Symptoms of a problem

A mixture misfire is a failure to ignite the fuel-air mixture or its untimely ignition. In any of the cases, the system counts the number of misses and delays, and, if necessary, turns off the idle cylinder or even a pair. On most cars, the first sign of a malfunction is the “check” symbol lighting up on the dashboard.

Also among the common signs can be noted:

- Smell of fuel from the exhaust pipe. Since the mixture did not ignite in the cylinder, it is discharged almost unchanged or partially neutralized.

- Shoots in the exhaust system. If a partial fire occurs, the catalytic converter is severely damaged, which can lead to popping noises.

- Loss of power. The engine does not work properly, causing the crankshaft to spin at a lower speed, resulting in a significant loss of power.

- Engine tripping. Failure of one or a pair of cylinders leads to the fact that the engine begins to vibrate during operation and other signs of malfunction appear.

In cars with an electronic control unit, there are several types of errors that indicate a breakdown.

- P0300. It is a sign of multiple failures in the process of ignition of the combustible mixture in different cylinders.

- P0301 - p0304. The last number shows which cylinder is not working properly.

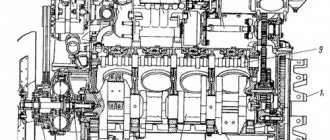

VAZ 21074 engine control system diagram

Wiring diagram of electrical connections of ECM VAZ 21074 - circuit elements. 1 — controller connector; 2 — mass air flow sensor; 3 — coolant temperature sensor; 4 — crankshaft position sensor; 5 — throttle position sensor; 6 — oxygen concentration sensor; 7 — speed sensor; 8 — ignition module; 9 — solenoid valve for purge of the adsorber; 10 — electric fan relay; 11 — electric fuel pump relay; 12 - main relay; 13 - fuse for the power circuit of the electric fuel pump relay: 14 - fuse for the power circuit of the main relay; 15 — fuse-link; 16-fuse protecting the constant power supply circuit of the controller; 17 - diode; 18 — idle speed regulator; 19 — nozzles; X1 - diagnostic block; X2 - connection block to the vehicle electrical system.

Characteristics of oils for VAZ

The service life of the engine depends on the correct selection of oil for injection VAZ 2107. The recommended quality standard for the lubricating fluid is given by the manufacturer. Any type of oil that meets API SJ/CF, SG/CD quality standards can be filled into the car.

The abbreviation API means that a lubricant meets the following basic criteria:

- cleaning properties;

- temperature regime;

- indicator of deposits on engine components before the first oil change;

- release of harmful substances;

- corrosive properties;

- effectiveness of protecting components from friction.

It is recommended to use the following types of oils.

| Oil brand for VAZ | SAE viscosity groups | API standard |

| RAVENOL LLO | 10W-40 | SJ/CF |

| SHELL HELIX SUPER | 10W-40 | SG/CD |

| TNK SUPER OIL | 5W-40, 10W-40, 15W-40, 20W-40 | SG/CD |

| TOTAL QUARTZ | 5W-40, 10W-40 | SL/SF |

| MOBIL SUPER M | 15W-40 | SJ/CF |

| LUKOIL LUX | 5W-40, 10W-40, 15W-40 | SJ/CF-4 |

| NOVOIL-SINT | 5W30 | SG/CD |

| CONSOL | 5W-40, 10W-40, 15W-40 | SG/CD |

| BIZOL GREEN OIL | 10W-40 | SL/SF |

| ESSO ULTRA | 10W-40 | SJ/CD |

| LUKOIL SUPER | 5W-40, 10W-40, 15W-40, 10W-30 | CF-4/SG |

| RAVENOL SUPER HD | 15W-40 | SJ/CF |

| LUKOIL SUPER | 5W-30, 5W-40, 10W-40, 15W-40 | SG/CD |

| ANGROL-SUPER | 5W30, 5W-40, 10W-40 | SG/CD |

| LUX | 5W30, 5W-40,10W-30, 10W-40, 15W-40, 20W-40 | SG/CD |

| ESSO UNIFLO | 10W-40, 15W-40 | SJ/CD |

Technical characteristics of the “Seven” injection engine

In carburetor systems, the creation of a combustible mixture is carried out directly in the chambers of the carburetor itself. However, the essence of the operation of the injection engine on the VAZ 2107 comes down to a different approach to forming the fuel-air mixture. The injector sharply injects the fuel itself into the working cylinders of the engine. Therefore, such a system for creating and supplying fuel is also called a “distributed injection system.”

The injection model VAZ 2107 is equipped from the factory with a separate injection system with four injectors (one injector for each cylinder). The operation of the injectors is controlled by the ECU, which regulates the flow of fuel to the cylinders, obeying the requirements of the microcontroller.

The injection engine on the VAZ 2107 weighs 121 kilograms and has the following dimensions:

- height - 665 mm;

- length - 565 mm;

- width - 541 mm.

The power unit without attachments weighs 121 kilograms

Injector ignition systems are considered more convenient and modern. For example, the VAZ 2107i has a number of important advantages over carburetor models:

- High engine efficiency thanks to precise calculation of the amount of fuel injected.

- Reduced fuel consumption.

- Increased engine power.

- Stability of idling, as all driving modes are controlled via the on-board computer.

- No need for constant adjustment.

- Environmentally friendly emissions.

- Quieter engine operation thanks to the use of hydraulic compensators and hydraulic tensioners.

- You can easily install cost-effective gas equipment on the “Seven” injection models.

However, injection models also have disadvantages:

- Difficult access to a number of mechanisms under the hood.

- High risk of catalytic converter damage on rough roads.

- Capriciousness regarding fuel consumed.

- The need to contact a car repair shop for any engine malfunctions.

Table: all 2107i engine characteristics

The VAZ 2107i power unit initially used AI-93 fuel. Today it is allowed to fill AI-92 and AI-95. Fuel consumption for injection models is lower than for carburetor models and is:

- 9.4 liters in the city;

- 6.9 liters on the highway;

- up to 9 liters in mixed driving mode.

The car has economical fuel consumption due to the use of an injection system

What oil is used

High-quality maintenance of an injection engine begins with the choice of oil, which is recommended by the manufacturer itself. AvtoVAZ usually indicates in the operating documents of such manufacturers as Schell or Lukoil and oils of the following type:

- 5W-30;

- 5W-40;

- 10W-40;

- 15W-40.

Video: owner’s review of the injection “Seven”

Wiring harness in the cabin

In the interior of the VAZ 21074 there are wiring harnesses:

- under the instrument panel. This bundle contains the wires responsible for the headlights, direction indicators, instrument panel, and interior lighting;

- stretched from the fuse box to the rear of the car. The wires of this bundle power the rear lights, glass heater, and gasoline level sensor.

The wires that are used in the “seven” for electrical connections are of the PVA type and have a cross-section from 0.75 to 16 mm2. The number of copper wires from which the wires are twisted can range from 19 to 84. The wiring insulation is made on the basis of polyvinyl chloride, which is resistant to temperature overloads and chemical influences.

The wiring harness under the instrument panel of the VAZ 21074 contains wires that are responsible for the headlights, direction indicators, instrument panel, and interior lighting.

To simplify the repair, maintenance and replacement of electrical equipment, the factory electrical wiring of VAZ 21074 vehicles has a set color.

Table: cross-section and color of wiring of the most important electrical appliances VAZ 21074

| Electrical circuit section | Wire cross-section, mm2 | Insulation color |

| minus battery - body mass | 16 | black |

| starter plus - battery | 16 | red |

| plus generator - battery | 6 | black |

| generator—black connector | 6 | black |

| terminal “30” of the generator—white block MB | 4 | pink |

| terminal “50” starter—starter start relay | 4 | red |

| Starter start relay—black connector | 4 | brown |

| ignition relay—black connector | 4 | blue |

| terminal “50” of the ignition switch—blue connector | 4 | red |

| terminal “30” of the ignition switch—green connector | 4 | pink |

| right headlight connector - ground | 2,5 | black |

| left headlight connector—blue connector | 2,5 | green (gray) |

| terminal “15” of the generator—yellow connector | 2,5 | orange |

| Radiator fan ED - “ground” | 2,5 | black |

| Radiator fan ED—red connector | 2,5 | blue |

| contact “30/1” of the ignition switch—ignition relay | 2,5 | brown |

| pin “15” of the ignition switch—single-pin connector | 2,5 | blue |

| cigarette lighter—blue connector | 1,5 | blue (red) |

What generators can be installed on the “seven”

The design of the VAZ 2107 allows the installation of not only the G-221A generator. Therefore, if necessary, the driver can install a more powerful device, however, this will require making some changes to the electrical circuit of the car. The question arises: what is the reason for the desire of a car enthusiast to change his “native” generator?

The G-221A was the optimal device for equipping cars at the beginning of their mass production. However, a lot of time has passed since the 1980s and today almost every driver uses modern electronic devices:

- acoustic system;

- navigators;

- additional lighting devices (tuning), etc.

Accordingly, the G-221A generator cannot cope with high loads, which is why drivers begin to look for more powerful units.

You can install at least three more powerful devices on the “seven”:

- G-222 (generator from Lada Niva);

- G-2108 (generator from the G8);

- G-2107–3701010 (injection model for a carburetor car).

It is important that the last two models do not require changes in the design of either the generator housing or its mountings. When installing a generator from Niva, you will have to make some modifications

Connection diagram G-221A

Being an electronic device, the generator needs to be used correctly. Therefore, its connection diagram should not cause ambiguity. It should be noted that drivers of “sevens” can usually easily connect all the generator terminals themselves, since the circuit is accessible and understandable to everyone.

The generator (item 2) is connected to the circuit in series between the battery (item 1) and the mounting block (item 3)Many car owners wonder where which wire should be connected when replacing the generator. The fact is that the device has several connectors and wires, and when replacing, you can easily forget which wire goes where:

- orange is not useful for connection, it can be left as is or connected to gray directly to autostart the car;

- a gray thick wire goes to the brushes from the relay regulator;

- a gray thin wire connects to the relay;

- yellow - coordinator of the control light on the control panel.

When working independently with the G-221A, it is better to sign the purpose of the wires so as not to connect them by mistake later.

To avoid errors, all wires have their own color designation

What engines is the VAZ 2107 equipped with?

The VAZ 2107 model was produced from 1982 to 2012. Over the 30 years of its existence, the car has been repeatedly refined and changed to more accurately meet modern requirements. Initially, the “seven” was conceived as a small-class rear-wheel drive car in a sedan body. However, in some countries the VAZ 2107 was refined and modified, which is why it can be considered a universal car model.

Depending on the year of manufacture and the country of origin (at different times, the VAZ 2107 was produced not only by the Russian AvtoVAZ, but also by factories in European and Asian countries), the model was equipped with different types of propulsion systems:

- LADA-2107 (engine 2103, 1.5 l, 8 cells, carburetor);

- LADA-21072 (engine 2105, 1.3 l, 8 cl., carburetor, timing belt drive);

- LADA-21073 (engine 1.7 l, 8 cells, mono injection - export version for the European market);

- LADA-21074 (engine 2106, 1.6 l, 8 cl., carburetor);

- LADA-21070 (engine 2103, 1.5 l, 8 cl., carburetor);

- LADA-2107–20 (engine 2104, 1.5 l, 8 cells, distributed injection, Euro-2);

- LADA-2107–71 (engine 1.4 l, 66 hp, engine 21034 for A-76 gasoline, version for China);

- LADA-21074–20 (engine 21067–10, 1.6 l, 8 cl., distributed injection, Euro-2);

- LADA-21074–30 (engine 21067–20, 1.6 l, 8 cl., distributed injection, Euro-3);

- LADA-210740 (engine 21067, 1.6 l, 53 kW/72.7 hp 8 cells, injector, catalyst) (2007);

- LADA-21077 (engine 2105, 1.3 l, 8 cl., carburetor, timing belt drive - export version for the UK);

- LADA-21078 (engine 2106, 1.6 l, 8 cl., carburetor - export version for the UK);

- LADA-21079 (rotary piston engine 1.3 l, 140 hp, originally created for the needs of the Ministry of Internal Affairs and the KGB);

- LADA-2107 ZNG (engine 21213, 1.7 l, 8 cells, central injection).

That is, in total there were 14 versions in the VAZ 2107 line - either with carburetor engines or with injection ones.

Technical characteristics of VAZ 2107 (carburetor)

The VAZ 2107 was initially equipped with a 1.5 and 1.6 liter carburetor. In the USSR in the 1980–1990s, almost all produced models were equipped with engines of this size - this power was quite enough for trips around the city and country roads. The engine uses AI-92 gasoline to create the air-fuel mixture. There were also 1.3 and 1.2 liter carburetors, but they were not particularly popular.

The carburetor on the “seven” does not have large dimensions: the device is 18.5 cm wide, 16 cm long, 21.5 cm high. The total weight of the entire assembled mechanism (without fuel) is 2.79 kg. The engine works with spark plugs of a certain type - brand A17DVR or A17DV-10*.

The maximum power was calculated according to GOST 14846: 54.8 kW (or 74.5 horsepower).

The diameter of the working cylinders is 79 mm, while the piston stroke can reach 80 mm. The established order of operation of the cylinders is carried out according to the 1-3-4-2 scheme (every auto mechanic needs to know this scheme, since if the cylinders are not started in an coordinated manner, the operation of the carburetor will be disrupted).

The crankshaft size is 50.795 mm, the shaft itself rotates at a speed of 5400 rpm. When viewed from the front of the car (radiator side), the crankshaft rotates clockwise. The flywheel installed on the model has an outer diameter of 277.5 mm.

The lubrication system on VAZ 2107 carburetors is combined, that is, the rubbing parts are lubricated both under pressure and by splashing. If you follow the recommendations of AvtoVAZ engineers, then you need to fill the carburetor engine of the “Seven” with oils that meet the API SG/CD standard. It is also recommended to select a lubricant according to the SAE (Society of Automotive Engineers in the USA) classification. Thus, if you combine these two principles for selecting oils, then it is better to fill the “Seven” carburetor engine with:

- oils produced by Lukoil in the Lux and Super versions;

- Esso brand oils;

- Shell Helix Super lubricants;

- Norsi Extra oils.

AvtoVAZ has established acceptable oil consumption during vehicle operation. Thus, a loss of 0.7 liters of oil per 1000 kilometers is considered acceptable (of course, if there are no leaks).

Where does this norm come from, 700 g per 1000. This is more like the GAZ-53 norm, at least on the farm where I worked at one time they gave a liter of oil for about 200 liters of gasoline. I wrote purely on my own occasion - I always kept MAX oil. in the crankcase, and did not leak or drip from anywhere, and when replacing the level was 2 matches below MAX. there was, and it was over 8000. This is normal oil consumption, as in the book “natural oil consumption for waste.” And when did it become when replacing MIN. I put it on capital, and, as it turned out, it was not in vain

Advanced

The service life of a carburetor engine before major overhaul is relatively short - approximately 150–200 thousand kilometers. However, due to the simplicity of the design, overhauls will not require large investments, and the updated engine will operate in the same mode as the new one. In general, the service life of the VAZ 2107 engine greatly depends on the driver’s driving style and care:

It depends on how you drive and what kind of oil you use. Ideally - 200 thousand, then capital is guaranteed

Enlightened

I used 270 thousand, I would have used more, but an accident forced me to disassemble it and replace everything that was needed without boring.

Sailor

Explanation of symbols

- 1 – radiator fan drive motor;

- 2 – mounting block block;

- 3 — idle speed sensor;

- 4 – engine ECU;

- 5 – potentiometer;

- 6 – set of spark plugs;

- 7 – ignition control unit;

- 8 – electronic crankshaft position sensor;

- 9 – electric fuel pump;

- 10 – indicator of the number of revolutions;

- 11 – lamp for monitoring the health of electronic systems and the brake system;

- 12 – ignition system control relay;

- 13 – speedometer sensor;

- 14 – special factory connector for reading errors using the BC;

- 15 – injector harness;

- 16 – adsorber solenoid valve;

- 17, 18, 19,20 – fuse box for repairing the mounting block that protects the injection system circuits;

- 21 – electronic fuel pump control relay;

- 22 – electronic relay for controlling the exhaust manifold heating system;

- 23 – exhaust manifold heating system;

- 24 – fuse protecting the heater circuit;

- 25 – electronic air sensor;

- 26 – coolant temperature control sensor;

- 27 – electronic air damper sensor;

- 28 – air temperature sensor;

- 29 – pressure control sensor and low oil pressure lamp.

General diagram of the electrical equipment of the VAZ 21074 injector

General diagram of the electrical equipment of the VAZ 21074 injector

1. Electrical connection diagram of the wiring harness of the instrument panel assembly LADA 21074

- — ignition switch unloading relay;

- — relay-interrupter of direction indicators;

- — windshield wiper relay;

- — brake signal switch;

- — switch for headlights and direction indicators;

- — windshield wiper and washer switch;

- — ignition switch;

- - hazard warning switch;

- — instrument cluster;

- — rear window heating switch;

- — rear fog light switch;

- — external lighting switch;

- — heater motor switch;

- — additional resistor for the heater electric motor;

- — heater electric motor;

- — indicator lamp for heated rear window;

- — brake fluid level warning lamp;

- — instrument lighting switch;

- - cigarette lighter;

- - watch;

- - reverse light switch;

- — hand brake sensor;

- — rear fog light relay;

- — block of the instrument panel harness to the ignition system harness;

- — glove box lighting;

- — mounting block.

A1, A2 - grounding points of the instrument panel wiring harness. A3 - grounding points for the heater motor.

2.Electrical connection diagram of ECM LADA 21074 injector

1 - controller; 2 — diagnostic oxygen concentration sensor; 3 — block of the ignition system harness to the right mudguard harness; 4 — block of the fuel level harness to the ignition system harness; 5 and 7 — electrical fuel pump harness pads; 6 — control oxygen concentration sensor; 8 — electric fuel pump; 9 — diagnostic block; 10 — speed sensor; 11 — idle speed regulator; 12 — throttle position sensor; 13 — coolant temperature sensor; 14 — mass air flow sensor; 15 — crankshaft position sensor; 16 — solenoid valve for purge of the adsorber; 17 — ignition coil; 18 — spark plugs; 19 — nozzles; 20 — block of the ignition system harness to the instrument panel harness; 21 — controller power supply fuse; 22 — ignition relay; 23 - ignition relay fuse; 24 — fuse for the electric fuel pump power supply circuit; 25 — electric fuel pump relay; 26 — block of the ignition system harness to the injector harness; 27 — injector harness block to the ignition system harness; A - to the “plus” terminal of the battery; B1 — grounding point of the fuel level sensor harness; B2, ВЗ — grounding point of the ignition system harness; 21074-3724026 — ignition system harness

3. Electrical connection diagram of the wiring harness of the right mudguard assembly LADA 21074.

- — mounting block;

- — block of the right mudguard harness to the left mudguard harness;

- — right side turn signal;

- - right headlight;

- — additional starter relay;

- — windshield washer pump;

- — blocks of the right mudguard harness and connecting starter wires;

- — starter;

- — rechargeable battery;

- — generator.

A1 is the grounding point for the right mudguard wiring harness. A2, A3 - grounding points of the connecting motor wire with the battery and housing.

4. Electrical connection diagram of the left mudguard assembly wiring harness LADA 21074.

- — mounting block;

- — block of the left mudguard harness to the right mudguard harness;

- - left headlight;

- — left side turn signal;

- — oil pressure warning lamp sensor;

- — coolant temperature sensor;

- — brake fluid level sensor;

- — electric motor of the windshield wiper;

- - sound signal;

- — engine electric fan.

A1, A2 - grounding points of the left mudguard wiring harness.

5. Electrical connection diagram of the flat rear wiring harness assembly for LADA 21074.

- — mounting block;

- — flat rear harness block to the ignition system harness;

- — right front door lamp switch;

- — right rear door lamp switch;

- — left front door lamp switch;

- — left rear door lamp switch;

- — right interior lamp;

- — left interior lamp;

- — electric fuel pump with fuel level indicator sensor;

- — rear window heating element;

- — additional brake signal;

- — right lamp;

- — left lamp;

- — left license plate light;

- — right license plate light.

A1 is the grounding point for the rear window heating element. A2 is the grounding point for the license plate light ground harness. A3 - A8 - grounding points of the flat rear wiring harness assembly.

Source

VAZ-2107 diagram

The VAZ-2107 car was produced from 1982 to 2014. Here are colored wiring diagrams (for the injector and carburetor) with a description of all the elements for various modifications. The information is intended for self-repair of cars. Electrical circuits are divided into several blocks for ease of viewing via a computer or phone; there are also circuits in the form of a single picture with a description of each element - for printing on a printer.

The “sevens”, like most modern cars, use a single-wire circuit for supplying electricity to electrical equipment. The other terminal of the consumer is always connected to the ground of the machine to which the negative terminal of the battery is connected. This solution allows not only to simplify the design of the on-board network, but also to slow down corrosion.

Modifications of VAZ 2107

It turns out that the seven had a lot of modifications, which sometimes even the workers of the plant in Tolyatti are not aware of. And we know and willingly share this information with fans of VAZ retro. The technical characteristics of the VAZ 21074 (shown in the table) are actually no different from other Ladas with a six-wheel engine, with the exception of some nuances that could not be noticed at all, but respecting the traditions of the plant, they are worth emphasizing.

So, the “pure” seven, 2107, came only with a four-speed manual transmission and a three-liter one and a half liter engine with a carburetor power system. But today we are not talking about it, but about its first modification, the seven with an engine from the VAZ 2106, which received the factory index 21074.

Characteristics of VAZ 2107

| Performance indicators | Meaning |

| Maximum speed, km/h | 150 |

| Fuel consumption l: | |

| City | 9,6 |

| Route | 6,9 |

| Mixed | 8 |

| Euro toxicity standard | Euro 2 |

| Engine | |

| Power unit volume, cm3 | 1451 |

| Fuel type | petrol |

| Number and arrangement of cylinders | 4/R |

| Supply system | Distributive injection |

| Number of valves | 8 |

| Maximum torque, N*m at rpm | 115 at 3450 |

| Maximum power, hp | 71 |

| Transmission | |

| Transmission type | Mechanical |

| Number of steps | 5 |

| type of drive | Rear |

| Suspension | |

| Front suspension device | Independent multi-link |

| Rear suspension device | Dependent, on coil springs |

| Front brake mechanism | Disk |

| Rear brake mechanism | Drum |

Initially, the seven was equipped with an engine with a capacity of 1.5 liters, but during the production process the power range was expanded.

Modifications of engines installed on the VAZ 2107.

| Options | Model range of VAZ engines | ||||

| 2103 | 2104 | 2106 | 21067 | 21067-20 | |

| Cylinder diameter, piston stroke | 76 80 | 76 80 | 79 80 | 79 80 | 79 20 |

| Working volume | 1,5 | 1,5 | 1,6 | 1,6 | 1,6 |

| Compression ratio | 8,5 | 8,5 | 8,5 | 8,5 | 8,5 |

| Supply system | carburetor | Distributive injection | carburetor | Distributive injection | Distributive injection |

| Rated power, kW | 52,5 | 52,5 | 54,8 | 54,5 | 53,5 |

| Rated speed | 5600 | 5000 | 5600 | 5000 | 5300 |

| Fuel brand | (AI-92) | (AI-92) | (AI-92) | (AI-92) | (AI-95) |

| Spark plug | A17DVR, FE65CPR, A17DV-10 | А17ДВРМ, BRISR, SUPER, LR 15YC | A17DVR, FE65CPR, A17DV-10 | А17ДВРМ, BRISR, SUPER, LR 15YC | А17ДВРМ, BRISR, SUPER, LR 15YC |

| Toxicity standard | Euro-0 | Euro 2 | Euro-0 | Euro 2 | Euro-3 |

↑ VAZ-2107 injection engine

Since 2006, the production of cars with a distributed injection system on the engine began. The four-cylinder unit has a power limit of 76 “horses”.

The air-fuel mixture is supplied individually to each cylinder through its own nozzle. The task of the atomizer is to convert the liquid state of the fuel into a gaseous state, which ensures rational mixing with air.

↑ Fuel consumption VAZ-2107 injector

Comparative characteristics of fuel consumption

| Engine 1.6 liters | Highway consumption, l/100 km | Consumption in the city, l/100 km | Combined cycle, l/100 km |

| carburetor | 6,9 | 10,2 | Around 9 |

| injector | 7,3 | 9,7 | Around 9 |

The precise calculation of fuel, as well as idle speed control and ignition distribution are controlled by an electronic control unit (ECU).

Information from electronics and mechanical sensors serves to generate signals to perform certain actions. When the pressure norm is exceeded (300 mPa), excess fuel is automatically discharged into the gas tank. The ECU issues commands to operate the injectors synchronously with the operation of the cylinders during the opening/closing phases.

The fuel injection dose depends on the time the injector is open. The time period is set based on data from sensors that determine mass fuel consumption and throttle valve position.

The injection version of the “seven” is adapted to Russian operating conditions. Although this model is no longer produced, at one time it earned recognition among domestic car enthusiasts.

Diagnostic connector

The ECU on the “Seven”, like on other cars, is also equipped with a diagnostic connector. Today, all connectors are manufactured according to the same OBD2 standard. That is, the “on-board vehicle” can be checked for errors and malfunctions using a conventional scanner with a standard cord.

The device for connecting the scanner to the ECU on a VAZ 2107 is compact in size

What is it used for?

The OBD2 diagnostic connector is equipped with a certain number of contacts, each of which performs its own function. By connecting the scanner to the ECU connector, you can carry out several diagnostic modes at once with high accuracy:

- view and decipher error codes;

- study the characteristics of each system;

- clear “unnecessary” information in the ECU;

- analyze the operation of car sensors;

- connect to execution mechanisms and find out their remaining resource;

- View system performance and saved data about previous errors.

A scanner connected to the diagnostic connector instantly identifies all errors in the operation of the ECU and deciphers them to the driver

Where is

The diagnostic connector on the VAZ 2107 is located in the most convenient place for work - under the glove compartment in the cabin under the instrument panel. Thus, there is no need to disassemble the engine compartment mechanisms in order to connect the scanner to the ECU.

Opening the glove compartment, you can see the ECU diagnostic connector on the left side

Technical characteristics of Lada (VAZ) 21074

The VAZ-2107 sedan is the most comfortable model of rear-wheel drive VAZ cars. The car is distinguished by original anatomical front seats with a high back, a more modern instrument panel with a tachometer, and an original radiator grille. In general, the VAZ-2107 can rightfully be called the most advanced and comfortable rear-wheel drive domestic sedan.

The automobile catalog contains a description, technical characteristics and photographs of the Lada (VAZ) 21074 car.

Causes of injector clogging

Typically, problems with the injection system occur when using low-quality gasoline. Heavy paraffins contained in such fuel settle on the walls of the system, cutting off the fuel supply. Manufacturers of high-quality gasoline add detergent to it - a special additive that dissolves deposits. Low-quality gasoline contains too much paraffin, which forms deposits faster than detergents can remove them.

Deposits form more intensively at low temperatures, so when the car is frequently driven with a cold engine, the injector becomes clogged more often.

Deposits can accumulate not only in the injectors. Often vapors settle on the throttle valve, which leads to a change in the proportions of the air-fuel mixture entering the cylinders.

Deposits of substances contained in low-quality gasoline may also appear on the back of the intake valve plates. This can lead to valve burnout or fuel detonation.

To clean the injection system of deposits, it is necessary to use special flushing fluid and equipment. You can wash the injector in a garage. To do this, you need a syringe and washing liquid. The latter is mixed with gasoline and poured into the injection system through the hose of the vacuum brake booster. First, the operation is performed with the engine turned off, then with the engine running. The mixture is fed into the running engine gradually, in small portions. As a result, the deposits dissolve, enter the engine cylinders and burn there. In this case, clouds of smoke may briefly appear coming out of the muffler.

Differences between cars of recent years of production

In cars of the last years of production (under the state car recycling program), in order to minimize the selling price, the maximum cost of elements was made relative to previously produced equipment. What we noticed: there are no ashtrays in the rear door trim; interior door handles are made of molded hard plastic (instead of rubberized material); There are no clothes hooks on the ceiling handrails; one weak and capricious sound signal “tablet” was used, instead of two “horns”. The 2010 car was not equipped with a pump. In addition, changes affected the appearance of the “seven”. Instead of a flat trunk lid, a lid with stamping from a VAZ-2105 appeared, and the plastic molding at the bottom of the body disappeared. They refused to paint the door pillars and frames black, and they abandoned the chrome-plated external door handles. Headlight washers and cleaners were no longer installed on cars of recent years of production.

VAZ 2107 is a five-seater passenger car of a classic layout with a front longitudinal arrangement of the power unit and rear drive wheels. The engine is a four-cylinder, four-stroke, eight-valve, in-line, carburetor or fuel injection system. The body is a supporting structure, all-metal, welded. Body type – sedan .

Overall dimensions of VAZ 2107

The VAZ 2107 car is equipped with a carburetor engine of the VAZ 2103 model with a working volume of 1.5 liters. The modification of the VAZ 21074 car is distinguished by the engine of the VAZ 2106 model with a displacement of 1.6 liters.

In recent years of production of this model, modifications of the VAZ 2107-20 car with a VAZ 2104 engine with a displacement of 1.5 liters and VAZ 21074-20 with a VAZ 21067 engine with a displacement of 1.6 liters, equipped with fuel injection, mechanical part (cylinder block, connecting rod) were produced -piston group, crankshaft) of these engines are respectively identical to the VAZ 2103 and VAZ 2106 engines. The VAZ 2104 and VAZ 21067 engines are equipped with more powerful generators and starters with planetary gearboxes. The installation of engines with distributed fuel injection in cars, as well as the use of a gasoline vapor recovery system and catalytic converters in exhaust systems, made it possible to reduce the toxicity of exhaust gases and fuel consumption, and increase the reliability of engine starting in cold weather. The body, chassis and transmission remained unchanged.

Predecessor – VAZ 2105, successor – Lada Granta.

This is interesting: Carburetor - educational program on the design and operation of the unit

Electrical diagram of VAZ 21074

In VAZ 21074 cars, electrical energy is delivered to consumers using a single-wire circuit: the “positive” terminal of each electrical device is powered from a source, the “negative” terminal is connected to “ground,” i.e., connected to the vehicle body. This solution simplifies the repair of electrical equipment and slows down the corrosion process. All electrical appliances of the car are powered from the battery (with the engine off) or the generator (with the engine running).

The wiring diagram of the VAZ 21074 injector contains an ECM, an electric fuel pump, injectors, and engine control sensors

Wiring diagram VAZ 21074 injector

The injection versions of the “Seven” released from the factory assembly line have the following indices:

- LADA 2107–20 - in accordance with the Euro-2 standard;

- LADA 2107–71 - for the Chinese market;

- LADA-21074–20 (Euro-2);

- LADA-21074–30 (Euro-3).

The injection modifications of the VAZ 2107 and VAZ 21074 use an ECM (electronic engine control system), an electric fuel pump, injectors, control sensors and monitoring engine parameters. As a result, there was a need for additional under-hood and interior wiring. In addition, the VAZ 2107 and VAZ 21074 are equipped with an additional relay and fuse box located under the glove compartment. The additional unit is supplied with wiring that supplies:

- fuses: main relay power circuits;

- controller constant power supply circuits;

- electric fuel pump relay circuits;

- The main thing;

Additional fuse and relay block VAZ 2107 injector located under the glove compartment

Providing electricity

The G7 is responsible for providing consumers with electricity:

- Battery voltage 12 V, capacity 55 Ah;

- generator type G-222 or 37.3701;

- voltage regulator Ya112V, which automatically maintains the voltage within 13.6–14.7 V.

Diagram of the power supply system for the VAZ 21074 injector includes a generator, battery and voltage regulator

Engine starting

The starting system in the VAZ 21074 is a starter and ignition switch powered from the battery. There are two relays in the starter circuit:

- auxiliary, which supplies power to the starter terminals;

- retractor, due to which the starter shaft engages with the flywheel.

The starting system in the VAZ 21074 is a battery-powered starter with a relay and an ignition switch.

Ignition system

In early versions of the seventh VAZ model, a contact ignition system was used, which included:

- ignition coil;

- distributor with contact breaker;

- spark plug;

- high voltage wiring.

The VAZ 21074 contact ignition system consists of a coil, distributor, spark plugs and high-voltage wires

In 1989, the so-called contactless ignition system appeared, the circuit of which included:

- Spark plug.

- Distributor.

- Screen.

- Hall Sensor.

- Electronic switch.

- Ignition coil.

- Mounting block.

- Relay block.

- Key and ignition lock.

In 1989, a contactless ignition system appeared, to the circuit of which a Hall sensor and an electronic switch were added

“Sevens” with injection engines use a more modern ignition circuit. The operation of this circuit is based on the fact that signals from the sensors are sent to the ECU (electronic control unit), which, based on the received data, generates electrical impulses and transmits them to a special module. After this, the voltage increases to the required value and is supplied to the spark plugs through high-voltage cables.

In injection "sevens" the operation of the ignition system is controlled by the electronic control unit of the ECU

Outdoor Lighting

The external lighting system includes:

- Block headlights with dimensions.

- Illumination of the engine compartment.

- Mounting block.

- Glove compartment lighting.

- Instrument lighting switch.

- Rear lights with dimensions.

- Illuminated numbers.

- Exterior lamp switch.

- External lighting indicator lamp (in the speedometer).

- Ignition.

The VAZ 21074 external lighting connection diagram will help in troubleshooting headlights and tail lights

Auxiliary equipment

Auxiliary or additional electrical equipment of the VAZ 21074 includes:

- electric motors: windshield washer;

- windshield wiper;

- heater fan;

- radiator cooling fan;

The connection diagram for windshield wipers uses:

- Gearmotors.

- ED headlight washer.

- Mounting block.

- Egnition lock.

- Washer switch.

Windshield wiper motors drive a trapezoid that moves the wipers across the windshield

Modifications

- LADA-2107 (engine 2103, 1.5 l, 8 cl., carburetor)

- LADA-21072 (engine 2105, 1.3 l, 8 cl., carburetor, timing belt drive)

- LADA-21073 (engine 1.7 l, 8 cells, mono injection - export version for the European market)

- LADA-21074 (engine 2106, 1.6 l, 8 cl., carburetor)

- LADA-2107-20 (engine 2104, 1.5 l, 8 cells, distributed injection, Euro-2)

- LADA-2107-71 (engine 1.4 l, 66 hp engine 21034 for A-76 gasoline, version for China)

- LADA-21074-20 (engine 21067-10, 1.6 l, 8 cells, distributed injection, Euro-2)

- LADA-21074-30 (engine 21067-20, 1.6 l, 8 cells, distributed injection, Euro-3)

- LADA-210740 (engine 21067, 1.6 l, 53 kW/72.7 hp 8 cells, injector, catalyst) (2007 onwards)

- LADA-21077 (engine 2105, 1.3 l, 8 cl., carburetor, timing belt drive - export version for the UK)

- LADA-21078 (engine 2106, 1.6 l, 8 cl., carburetor - export version for the UK)

- LADA-21079 (rotary piston engine 1.3 l, 140 hp, originally created for the needs of the Ministry of Internal Affairs and the KGB). Years of production: 1986—1991

- LADA-2107 ZNG (engine 21213, 1.7 l, 8 cells, central injection)

Car wiring diagram

1 – radiator fan drive motor; 2 – relay and fuse block (mounting block); idle speed sensor; 4 – engine control unit; 5 – potentiometer; 6 – set of spark plugs; 7 – ignition control unit; 8 – electronic crankshaft sensor; 9 – electric fuel pump; 10 – tachometer 2107; 11 – lamp for monitoring the health of electronic systems; 12 – ignition system control relay; 13 – speed sensor; 14 – diagnostic connector; 15 – set of injectors; 16 – adsorber solenoid valve; 17, 18, 19 – fuse block protecting the injection system circuits; 21 – electronic fuel pump control relay; 22 – electronic relay for controlling the intake pipe heating system; 23 – intake pipe heating system; 24 – fuse protecting the heater circuit; 25 – electronic oxygen level sensor; 26 – cooling system temperature control sensor; 27 – electronic air damper sensor; 28 – air temperature sensor; 29 – pressure control sensor.

Generator set belt for VAZ 2107

The VAZ 2107 car was produced from 1982 to 2012. Initially, the model was equipped with a smooth drive belt (old model). Over time, the “seven” was modified several times and at the end of the 1990s, the generator began to work with a new type of belt with teeth.

The operation of the generator and the entire vehicle depends on the quality of the drive belt.The design numbers and sizes of the belts are indicated in the vehicle’s service book:

- 2101–1308020 (smooth surface), dimensions - 10.0x8.0x944.0 mm;

- 2107–1308020 (toothed surface), dimensions - 10.7x8.0x944.0 mm.

How to tension a belt on a generator

The operation of the generator, as well as the water pump, primarily depends on the correct tension of the belt on the pulley. Therefore, existing rules cannot be neglected. The belt is installed and tensioned in the following order.

- Place the assembled generator in place, lightly tightening the fixing nuts.

- Take a pry bar and use it to fix the gap between the generator housing and the pump.

- Place the belt on the pulley.

- Without releasing pressure from the pry bar, pull the belt onto the pulley.

- Tighten the top nut securing the generator until it stops.

- Check the degree of belt tension - the rubber should not sag, but it should not be too tight.

- Tighten the lower nut securing the generator.

Video: how to tighten the alternator belt

Checking the degree of tension is done with two fingers. You need to press the free part of the belt and measure its deflection. The optimal deflection is 1–1.5 centimeters.

Thus, we can say that independent maintenance of the generator on a VAZ 2107 is quite possible and does not fall into the category of impossible tasks

It is important to follow the recommendations and algorithms for this or that work in order to carry out quality repairs or diagnostics. However, if you have doubts about your skills and abilities, you can always turn to professionals for help.

On-board computer for VAZ 2107 injector

The state, by the way, is not the only BC model that can be installed on a car with a 21074 engine, but we will still start with it, as with it officially developed under the wing of the automobile plant. Officially, the factory declares the device as intended for installation instead of a button plug. Well, it’s a good alternative, let’s see what it can do besides its main declared function.

Video tutorial on installing an on-board computer in a VAZ 2107

The device is fully compatible with January controllers versions from 5.1 to January 7.2, as well as Itelma, Avtelm 73 under Euro3, but is not intended to work with Bosch controllers, which are installed on nines. Therefore, the State 2107×1 works only with an injection seven engine. The device is quite easy to understand. It only has two buttons and three numbers. As a plug, you can't think of a better one. But besides this, the device has as many as 30 functions. It makes sense to dwell on some of the most useful ones in more detail.

Protection of electrical circuits of VAZ 2107

The purpose of the fuse box is to protect wires from fire and the battery from discharge during a short circuit.

The VAZ 2107 is equipped with a disposable fuse block, which is located under the hood near the battery - on the right on the partition between the engine compartment and the passenger compartment. This location was not chosen by chance - the fuses are located as close as possible to the battery in order to reduce the number and length of unprotected electrical networks. The fuse location diagram is printed on the cover of the unit, which allows you to quickly navigate in the event of a blown fuse.

When replacing a failed fuse, its rating must be observed. This indicator is not marked on the cover of the fuse block, so you can find it out either from the VAZ 2107 diagram (injector) or based on the markings on the fuse to be replaced.

Important: failure to comply with the rating may lead to electrical wiring and fire. This can happen if the new fuse is rated for significantly higher current. The fuse block also contains electrical relays

The difference between the fuse block of the injection variation of the “seven” and the carburetor one is only in the presence of additional fuses for the ECM, fuel pump and other devices typical only for an injection car

The fuse box also contains electrical relays. The difference between the fuse block of the injection variation of the “seven” and the carburetor one is only in the presence of additional fuses for the ECM, fuel pump and other devices that are typical only for an injection car.

Model characteristics - convenience and practicality

The injection model has a 1.6 liter engine. The design of the car has been improved with hydraulic compensators, which make the engine much quieter. The car's rear-wheel drive makes it stable on the roads, especially in the winter when there is ice outside. Overall, this car is very convenient for our roads and practical. The carburetor model had very high fuel consumption, but this problem was eliminated in the injection car.

The VAZ 2107 was created on the basis of the VAZ 2105 prototype, because it had proven itself very well in the domestic market at one time.

The design of the VAZ 2107 chassis also makes the car practical and durable in off-road conditions. The car has an independent front suspension, and the rear part contains a strong beam. This car model can be repaired at any service station. The price of the VAZ 2107 is especially pleasing; it is significantly lower than the cost of other VAZ models. The availability of spare parts for cars of this brand also pleases owners, because they can be purchased without much difficulty at any auto store.