Oil pump, what is it? Concept and purpose of an oil pump

A car oil pump is a device that creates pressure on the lubricant in the system, so that it flows to the moving elements of the internal combustion engine. Pressure is necessary to supply lubricant (oil) to those engine elements that require forced lubrication, for example the camshaft located in the cylinder head, that is, much higher than the oil tank and without the pressure created by the oil pump, lubricant will not reach it

The car oil pump is driven by the crankshaft or through the drive shaft from the camshaft

According to the nature of control, they are divided into two types: adjustable and unregulated

- Adjustable - thanks to the ability to regulate performance, it creates stable pressure in the system

- Unregulated - constant lubricant pressure is maintained due to the presence and operation of a special pressure reducing valve

Depending on the design, they are also divided into:

1. Rotary type - pressure is created due to the rotor blades

2. Gear type - the oil receives pressure due to the operation of gears.

They in turn are divided into:

- external gears - when two gears are located next to each other,

- internal gears, when one gear is located inside another.

The difference in gear placement does not affect performance, but does affect the size of the device. Due to the fact that the gears are located in each other, much less metal is required to accommodate them, and therefore the internal gear is smaller in overall dimensions

Car mirrors for the driver are reliable assistants. If they have insufficiently good optics, or are absent altogether, driving a car becomes very dangerous. Percala Priora

Types of oil pumps, their design and operating principle

The pump's task is simple: pump motor oil in a circle. But there are several design options, since engineers all over the world continue to improve every, even the smallest, component of the car.

By design, pumps are rotary, gear (with external and internal gears) and vane (plate).

- The simplest gear oil pump consists of two gears with elongated teeth, installed in the working chamber so as to mesh. One of the gears is connected to the pump shaft, that is, it is driving, the second is driven, and rotates only due to engagement with the first. Engine oil is picked up by the gears during rotation and transferred to the opposite side, into the oil passages. This is a diagram of an external gear pump.

External Gear Pump - The internal gear pump has a different design. Its working unit consists of two gears inserted into each other. In this case, one gear (large) has teeth on the inner circle, and the second (smaller) has teeth on the outer. These gear teeth mesh to form a crescent-shaped cavity. Oil is pumped as the inner gear rotates, causing the outer gear to also rotate, moving oil along with the drive gear.

Internal Gear Pump - The principle of operation of a rotary pump is similar to that of an internal gear pump. The rotary one also has two nested elements (rotors) and oil pumping also occurs due to their rotation.

Rotary pump design: (1 - suction cavity; 2 - oil; 3 - external rotor; 4 - discharge cavity; 5 - drive shaft; 6 - internal rotor) - A vane pump is a working chamber into which a cylindrical rotor with slots is inserted. Flat slide plates are inserted into the slots and can move freely in these slots. When the rotor rotates, the space between it and the walls of the working chamber is divided into sectors. These sectors capture portions of liquid and transfer it to the discharge channel. The design of the vane pump allows you to adjust its performance by moving the stator and thus changing the volume of the working chamber.

Vane pump

According to adaptability, adjustable and unregulated types of pumps are distinguished.

- The former have the ability to change performance depending on the engine’s current need for lubrication. Adjustable pumps ensure that the engine receives as much oil as it needs at all times.

Design of a regulated rotary pump: (1 - intermediate housing; 2 - outer rotor; 3 - inner rotor; 4 - regulator spring; a) with reduced oil pressure; b) with increased oil pressure) - The performance of unregulated pumps depends solely on the speed of rotation of the crankshaft. For most cars, this is quite enough, unless you tune them for racing. To avoid creating too high pressure in the lubrication system when the engine gains power, unregulated pumps are equipped with a pressure reducing valve. It opens when the pressure reaches a critical point, and part of the oil goes back into the crankcase, that is, it serves to stabilize the pressure in the lubrication system.

Pump drive types are electrical and mechanical.

- Electric oil pumps are quite rare as a design solution. They are used in turbocharged engines designed for high (sports) loads. The electric drive is needed to ensure that the pump continues to operate after the engine stops, cooling the hot turbine.

- Mechanical oil pumps driven by the engine crankshaft are used in most vehicles. The drive can be belt or gear, it depends on the design solution. The speed of the pump (and its productivity per unit time) depends on the load on the engine. This has its own logic: the faster the motor runs, the more it needs cooling, cleaning and lubrication.

The operating principle of some oil pumps

Where is the oil pump located? If we talk about a lubrication system with a “wet” sump, that is, a conventional one, then in it the pump is located at the bottom, supplying oil to the system from the sump, from the bottom up. If this is an unregulated pump type, then when excess pressure is created, excess oil will drain through the pressure relief valve back into the crankcase. One pump is enough for a conventional engine.

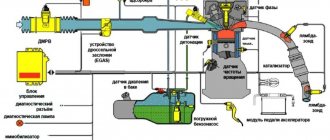

Location of the oil pump along with other engine elements: (1 – oil pump; 2 – oil pump gasket; 3 – oil pump receiver; 4 – crankcase gasket; 5 – crankcase; 6 – crankshaft position sensor)

A dry sump lubrication system, where a separate reservoir is provided for oil, is installed on powerful sports cars, which means it is designed for high loads. Two or even three oil pumps can be installed on such an engine, since at maximum speed such an engine requires both cooling and lubrication.

Gear type oil pump design

Gears are placed in the body of the automobile oil pump, one of which is the drive (first), and the other is the driven (second). The gears draw oil from the suction port into the system, pushing the lubricant through the discharge port. Engine speed directly affects performance. If, during operation of such an oil pump, excessive oil pressure is created, then the pressure relief valve is automatically activated and part of the oil is sent to the engine crankcase. Therefore, the gear type of oil pump, in its operating scheme, belongs to an unregulated pump

Rotary type oil pump design

- Pump suction cavity

- Lubricant (oil)

- External rotor

- Discharge cavity

- Oil pump drive shaft

- Inner rotor

An oil pump, rotary type, is a mechanism whose design consists of internal (drive) and external (driven) rotors located inside the oil pump housing. When the pressure rises in an unregulated rotary pump, the pressure relief valve automatically operates

In an adjustable rotary, constant oil pressure is maintained due to the presence of a movable stator, which in turn has an adjusting spring, which allows maintaining stable oil pressure regardless of the crankshaft speed. Constant pressure of the lubricant is maintained by the ability to change the size of the cavity between the outer and inner rotors, thanks to the rotation of the stator in the required direction

Types and design of pumps

The basic operating principle of all engine oil pumps is the same: suction of engine oil from the oil pan (oil tank) and injection into the lubrication system lines. Structurally, these can be gear, rotary and vane pumps with or without the possibility of forced adjustment of the pressure level. The way they are activated also differs.

Gear pumps

This type of mechanism is unregulated. This oil pump is driven from the engine crankshaft. In practice, this means that the pressure level directly depends on the engine speed. To ensure that the oil pressure in the discharge line of the lubrication system remains constant and does not exceed critical values, such oil pumps are always supplemented with a pressure reducing valve.

External Gear Oil Pump

Structurally, a gear pump consists of the following elements:

- Drive gear connected to the crankshaft.

- A driven gear driven by a drive gear.

- Sealed housing with discharge and suction channels.

- Oil pump pressure reducing valve - it is a plunger with a spring, which, when the pressure increases, is pressed out, opening the oil discharge channel.

- Seals (oil seals).

Gear pumps can be:

- With external gearing - the gears are located side by side and have external teeth. The disadvantage of this type is the difficulty of achieving a high level of compression, since this provokes an increase in specific pressures in the tooth engagement zone. And although the problem can be solved by using a special relief groove, pumps with such a groove are ineffective for a wide range of rotation speeds and at low speeds the performance will be very low.

- Internally geared - the drive gear has external teeth and is located inside the driven gear, the teeth of which are directed inward. The gears do not have a common axis and form a semicircular gap (cavity). This oil pump has a more compact size.

Internal gear oil pump

The principle of operation of a gear pump is very simple: the lubricant enters through the suction channel, where it is compressed by the gears and pushed out under pressure into the discharge channel. Internal gear oil pumps can also be equipped with a crescent baffle. It is installed between the rotor teeth in the area of maximum distance from each other. Thanks to this, the injection cavities are sealed and a higher operating pressure is ensured.

Oil pumps in automobile engines are always driven by the engine. The transmission can be carried out by means of gears, drive chains or belts.

Rotary pumps for pumping motor oil

Rotary type oil pumps are similar to internal gear ones. However, instead of gears, oil compression is carried out using a stationary stator (larger diameter) and a movable rotor (located inside the stator). Such pumps can be unregulated (with a pressure reducing valve) or adjustable.

ICE rotary oil pump

Fixed rotary oil pumps are driven by the crankshaft and produce a level of pressure proportional to its rotation. Excess pressure, as in gear oil pumps, is relieved by a pressure reducing valve.

The difference between adjustable rotary pumps is the presence of a movable stator and a special adjustment spring. The adjustment process itself is based on the principle of changing the volume of the working cavity (the gap between the rotors), which is carried out by turning the stator. So, if the crankshaft speed increases, the engine consumes more oil, which leads to a decrease in pressure.

The spring reacts to this and moves the stator, changing the position of the driven rotor and changing the working cavity of the pump. The performance of the oil pump increases. An adjustable oil pump allows you to maintain a stable pressure level regardless of engine operating mode.

Vane or vane oil pumps

Operating Principle of a Vane Pump

For some types of engines, a vane or vane oil pump may be used. This design allows you to adjust performance based on engine speed.

A vane pump consists of a housing, inside of which there is a rotor and a stator. Their axes are shifted, due to which a crescent-shaped gap is formed in the lower part. The rotor is also equipped with movable plates inserted into special grooves. Under the influence of centrifugal force in the gap between the rotor and stator, they move out and form separate oil compression chambers. As the rotor rotates, the volume of the chambers constantly changes. When the volume increases, a vacuum is created and oil is sucked in. As the chamber decreases, the pressure increases and pumping occurs.