Reasons why the fuel pump does not pump gasoline when the ignition is turned on

The gasoline pump serves to supply fuel from the tank and maintain the pressure in the line necessary for the operation of the injectors. Interruptions in the supply of gasoline lead to a disruption in the composition of the air-fuel mixture, which leads to poor-quality combustion and misfires, the engine begins to stall, respond sluggishly to the gas pedal or stall. If the fuel pump (FP) does not pump, the engine will not start at all.

Similar symptoms not related to the fuel pump

The symptoms that appear due to a lack of fuel in the supply line are quite typical and are very similar to problems with other systems. How to eliminate possible problems using the elimination method:

- Unscrew and inspect the spark plug skirts. When there is not enough fuel, the electrodes remain clean or become covered with a white coating. This is further evidence of a malfunction in the power system.

- Replace spark plugs. If they wear out, they create a similar effect - failures, difficult starting, and a drop in engine power.

- Check the functionality of the throttle position sensor (TPS) and idle air control.

- Measure the compression in all engine cylinders. Due to excessive wear, the naturally aspirated engine is unable to create the required pressure and vacuum; the mixture burns poorly, which is why identical symptoms occur.

When troubleshooting, take into account one important factor - the service life of the fuel pump, which is at least 100 thousand kilometers. The longer the operating period of the unit, the lower the fuel pressure it creates at the outlet. The reason is wear of the membrane and other internal parts. If the pump has served 150 thousand km or more, you should think about purchasing and installing a new spare part.

Symptoms of a fuel pump malfunction and methods for diagnosing them on an injection engine

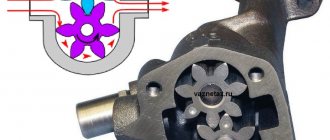

The power systems of modern fuel-injected internal combustion engines use an electric fuel pump. Depending on the installation location, there are submersible (installed in the tank) and flow-through fuel pumps (cut into the fuel supply line).

Main components of an electric fuel pump:

- two-piece body;

- DC motor;

- pumping section.

According to its design, the section can be rotary, blade, gear or turbine type. The latter option, due to its simplicity of design, has earned the greatest popularity. The rotation of the impeller attached to the electric motor shaft creates zones of high and low pressure, due to which fuel is taken and pumped from the tank into the pipelines.

Motor power circuit

In addition to the submersible fuel pump, the fuel module located in the tank includes:

- float type fuel level indicator sensor;

- critical gasoline level sensor;

- coarse filter;

- built-in fuel pressure regulator (RDT). This type of RTD is found on returnless power systems. Another type of design involves the presence of a fuel return line and a regulator mounted in the fuel rail;

- inlet and outlet fuel lines;

- electrical connectors.

Symptoms of a worn fuel pump motor:

- uncertain engine start;

- failures when sharply pressing the accelerator pedal;

- insufficient power at high speeds;

- The engine periodically stalls and refuses to start for some time. Often in such cases, several blows to the tank help bring the fuel pump back to life.

The cause of the described symptoms is worn brushes and the electric motor commutator. When the brushes are worn out, they do not press well against the lamellas of the commutator, which is why the current in the circuit drops, which leads to a decrease in the performance of the fuel pump.

Wear of electric motor components is the most common reason why the fuel pump does not pump gasoline well.

If power comes to the connector, but fuel does not flow from the pump, the reason may be melting of the plastic housing due to overheating or critical wear of the brushes/commutator. In this case, when you turn on the ignition, you will not hear a characteristic buzzing sound from the fuel module. Sometimes a situation in which the fuel pump pumps, but no gasoline comes out, occurs due to poor fixation of the corrugation going from the pump to the outlet fittings of the fuel section. Due to the pressure created by the pump, the corrugation jumps off the fitting.

If the gas pump works but does not pump enough gasoline, first of all pay attention to the coarse and fine filters. Clogged filters can be identified by the fact that the fuel pump hums louder than usual. Please note that operation under load reduces the service life of the transformer. The cause of insufficient pressure may also be a faulty fuel pressure regulator, which discharges too much fuel into the return line.

Failure of the fuel pump due to wear of the elements of the pump section occurs only in the case of low-quality components. You are more likely to replace the fuel pump due to worn brushes than to face mechanical wear on the pump section components.

Pump operation

Anything can happen while operating a car. In particular, the fuel pump may break down. Or contamination of the fuel tank, therefore, the filter installed at the bottom of the pump

It is worth paying attention to the fact that VAZ cars are very popular in our country. There are a lot of spare parts for them, you can find them in any auto store.

True, the quality of products is not always good. Sometimes you come across outright fakes on the market that cannot last even a few months. Of course, you can run into a low-quality spare part even if you purchase it for a foreign-made car. The service life of the VAZ 2110 pump is about 100 thousand km.

How to check the fuel pump?

The most reliable diagnostic method is to check the gasoline pressure in the fuel line.

On sale you will find ready-made kits with adapters for connecting to the most common power systems. You can build the device with your own hands from a pressure gauge with a scale of up to 6 kg/cm2, a hose, adapters and fittings. To check the pump you need:

- Relieve the residual gasoline pressure in the line.

- Connect the pressure gauge across the engine power supply system. Some cars have a standard fitting to check the performance of the pump.

- Turn on the ignition. A value of 3-4 kg/cm² is considered normal. The exact parameters for a specific engine are in the repair and operation manual.

- Start the engine. A working fuel pump creates excess pressure (about 7 kg/cm²), which is released into the tank by the regulator. Therefore, in all engine operating modes, the pressure in the ramp should not deviate significantly from the standard values. When diagnosing, try to simulate the conditions under which the symptoms of a faulty fuel pump manifest themselves most often (engine temperature, load, etc.)

VAZ 2110 fuel pump is a common cause of breakdown

The new VAZ 2110 models use injection engines, which are so popular today. To confidently drive any car, you need to know what can break down in it in order to quickly fix the breakdown or prevent it. The fuel pump of the VAZ 2110 is one of the most vulnerable points of this car. If the fuel system is not properly maintained, it will quickly fail.

The fuel pump in injection engines is very important, since it is the one that supplies the fuel injectors with the required pressure. If there is no pressure or it is incorrect, the injectors will supply fuel to the engine in the wrong dosage.

Fuel pressure is measured in the fuel rail using a special device.

In essence, the device for measuring fuel pressure on a VAZ 2110 is the same pressure gauge, only for measuring liquid pressure. If the pressure in the ramp on a VAZ 2110 does not fit into the values of 3.6-4 atmospheres, then the car is faulty and needs to be repaired urgently, as this can lead to failure of the fuel pump, if it has not already failed.

Symptoms of VAZ 2110 breakdowns

If suddenly the car begins to twitch at high or medium speeds, this indicates a drop in fuel pressure in the rail. The same applies to the case when the engine develops dips or even stalls.

The fuel pressure in the system can drop not only when the fuel pump fails, but also when the RTD or even the injectors themselves fail.

The fuel pump on the VAZ 2110 constantly pumps gasoline while the engine is running. In this case, excess gasoline is simply returned back to the gas tank through the return channel. It is on this channel that the check valve is installed. To check it, use a pressure gauge. After the engine is turned off, the gasoline pressure should drop gradually, not suddenly. The slower the pressure drops, the better the quality of the RTD valve.

Checking the fuel pump

On the VAZ 2110, the fuel pump is located directly on the gas tank; to check it, you need to perform several steps. First of all, you need to listen to how the fuel pump works; if it does not work evenly, then there are problems.

Before checking the fuel pump, you need to check the fuel filters, since they are most often the cause of everything. With a clean filter, the pressure gauge needle should tremble a little when the pump is running, but if suddenly the needle deviates within 0.3 atmospheres or more, then the filter may be clogged and needs to be changed.

In addition to all of the above, the system can be checked without a pressure gauge; to do this, disconnect the gas line and insert it into a clean container. After power is supplied to the fuel pump, it must pump at least 1.5 liters of gasoline in a minute.

A more professional way to check the fuel pump is with a pressure gauge, measuring its pressure. As the fuel pump wears out, the pressure drops and the car significantly loses its potential. To check the pressure of the fuel pump, you need to connect a pressure gauge and pinch the gasoline return hose with pliers. If the pressure is not lower than 4 atmospheres, then the pump is ok.

You can also spin the engine up to 3000 rpm and look at the pressure gauge readings. Under no circumstances should the pressure drop.

If suddenly the fuel pump fails, then it will have to be replaced, and you should not regret it for your VAZ 2110. If this pump breaks down again, you won't be able to drive the car. For replacement, it is best to choose high-quality imported pumps that can deliver up to 7 atmospheres. Such a pump will not only last longer, it will also improve the quality of mixture formation when leaving the nozzle.

“Likes” on social media networks:

Connection diagram

Above is a standard connection diagram for a fuel injection pump. The ECM (controller), after successfully polling the immobilizer, energizes the coil winding of the fuel pump relay (pins 85, 86). Under the influence of electromagnetic induction, power contact 30 (constant “+” from the battery, protected by fuse X) and contact 87 close, which leads to the inclusion of the fuel pump. Main faults:

- fuse blown; Attention! Replace the burnt-out fuse-link with a fuse of standard rating. Installing an insert designed for high current may result in a vehicle fire.

- formation of oxides inside the connectors, burning of the power contacts of the fuel pump relay. Parasitic resistance leads to a drop in current in the circuit and a decrease in the performance of the nose;

- chafing, breaking wires;

- breaking off the latch of the power connector going to the fuel module. Often in this case, contact is broken when driving over uneven surfaces.

Video: Fuel pump does not work. How to find and eliminate the cause.

The fuel pump does not work, the relay turns on.

Checking relay power.

In the case when the fuel pump relay turns on when the ignition is turned on, but the pump itself does not work, you need to check the power at terminal 87 of the fuel pump relay. To do this, touch terminal 87 of the relay socket with the output of the control lamp connected to the vehicle ground, and the lamp should light up. If the lamp does not light, it means the fuse has blown or there is a break in the wire.

If there is power at terminal 87, you should remove the relay from the socket, and instead place a jumper between pins 87 and 30. In this case, if the pump and connecting wires are working properly, the pump should start working and if this happens, the relay should be changed. If the pump does not start working, then, without removing the jumper, you need to touch the power wire on the fuel pump with a test lamp connected to the vehicle ground.

Checking the fuel pump power circuit.

If a submersible pump is installed on the car as part of the fuel module, you need to remove the connecting connector and touch one of the thick wires. When you touch one of them, the indicator lamp should light up. If the lamp does not light up on any of the wires, then it is necessary to eliminate the break in the wire from the fuel pump relay to the module connector or the pump itself, if the pump is of a remote type. One of the reasons for the break may be the anti-theft blocking of an installed non-standard alarm system.

In the case when the test lamp lights up on one of the thick wires of the connector or one of the terminals of the remote pump, you need to connect these terminals with a test lamp to each other. In this case, the control lamp should light up. If the lamp does not light, it is necessary to eliminate a break or poor contact in the wire connecting the pump to the vehicle ground.

If, when checking the wires and relay for turning on the fuel pump, no malfunction is detected, the electric motor of the fuel pump or its connection to the module connector is faulty. It is not difficult to find the cause by removing the fuel pump module from the tank. If there is poor contact with the connector, melting of the plugs will be visible. If melting is not noticed, then to check the pump itself, you can connect it to the battery. It should be taken into account that operating a submersible pump without liquid will damage the pump. A faulty pump should be replaced.

Power check

You can establish the presence of voltage at the TN connector using a simple test to check electrical circuits. To check the fuel pump, in the electrical diagrams for your car model, find the pinout of the electrical connector of the fuel module. For the pump motor to operate, “–” and “+” are required. If, after turning on the ignition and connecting the control contacts to the corresponding pins of the block, the light comes on, then everything is in order with the supply voltage. Using this method, you can check for the presence of +12V and ground in the fuel pump relay connector, and establish the presence of supply voltage from the ECM to the relay. If the fuel pump does not turn on, but there are no problems with the components of the electrical circuit, the reason is in the fuel pump itself.

The most convenient way to determine why there is no power to the fuel pump is to use a multimeter. Let's say that + 12V to the pump comes from the relay, but does not reach the fuel module connector. In this case, it is necessary to ring the wires from the relay to the fuel section. In ohmmeter mode, you will not only find an open, but you will also be able to see the parasitic resistance in the circuit. When considering possible reasons why the fuel pump does not pump, do not forget about the immobilizer failure. Often in such cases the engine starts, but stalls after a few seconds.

Methods for checking the fuel pump

It is very simple to find out whether a mechanical fuel pump is working or not; to do this, simply disconnect the end of the hose connecting the pump to the carburetor, and, lowering it into an empty bottle, press the manual pumping lever located on the pump several times. Gasoline should flow out of the hose in a pulsating stream. This will allow you to find out whether the internal elements of the pump are working properly or not.

To understand why the fuel pump does not work on an injection engine, you should first “ring” its electrical circuit. It is better to start checking from the end point, that is, from the pump itself. A test lamp is connected to its terminals, and if, when you turn the key in the ignition switch, it lights up, then everything is in order with the electrics, you need to look for a breakdown in the pump itself, if not, then in the fuse, relay or wiring.

To check the fuel pump itself, you need to find out what pressure it creates in the fuel rail:

- At idle speed, its value should be in the range of 0.23-0.25 kPa.

- During engine start – 0.3 kPa.

- When you press the accelerator - 0.28-0.3 kPa.

- When the return tube that returns excess gasoline to the tank is compressed, the pressure should rise to 0.4 kPa.

If in any of the modes the pressure does not correspond to the norm, therefore, the fuel pump does not work as it should - its elements are severely worn out and require repair or replacement.

Carburetor power system

Possible reasons why gasoline does not flow into the carburetor:

- clogging of the fuel line from the tank to the mechanical fuel pump;

- diaphragm breakthrough;

- clogging of the filter element;

- wear of the eccentric, pusher and/or balancer;

- production of valves and their seats;

- Broken spring diaphragm.

Source

Purpose and principle of operation of the fuel pump

The fuel pump is designed to move fuel from one point to another. In a car, the first point is the fuel tank, and the second is the engine, where the pump occurs. This process occurs at a predetermined pressure, which is maintained by the pump reducer, which is a very important point.

Due to the type of drive, fuel pumps are divided into 2 types: electrical and mechanical. Inside the first of them there is an electric motor with a mini-pump, which is powered from the network and smoothly pumps fuel into the engine. The second type is found less frequently because it is mounted in the carburetor and operates through the movement of a lever.

What to do if the fuel pump does not work?

I think for those who do not understand at all what and how it works in a car. You should read one of the articles on the topic “car fuel system”. So at least you will have an idea of what will be discussed next. And for those who have an idea of what a fuel system is, let’s move on.

Diagnostics

In order to understand what is wrong with the system. It is necessary to carry out diagnostics. You can create a checklist of possible faults for yourself:

- relay

- circuit breakers

- ECU

- fuel pump (wiring, motor)

CHECKING THE ECU, RELAYS AND FUSES KALINA

First, let's check the fuel pump relay. Its location is under the passenger's feet on the left. Where is the air duct located?

Unscrew the screw and tighten the panel. Next we will see the relay block. Unscrew the nut with a 10mm wrench or a socket. We take out the block with the relays and find what we need. Look at the photo below:

Relay 30A, 12V. In order to check for functionality. You can remove exactly the same relay, with the same parameters, and install it in place of the previous one. If the engine does not start, then the problem is not with the relay. It's working for us. So we are looking for the problem further.

You can also check the ECU there. The fact is that on the Lada Kalina the ECU unit is located under the heater radiator. And it often happens that antifreeze gets on the block. As a result, the ECU floods. Which, in turn, stops working correctly. And one of the reasons may be a refusal to start the car engine.

To check the ECU simply, look for the possibility of a leak in the heater radiator. When will you diagnose the fuel pump relay?

CHECKING FUSES

To check the integrity of the fuses. It is necessary to open the panel near the gear shift knob. Where is the diagnostic connector located? And there find fuse 3 (count from the driver). We take it out and see if it is intact. If it’s intact, then we look for the reason further.

Checking the fuel pump of a carburetor car (mechanical)

Mechanical fuel pump - diagram

To check the operation of the fuel pump, you should:

- Remove the fuel hose from the carburetor inlet fitting.

- Immerse the hose in a specially prepared transparent bottle. By actively using the pumping lever manually, we notice how strong and dense the fuel is supplied. Air impurities should not be visually noticeable.

Delayed jet output is not a sign of a breakdown, especially if the car has been parked for a long time. As a rule, diaphragms eight and nine are the main cause of malfunction.

Be that as it may, you need to inspect both the strainer and the inlet/outlet valve.

Even if the gaskets are replaced, fuel may leak. In this case, the problem lies in the tightness of the fuel pump housing due to deformation during repairs.

Let's summarize:

The causes of fuel pump problems, both electrical and mechanical, are varied, and the need to find/fix a breakdown may take you by surprise along the way. By following the above recommendations, you will be able to independently carry out the entire necessary set of measures to diagnose this device. And you should start with the power supply (if it is an electric fuel pump) and the operation of the diaphragm when checking a mechanical fuel pump. Very often, the unstable operation of a fuel pump is not due to its breakdown, but to related parts - a filter, check valve or injectors.

Zavolzhsky Motor Plant (ZMZ) is one of the first domestic manufacturers of automobile engines to begin producing engines with an injection power system. One such high-quality engine can be called the ZMZ 405 - an engine from a family of four-cylinder engines that have been produced for almost 15 years. For the first time, this particular engine hit the market back in 2000, installed on the GAZ-3111 car. The plant itself positions the engine as an engine for small trucks and minibuses. It is installed on them - various cars of the GAZelle and Sobol injector line have this engine.

Over the past time, the ZMZ 405 has established itself as an excellent, unpretentious engine, ready for even the greatest difficulties on the road. The 405 motor is capable of withstanding heavy loads and this will not affect its service life. Also, the design of the motor is based on the unprecedented simplicity of the device - this engine, installed on any car, can be repaired and maintained by anyone in an ordinary garage with minimal knowledge, everything is done according to the included book and does not raise any questions. The same applies to fuel system repairs. In particular, the engine fuel pump injector is very easy to repair yourself.

Fuel block diagnostics

If all of the above did not give positive results. The engine still doesn't catch on. Then it's time to move on to diagnosing the fuel unit.

Now we need to disassemble the fuel block and check the pump itself. As well as a fuel level sensor with wiring.

Checking the fuel pump

There are several ways to check the fuel pump for functionality. But since we already took out the fuel block. Then I will tell you only about one thing.

And so, we take out the fuel pump and connect it to the battery for a few seconds. That is, we apply 12V voltage for a few seconds. 1-2 seconds is enough to check. During this time, you will have time to hear the hum of the motor. If there is no buzzing, then we replace the pump.

In my case, the motor was fine. But the fuel pump still didn't work. All that remained was to check the fuel level sensor and the wiring from it. Which is what I did next.

Checking the fuel level sensor

We remove the fuel level sensor and check the wiring.

Now we see that one contact has burned out and the power has disappeared. it is necessary to replace the sensor along with the wiring. And the fuel pump will work as before.

Preventing fuel pump breakdowns

To extend the life of the fuel pump, you need to:

Monitor the quality of fuel filled into the car. Completely eliminate even the possibility of water getting into the tank. During scheduled maintenance, be sure to change the fuel filters. In case of mechanical damage to the fuel tank, it is necessary to dismantle the fuel pump and check its condition. Periodically clean the fuel tank from possible accumulation of sediment, consisting of tiny solid particles found in gasoline.

Following these simple rules will have a beneficial effect not only on the fuel system, but also on the engine itself.

Why doesn't the fuel pump deliver gasoline?

One of the most important elements of the fuel injection system of a gasoline engine is the electric fuel pump, which is located in the fuel tank of the car. The fuel pump pumps fuel into the system from the gas tank, creating a certain pressure.

Auto repair experts identify the following common fuel system problems that are related to the fuel pump:

- The fuel pump pumps poorly and does not create the required pressure;

- the fuel pump does not pump when the ignition is turned on;

Considering that the fuel pump is an electromechanical device, the most common fuel pump malfunctions are related to both the mechanical and electrical parts. Next, we will look at what signs indicate a breakdown of the fuel pump and why the fuel pump stops pumping partially or completely.

Why is the fuel pump humming?

The electric fuel pump on cars with an injector is a submersible fuel pump that is installed directly in the gas tank. Structurally, such a pump is an electromechanical device that takes fuel from the tank and supplies it to the engine. The task of the fuel pump (BN) is to pump fuel into the fuel line. As a result, the necessary pressure is created in the fuel rail for subsequent injection of gasoline using injection nozzles.

The list of common faults includes the following:

- the fuel pump hums/whistles;

- The fuel pump gets very hot;

- The fuel pump does not turn off;

Next, we will look at the main reasons why these problems occur, and also consider the available ways to check the fuel pump yourself.

Signs of fuel pump malfunctions

The main symptoms of fuel pump failure, as well as malfunctions in its operation, are:

- the car starts with difficulty, the engine runs unstable, there are dips, jerking when pressing the gas pedal, etc.;

- the pump does not pump after turning on the ignition, does not turn the starter and does not pump the fuel pump, the engine does not start;

There have also been cases when the fuel pump stops pumping while driving. In such a situation, the engine begins to malfunction and stalls immediately after the remaining gasoline in the fuel line is used up. The problem can occur either regularly or periodically.

Removal, disassembly, replacement

If after checking it turns out that the pump does not produce the required pressure, it is dismantled and disassembled. The submersible pump is mainly installed under the rear seat in the cabin. There is a hatch that needs to be opened and the device removed. On used cars, it is also recommended to flush the fuel tank, as harmful deposits can re-clog the parts.

The pump is disassembled in order to replace the mesh (coarse filter). After the mesh has been replaced or cleaned, the RTD is checked. This is a sensor mounted on the fuel rail. It regulates the pressure, and if it malfunctions, noise and whistling from the fuel pump may occur.

If the fuel pump itself is faulty, then most often it is a failure of the motor. It deteriorates due to low-quality gasoline, poured over a long period of time, or a short circuit. Signs of a faulty motor are identified by sudden changes in pressure, which can be recorded with a pressure gauge. And, of course, if the pump motor is faulty, the hum becomes as loud as possible.

In many cases, the motor itself must be replaced; it is not necessary to buy a new submersible pump. At the same time, it is recommended to replace gaskets and seals, which wear out over time.

If the device does not turn off and constantly buzzes, this indicates an electrical fault. Most likely, the circuit contacts are stuck or burnt, or a short circuit has occurred.

Video: fuel pump hums

Forget about fines from cameras! An absolutely legal new product - Traffic Police Camera Jammer, hides your license plates from the cameras that are installed in all cities. More details at the link.

- Absolutely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter connector;

- Does not cause interference to radios and cell phones.

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, the battery is charged, the spark plugs are dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

In the second case, when you press the gas, the pressure does not increase; in the latter case, the pressure gauge needle rises, but very slowly or jerkily.

A decrease in pressure below the norm will lead to the fact that the engine may not start or start with difficulty, stall, jerk, operate unstably and with failures. If this happens due to the fault of the pump and not the fuel filter, then there is a high probability that the coarse filter screen of the fuel pump is clogged. In this case, there is no need to change the fuel pump itself, since it will be enough to replace or even clean the mesh.

If you suspect that there is no voltage to the fuel pump, there is a quick way to check. It is enough to turn the ignition key and listen, as when you turn the key you should hear a slight hum from the fuel pump. If such a buzzing noise is not heard, it means there is no power to the fuel pump, there are problems with the wiring, etc.

The fuel pump is very noisy: troubleshooting

In most cases, an increase in noise level occurs due to an increasing load on the gas pump, which becomes more difficult to pump the required amount of fuel. Overheating or failure of the pump itself is less common.

At the initial stage, it should be understood that if the gas pump makes a sound (albeit different from normal), then power is supplied to the device and the pump itself reacts to the supply of electricity. Based on this, the problem can be localized faster. Before diagnostics, it is recommended to replace the fuel filter to eliminate the possibility of a decrease in throughput in this area.

There is also a simple solution that allows you to quickly check the status of your device. The method involves removing the return hose and inserting it into a separate container suitable for pouring gasoline. Next, you need to measure how much fuel is drained back into the tank. The norm for many gas pumps is a minimum value of 1.5 liters per minute or more. The disadvantage of such measurements can be considered very approximate readings, which do not allow obtaining accurate data.

Fault repair

If there is no power to the block, we begin troubleshooting by checking the fuses of the fuel pump power supply circuit. They are located on a special separate panel located in the car interior under the glove compartment.

Fuel pump fuse VAZ 2107

The middle relay and fuse F3 located nearby are responsible for the operation of the fuel pump.

1 – fuse, power circuits of the main relay;