenness to the frame or body of the car and has a positive effect on the smoothness of the car.

Rice. 7.10. Suspension of the front (a) and rear (b) wheels of a GAZ truck: 1, 4 - brackets; 2,11, 12 – supports; 3 – shock absorber; 5, 10 – cups; 6 – cover; 7, 16 – springs; 8, 14 – stepladders; 9 – compression limiter; 13, 17 – linings; 14 – main spring; 15 – suspension

Design options for the front and rear spring suspension supports are shown in Fig. 7.11. The front supports of such springs are stationary, and the rear ones have the ability to move in the longitudinal direction by turning the shackle (a), due to the deformation of the rubber supports (b) and the longitudinal displacement of the end of the spring, sliding the rear end of the spring along the support (c).

. Rice. 7.11. Typical designs of front and rear spring mounts: a – on metal pins; b – on rubber bushings; c – with an overhead eyelet of the front support and a sliding rear support

Air suspensions are widely used on buses. In Fig. Figure 7.12 shows the design of the rear suspension of the pneumatic type. This dependent suspension is made of four rubber-cord cylinders. Longitudinal forces and reactive moments are transmitted through rods 2 and 9. The elastic element of the suspension is double round cylinders 7, equipped with additional reservoirs 3 with compressed air. The cylinders are fixed between the body and brackets 8. The suspension has a body position regulator 1, which is connected through rods and levers to bracket 8. The regulator ensures a constant height position of the body under different vehicle loads. On each side of this suspension there are two shock absorbers that dampen body vibrations.

Rice. 7.12. Bus air suspension: 1 – body position adjuster; 2, 9 longitudinal rods; 3 – air reservoir; 4 – shock absorbers; 5, 6 – buffers; 7 – cylinders; 8 — bracket

Shock absorbers

Shock absorbers

are devices that dampen vibrations by converting mechanical energy into thermal energy and dissipating it into the environment.

Currently, hydraulic shock absorbers of the telescopic type are predominantly used on cars (Fig. 7.14). Hydraulic shock absorbers dampen vibrations of the body and wheels due to the increased resistance they create to the flow of fluid from one cavity to another through calibrated holes and valves. Shock absorbers ensure constant contact of the wheels with the road, preventing them from tearing off the supporting surface when driving over uneven surfaces. This property is simultaneously aimed at increasing vehicle safety.

The following requirements apply to shock absorbers:

• low attenuation when the car moves over small uneven surfaces;

• increase in attenuation with increasing vehicle speed;

• minimal load from the shock absorber on the body;

• stable operation when driving in different road conditions and at different air temperatures.

Types of hydraulic telescopic shock absorbers are shown in Fig. 7.13.

|

Advantages and disadvantages of McPherson

Let's pay attention to the advantages of this type:

- simple multi-link design of the car, the basis is a stabilizer,

- the engine compartment of the car can be enlarged,

- Easy to maintain, especially the stabilizer and multi-link design.

Now let's look at the disadvantages:

- The camber angle when the lever comes into play is not the best for a multi-link unit,

- if you overload the car, the stabilizer suffers, since the multi-link device does not work,

- the hood line also drops when the stabilizer reaches its maximum point in the multi-link arrangement.

Double wishbone suspension

Let's pay attention to the suspension, which is performed on a wishbone, located two on each side.

This is a less common form, which has the advantage that it has many design possibilities, it is also possible to obtain optimal wheel camber when driving, and the hood lowers low. As for the disadvantages, these are more complex repairs, as well as the large mass of the device.

Let's highlight three main groups. Firstly, the presence of levers, secondly, the presence of springs and stabilizers, and thirdly, shock absorbers. The last two components are the cornerstone of a quality car. They contribute to the excellent movement of the car, determine its smooth ride, and ease of control.

Let's sum it up

As we have seen, the suspension is a rather capricious device in a car. There are many different types of this component, each with its own advantages and disadvantages. We looked at two main types. This is a MacPherson knot and a double lever design. In addition to the front suspension, there is also a rear suspension, which we did not consider in this article. Comparing MacPherson and double lever devices, we can conclude that for the money it is better to have the first type, but as for quality, the second is suitable.