Household oil radiators [ edit | edit code ]

An oil-filled radiator is a mobile heating battery. Device: inside a sealed housing there is an electric coil, the housing is filled with mineral oil. The surface temperature of the oil heater does not exceed 150 °C. Heat is transferred from the coil to the oil, then from the oil to the body, and from the body to the air. Devices of this type are reliable, durable, silent, capable of retaining heat for a long time after a power outage, and are also considered very safe. The main advantages of oil radiators are low price, mobility and low noise level. The disadvantages of a traditional oil-filled heater include a long warm-up time (10-20 minutes).

Modern oil heaters have the following set of functions:

- Several operating modes.

- Climate control function

- On/off timer, the radiator will heat the room by a certain time.

- Overheat protection function.

- Self-twisting wire.

- Remote control for oil heater.

- Hanger for drying things.

Convection radiators [edit | edit code ]

Many radiators, in addition to dissipating part of the heat by radiation, remove the other part of the heat by natural or forced (fan) convection and are a combination of a radiator and a convector. Convection heaters are heating radiators with fins hung on their pipes. Convection heaters heat up a room quickly. Such heaters are often installed in industrial premises: garages, workshops, warehouses. Modern convection heaters are made of copper and aluminum. The coolant comes into contact only with copper, and heat-conducting plates and the body are made of aluminum.

Convection heaters create the effect of an air heat fan and mix the layers of air in the room well, but this can also be a negative factor, since drafts are created in the room, dust does not settle, being constantly in the air.

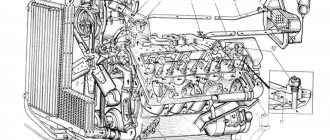

Engine radiators [edit | edit code ]

In an internal combustion engine, the radiator is a heat exchanger that combines two circuits of the cooling system. Tubular-plate and tubular-tape radiator grilles are mainly used. In the radiator, suture or seamless tubes made of brass tape up to 0.15 mm thick are used for the passage of coolant. Aluminum radiators are also used: they are cheaper and lighter, but the heat transfer properties, all other things being equal (dimensions, heat transfer area, etc.), and reliability are lower.

On diesel locomotives, a similar device is called a “refrigerator”.

An automobile radiator, the device of which includes two tanks - upper and lower, as well as tubes between them, performs the most important function and is responsible for preventing engine overheating. How this happens, and what types of this unit we can find in our cars, we’ll talk a little lower.

Radiator design

All types of radiators have a similar design, including the following elements:

- Core (lattice). It consists of metal plates pierced with hollow tubes connecting the radiator barrels.

- Upper and lower tanks. Like tubes, they are made of light alloy materials - copper, aluminum or brass.

- Inlet and outlet pipes. The inlet pipe supplies hot coolant (coolant), the radiator reduces its temperature, and the outlet pipe closes the system through a thermostat. A tee is installed at the inlet to connect an expansion tank, which compensates for changes in the volume of liquid due to fluctuations in thermal conditions.

- Neck with lid, with installed vacuum valve.

- Temperature sensor. How the control device informs about the coolant temperature, and when the operating parameters increase, allows you to start forced cooling.

- Mounting brackets.

Important! Some models are equipped with a coolant drain tap, as well as a statically fixed protective casing and a fan with an electric or forced drive.

Car copper radiator or aluminum?

The radiator heats the air in heating, air conditioning and ventilation systems. In the recirculation system, it cools exhaust gases, oil that is in the lubrication system, air from the turbocharging system and working fluid in the case of an automatic transmission. There are several types of cooling systems: liquid, air and combined. In the first case, cooling occurs due to the flow of liquid, in the second - through air, and in the third, accordingly, the air and liquid systems are combined.

The most common material from which the core of modern radiators is made is aluminum . This is justified by the fact that automotive aluminum cooling radiators are very light, and their cost is significantly lower than copper ones. However, they have very low thermal conductivity and are susceptible to corrosion. An automobile copper radiator has more advantages, including: corrosion resistance, high efficiency, and excellent thermal conductivity. It is also more durable and, accordingly, durable. But the main disadvantage is the high cost.

Until recently, radiators made of steel were in demand, but due to its low thermal conductivity, which is four times less than that of aluminum, these options are almost never found today.

What types of radiators are there?

Cooling and heating radiators can be divided into two groups, the first is the copper-brass group, and the second is the aluminum-plastic group. The division is, of course, very arbitrary, since there are quite a lot of variations, such as plastic + copper or copper + aluminum + plastic. For example, there are no exclusively copper radiators; brass, copper and sometimes steel are always present. Not every car enthusiast knows that radiators on the VAZ “classic” have a honeycomb core consisting of brass tubes and steel heat sinks, and only export versions of the “classic” radiators had copper heat sinks for use in hot countries.

In turn, aluminum radiators are divided into two additional groups: all-brazed ones, in which the entire structure (tanks + honeycomb core) or only the core (honeycombs) are fused together, while stacked radiators are made without the use of welding, exclusively mechanically, using the flaring method.

Since copper and brass have much more efficient heat transfer than aluminum, such radiators are preferable, especially since there is always the possibility of repairs in areas remote from large cities (for example, a collective farm or urban settlement). The price for the high efficiency of the almost precious metal is the price of the final product, which is more than twice as high as its aluminum counterpart. Recently, many manufacturers have switched to using aluminum radiators in their cars (it is cheaper), but some, for example Japanese manufacturers, remain true to the traditions of quality and to this day produce copper heater radiators and copper cooling radiators. Where high radiator efficiency is required, which by the way is expressed in Kilowatts, manufacturers try to use only copper radiators, for example, MAN, SCANIA, DAFF trucks or our KRAZ trucks, etc.

Recently, combinations of tinned steel barrels and copper radiators have also been gaining momentum, which cannot be compared in terms of durability with brass ones, and who exactly do you think is “sinning”? That's right, a domestic manufacturer. But if this is honestly stated on the manufacturer’s websites, then at the market, when buying a new radiator, you will not understand what’s what.

Aluminum radiators find their use in cars and trucks, but due to the fact that they are made of poorly soldered materials, they have not received widespread and professional service. With rare exceptions, there are specialists who have developed their own technologies for repairing aluminum parts of honeycombs and plastic barrels, but again, repair technologies differ from master to master in both technique and quality. Argon welding of a honeycomb part is ineffective, since the thickness of the honeycomb rarely exceeds a quarter of a millimeter, so the main type of such repairs is soldering with a torch and working with special adhesives.

It is difficult to say which radiator is better, since both have their own advantages and disadvantages. For example, copper radiators and stoves are more efficient, while aluminum products are cheaper and lighter (if the weight of the machine is critical). In addition, you should not assume that all aluminum radiators have low efficiency; on the contrary, Japanese models (it’s hard to say how they achieve this) are twice as thin and smaller in area than the copper counterpart produced in the CIS, but twice as efficient. If we talk about Chinese and domestic manufacturers, then Chinese aluminum radiators generally do not stand up to any criticism, and domestic samples do not shine with the quality of materials and efficiency.

The service life of radiators strongly depends on such factors as the environment in which the car is used (aluminum radiators do not last long near the ocean and sea, just as salt from the road is not good for them), the quality of the coolant used, the general running of the car and many others . But in general, copper radiators last somewhat longer than their aluminum-plastic brothers, since they do not contain plastic and rubber parts that dry out and crack over time.

Car radiator - design of the heat transfer system

As for their design, they are divided into the following types: tube and soldered. Options with round tubes are a unit assembled from panels with round aluminum tubes strung on them. Their main advantage is an acceptable pricing policy due to low cost. The disadvantages include low strength, small heat transfer surface and the need for high-quality gaskets, which are not always available.

Radiators with oval tubes, which are in the middle price category, are slightly better in operation. This is possible due to the oval cut, which increases the area that gives off heat. Disadvantages: low strength, need for high quality gaskets. Soldered radiators, which are distinguished by higher strength and heat transfer, also have a cost that not everyone can afford. Thus, it is not so important which car radiator, aluminum or copper, you choose, the main thing is the right combination of device and radiator material.

The radiator is one of the key and most important elements of a liquid cooling system. The main task is to dissipate into the atmosphere the heat that was removed from the engine by the coolant. The radiator of the engine cooling system can be considered the most important part of the power unit itself.

Devices similar to a modern radiator were installed on the earliest versions of cars with internal combustion engines, since without the specified cooling element, the operation of the power plant becomes simply impossible. This device is directly responsible for maintaining the normal operating temperature of the engine within strictly specified limits. Such protection protects the motor from overheating, which will inevitably damage almost any internal combustion engine.

Read in this article

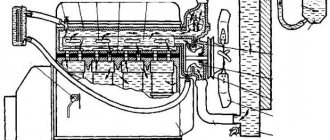

Cooling radiators: design features and operating principle

The radiator uses air flow to reduce the coolant temperature. Thanks to a special pump, the coolant circulates in a circle, washing the heated walls and cylinder heads. This allows heat to be removed from heated engine parts, and therefore ensures safe and uninterrupted operation. The radiator, as a rule, consists of the following elements: lower and upper (or side) tanks, core, fasteners. The core consists of transverse plates through which vertical tubes pass. Such a device allows you to increase the area of contact of the coolant with the walls of the tubes, thereby increasing the intensity of the reduction in the temperature of the working fluid. This type of radiator is called plate-type and is most often found on the new radiator market.

The materials used to make devices must have high thermal conductivity. Brass has traditionally been used for the manufacture of structural elements, but recently the combination of plastic and aluminum has become more popular. Aluminum has many advantages. Firstly, the use of aluminum reduces the cost of the part production process and reduces its final cost. Secondly, aluminum is much lighter, and accordingly, an aluminum radiator is 2-3 times lighter than its brass or copper counterpart. Thirdly, aluminum radiators are more environmentally friendly because they do not contain lead (lead solder), which is an environmental pollutant. In the end, aluminum radiators are more durable than copper and brass ones under the same operating conditions: the service life of an aluminum radiator is on average 10 years, a copper or brass radiator will last you about 6-8 years. Currently, most manufacturers have already abandoned the production of copper and brass radiators in favor of aluminum ones.

The history of the radiator

The water cooling system appeared at the dawn of engine building. The radiator concept was first used on the first production car, the Benz Velo, which went on sale in 1886. This idea for the device was continued to be developed by Wilhelm Maybach, who designed a product with honeycombs. The development has found application in the design of the Mercedes 35HP model. Over the subsequent decades and to this day, the radiator design has not undergone any major changes, remaining practically in the same form as in the days of Maybach.

Thanks to this effect, coolant entered the radiator. The thermosyphon effect is based on the fact that the density of water decreases when heated. Thanks to this property, heated water rushes upward. As a result, the heated liquid ended up in the device, penetrating there through passage through the upper pipe.

The water cooled inside the radiator, and the density of the liquid increased again. This led to water sinking into the lower part of the radiator, and from there it penetrated back into the engine jacket through the lower pipe. The main disadvantage of systems with a thermosyphon effect was that they could not provide proper cooling against the backdrop of the ever-increasing power of the internal combustion engine. Such systems quickly replaced solutions that were based on the use of a centrifugal water pump (pump).

Radiator in a liquid cooling system

The main task of the element is to remove heat from the power plant into the atmosphere by cooling the liquid that passes inside through the channels. To ensure better heat dissipation, the device is mounted in a place where there is the best airflow with oncoming air flow while the car is moving. A typical installation location in the engine compartment is the area behind the radiator grille at the front of the vehicle. It is worth noting that even in cars with a rear-engine engine, the radiator is often installed at the front. The difference is the laying of longer cooling system lines to the engine.

There are other places to mount a cooling device, but they are less common. Cars with a rear-engine layout may have a radiator that is mounted along the side wall. This solution can be found on sports cars that have two cooling radiators located along both walls of the engine compartment. Effective airflow is achieved through the use of air intakes. This air intake is located at the rear of the machine on the side walls.

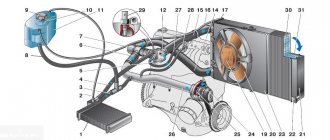

Radiator design

a – device; b – steam valve is open; c – the air valve is open.

- The radiator has an upper (1) and lower (7) tank. These tanks are connected to each other by tubes (5) made of brass or aluminum. Plates (6) are attached to these tubes by soldering, which increase the surface cooling area of the element. Through this surface, heat is removed from the coolant and released into the environment.

- The upper tank has a filler neck for refilling with coolant. The neck is closed with a plug (3). This plug has steam (11) and air (12) valves.

- The upper tank also has a pipe (2) to connect the radiator to the engine cooling jacket. This connection is made using a rubber hose. Additionally, there is a steam pipe (4), as well as an electric thermometer sensor (13).

- The lower tank (7) has a pipe (8) for connecting the device to the pump (pump). There is also an additional tap that can drain the coolant. The radiator is secured to the car frame with special fasteners (9).

Adjusting the coolant temperature

The thermostat is responsible for maintaining a constant temperature in the engine cooling system. This element distributes the movement of coolant along the circuits. These contours are called the small and large circle. The engine jacket can be considered a small circle, the flow movement through the radiator is a large circle. A situation arises when cooling by outside air when the coolant moves in a large circle in hot weather or under load is not enough. To ensure efficient removal of heated air and maintain a constant coolant temperature, one or a number of fans are additionally installed. Such fans can have a mechanical drive (viscous coupling) or an electric drive.

Regulation of thermal conditions with a “curtain”

The liquid cooling system of an internal combustion engine can be equipped with double thermal control. The first regulator is the thermostat, which we have already discussed. The second thermoregulating element is the curtain-blind.

Devices with double regulation have blinds installed directly in front of the radiator. Thanks to this solution, in severe frosts the radiator can be covered, reducing the intensity of the outside air blowing. Heat removal will be reduced, and the heat itself can be used more efficiently to maintain the operating temperature of the internal combustion engine and intensive heating of the vehicle interior.

Blinds are metal plates that are connected to each other by hinges. These curtains can be positioned vertically or horizontally in front of the device. This solution is controlled by a handle from inside the car, and can also be implemented automatically in separate designs. The principle of operation of the mechanical device is that by pushing or pulling the handle in the cabin, the driver rotates the plates. The gap between the blinds changes and the intensity of air flow to the radiator is adjusted. The result is an effect on the coolant temperature.

Main symptoms of malfunctions

The following signs are a reason to worry about the health of the radiator and make a decision about its urgent repair:

- Coolant leakage. It is determined by a correctly carried out external inspection of the car parking area, as well as monitoring the coolant level. If the unit leaks or the tightness of the connections is broken, characteristic antifreeze stains remain in the parking area.

- The engine temperature does not decrease. This can be judged by the frequent turning on of the fan and the hot inlet and outlet pipes.

- The temperature of the internal combustion engine is increased, but the cooling unit does not even warm up. The reason is clogged radiator tubes. They can become clogged as a result of mixing incompatible types of antifreeze and running water with salts or oil penetration.

Important! If there is any malfunction of the cooling system of the internal combustion engine, it is not recommended to use the car, but repairs are necessary. Elimination of minor leaks can be done with your own hands, but it is not recommended to do it yourself if it involves structural intervention without professional training and special tools.

Principle of operation

For proper functioning, modern liquid cooling systems take into account many important parameters during operation. Special sensors take readings of engine temperature, coolant and engine oil temperatures, outside temperature, etc.

If we briefly describe the principle of operation of the cooling system, then the liquid pump should be taken as the starting point. This element causes the coolant to constantly move and circulate in a circle. In this case, the passage through the engine cooling jacket (small circle) allows the liquid to wash the hot walls of the cylinder head and cylinders. When the temperature of the coolant rises, then at certain indicators the thermostat is triggered and allows the liquid to enter the large circle (radiator). This way, it is possible to avoid engine overheating and effectively transfer excess heat from heated engine parts to the fluid. When hot liquid enters the cooling device, heat is removed from it into the surrounding atmosphere. The full cycle ends, and the cooled liquid moves similarly through the new cycle.

Selection of engine cooling radiator by size

The radiator of the cooling system belongs to the category of spare parts that does not require replacement “according to the list” - it is enough to install the radiator once, and then replace it in case of failure.

Without going into details, let's look at the operation of the cooling system. And it works like this: the coolant takes heat from the heated engine, is sent through pipes to the radiator by pumps, cools there and is sent back to the engine. The system itself is well thought out; oil, fuel mixtures and coolant never mix in it. The speed of fluid flow is adjusted automatically: the faster the engine crankshaft moves, the more actively the pump drives fluid through the tubes. It is enough for a car enthusiast to monitor the level of coolant and the absence of mechanical damage to parts. In words everything is simple, but in reality it is not.

The fact is that the operating temperature in a car’s cooling system can reach 120 degrees, and the pressure can reach 2 kg/cm². The parameters change quite quickly, i.e. there is no talk of their smooth change. In this case, the liquid does not boil due to high pressure. If boiling of the coolant is detected, we can also talk about depressurization. The cooling system is capricious, but it also works in very harsh conditions.

Diagnosis and repair of radiator faults with your own hands

The main diagnostic procedure is periodic monitoring of the engine cooling system for leaks and a decrease in the volume of coolant in the expansion tank. You can control the amount of liquid visually. Since the liquid is constantly heated and cooled, over time the water included in any coolant partially evaporates, which leads to a general decrease in volume.

If we talk about radiator malfunctions, then the main one is contamination of its cells and channels, as well as their destruction. Contamination leads to the fact that the circulation of liquid inside the device worsens; when moving in a large circle, the coolant does not have time to cool down. In such conditions, the fan power ceases to be enough, so overheating of the engine is inevitable.

When repairing an engine cooling radiator with contaminated honeycombs, it is worth starting with the usual washing of the core with running water. It is necessary to disconnect the lower pipe, and then begin to pour water through the neck. It is highly advisable to flush the honeycombs of the cooling device with water under pressure. In some cases, when the radiator is heavily clogged, it can be unsoldered and the upper and lower tanks can be dismantled. After dismantling, it becomes possible to clean the core mechanically.

During operation, the upper or lower tank, as well as the honeycombs themselves, begin to leak. This occurs due to the use of low-grade coolants, mechanical damage, etc. If the leakage is insignificant, then you can try to fill or fill the radiator with a solution from a car dealership specially designed to temporarily eliminate such defects. The “old-fashioned” methods include adding a large portion of mustard powder, which soaks and tightens the crack. Both the first and second methods do not completely repair the device, but only allow you to eliminate the leak while traveling to the service station and bringing the car in for repair.

As for the expansion tank, the cap on it must be unscrewed with the same caution when the engine is warm. Twist the plug slightly, but not all the way. You will hear a characteristic sound of air escaping, similar to the sound that occurs when you open the cap on a bottle of sparkling water. After such bleeding, the reservoir cap can be gradually opened completely and the coolant can be checked or topped up.

Do-it-yourself flushing of the engine cooling system radiator. How and what is the best way to flush the radiator from the inside without removing it from the car. Recommendations.

Basic malfunctions of a car radiator of the engine cooling system. Soldering a brass radiator, do-it-yourself repair of an aluminum radiator.

Rust in the engine cooling system and engine: what to do and how to remove contaminants. Affordable methods for cleaning the cooling system with your own hands.

The principle of operation of sealant for the engine cooling system. When to use sealant, what results to expect. Possible consequences, advice.

Causes and results of diesel engine overheating. What to do if the diesel engine is overheating: diagnostics and troubleshooting. Important recommendations.

How often does antifreeze need to be replaced? Self-cleaning of the cooling system from dirt, scale and rust. Products for flushing the internal combustion engine cooling system.

DIY engine radiator repair

Troubleshooting is divided into stages, including dismantling the unit, restoring its appearance and internal condition, direct repair, installation in a regular place with a standard performance check.

Preparation for repair

Preparatory activities are presented as follows:

- The car is installed on a flat area under a canopy or in a garage. If dust or natural precipitation gets inside the cooling system, it will cause subsequent malfunctions.

- Turn off the electrical power by removing the negative terminal from the battery.

- A container is installed under the bottom and the coolant is drained through the valves of the cylinder block and radiator. If the design does not provide for it, the lower pipe will need to be removed.

- At the connectors, disconnect the wires of the fan and temperature sensor, and disconnect the pipes.

- Unscrew the bolts to prevent thread damage. You will need wrenches with the appropriate head size. Remove the radiator. Installation after repair is carried out in the reverse order. It is better to change the coolant to a new one.

Important! To avoid thermal burns when draining antifreeze, it is necessary to wait time for the engine and attachments to cool down.

Washing outside and inside

In order to accurately diagnose damage, external and internal channels are cleaned. To do this, you need a source of pressurized water or an air compressor. The work order is presented:

- the liquid inlet and outlet pipes, as well as the temperature sensor seat, are plugged;

- Use a stiff brush under running water to remove external contaminants;

- to remove internal deposits and dirt, use a certified cleaning liquid by pouring it inside the radiator for the time specified by the manufacturer;

- the chemical composition is drained, the cavity is washed with running water.

After cleaning, damage is diagnosed and the quality of connections of structural elements is checked.

Important! The cleaner and water must be drained into a container specially designated for this purpose. Getting them on your hands, other open areas of the body or in the soil is extremely undesirable.

Cellular repair

If mechanical damage to the cells is detected, the following troubleshooting options are possible:

- Microscopic damage is removed using epoxy glue or “cold welding” technology.

- It is enough to clean thin cracks from oxide, degrease and solder. For work, use a powerful electric soldering iron or heated with a gas burner. Particular care must be taken when working at the base of the honeycomb - high temperatures can cause the structure to desolder.

- In case of significant damage, part of the cellular tube is cut out, and the remaining ends are bent and soldered. If 1-2 cells are removed, the efficiency of the radiator will not decrease.

Important! After repairs, it is recommended to check the quality of soldering by creating an internal water pressure slightly greater than that provided for by the technical characteristics of the product.

Prefabricated radiators

Malfunctions of this type of product, as a rule, do not affect the honeycomb part. The sealing rubber gaskets used in the process of securing the tubes by rolling fail. Provided that high-quality antifreeze is used, the service life of gaskets in units of Western manufacturers is 10–16 years, for domestic models it does not exceed 11 years, and for copies of Eastern manufacturers it is not predictable.

Due to the high cost of special solders for soldering and the painstaking work, specialists repair mainly foreign products; repairing a radiator, for example, on a Zhiguli car is simply impractical.

All-soldered radiators

Since all-soldered versions of cooling units are not installed on cars in the budget segment and are classified as expensive, their repair is always worthwhile. During self-repair, specialists focus on the following:

- the difficulty of soldering corner packages of tubes - the difference in metal thickness does not make it difficult to heat the joining surfaces equally;

- Carrying out work with special care in places where metal adheres to plastic tanks - careless use of a soldering iron will lead to additional damage;

- the expediency of violating the integrity of the rolling of the tanks, and if such a need is unconditional, then the connection should be made to photopolymers.

Despite the complexity of the work, a new radiator will cost much more than the cost of purchasing materials for repairs and the time spent carefully soldering the damage.