What is compression and how is it measured?

Compression is the amount of maximum pressure created in the cylinder when the piston moves from bottom dead center (BDC) to top dead center (TDC), when the engine is idling with the starter. The concept of “compression” should not be confused with the concept of “compression ratio”, which is a calculated value and denotes the ratio of the volume of the piston space above the cylinder when the piston is at bottom dead center (BDC) (full volume of the cylinder) to the volume of the space above the cylinder when the piston is at the top. dead point (TDC), that is, to the volume of the combustion chamber. Compression testing is one of the simplest and most accessible ways to diagnose an engine. The apparent simplicity of the procedure for measuring compression has gained fame as a kind of “universal” method, capable of not only identifying a malfunction, but also generally assessing the technical condition of the engine as a whole. But this universality is deceptive - the obtained measurement results often require special analysis, and it is not always correct to draw unambiguous conclusions from them, since the pressure in the cylinder at the end of the compression stroke, when the piston is at top dead center (TDC), depends on a number of factors.

How do you check engine compression?

The most common device for these purposes, which will help determine has the compression dropped in the engines - compression gauge. This device is a pressure gauge connected by a hose to a fitting and a check valve. As the engine crankshaft rotates, air is forced into the hose until the pressure in the hose equals the maximum pressure in the cylinder. Its value will be recorded by a pressure gauge. Unlike simple domestic designs, foreign analogues are produced with sets of adapters (adapters) that allow measurements to be taken on cars of any make and model. Compressographs are also easy to use. Their purpose is the same, but the measurement results are recorded on paper or special plastic cards, which makes it possible to archive them for subsequent comparison at different periods of vehicle operation. The disadvantage of the compressor is the difficulty of assessing the dynamics of pressure increase when cranking the crankshaft.Modern motor testers quickly and efficiently measure compression. These devices actually record not the pressure, but the amplitude of the pulsation of the electric current consumed by the starter during cranking - the higher the pressure in the cylinder, the greater the expenditure of starter power to rotate the crankshaft. Thereby, if the engine compression has dropped, it is possible to simultaneously measure the compression in all cylinders in just a few revolutions, without resorting to turning out the spark plugs, which is important for multi-cylinder engines. The disadvantage of a motor tester is that the results obtained are expressed in relative units, for example, as a percentage of the cylinder that works better. Only the most expensive engine testers are capable of measuring the absolute value of compression in each cylinder, but this is only possible on the basis of a large number of statistical data for a specific engine model and their comparison with the actual pressure in the cylinder.

Compression recovery

There are several ways to restore compression in an engine, and all of them are effective when it is slightly reduced from normal, and only if there is no mechanical damage to the cylinder-piston group.

Grandfather methods

If the diagnosis reveals that the decrease in pressure is associated with the presence of rings, then you can raise it without resorting to expensive means, here are a couple.

- Quite an effective way. We take equal parts: kerosene, acetone and pure oil. Mix, pour 50 ml into the cylinders and screw in the candles. Let it sit for about ten hours. Unscrew the spark plugs and turn the engine for a few seconds. We put the spark plugs in place, start and warm up the engine to no more than 40°C. We flush the system and change the oil.

- An easier way. Pour one hundred grams of clean oil into each cylinder and periodically turn the crankshaft a little in one direction or another. Repeat if necessary.

Special means

If you don’t trust folk remedies or they didn’t help, then you can find special products on sale, both imported and domestic. They can not only de-coke the deposited rings, but also completely clean the combustion chamber, clear deposits on the operating chamfer plates of the valves, both intake and exhaust.

However, please note that some products may be difficult to use or may require advanced skills. All this is usually described in the instructions

Additives

Various additives (another name for tribocomposition) used to increase engine compression are also an effective means

It is important only to purchase products from trusted or well-known manufacturers. Of course, there are fewer fakes now, but they still exist

Various additives are used for diesel and gasoline engines.

Using additives is the easiest way; just pour them into the engine. Over time, this leads to a positive result if there are no other reasons for poor compression, such as stuck rings.

The active substances added to the additive are deposited on the rubbing surfaces, leveling them and reducing friction, and the reduced friction reduces engine noise. Compression in the cylinders is leveled out and increased, and as a result, power.

There are a lot of manufacturers of such additives, and the most famous are: Liqui Moly (CeraTec additive), Suprotec (Suprotec Active Plus composition) and others. The rating of the tested tribotechnical compounds was carried out on the Za Rulem website.

https://youtube.com/watch?v=_iFdDrfLobY

Source

What affects engine compression?

First of all, we note the position of the throttle valve: the more it is open, the more air entering the cylinder, the higher the compression and vice versa - a closed valve will reduce the pressure in the cylinder. Naturally, the amount of air entering the cylinder is also affected by the degree of contamination of the air filter. Compression is also affected by irregular valve timing , for example, during installation or as a result of jumping of the camshaft drive belt or chain. This leads to a change in the closing moment of the intake valve, shifting the beginning of compression in the cylinder to one side or another. Then the compression values will be different. The clearances in the valve drive (in the absence of hydraulic compensators or when they are faulty) have a rather strong effect on compression.

So a small gap in the intake valve drive will lead to their closing later and, accordingly, to a decrease in compression. At the same time, small clearances in the exhaust valves will increase the so-called valve overlap - the amount of crankshaft rotation angle during which both valves in the cylinder are open simultaneously. The result is the same - compression will decrease. The engine temperature will also affect compression - the lower it is, the more the air compressed in the cylinder will be cooled, and the lower its pressure will be. The engine temperature affects the thermal clearances in the valve actuator, which in turn affects the measurement results. But that's not all. Malfunctions of fuel equipment; oil entering the combustion chamber through valve guides, piston rings, crankcase ventilation system and turbocharger seals; The degree of charge of the battery and a malfunction of the starter can affect the amount of compression. As is clear from the above, if your engine has lost compression in one cylinder, two cylinders or 4 cylinders, there may be several reasons.

| How to diagnose the engine yourself, read our article: “Do-it-yourself car engine diagnostics” “...It is impossible to insure for all eventualities, but it is possible to reduce the likelihood of such a problem, for example, with an engine. To do this, you need to learn how to assess the technical condition of the engine or diagnose it. This is especially true after winter cold and sudden changes in the temperature of the surrounding atmosphere. Diagnosing a car engine with our own hands will help us understand what kind of repair work we may encounter in the warm season..." Go to article... |

Compression concept

Translated into Russian, compression means “compression”. If there are no mixture leaks, then the engine operates at full power. Thus, compression is the pressure in the combustion chamber that occurs at the highest point of the compression stroke. Compression can be measured in pascals, kilograms per centimeter, but the generally accepted unit of measurement is atmospheres.

Pressure readings on the pressure gauge

The optimal pressure in the cylinders is determined by the technical characteristics declared by the manufacturer. If the engine is running at full speed, then when the piston moves down, the required amount of air enters the cylinders, then the piston begins to move up, and fuel is injected into the chamber. When a spark occurs, the mixture detonates and should burn without residue. In this case, exhaust gases are released, the amount of which should be minimal.

Checking compression is the most practical way to determine the condition of the mechanical parts of the engine without the need to disassemble it. These diagnostics will help you identify problems that are negatively impacting engine performance. Once you get accurate results, it will be easier to make an informed decision about what to do next.

How to check engine compression correctly?

If we take into account all the factors listed above, then when measuring compression the following simple rules must be followed:

- the engine must be “warm” “warm up”;

- the fuel supply must be turned off (you can turn off the fuel pump, injectors, or use other methods to prevent fuel from entering the cylinders);

- on gasoline engines, it is necessary to remove all spark plugs (selective removal of spark plugs is unacceptable, as it increases the rotational resistance and arbitrarily reduces the speed when the engine is cranked with the starter);

- The battery must be fully charged and the starter is working properly.

Compression is measured with both the throttle valve open and closed. Moreover, each method gives its own results and allows you to identify its own defects. So, when the damper is closed, little air will enter the cylinders, the compression will be low and will be about 0.6-0.8 MPa. Air leaks in this case are comparable to its entry into the cylinder. As a result, compression becomes especially sensitive to leaks - even with small leaks, its value drops several times. This measurement allows us to draw conclusions or assumptions about the following engine defects:

- about unsatisfactory fit of the valve to the seat;

- about valve freezing, for example, due to improper assembly of the mechanism with hydraulic pushers;

- about defects in the camshaft cam profile in designs with hydraulic lifters, including uneven wear or runout of the back side of the cam

- about a lack of tightness caused by a burnout of the head gasket or a crack in the wall of the combustion chamber (these defects are accompanied by white smoke, the formation of an emulsion in the oil, and increased pressure in the cooling system)

When measuring compression with the throttle open, the picture will be different. A large amount of incoming air and an increase in pressure in the cylinder contribute to an increase in leaks. But the compression does not drop so significantly (to approximately 0.8 - 0.9 MPa). Therefore, the measurement method with an open throttle is better suited for determining more “severe” engine defects, such as;

- breakdowns and burnouts of pistons:

- breakage or freezing (coking) of rings in the piston grooves;

- deformations or burnouts of valves:

- serious damage (scoring) to the cylinder surface:

In both measurement methods, it is advisable to take into account the dynamics of pressure growth - this will help to establish the true reason why the compression in the engine has dropped with greater probability. So, if at the first compression stroke the pressure measured by a compression meter is low (0.3-0.4 MPa), and during subsequent strokes it increases sharply, this indirectly indicates wear of the piston rings. In this case, pouring a small amount of oil into the cylinder (3 - 5 cc) will immediately increase the pressure on the first stroke and the compression in general. On the other hand, when on the first stroke the pressure reaches 0.7-0.9 MPa, and on subsequent strokes it almost does not increase, most likely there is a leak in the valve or head gasket. To more accurately establish the cause, it is necessary to use other diagnostic tools or indirect signs.

What additives are best to pour into a diesel engine?

If you have a car with a diesel engine, its compression may decrease over time, the car begins to operate noisily and smokes. What additives are best for a diesel engine? Let's figure it out.

- AS-627.

The Russian manufacturer ASTROhim has developed the most budget-friendly additive for AC-627 engines. It can be added to oil; it is suitable for use on diesel and gasoline power units.The additive shows itself best in engines with high mileage. The composition reduces gaps that appear as a result of severe wear of engine elements. This allows you to seal the pistons in the cylinders on a diesel car.

Thanks to the use of the additive, compression is improved, not only on passenger cars, but also on trucks, special, construction and agricultural equipment. The additive can be used with all types of oils; during operation, the composition helps maintain the best balance of the lubricant.

Russian car enthusiasts claim that, despite the low cost, the AC-627 additive improves car compression, the diesel engine starts easily, and its power increases.

- RESURS diesel.

Among the best additives for restoring engines that run on diesel fuel is the domestic remetallizing additive RESURS diesel.Just add it to the oil when you change it and the oil filter. The additive is not afraid of the effects of centrifuges and turbines, and eliminates dry friction when starting a cold engine, as well as under increased loads.

The manufacturer of the additive claims that with its help you can extend the service life of the engine up to 20,000 km, and the turbocharger by 1 year. What other benefits do you get from using a remetallizant additive? Oil waste is reduced by 5 times, the car consumes 10% less diesel fuel, and compression increases by 40%. The additive can be used when the car's mileage is more than 60,000 kilometers.

RESURS diesel has gained great popularity among car owners. They note that engine power increases, noise decreases, and engine starting is easy.

- Suprotec – tribotechnical composition “Active diesel”.

"Suprotec Active Diesel" consists of fine mineral powders with a unique composition, the fractionation of which is selected in a certain way. Thanks to this, a layer is formed on the inner surface of the motor that prevents friction and wear.Compared to other oil additives, which improve gliding but must always be added to the lubricant, the tribotechnical composition "Suprotec Active Diesel" is poured once or regularly, but for a long time.

This additive acts comprehensively: carbon deposits are removed from the surfaces of the engine, as a result it works better and wear is reduced. After this, a protective nanofilm with a reduced coefficient of friction appears, at the same time micro-scratches on the surface of the motor are smoothed out.

Which additive is better for an engine if it is quite worn out, but there is no excessive oil consumption, there is no increased pressure of crankcase gases and the compression is 8 kg/cm2? In these cases, the tribotechnical composition “Suprotec Active Diesel” is ideal. .

After using the additive, the engine will work better. Many car owners note that the car begins to consume less fuel, noise decreases, and engine life increases. The car accelerates quickly. However, if the power unit is “killed,” the tribotechnical composition “Suprotec Active Diesel” will not help, but the manufacturer indicates this on the packaging.

- Bardahl Full Metal.

Thanks to the cutting-edge developments contained in the Bardahl Full Metal additive, produced in Belgium, it is possible to improve the performance of even the most worn-out diesel engine.Bardahl's patented Polar Plus technology improves oil film adhesion. The car can stand in the cold for a day, but the lubricant will remain on the surface of the motor, making the gaps in the piston group smaller. Due to the oil film, friction in highly loaded components (crankshaft, camshaft) will decrease.

Which engine additive is best to reduce diesel fuel and oil consumption? Without a doubt, this is Bardahl Full Metal. With its help, the concentration of soot and burning in the exhaust gases will decrease, and the car will stop smoking. The additive does not contain solid particles, which means that the oil filter, as well as the internal cavities of the engine, will not become clogged.

Many car owners note that the use of Bardahl Full Metal makes it easier to start the engine and increases power. A diesel car will stop smoking. The only disadvantage of the additive is its cost.

How to use measurement results in practice?

The basic rule to remember: in most cases, the results of compression measurements are relative. This means that, first of all, it is necessary to rely on the difference in compression values of different cylinders, and not on its absolute value itself. Here are just two examples that confirm the validity of this statement. A relatively new engine cannot be started. The compression in the engine has dropped. Compression in the cylinders is 0.5 - 0.6 MPa (5 - 6 kg/cm2), which is approximately half the norm. The reasons may be mechanical failure or wear of parts of the cylinder-piston group. But the same drop in compression can be observed due to a malfunction of the fuel supply system. Excess fuel enters the cylinders, it washes away the oil from the cylinder walls, and the piston rings no longer properly seal the combustion chamber cavity. Another case: in an old engine the compression is 1.1 - 1.2 MPa. Norm! However, the engine consumes more than 1 liter of oil per 1000 km. This is understandable if you take into account the wear of rings, pistons and cylinders. What's the matter? The answer is simple, a large amount of oil penetrating into the combustion chamber seals the gaps in wear areas. As we can see, the measurement results should be treated with caution. And, in order not to make mistakes in your conclusions during repairs, you should know in which cases you can confidently rely on the measurement results, and when you can only take note. Table 1 contains a list of faults and data from some compression measurements, if any. Of course, this data does not have specific meanings, but will only make it somewhat easier to determine the direction of troubleshooting. Table 1. Some defects and malfunctions of gasoline engines identified by compression measurements

| Malfunction | Symptoms of a problem | Compression, MPa | |

| open damper | closed damper | ||

| Fully working engine | None | 1,0-1,2 | 0,6-0,8 |

| Crack in the piston bridge | Blue exhaust smoke, high crankcase pressure | 0,6-0,8 | 0,3-0,4 |

| Piston burnout | The same, the cylinder does not work at low speeds | 0,5-0,5 | 0-0,1 |

| Occurrence of rings in piston grooves | Same | 0,2-0,4 | 0-0,2 |

| Piston and cylinder scuffing | The same, unstable operation of the cylinder at idle is possible | 0,2-0,8 | 0,1-0,5 |

| Valve deformation | The cylinder does not work at low speeds | 0,3-0,7 | 0-0,2 |

| Valve burnout | Same | 0,1-0,4 | 0 |

| Defective camshaft cam profile (for designs with hydraulic tappets). | Same | 0,7-0,8 | 0,1-0,3 |

| Increased carbon deposits in the combustion chamber in combination with worn valve stem seals and rings | Increased oil consumption with blue exhaust smoke | 1,2-1,5 | 0,9-1,2 |

| Increased wear of the cylinder-piston group | Increased fuel and oil consumption due to waste | 0,2-0,4 | 0,6-0,8 |

What additives are best to pour into a gasoline engine?

What is the main difference between a power unit that runs on gasoline? The temperature in the combustion chambers is as high as possible. This means that additives must be heat-resistant, as well as the coatings and films they create on the surface.

- Suprotec – tribotechnical composition “Active gasoline”.

If you don’t know which engine oil additives are best, pay attention to the Russian-made restoring additive that will protect the engine from wear - “SUPROTEK” (Active tribological composition for gasoline engines).

Suitable for adding to oil if your car's mileage is no more than 50 thousand km. Moreover, the composition can be used both in naturally aspirated engines and in engines with turbines and forced power plants.SUPROTEC Active gasoline does not change the properties of the oil, but creates new films that reduce friction. Thanks to the structure of the film, worn parts are restored, and the gaps between rubbing surfaces are reduced. With this additive, the engine will last longer, even if it is under maximum load.

Car owners have noticed that the SUPROTEC Active gasoline composition makes it easier to start a cold engine. If you don’t know which engine additive is best, if the engine “eats” oil or fuel, then use this additive.

- Hi-Gear SMT2.

What is the best engine additive if the engine is quite old? Hi-Gear SMT2 will help.The mixture is poured into oil, resulting in reduced friction between surfaces. This is necessary if the pistons and connecting rods are worn out and significant gaps have appeared.

Due to the SMT2 conditioner, which is included in the additive, the dynamic load on the main engine elements is reduced and its service life is increased.

Note!

Conducted studies confirm that with the use of such an additive, the engine will last 2–2.5 times longer, and expensive repairs can be postponed.

Reviews from car owners about Hi-Gear SMT2 are mixed. Some confirm that the engine lasts longer, starts easily, and consumes less gasoline. However, other car owners note that the positive effect of using the additive does not last long.

- Liqui Moly CERATEC.

If you are looking for which engine additives are best, reviews favor German-made Liqui Moly CERATEC. The composition is made on the basis of a molybdenum-organic complex with ceramic microparticles.Constant use of the additive will increase the wear resistance of metal engine elements. Anti-friction properties are ensured by smoothing out microscuffs in the motor, which means sliding improves.

Liqui Moly CERATEC is effective for 50,000 kilometers. As soon as you add the additive to the oil, its consumption will decrease, the car will consume less fuel, and the engine will start to run quietly.

Russian car owners are confident: Liqui Moly CERATEC makes engine operation economical, its service life is extended, and the additive lasts quite a long time. The only disadvantage of the composition is its cost.

The compression in the engine has dropped - will SUPROTEC compounds increase the compression in my engine?

So, we know what compression is, how to measure it correctly and how it can be measured, we know the factors influencing the measurement results, and now we can talk about the possibility of partial or complete restoration of compression using the SUPROTEC lubricant composition.

The SUPROTEC lubricant composition is not an additive or additive to the lubricant, since it does not improve its characteristics, but interacts directly with the metal surfaces of the contact zones (friction surfaces) of parts of components and mechanisms.

SUPROTEC compositions help the “friction couple” system (for example, piston ring - liner, shaft journal - bearing liner, etc.) reach a new qualitative level of energy balance (more optimal contact conditions for friction parts), they act as a catalyst and initiate process of adaptation of the friction pair system. SUPROTEC compositions have the effect of restoring friction surfaces (forming a protective layer up to 15 microns thick) and the effect of optimizing the geometry of friction surfaces. In addition, the created metal structures (protective layers) have increased oil-retaining ability - the protective layer holds oil on the surface much stronger than a normal surface, which shifts the friction mode to the region of semi-fluid or hydrodynamic friction (the work of an “oil wedge”).

Engine oil additive "Suprotek Active Plus"

Restores compression, reduces fuel consumption and oil waste, reduces wear rate and extends the life of internal combustion engines of any type. Facilitates cold starts and protects against overheating in traffic jams.

more reviews

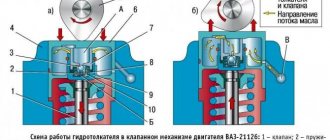

Figure 1 shows all the parts and mechanisms of the engine that are directly related to the amount of compression; all of them are, to one degree or another, subject to friction processes, and accordingly, SUPROTEC compositions can have an effect on them (only the cylinder liner is not shown).

Rice. 1

Friction parts of such units as the cylinder-piston group, crank mechanism, gas distribution mechanism primarily determine the condition and service life of the engine, and, in addition, are the most expensive spare parts.

During normal operation of the engine, SUPROTEC compositions form a new structure layer by layer on the “base metal”, which is based on a crystal lattice of iron.

But this happens only in zones of direct contact of rubbing surfaces, and the load and temperatures in the contact zone must be significant.

Rules for choosing engine additives

Manufacturers of various additives are confident that the product they sell can increase the service life of the engine.

However, the opinion of Russian car owners about the properties of additives is divided. Some believe that the additive saved them from major engine repairs. Others are sure that this is a waste of money. Obviously, even the best engine additive will not help if the engine is completely worn out.

The use of the additive is preventive in nature and allows you to eliminate minor breakdowns in the engine.

The additives produced today are highly specialized. Information about what exactly they are intended for is contained on the packaging. But rarely does anyone read the instructions from the manufacturer; usually the car owner simply fills in the additive, but what he gets is not at all what he expected. Which engine additive is best? To answer this question, you need to consider the following points:

- Decide what you need the additive for . If an engine consumes too much oil, it does not need a compression additive. Better choose sealants.

- The additive will help if the car is noisy and smokes . The main thing is to choose an additive that is suitable for your engine. What is important here is both the type of engine - gasoline or diesel - and the oil - mineral, semi-synthetic, synthetic.

- What additives are best for engine restoration if the car service center told you that the engine is “killed” ? This is where a remetallizant additive can help. It contains metal microparticles that protect the engine surface from the inside. Thanks to this additive, the gaps will become smaller, the car will start easily, and traction will appear. However, such an additive will not last long: several tens of thousands of kilometers.

To find out which engine oil additives are best, read the review below. The top best additives include only those additives that have gained popularity among Russian car enthusiasts.

A little theory

Most novice car enthusiasts and many more experienced car owners do not always clearly understand what compression is and what it affects during engine operation. So, let's conduct a small educational program for beginners.

Basically, the indicator greatly affects the start of the internal combustion engine, especially at low temperatures, as well as the stability of its operation. And, of course, this is most critical for diesel engines, where fuel ignition occurs precisely due to sudden compression, and not from an electric spark in the combustion chamber.

In addition, with low compression, the pressure of crankcase gases increases. Because of this, the amount of oil vapor that enters the intake increases. As a result, the combustion chamber becomes more and more dirty, the toxicity indicator increases, high oil consumption, etc.

Pros and cons of different types of additives

| Additive type | pros | Minuses |

| Remetallizants | compression is restored; gasoline consumption is reduced; a protective layer is formed on the parts; relative cheapness. | the strength of the protective layer is much lower than the strength of the parts; The additive must be re-added at every oil change. |

| Teflon-containing | reduction of friction of working surfaces. | high price; poor durability of the coating; the protective layer is afraid of high temperatures; increases the concentration of phosgene in exhaust gases; Long-term use may cause a layer of carbon deposits to form on the piston rings. |

| Conditioning additives | significant reduction in friction; formation of a protective layer on the surfaces of parts. | high degree of toxicity; The paraffin-containing protective coating is resistant to high temperatures. |

| Layered modifiers | dramatically reduce friction. | a constant high concentration of the substance in the oil is necessary, otherwise the effect disappears; sulfur compounds enhance the corrosive properties of exhaust gases; graphite particles settle on the valves, impairing their performance. |

| Additives-geomodifiers | are close in composition to metals, forming a durable protective layer on their surface; reduce oxidation and extend the life of the oil; significantly reduce friction; are not afraid of high temperatures. | The engine must have aluminum liners made using Nikosil technology. |

Of course, any additives will not cancel major repairs. Their effectiveness is not limitless. However, selecting them correctly and starting to use them immediately after purchasing a car will significantly delay expensive repair work and extend the overall service life of the car.