Oil filter replacement intervals

If you want to keep your engine safe and sound, we advise you to regularly change the oil filter. The oil filter is the main protection of the crankshaft and moving engine parts. If its operation is unstable, the car’s engine quickly fails.

If you have neglected the recommendations for replacing the oil filter for a long time, then be sure that such an amount of dirt has accumulated in it that it hardly passes the oil or, in general, it does not pass at all.

The last assumption is exaggerated, since the design of oil filters provides a bypass valve, which means oil circulation in any case, even when the filter is clogged. But you can imagine what kind of oil it will be. Therefore, do not bring the situation to a critical point.

Various automobile concerns and oil filter manufacturers recommend different intervals for changing cleaning components. As a rule, these periods are very short, since manufacturers care about their reputation and therefore recommend frequent replacement of filters.

Experts advise replacing it every 8-12 thousand km, which coincides with the timing of engine oil changes. However, if you have any doubts about the purity of the oil or any bad signs appear, you can replace the filter ahead of schedule. The benefits of timely replacement are obvious, judge for yourself: if an engine can be purchased from $2000, then a new filter will cost you $10 - $20. Therefore, do not leave replacing the air filter for later.

Causes of engine oil starvation

There may be several reasons.

- There is not enough oil in the engine - the level is low, someone leaked it and did not top it up

- The oil has not been changed for a long time, it has thickened, collected in pieces on the walls of the engine and does not flow into the sump

- The oil receiver screen is clogged

- The oil filter is clogged and the bypass valve is stuck

- The oil injectors are stuck in the open position and the pressure in the system has dropped

- The pressure reducing valve on the oil pump is broken and oil flows through it into the return line.

- Oil channels clogged

- Come up with a reason yourself (if possible, write down in the comments what other reasons there may be)

1. Any engine consumes oil due to waste - some more, some less. If you don’t look under the hood and check the oil level for a long time, then at one point the oil will become so low that it will no longer reach the oil receiver. First, this will happen when the car leans over while climbing a hill, then when it turns at speed and the oil, under the influence of centrifugal force, rushes away from the oil receiver. It is, of course, small things, but gradually the oil will become less and less, but it will stop flowing to the most remote corners of the engine.

2. When the oil is not changed for a long time, some kind of thick and non-flowing fuel oil is formed in it, which likes to collect on the walls of the block and in the head. The liquid fraction is becoming less and less, and hence we look at point 1. This happens especially often on modern cars, on which the manufacturer recommends extended oil change intervals (Long Life, up to 30,000 km). And if at the service you come across not very responsible technicians who do not drain all the old oil, there will be problems. Change the oil at least once every 10,000, or better yet, more often.

3. The dung that forms in the old oil (see point 2) can clog the oil receiver screen and then the oil will stop flowing into the lubrication system. Although the grid becomes clogged for other reasons.

4. The oil filter consists of a housing and the actual paper filter element. All the smallest particles of dirt clog the pores in the paper and over time the filter's throughput is lost. To prevent oil starvation when the filter is clogged (usually this does not happen if you change the oil on time, although how much dirt gets into the engine also depends on the air filter and operating conditions on dusty roads), the filter has a bypass valve - in In the normal position it is closed, but as soon as the flow capacity is lost, the valve opens under the influence of vacuum created by the oil pump. When the valve jams, naturally the oil will not come from anywhere, and less and less oil will circulate through the lubrication system with less pressure.

5. Some engines, mostly turbocharged ones, have oil injectors that spray oil onto the pistons to cool them. The injectors open under pressure, and when there is no oil pressure in the system, they close. If the injector is faulty and opens, the pressure in the system will decrease, which means the oil will not reach remote corners of the engine. Although if you have a budget foreign car with a low-power engine, such as a Ford Focus or Chevrolet Aveo, then you should not worry - they do not have such a system

6. The oil pump has a pressure relief valve, which is designed to relieve excess pressure. If it jams, the pressure in the system will drop, especially at low speeds, which will lead to oil starvation.

7. The engine lubrication system consists of oil channels. The most vulnerable part is the crankshaft. The crankshaft has oil channels through which oil flows from the main journals to the connecting rods. These channels are very narrow and can very easily become clogged with all sorts of dirt, which will lead to oil starvation of the connecting rod bearings.

8. You can come up with some other reasons, if you missed something, write in the comments

Signs of a clogged oil filter

If the oil filter has become unusable, then you most likely will not find out about it until you contact a car mechanic or remove it yourself. It's all about its bypass valve, which was already written about above. If the filter is clogged, it will allow unrefined oil to pass through, which is still better than not having it at all. But not everything is as ambiguous as it might seem at first glance. First, listen to your “horse”.

- Overheat. When moving engine parts rub against each other without sufficient lubricant, excessive heat is generated. Due to this factor, the engine mechanism begins to wear out faster, which causes additional stress on the cooling system. In addition, unfiltered contaminants form sediment and begin to be deposited in the engine, which causes a decrease in thermal conductivity. The result of this is engine overheating. Normal engine operation takes place at a temperature of no higher than 80 - 100 ° C; if this indicator is increased, this indicates that the oil filter is dirty.

- A leak. A faulty or clogged filter does not respond well to changes in temperature conditions inside the motor. Faulty oil filters can rupture or burst, causing oil to leak. Therefore, if you notice any fluid leaking from your car, contact a mechanic immediately.

Types of oil filters

Oil filters come in the following types:

- Full-threaded. In them, the entire oil flow is passed through a filter, and already purified oil is supplied to the engine. The main role in these filters is played by the bypass valve, which regulates the oil pressure in the engine.

- Partial flow. They have two purification circuits, in one it passes freely, in the other it is filtered. The quality of such cleaning is much higher than that of the first option, but the price is much higher.

- Combined. Combines the advantages of both types of filtration. They clean oil perfectly, but their price is high.

If you are the owner of a car with a carburetor engine, you can use inexpensive coarse filters that allow particles larger than 20 microns to pass through. Injection engines require filters that do not allow particles larger than 10 microns to pass through.

Oil filters produced for gasoline engines are not suitable for diesel cars. Diesel is more demanding on oil quality, so cleaning is carried out more thoroughly. Due to this, the size of diesel filters, as a rule, exceeds the size of gasoline filters.

Where is the oil filter located?

If you have come to the conclusion that you can handle replacing the oil filter yourself, then before starting the operation you must clearly understand the entire sequence of your actions.

- Find the oil filter. It is located at the bottom of the engine on a sump. (see photo).

- Next, before the replacement procedure itself, drain the oil. It must be drained when the engine is hot, for example, after a trip. If the car is parked for a long time, then start the engine so that it warms up to operating temperature.

- Keep in mind that the brand of oil poured into the engine must be the same as what it was before the replacement. If you decide to change the brand of oil, then flush the lubrication system with flushing oil or with the oil used subsequently.

- Flushing involves draining the used oil and then filling in new oil to the level of the lower mark. Old oil should not be poured onto the ground; place a previously prepared container. After draining the used oil, start the engine and let it idle for 10 minutes. Next, you can change the oil filter. After replacing it, fill in new oil to the required level - the upper mark on the dipstick.

After this procedure, prepare all the necessary tools and begin replacing the oil filter.

How to change the oil filter

This procedure, if combined with replacing the engine fluid, is the easiest way to increase the service life of the engine. If the time for mileage has not yet come, then this should be done once every 6 months. Algorithm of actions when changing the oil and filter:

- Warm up the engine for a couple of minutes at idle speed, turn it off, unscrew the oil filler cap, place a container under the crankcase and drain the oil (this can be done immediately after the trip). If you are not going to use the flushing compound, then screw the bolt (or nut, depending on the car model) into place.

- Remove the old filter using a dry cloth or gloves. If this cannot be done, you will have to find a special puller that fits around the body of the product. Don't forget to place a small container down: oil will flow out of the filter. Pay attention to the gasket: it may stick to the engine - it needs to be removed.

- Take the new filter and lubricate the rubber o-ring with fresh engine fluid. Screw the product into place by hand.

- Fill in new oil (if you intended to do so) and close the cap under the hood.

- Start the engine and make sure the oil pressure warning light goes out.

At the final stage, place a clean cardboard or newspaper under the motor. The absence of traces of oil will confirm that the filter is installed correctly.

Oil filter replacement tools

- New filter. The price of the product depends on the preferences of the chosen brand of oil. Experts recommend marking the oil as 5w30.

- Container for draining used oil . Choose a container that is shallow but fairly wide to minimize the possibility of oil spilling on the ground.

- Latex gloves. Designed to protect hands from burns that can be caused by hot oil when unscrewing the oil pan drain plug.

- Gate. Needed when the drain plug is too tight.

- Replaceable socket head. Used in conjunction with a collar, the size must match the drain plug.

- Band wrench. If access to the full flow oil filter is limited, it will allow you to remove it without any obstruction.

- Socket wrench. It is fixed at the end of the filter and then rotates using a ratchet drive or gate. The dimensions must match the filter housing.

- Rags and old newspapers.

Oil filter parameters

When selecting an oil filter, pay attention to the parameters that must meet the requirements of the car manufacturer:

With dimensions , it would seem that everything is clear: you need to focus on the diameter and length. But not all drivers know that the size and method of fitting the rubber seal also play an important role. Filters can be identical in size, but differ in the size of the seal. And if this factor is not taken into account, the likelihood of improper fit and oil leakage between the engine and the filter housing increases.

There are several types of landing threads

There are other options, but they are extremely rare. It is quite easy to confuse threads, especially metric and inch. For example, 13/16–16 UNF is similar in size to M20x1.5.

The key size is important for those who change the oil themselves. The fact is that on some cars it is quite difficult to unscrew a soured filter without a special key. And not every motorist has a set of these special tools in his garage.

The response pressure of the bypass valve is perhaps the main parameter in terms of operation. If the wrong valve opening pressure is selected, the filter can paralyze the operation of the lubrication system or completely stop purifying the oil, passing the flow past the filter element. Therefore, you must strictly follow the car manufacturer's instructions.

Step-by-step instructions for replacing the oil filter

- To have free access to the oil filter and oil pan, lift the car with a winch or drive it onto an overpass. You can also use a jack and supports.

Attention! Do not work under a vehicle supported only by the bumper or supported by a jack alone.

- Lie under the vehicle and locate the oil pan drain plug and engine oil filter. Please note that the exhaust system components will remain hot throughout the replacement procedure. Therefore, if your hand skin is unprotected, avoid contact with heated surfaces.

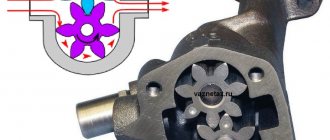

Oil pump malfunctions:

- gasket damage;

- oil filter clogged;

- the filter is not secured securely;

- increased wear of main parts;

- failure of the pressure reducing valve.

The oil pump in a car has a fairly long service life and breaks down infrequently. Most often, breakdowns are caused by improper operation of the car engine, poor-quality repairs or the use of low-quality oil. A decrease in oil pressure and an increase in its consumption are the main signs of a malfunction of the oil pump, after detection of which the system should be immediately diagnosed and the cause of the failure eliminated.

Oil filter device

The filter is part of the engine lubrication system. It is usually installed on the oil pump housing. To connect the filter, there is a hollow rod with an external thread that matches the internal thread in the filter outlet. A filter element, a check valve and a bypass valve are installed inside the housing. To ensure a tight fit to the oil pump body, a rubber O-ring is installed around the outlet hole in the flat end of the filter.

To unscrew the filter, use a special belt or segment wrench, which can be purchased at an auto parts store.

In some lubrication systems (for example, the Opel Corsa D), the filter housing is a stationary and non-replaceable element, and the valves are built into it. In such systems, only the soft filter element is changed.

Oil filter elements

- Housing

, which serves to protect the filter elements. - Oil inlet and outlet holes

;

a threaded hole

in the center with which the filter is attached to the engine. - Anti-drainage valve with rubber cover

; it prevents oil from pouring back into the filter when the engine is turned off. - The spring

, together with the anti-drainage valve, prevents oil from pouring into the filter when the engine is not running. - Filter media

, which can be made from synthetic materials, cellulose fibers, polyester or glass. Responsible for cleansing the oil, retaining mechanical impurities. -

steel tube - Safety valve

, which is located on the reverse side opposite the threaded hole. The valve serves to stabilize the pressure. - The filter cover

and

o-ring

are responsible for the tightness of the equipment.

Operating principle of the oil filter

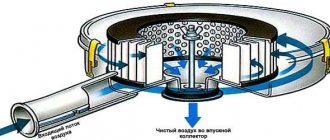

After the engine starts, oil under pressure begins to flow from the pump into the oil filter through small inlet holes located in a circle at the end of the filter.

The bypass valve, under the influence of pressure, allows oil to pass into the cavity between the filter housing and the filter element. The oil “leaks” through it, is filtered and enters the internal cavity of the oil filter. After this, having passed through the outlet, it continues to move through the lubrication system to the rubbing parts.

The vast majority of modern cars use a filter element made from repeatedly folded paper.

When the filter element is dirty or in cases of high engine oil density, a bypass valve opens in the filter. It allows the oil to pass inside the filter and further throughout the system without cleaning, bypassing the filter element. A bypass valve is provided to prevent oil starvation of the engine.

After the engine is turned off, the pump stops supplying oil to the filter. The check valve closes, preventing oil from flowing from the top of the lubrication system back into the engine sump. This allows the lubricant to remain in the area of the rubbing parts of the timing mechanism and reduces their wear the next time the engine is started.

Oil filter in turbocharger operation

We all know that oil plays a key role in the long-term operation of a turbocharger, and often it is oil (oil contamination, untimely replacement, etc.) that causes turbocharger failure. Dirty oil kills the turbocharger, it affects the turbine much more than any other part of the diesel engine. Under extreme loads, the rotation speed of the turbine shaft can be 250 rpm, and at this time, engine oil is the only thing that cools the turbine, gives it lubrication and prevents metal parts from rubbing against each other. That's why it's vital to keep your oil clean and your oil filter in good working order—the best protection for your turbocharger and engine. The turbocharger has to work under difficult conditions: at high speeds and at high temperatures, and clean filtered oil will protect the turbine from wear.

As mentioned above, a lot of contaminants remain on the filter element that the system cannot remove on its own, so do not forget to check the cleanliness of the filter from time to time and change it if necessary. An oil filter will extend the life of your turbocharger and engine.

22.06.2018

Malfunctions of the oil pump will inevitably lead to disruptions in the lubrication system of the internal combustion engine. serves to ensure pressure in the oil supply system. Symptoms of malfunctions and interruptions in the operation of the device indicate serious problems that require immediate attention.