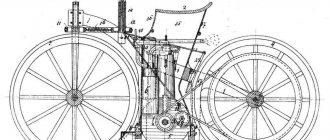

Single cylinder internal combustion engine

- the simplest piston internal combustion engine with only one working cylinder. The single-cylinder engine is completely unbalanced and runs unevenly. Single-cylinder engines are characterized by the smallest ratio of the surface area of the working cylinder to the working volume compared to multi-cylinder engines, which ensures the lowest heat loss in the working process and high indicator efficiency. At the same time, single-cylinder engines are characterized by significantly greater thermal and mechanical stress of parts compared to multi-cylinder engines. The specific gravity of single-cylinder engines is higher than that of multi-cylinder engines of the same displacement.

In the past, single-cylinder engines (due to the simplicity of the design) were widespread and their working volume was practically unlimited from above - on ships and in stationary installations there were low-speed single-cylinder engines with a working volume of up to 12 liters (for example, the Pioneer diesel calorizer engine with a power of 33 kW, released on ). Currently, the distribution of single-cylinder engines is also quite widespread due to their simplicity, low cost and low weight, but the working volume is limited.

Single-cylinder engines for aircraft models are characterized by the smallest displacement - 1 cm³ - 10 cm³. Gasoline two-stroke engines of manual lawn mowers (trimmers) have a working volume of 15 cm³ - 36 cm³. Chainsaws use engines with a working volume of 36 cm³ - 100 cm³. Mopeds use single-cylinder engines with a displacement slightly less than 50 cm³. To drive small electric generators, single-cylinder engines with a working volume of 60 cm³ - 420 cm³ (Yanmar L100 diesel) are used. Single-cylinder two-stroke engines with a working volume of 125 cm³ - 350 cm³ are used on motorcycles. For example, the Russian motorcycle IZH-Planet has one of the world’s largest serial single-cylinder two-stroke engines with a displacement of 346 cm³. Four-stroke motorcycle engines have a displacement of up to 800 cm³ (suzuki dr800).

For tractors DT-14 and self-propelled chassis DSSh-14, a single-cylinder diesel engine with a displacement of 1.03 liters and a power of 14 hp was produced. In China, as of 2013, single-cylinder diesel engines S1100 and S1115, developed in the 1930s, continue to be produced with a displacement of 905 cm³ and 1194 cm³, respectively. These engines are widely used to drive heavy walk-behind tractors and small tractors.

There are two main types of engines: two-stroke and four-stroke . In two-stroke engines, all operating cycles (the processes of inlet of the fuel mixture, exhaust gases, purge) occur during one revolution of the crankshaft in two main strokes. Engines of this type do not have valves; their role is played by a piston, which, when moving, closes the intake, exhaust and purge windows. Therefore, they are simpler in design. The power of a two-stroke engine with the same cylinder dimensions and shaft speed is theoretically twice that of a four-stroke engine due to the greater number of operating cycles. However, incomplete use of the piston stroke for expansion, poorer release of the cylinder from residual gases and the expenditure of part of the generated power on purging lead to an increase in power by only 60.70%.

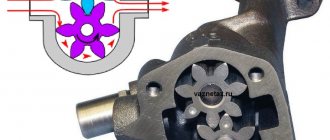

The engine consists of a crankcase in which the crankshaft and cylinder are mounted on bearings on both sides. A piston moves inside the cylinder - a metal cup surrounded by spring rings (piston rings) inserted into grooves on the piston. Piston rings prevent gases generated during fuel combustion from passing between the piston and the cylinder walls. The piston is equipped with a metal rod - a pin; it connects the piston to the connecting rod. The connecting rod transmits the linear reciprocating motion of the piston into the rotational motion of the crankshaft. All rubbing surfaces and bearings inside two-stroke engines are lubricated using a fuel mixture into which the required amount of oil is mixed. The figure shows that the fuel mixture (blue color) enters both the crank chamber of the engine (this is the cavity where the crankshaft is fixed and rotates) and into the cylinder. There is no lubricant there anywhere, and even if there was, it would have been washed away by the fuel mixture. This is the reason why oil is added in a certain proportion to gasoline. The type of oil used is special, specifically for two-stroke engines. It must withstand high temperatures and, when burned together with the fuel, leave a minimum of ash deposits.

Read also: Reduction gear on a walk-behind tractor

see also

Principle of operation. The entire working cycle in the engine is carried out in two strokes

1. Compression stroke. The piston moves from the bottom dead center of the piston (in this position the piston is at the bottom dead center, hereinafter we call this position for short BDC) to the top dead center of the piston (hereinafter TDC), blocking first the purge and then the exhaust window. After the piston closes the exhaust window in the cylinder, compression of the combustible mixture that previously entered it begins. At the same time, in the crank chamber, due to its tightness and after the piston closes the purge windows, a vacuum is created under the piston, under the influence of which a combustible mixture enters the crank chamber from the carburetor through the inlet window and the slightly open valve.

2. Power stroke. When the piston is positioned near TDC, the compressed working mixture is ignited by an electric spark from the spark plug, as a result of which the temperature and pressure of the gases increase sharply. Under the influence of thermal expansion of gases, the piston moves to BDC, while the expanding gases perform useful work. At the same time, going down, the piston creates high pressure in the crank chamber (compressing the air-fuel mixture in it). Under the influence of pressure, the valve closes, thus preventing the combustible mixture from entering the intake manifold again and then into the carburetor. When the piston reaches the exhaust window, it opens and exhaust gases begin to be released into the atmosphere, the pressure in the cylinder decreases. With further movement, the piston opens the purge window and the combustible mixture compressed in the crank chamber flows through the channel, filling the cylinder and purging it of exhaust gas residues.

Ignition principle. Since the fuel mixture takes time to ignite, the spark appears at the plug a little earlier than the piston reaches TDC. Ideally, the faster the piston moves, the earlier the ignition should be, because the piston reaches TDC faster from the moment of spark. There are mechanical and electronic devices that change the ignition angle depending on engine speed. Almost for scooters before 2000. There were no such systems and the ignition timing was set based on optimal speed.

Sixteen cylinder engines

Currently, these engines are not used in production cars. In 1930, under the Cadillac brand, a V16 model with a 7.3-liter sixteen-cylinder engine producing 185 hp was released. The V16 turned out to be the only production passenger car with a V16 engine.

The largest and most powerful diesel engine in the world reaches 13.5 meters in height and 26.59 meters in length. It only has 14 cylinders

Much later, in 1987, BMW installed a V16 engine on the E32 seventh series car as an experiment. The engine displacement was 6.76 and the power was 408 hp. To place the engine under the hood, the cooling system radiators had to be moved to the trunk.

Under the hood of the Bugatti Veyron Vitesse supercar there is a W16 engine with a power of 1200 hp. With. at 6400 rpm. The torque of the power plant consisting of 4 blocks of 4 cylinders each is 1500 Nm in the range of 3000-5000 rpm.

Disadvantages of two-stroke engines:

1. Higher fuel consumption. Let us remind you that the approximate consumption can be calculated using the formula: for a two-stroke 300 grams per horsepower, for a four-stroke 200 grams. 2. Noisy. At maximum speed, two-stroke engines tend to be slightly louder than four-stroke engines. 3. Comfort. Four-stroke engines do not vibrate as much at low speeds (Applies only to two-cylinder engines. Single-cylinder and two-stroke and four-stroke engines vibrate approximately the same) and do not smoke as much as two-stroke ones. 4. Durability. Quite a controversial point. There is an opinion that two-stroke engines are less durable. On the one hand, this is understandable, because the oil for lubricating the rubbing elements of the engine is supplied along with gasoline, which means it does not work as efficiently as in four-stroke engines where the rubbing elements literally float in oil. But on the other hand, a four-stroke engine is much more complex in design than its competitor, consists of a much larger number of parts, and the golden principle of mechanics “The simpler the more reliable” has not yet been canceled.

Read also: DIY pipe bender for greenhouses

The internal combustion engine is the main type of automotive power unit today. The operating principle of an internal combustion engine is based on the effect of thermal expansion of gases that occurs during combustion of the fuel-air mixture in the cylinder.

Single cylinder engine

A single-cylinder internal combustion engine

is the simplest piston internal combustion engine, having only one working cylinder. The single-cylinder engine is completely unbalanced and runs unevenly. Single-cylinder engines are characterized by the smallest ratio of the surface area of the working cylinder to the working volume compared to multi-cylinder engines, which ensures the lowest heat loss in the working process and high indicator efficiency. At the same time, single-cylinder engines are characterized by significantly greater thermal and mechanical stress of parts compared to multi-cylinder engines. The specific gravity of single-cylinder engines is higher than that of multi-cylinder engines of the same displacement.

In the past, single-cylinder engines (due to the simplicity of the design) were widespread and their working volume was practically unlimited from above - on ships and in stationary installations there were low-speed single-cylinder engines with a working volume of up to 12 liters (for example, the Pioneer diesel calorizer engine with a power of 33 kW, released on ). Currently, the distribution of single-cylinder engines is also quite widespread due to their simplicity, low cost and low weight, but the working volume is limited.

Single-cylinder engines for aircraft models are characterized by the smallest displacement - 1 cm³ - 10 cm³. Gasoline two-stroke engines of manual lawn mowers (trimmers) have a working volume of 15 cm³ - 36 cm³. Chainsaws use engines with a working volume of 36 cm³ - 100 cm³. Mopeds use single-cylinder engines with a displacement slightly less than 50 cm³. To drive small electric generators, single-cylinder engines with a working volume of 60 cm³ - 250 cm³ are used. Single-cylinder two-stroke engines with a working volume of 125 cm³ - 350 cm³ are used on motorcycles. For example, the Russian motorcycle IZH-Planet has one of the world’s largest serial single-cylinder two-stroke engines with a displacement of 346 cm³. Four-stroke motorcycle engines have a displacement of up to 800 cm³ (suzuki dr800).

For tractors DT-14 and self-propelled chassis DSSh-14, a single-cylinder diesel engine with a displacement of 1.03 liters and a power of 14 hp was produced.

Source

The most common types of engines

There are three types of internal combustion engines: piston, rotary-piston power unit of the Wankel system and gas turbine. With rare exceptions, modern cars are equipped with four-stroke piston engines. The reason lies in the low price, compactness, light weight, multi-fuel capability and the ability to be installed on almost any vehicle.

The car engine itself is a mechanism that converts the thermal energy of burning fuel into mechanical energy, the operation of which is ensured by many systems, components and assemblies. Piston internal combustion engines are two-stroke and four-stroke. The easiest way to understand the operating principle of a car engine is to use the example of a four-stroke single-cylinder power unit.

A four-stroke engine is called because one working cycle consists of four piston movements (strokes) or two revolutions of the crankshaft:

Carburetor engine

A carburetor engine is a separate type of internal combustion engine (ICE) with external mixture formation . In a carburetor internal combustion engine, the combustible mixture passes through the manifold into the engine cylinders and is produced in the carburetor.

Carburetor is a structure in the power supply system of internal combustion engines, which serves to mix gasoline with air, form a combustible mixture and adjust its consumption. Today, carburetor systems are being replaced by injection systems.

The mixture is gasoline vapor mixed with air. When it passes into the engine cylinders, it mixes with exhaust gases and forms a working mixture, which at a specific moment is ignited by the ignition system. The mixture is ignited due to the fact that gasoline is supplied in gaseous form and there is a sufficient amount of air for combustion.

Carburetor engines are divided into four-stroke and two-stroke. The working cycle of a four-stroke carburetor engine consists of four strokes, they consist of four half-turns of the crankshaft; two-stroke engines consist of two half-turns of the crankshaft. Two-stroke engines are the lightest and are used in motorcycles, cultivators, chainsaws and other devices.

Engines of this type are divided into two subtypes:

General structure of the internal combustion engine

To understand the principle of operation of the motor, it is necessary to briefly imagine its structure. The main parts are:

- cylinder block (in our case there is one cylinder);

- crank mechanism, consisting of a crankshaft, connecting rods and pistons;

- cylinder head with gas distribution mechanism (GRM).

The crank mechanism ensures the conversion of the reciprocating motion of the pistons into rotation of the crankshaft. The pistons move thanks to the energy of the fuel burning in the cylinders.

The operation of this mechanism is impossible without the operation of the gas distribution mechanism, which ensures the timely opening of the intake and exhaust valves for the intake of the working mixture and the release of exhaust gases. The timing belt consists of one or more camshafts with cams, pusher valves (at least two for each cylinder), valves and return springs.

An internal combustion engine can operate only with the coordinated operation of auxiliary systems, which include:

- an ignition system responsible for igniting the combustible mixture in the cylinders;

- an intake system that provides air supply to form a working mixture;

- a fuel system that ensures a continuous supply of fuel and a mixture of fuel and air;

- a lubrication system designed to lubricate rubbing parts and remove wear products;

- an exhaust system that removes exhaust gases from the internal combustion engine cylinders and reduces their toxicity;

- cooling system necessary to maintain the optimal temperature for the operation of the power unit.

Single cylinder internal combustion engine

A single-cylinder engine is the simplest design with a single working cylinder. A single-cylinder engine is completely unbalanced and therefore runs unevenly. Engines of this type have the smallest ratio of cylinder surface area to working volume. This is an important parameter, since heat loss during engine operation is minimal, which means that the efficiency of a single-cylinder engine is the highest.

The popular terms “long block” and “short block” have nothing to do with the number of cylinders and the length of the block, since we are talking about height. Long block - complete motor without attachments

The disadvantage of the design is the high stress on the parts of the crank mechanism compared to multi-cylinder engines. They operate on a push-pull cycle, in which working strokes occur twice as often. In reality, this means that the engine operates at very high speeds, and the parts are subject to enormous loads. In addition, the ability to increase the volume of a single piston is limited by the threshold for detonation, which means that the volume can only be increased to a certain limit. Because of this quality, single-cylinder engines are not practical in heavy-duty four-wheelers. Most often they are used as a power plant for light motorcycles or mopeds. Of the four-wheeled vehicles, such engines were installed only on motorized wheelchairs for the disabled.

Motor duty cycle

As mentioned above, the cycle consists of four measures. During the first stroke, the camshaft cam pushes the intake valve, opening it, the piston begins to move from its highest position downwards. In this case, a vacuum is created in the cylinder, thanks to which the finished working mixture, or air, if the internal combustion engine is equipped with a direct fuel injection system, enters the cylinder (in this case, the fuel is mixed with air directly in the combustion chamber).

The piston communicates movement to the crankshaft through the connecting rod, turning it 180 degrees by the time it reaches its lowest position.

Read also: Four-roll rolling machine vsmo

During the second stroke - compression - the intake valve (or valves) closes, the piston reverses its direction of movement, compressing and heating the working mixture or air. At the end of the stroke, the ignition system delivers an electric discharge to the spark plug, and a spark is formed, igniting the compressed fuel-air mixture.

The principle of fuel ignition in a diesel internal combustion engine is different: at the end of the compression stroke, finely atomized diesel fuel is injected into the combustion chamber through a nozzle, where it is mixed with heated air, and the resulting mixture self-ignites. It should be noted that for this reason the compression ratio of diesel is much higher.

Meanwhile, the crankshaft turned another 180 degrees, making one full revolution.

The third stroke is called the power stroke. The gases formed during fuel combustion, expanding, push the piston to its lowest position. The piston transfers energy to the crankshaft through the connecting rod and turns it another half turn.

Upon reaching bottom dead center, the final stroke begins - release. At the beginning of this stroke, the camshaft cam pushes and opens the exhaust valve, the piston moves up and expels exhaust gases from the cylinder.

ICEs installed in modern cars have not one cylinder, but several. To ensure uniform operation of the engine at the same time, different strokes are performed in different cylinders, and every half revolution of the crankshaft, a power stroke occurs in at least one cylinder (with the exception of 2- and 3-cylinder engines). Thanks to this, it is possible to get rid of unnecessary vibrations, balancing the forces acting on the crankshaft and ensuring smooth operation of the internal combustion engine. The connecting rod journals are located on the shaft at equal angles relative to each other.

For reasons of compactness, multi-cylinder engines are made not in-line, but V-shaped or opposed (the calling card of Subaru). This saves a lot of space under the hood.

Inline three-cylinder engine

In this configuration, three cylinders are arranged in a row, the pistons rotate a common crankshaft.

The three-cylinder engine is unbalanced in both four-stroke and two-stroke versions. Its relative prevalence is explained by its ease of production. In the four-stroke version, the engine does not operate smoothly, so the use of a balancing shaft is required. Used on small displacement cars such as the Opel Corsa or Pajero Mini, often in combination with a turbo to increase power. balancing (smoothing) shaft, which rotates at the speed of the crankshaft, but in the opposite direction and compensates for the 1st order moment.

Two-stroke engines

In addition to four-stroke piston internal combustion engines, there are two-stroke ones. The principle of their operation is somewhat different from that described above. The design of such a motor is simpler. The cylinder has a window - an inlet and an outlet, located above. The piston, being at BDC, closes the inlet port, then, moving upward, closes the outlet and compresses the working mixture. When it reaches TDC, a spark forms on the spark plug and ignites the mixture. At this time, the intake window is open, and through it another dose of the fuel-air mixture enters the crank chamber.

During the second stroke, moving downward under the influence of gases, the piston opens the exhaust window, through which the exhaust gases are blown out of the cylinder with a new portion of the working mixture, which enters the cylinder through the purge channel. In this case, part of the working mixture also goes out into the exhaust window, which explains the gluttony of the two-stroke internal combustion engine. » alt=»»> This operating principle allows you to achieve more engine power with a smaller displacement, but you have to pay for it with higher fuel consumption. The advantages of such motors include more uniform operation, simple design, low weight and high power density. Disadvantages include dirtier exhaust, lack of lubrication and cooling systems, which threatens overheating and failure of the unit.

Inline four-cylinder engine

The most common engine configuration today is an in-line four-cylinder. The plane of the cylinders can be strictly vertical or at an angle, as in some Volkswagen engines.

Four-stroke L4 engines are unbalanced, but, like three-cylinder engines, they are easy to manufacture. Modern inline four-cylinder engines rarely have a displacement of more than 2.3 - 2.4 liters. The limitation is associated with an increase in the level of vibration, which is why modern large-displacement engines often use stilling shafts. Used on a huge number of cars of different brands and models.

Differences between two-stroke and four-stroke engines

Among the main differences, as already mentioned, is a different gas exchange system.

In a two-stroke engine, both the process of filling the combustion chamber and its cleaning are carried out together with the compression and expansion stroke. For this purpose, the cylinder has special technological holes for the inlet of the mixture and the release of gases. Units with this design do not have a timing mechanism, which makes these motors much simpler and lighter.

Read also: How to solder with a Chinese soldering iron

Frequent malfunctions of 4-stroke internal combustion engines

To study the features of repairing engines of this type, you need to know something about its main problems. But he has only one problem - high temperature. Since heat loss has become minimal, rubbing parts have become more vulnerable to mechanical stress, which means they need high-quality cooling. The fact is that the main liquid that comes into contact with these parts at the maximum level - oil - cannot provide proper heat removal. Therefore, two cooling systems are being developed for such a motor: air and liquid with a special thermostat system.

You can repair such an engine yourself. This requires a minimum of knowledge and a standard set of tools. If during operation there are various knocks that come from the cylinder head, then the valve mechanism needs to be adjusted. All adjustments are made with the engine removed and the valve cover removed. In addition, it is necessary to remove the special cover on the generator, under which the nut is located. By rotating this nut, we rotate the crankshaft to set the piston to top dead center. To determine this moment, it is necessary to bring the special marks on the rotor into alignment. After this, measuring probes are installed under the camshaft cams and the thermal clearances of the valves are measured. Naturally, this procedure must be performed on a cold engine, otherwise the adjustment result will not be correct.

After this, the motor must be assembled and checked. It is installed on the unit and started up. If it runs smoothly without noise, then the valve adjustment was successful.

That's all. This is how you can easily repair a single-cylinder four-stroke engine with your own hands without the help of car service specialists. This will help you save a lot on their services and give you invaluable experience.