Some car problems are especially annoying because they are difficult to diagnose. Experienced drivers with considerable experience know well how difficult it is to identify the source of a malfunction when the engine speed “floats” or does not drop at idle. The engine vibrates, may periodically stall, “triple” and be difficult to start. There are quite a few reasons for this behavior of the power unit - this is the problem. But a car enthusiast should perform initial diagnostics on his own before contacting a car service center.

Causes and symptoms of malfunctions

Unstable engine idling is a reaction of the power unit to a problem that has arisen in one of the following vehicle systems:

- ignition circuit elements;

- electronics that control the injector;

- fuel supply;

- malfunction of the motor itself.

To figure out why the engine speed “floats”, it is recommended to use the method of elimination, moving from simple to complex. First you need to check your own suspicions - after all, only a car enthusiast knows what happened to the car shortly before the “shaking” of the engine appeared. Remember the latest repairs or replacement of parts in one of the listed systems and dig in this direction.

Advice. During the diagnostic process, pay attention to additional symptoms that appear at idle and engine operating speeds. These signs will help narrow down the circle of “suspected” elements and components of the car.

Ignition system problems

In this case, unstable operation of the engine at idle is accompanied by skipped ignition cycles in one or more cylinders - the engine begins to “triple”. The reasons lie in the malfunction of the following elements:

- spark plug;

- high voltage wires;

- high voltage coil (one common ignition module is installed on the injector);

- in carburetor engines - the main distributor (distributor).

A non-working spark plug or armored wire is detected by the old “old-fashioned” method - alternately removing the tips from the spark plug contacts while the engine is running. If, when the “cradle” is turned off, the speed of the power unit does not drop, you need to check the resistance of this wire and the condition of the electrodes. It is advisable to unscrew all the spark plugs in order to compare the color of the soot on the working part. A faulty spark plug will be indicated by black soot - remnants of unburned fuel.

Important point. Ignition system problems are characterized by stable “shaking” of the engine and shots into the intake manifold. If the engine speed “floats” (periodically increases and falls), the cause should be looked for elsewhere.

High-voltage wires can be easily checked for open circuits with a multimeter - the resistance should be in the range of 3.5–10 kOhm. The coils or ignition module are diagnosed in a service station. A separate story is the problem of the distributor installed on carburetor versions of the car. The following faults may cause unstable operation:

- a crack in the distributor cover where the wires are connected;

- the moving contact - the slider - has failed;

- The Hall sensor is heavily contaminated with metal shavings;

- mechanical ignition contacts are burnt;

- The bearing of the contact pair is worn out.

Electronics problems

Vibration and increased idle speed on a warm engine often occur due to the accumulation of errors in the controller’s memory. Cleaning is simple: disconnect the negative terminal of the battery for 15 minutes. Often this technique immediately gives a positive result - the power unit begins to operate in normal mode.

Recommendation. If cleaning must be carried out constantly, you should contact a service station. The reason for the accumulation of errors must be determined by a master electronics engineer.

The reason for the unstable speed of the power unit is often the operating algorithm of the electronic control unit. When one of the key sensors becomes unusable, the controller turns on emergency mode and prepares the air-fuel mixture, relying on working devices. Characteristic symptoms:

- The motor shakes and runs unstably.

- The injector supplies an enriched air-fuel mixture, which increases gasoline consumption.

- Black smoke comes out of the exhaust pipe.

- Soot is deposited on the spark plug electrodes.

In a modern car, more than one sensor is responsible for the engine idle speed. Information is transmitted to the controller by several main devices:

- Mass air flow sensor - intake air flow meter or its successor - absolute pressure sensor (MAP);

- lambda probe – measuring the amount of oxygen in the exhaust gases;

- DPDV – throttle position detector connected to the accelerator pedal;

- crankshaft position sensor (CPS).

The easiest way to check these devices is to disconnect the electrical connectors one by one, observing the behavior of the motor.

On which sensor, disconnecting the block will not bring changes, that element has failed. Be sure to clean the working surface of the DPKV - metal shavings are often magnetized to it, preventing the rotation of the toothed pulley from being properly recorded.

Fuel supply problems

Intermittent idle speed may be associated with the following problems with the fuel supply system:

- Damage to the idle air regulator built into the throttle valve block.

- Lack of fuel due to a drop in pressure in the fuel rail. The reasons are clogged coarse and fine filters, a malfunction of the bypass valve or electric fuel pump. In carburetor engines - the development of a mechanical pump drive.

- The canister purge valve is stuck in the open position.

- Worn or heavily soiled injector nozzles.

An important nuance. If the engine is unable to develop normal speed due to lack of fuel, the malfunction will appear in all modes, not just at idle. Low pressure in the fuel rail leads to a drop in power of the power unit and “dips” during movement.

A problem with the supply of gasoline or diesel fuel is detected by measuring the pressure in the fuel rail, where a special fitting is installed. If it is insufficient, the filters, relief valve and pump are checked. A stuck adsorber valve can be easily disassembled and replaced if necessary.

Intake manifold and pipes

With the advent of plastic intake manifolds, owners began to encounter air leaks more often. For various reasons, cracks formed in them, barely visible to the eye. But this is quite enough for the engine speed to fluctuate after warming up.

Intake manifold

The problem may be deeper. So, air is often sucked in due to a damaged or simply dried out manifold gasket. This problem is relevant for both plastic and aluminum intake systems. The revs fluctuate when hot, the engine stalls and is difficult to start. Broken vacuum tubes have a similar effect. The loss of vacuum is noticeably displayed when the car is running. And if it is a brake booster vacuum pipe, in addition there will be problems with braking.

The search for microcracks can take a long time, but there is a way to quickly find even the slightest leaks. This is a smoke generator. The device accurately finds all leaks without harming the engine.

Smoke generator

About air leaks

The penetration of foreign air into the cylinders of a running engine is imperceptible while driving, since the proportion of non-flammable gas is relatively small. But “floating” and high engine speeds appear at idle, when little fuel is supplied to the chambers. Air leakage due to the movement of the pistons is possible from the following places:

- gaskets under collectors and at other joints;

- broken vacuum booster of the brake system;

- throttle body;

- various vacuum connections;

- adsorber purge system.

To detect air leaks at gaskets and joints, you can use another old method. Fill the syringe with gasoline and squeeze the fuel onto the suspected leak. The operation is performed with the engine running. If fuel penetrates into an invisible gap, it will inevitably be drawn by the pistons into the combustion chambers. The speed of the power unit will increase and will not decrease until you stop filling the gap with gasoline.

A lot of problems for motorists are caused by unstable engine operation, especially at idle speed. Such troubles are accompanied by uneven rotation of the crankshaft or shaking of the power unit. Let's try to figure out what causes such results and how to prevent it.

Throttle position sensor

TPS affects idle speed and the operation of the car in motion. If there is a malfunction of the TPS, the speed fluctuates when it is hot, the engine stalls, stalls, and when accelerating the car jerks. The control unit cannot understand what position the throttle is in and selects the mixture incorrectly.

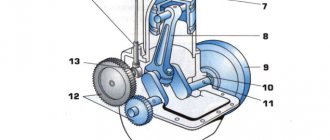

TPS device

The sensor fails for various reasons:

- the slider drive gear is worn;

- the resistive layer is erased (because of this, contact is lost);

- contact on the slider is lost (often due to wear on the slider itself or when the needle breaks).

A working sensor should have a resistance of 2 to 10 ohms, depending on the position of the gas pedal (with increasing pressure, the resistance increases). You can try cleaning the sensor, but if it is a mechanical failure, only replacement will help.

Causes of malfunctions

There are quite a few reasons that cause engine instability. And they largely depend on the type of unit itself. Therefore, it would be useful to consider all options.

Domestic classics

Here, as in the case of foreign cars, there are several reasons.

- Failure of the idle speed during operation or incorrect adjustment of it, due to which the tincture was shifted to the fuel assembly (fuel-air mixture) combination. Eliminating the problem is possible by adjusting the speed to the required parameters.

- Engine instability is possible due to a malfunction of the solenoid valve in the carburetor. This provokes the motor to work only with the choke extended. If you remove it, the engine will stall.

- When the jets or idle speed channels become dirty, the fuel entering the engine suffers from a lack of air. The problem can be easily solved by cleaning the nozzle.

- The intake of excess air masses by the carburetor system provokes a lean mixture, which leads to engine throttling.

- The float chamber suffers from excess or lack of gasoline.

- The air filter is clogged, which can be easily eliminated by replacing the part.

Modern monsters

Modern cars equipped with electronic injection, as well as injection units, also suffer from an overabundance of various problems. This is where sensors most often break down. Without receiving the necessary information, the ECU (electronic control unit) malfunctions, disrupting the operation of the unit, causing instability in speed.

There are several main reasons:

- contamination, wear or poor quality of spark plugs;

- dysfunction of the mass air flow sensor (mass air flow sensor);

- air leakage from the intake system;

- damage to high voltage wiring;

- breakdown of the idle speed regulator;

- malfunction of the EGR sensor.

If the engine is idling unstable, first of all check the idle speed regulator, located near the sensor that controls the throttle valve, with a multimeter.

Diesel injector nozzles

If you have a diesel car, it is important to check the injection system, namely the nozzles. Their average resource is 100 thousand kilometers. When the atomizer wears out, the speed on a warm engine fluctuates and white smoke comes out. Also, faulty nozzles “bite”, which is why they make a specific click.

Fuel injector nozzles

Having identified a problem, do not hesitate to fix it. Jammed nozzles wash away the protective film from the cylinder walls, which leads to the formation of scoring. This entails an irreversible process of engine destruction with a drop in compression and oil consumption.

Diagnosis of problems

Mechanical damage

The largest and most difficult to diagnose group includes mechanical damage that causes unstable idle speed.

Reduced compression of one or more cylinders. The reason may be:

- broken gasket;

- loose fit or burnout of the valve itself;

- wear of the CPU group (cylinders).

The malfunction can be determined using a compression gauge or leakage tester. It's much easier.

Impaired functionality of the engine head can be caused by:

- loose fit;

- jamming of hydraulic compensators;

- seat wear;

- breakage of the spring in the valve;

- other.

This can be checked using a vacuum sensor or when disassembling the head.

- Problems with the gas distribution mechanism. In engines equipped with a timing belt (gas distribution mechanism), an error with the marks is possible when replacing the element. It is also possible that the belt may involuntarily move one or more teeth, which indicates improper tension or stretching of the belt. Chain engines suffer from chain stretch during operation. Diagnostics is carried out using a pressure sensor without preliminary disassembly.

- EGR valve jamming. Overfilling the cylinders with exhaust gases disrupts idle stability and can cause the engine to stop. Neither European nor Japanese cars are immune from this problem. Diagnostics is carried out with a smoke generator.

- Suction of air masses by the intake manifold. Taking into account the control system of the unit or the location of the suction, this malfunction can make the mixtures in one or more cylinders too lean, which significantly affects the functions of the engine. Diagnostics is also carried out using a smoke generator.

Ignition system

A breakdown in this system can cause misfires or minor interruptions that cause instability. The reasons for this lie in the burnout of high-voltage wiring, breakdown of the spark plug insulator, and interturn short circuit of the coil. The problem is determined by a motor tester or by substitution.

The problem can be eliminated by replacing the spark plugs, respectively, setting the ignition timing, focusing on the spark plug from the first cylinder.

Nutrition

- Contamination of the injectors significantly reduces the spray pattern, disrupting the mixture formation process in the cylinders. This causes uneven engine function.

- The performance of the fuel pump, and, consequently, the fuel pressure can make the mixture too lean/over-rich, which also affects the engine.

- The quality of the fuel is also important. Quite often it contains water, rust, and other harmful components. Poor fuel increases the load on the engine, but reduces output, after which the speed begins to fluctuate. Periodic monitoring of the internal condition of the gas tank will help you avoid problems.

Motor control system

To fully carry out diagnostics, you will need to acquire a scanner. Typical problems with this system include the following.

- Lambda probe (oxygen sensor). Its mechanical damage results in the issuance of incorrect readings of the amount of oxygen remaining in the exhaust gases. Consequently, the composition of the mixture can change significantly, which leads to problems with engine functions. Usually, problems with the sensor are indicated by the corresponding indicator.

- The temperature sensor, having failed, provokes a change in the composition of the mixture, as well as in the idle speed.

- In the idle speed regulator, the rod often jams, provoking changes in speed.

- A malfunction of the RTM sensor (real time monitor) leads to a change in the composition of the combustible mixture, affecting the functionality of the engine.

Failure of any of the listed elements is associated with unpleasant consequences, causing failures and instability of the engine at idle.

Troubleshooting

Carburetor failure

Popping sounds from the carburetor indicate that the fuel level is too low, and a popping muffler indicates that the fuel level inside the float chamber is too high. In addition, a clear sign of a carburetor malfunction will be black smoke coming out of the exhaust pipe.

To solve the problem, you will have to remove the carburetor cap and carefully inspect the float. Then the fuel level is set and the dimensions of the float stroke are adjusted.

If the crankshaft speed (rotation speed) was not set at idle, adjustment is carried out on a warm engine using quantity/quality bolts. First, use the quantity screw to set the minimum permissible CV (rotation frequency) of the crankshaft, increasing it slightly.

After that, the maximum permissible frequency is set with a high-quality screw, and the screw itself is slowly tightened until the engine shakes. Then the quality screw is released ¼ turn. Having completed the adjustment, raise the throttle valve with sharp movements, repeating the procedure several times.

If there is excessive consumption of fuel and there is unstable engine operation, check the tightness of the needle valve design by turning the carburetor cover upside down with the floats and supplying the fuel pipe with a small piece of rubber hose. You need to try to create a vacuum inside the tube.

If there is no vacuum, you will have to replace the shut-off valve together with the seat. If the nozzle is clogged, the cover is removed from the carburetor and all remaining gasoline is removed from the chamber using compressed air. The jets are treated with a special cleaner designed for carburetors.

What is high engine speed

High revolutions can be defined as the engine working too hard, which is a deviation under idle conditions. In this situation, irregular fuel distribution occurs and the unit overheats. It is important that at the moment of startup, high speeds are not considered a breakdown. But after that they must fall.

High rpm can be determined in three ways:

- look at the tachometer. If its readings at idle speed exceed 950 rpm, it’s time to be alarmed. Although lower indicators may also be a cause for concern: it all depends on the design features of the internal combustion engine; if other indicators are the norm, this will be indicated in the technical passport;

- by ear (if the speed increases, the internal combustion engine begins to operate more noisily);

- a car with an injector has a special indicator on the dashboard (“Check engine”), which will light up in case of deviation.

Tachometer shows engine speed

Causes of uneven engine idling

Experts divide the main reasons for rough idling into two categories:

A malfunction of the air system (intake) can be considered separately, but it is more appropriate to include it in the list of problems with the fuel system. The fact is that both of them are inextricably linked and affect the stability of the power unit in idle mode and under load.

- Fuel-air system and fuel. A poor fuel-air mixture is often the reason why the engine idles rough. Such a “poor” mixture is that there is too little fuel in it and too much air.

A more serious problem can be considered a problem with the idle air valve (also known as the idle air regulator, the secondary air regulator), which is sometimes called the idle air sensor. Owners of carburetor cars also know this part as the “solenoid valve.”

Excess air can also be sucked in through, for example, broken holes in the throttle valve axis on the carburetor. In this case, the problem may not become noticeable immediately: gasoline consumption will gradually increase, and interruptions in idling will appear.

- Poor quality fuel. Because of it, the idle speed also often “floats”. This phenomenon is especially strong when using so-called eco-gasoline. It contains a certain amount of ethanol. Ideally, this not only makes the exhaust gases less toxic, but also helps clean the fuel system.

- The fuel pressure regulator (aka low pressure bypass valve) has failed. Its task is to maintain the required fuel pressure while the engine is running in any mode.

This breakdown is indicated not only by uneven engine operation at idle, but also by interruptions if you sharply press the gas pedal, a drop in power, and a strong increase in fuel consumption.

- The injectors are clogged (the channels are coked). Due to poor operation of the injectors, the fuel mixture is of inadequate quality in composition, which leads to disruptions in the operation of the power unit in different modes and increased fuel consumption.

- Air damper malfunction. This is usually a mechanical interference, which also leads to the formation of a poor-quality fuel-air mixture. As already mentioned, this causes the engine to run unevenly.

- The idle speed on the carburetor is not adjusted. In this case, under load the engine will operate normally, but at idle it will sometimes jerk, and at the same time there may even be a slight popping sound in the muffler. A relatively simple problem that you can deal with yourself by tightening the required adjusting screw.

Electrical problems

First of all, let's start with the ignition system. More precisely, the cause is too large a gap between the electrodes on the spark plugs.

Here the symptoms will be almost the same as with poor idle speed adjustment on the carburetor. The problem can be easily resolved by reducing the gap between the electrodes.

Unstable engine operation without load can also be caused by engine tripping. That is, one of the cylinders is not working.

Electronic control unit

This is a rarer reason, but it should not be excluded from the list, especially if the car is older than 15 years. During this time, anything can happen to the ECU - oxidation of contacts, broken tracks, damage to capacitors and resistors. It is possible that one of the damaged elements is responsible for supplying fuel or reading information from sensors. Only an experienced diagnostician can determine the essence of the problem. And since the ECU contains emergency sensor values in case of a malfunction, the engine may operate unstably at idle. The problem is especially aggravated when hot and under load, since standard fuel injection corrections are not suitable in this operating mode.

Electronic control unit

What's next? There are 2 solutions to the problem - repairing the old ECU board by resoldering damaged parts, or replacing the unit with a new one and then reflashing it. Simply “tossing” a block from another car will not work – adaptation of the immobilizer key is often required. You can start the engine only after “registration” of the old key into the new block.