The internal combustion engine consists of a housing, which includes a cylinder block and a cylinder head, connected to each other. The top of the cylinder head is closed by a valve cover, and the bottom of the cylinder block is closed by the crankcase. The cylinder head experiences thermal loads and pressure of 35-40 kg/cm2, is attached to the cylinder block with bolts or studs and is separated from it by a gasket. In the cylinder head, the inlet and outlet channels are designed for lubrication and cooling. Thus, the cylinder head is a fundamental component of internal combustion engines.

Manages the work processes occurring inside:

- valve operation,

- combustion chambers,

- circulation of lubricant, cooling,

- fuel supply,

- gas outlet

How the cylinder head works

It is a complex and sophisticated part of petrol and diesel engines. Cylinder heads in automobile engines are made of light metals or aluminum alloys and cast. Cylinder head components differ depending on the type of fuel the engine runs on.

Cylinder head components, purpose.

- Intake and exhaust valves are used to enter the air-fuel mixture and exhaust exhaust gases.

- Camshafts open and close valves and are driven by a timing chain or drive belt connected to the engine's crankshaft.

- Injectors (gasoline), through which gasoline is injected directly into the internal combustion engine;

- Injectors (diesel), used to inject diesel fuel directly into the combustion chamber or into the intake chamber;

- Spark plugs (gasoline) or glow plugs (diesel) initiate combustion in the engine (gasoline) or are a cold starting aid (diesel).

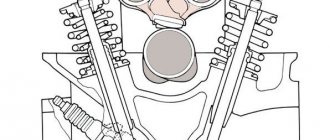

The photo shows the operation of a 4-stroke gasoline engine.

- In position 1, the piston is at bottom dead center; The camshaft cam opens the intake valve, the cylinder is forcibly filled (by the starter) with a mixture of gasoline and air.

- In 2 – the piston has reached the top point, with the valves closed, the mixture is compressed, the temperature and pressure in the combustion chamber increase.

- In 3 – the mixture ignites, gases are formed that push the piston down; power stroke, the crankshaft connected by connecting rods to the piston converts translational motion into shaft rotation.

- In 4 - the piston passes the lower point and moves upward by inertia due to the flywheel, the exhaust valve opens, and exhaust gases are discharged through channels into the exhaust pipe.

The compression temperature reaches 300-400°C, and the pressure is 0.1-0.15 MPa, and at the moment of ignition - 2500°C and 3-4 MPa. The presence of complex components in the cylinder head leads to expensive repairs if the problem is not corrected in time: knocking of valves, wear of camshaft cams, destruction of the gasket.

Cylinder head crack repair

There are different ways to repair a cylinder head and each of them has its pros and cons.

Crack welding is considered to be the highest quality and most effective. For repairs, a special material is used, which in its composition is close to the composition of the cylinder head, is able to withstand high temperatures and is resistant to expansion during heating and cooling. Welding a crack in the block head is carried out after careful preparation of the damage site. It is cleaned and deepened so that the seam has greater adhesion contact with the body of the block. The groove is expanded to 6-8 mm in depth and width. After this, the cylinder head is heated to 200-250 °C, this is necessary in order to reduce stress in the metal, as well as to avoid cracking of the seam during cooling and reheating. Welding is done either using a gas torch or using argon-arc welding. Upon completion of the work, the seam should be cleaned, milled and polished. Afterwards, the repair site is checked again and, based on its results, the head is either installed in place or subjected to re-repair.

The advantage of such a repair is its reliability; the seam is very strong, and new cracks no longer appear. The disadvantage of this repair method is that not everyone has welding, and besides, such repairs will cost much more than alternatives.

Less effective methods of repairing cracks are cold welding and pinning

The first option involves treating the damage site, deepening the crack for better contact, after which a layer of cold welding is applied to the crack. After cooling, the area is processed with a file, grinder or special attachments for a drill.

Installation of pins. The principle of repair using this method is to drill out the crack and install copper pins along its entire length. Each subsequent pin must overlap the previous one in such a way as to completely cover the joint. After the ends are trimmed, but not completely, the protruding remains of the copper pins are riveted with a hammer, forming a continuous seam. If necessary, the effect can be improved using epoxy or cold welding.

The advantages of such repairs are low cost and ease of implementation. Anyone can seal a crack in a cylinder head using cold welding; you don’t need any special skills to do this. equipment or skills. The disadvantages of the last two methods are that the seam is not as strong as in the case of welding.

Causes of cylinder head defects

The task of the cylinder head is to create an air-fuel mixture in the combustion chamber and ignite it at the right moment. Cylinder heads are not immune to damage. Defects arise, both initially unnoticed and during accidents or fatigue wear.

These damages are caused by the following factors:

- excess load on the cylinder heads;

- insufficient or incorrect maintenance;

- manufacturing defect;

- lack of protection against freezing and corrosion in the coolant circuit;

- inadequate lubrication.

How to check the cylinder head after grinding?

In principle, checking the cylinder head is not so difficult.

Clean the cylinder head from dirt, oil, and chips. Carefully inspect the head from all sides to ensure that there are no holes or cracks.

In specialized workshops, the plane of the block head is checked with a special template.

At home, when this template is not available, you can check the flatness with a wide, long metal ruler. It must be applied to the plane of the head with its edge; the figure shows in which places to apply it

And check the gaps with a feeler gauge. The gap is checked along the entire perimeter. Ideally, there should be no gaps. But if there is a gap of no more than 0.01 mm, then this is allowed.

I will emphasize and highlight: a new or ground cylinder head, the gap is exactly NO MORE than 0.01 mm.

Because if the gaps are left at 0.1 mm (this is the typo in some repair instructions), there will be a high probability of the head gasket breaking. And this again means disassembling and repairing the cylinder head, or even the entire engine, up to its replacement.

The cylinder head must also be checked for leaks. This can be done, for example, by pouring kerosene into the cooling cavity by plugging the liquid supply hole. Pressure testing is also done with compressed air at about 1.5 - 2 atmospheres, but this of course requires a compressor, a bath, that is, certain conditions.

When the head has been checked, ground, and again checked for flatness and tightness, then you can install the valves, having previously ground them in, and after assembly, also check them for leakage with kerosene. If the kerosene does not leak for about half an hour, then this is a good sign that the valve is ground in.

Of course, don’t forget to clean the cylinder block from carbon deposits, rinse it from dirt, clean and blow out all the channels. Wash the crankcase, the oil pump intake screen, and make sure the oil pump itself is working. Well, you can begin the final assembly of the motor.

Repair cylinder head defects in the workshop

Regular engine maintenance and care is important to prevent damage. Repair work on cylinder heads, such as replacing the cylinder head gasket, is complex and demanding. Work on adjusting valves, replacing components, repairing camshafts, selecting and adjusting spark plugs is performed by experienced mechanics in an equipped workshop.

This is what the main head looks like with the valve cover removed.

- – OHC cylinder head, exploded view of valve, seals, springs.

- – cylinder head, camshaft and bearing cap.

Repairing the cylinder head is labor-intensive and complex. Along with replacing the cylinder head, the gasket, engine oil, and coolant are changed. Check the timing belt adjustment.

How to check the flatness of the cylinder head.

Repairing a cylinder head, as you understand, is a long, tedious job that requires special care. If you think it’s like pissing two fingers, you’re very mistaken. I'll tell you why. First you need to remove the head; on some cars it is easier to remove the entire engine than to remove only the head. The removed head must be thoroughly washed with diesel fuel or, better yet, gasoline, but it would be very good to put it in a bath with caustic soda.

It is necessary to check the plane, for this I have a special ruler that is perfectly flat, made at the ultra-precision instrument factory specifically for measuring the unevenness of flat surfaces. How a person who doesn’t have such a device can measure the plane of the cylinder head, I don’t even know... But if you still find something suitable with a perfectly flat surface, then do the following: 1. Clean the plane of the head from carbon deposits, scale and remnants of the old cylinder head gasket. 2. On the cleaned cylinder head plane, place your “measuring device” along the length of the head and look at the gap between the device and the cylinder head plane, move the device along the entire plane, place it diagonally and look for the gap again. If there is no gap, then the cylinder head plane is in order; if there is a gap of 0.5-1mm, then it is better to trim the head or, if finances allow, to install a new one. if the gap is more than 2mm, then the head needs to be restored, that is, it must be trimmed. When facing the cylinder head, the curved layer of the plane is removed, after which the cylinder head can be used again. PS A driver who checks the engine oil at least once a week, seeing that the amount of oil has doubled and the radiator is half empty, will simply add more antifreeze to the radiator and move on, and in a few days he will be sent for repairs and spare parts.

What are the signs of gasket depressurization?

- White smoke comes out of the car's exhaust pipe.

- The oil level has been reduced for a short period of time.

- Milky engine oil if coolant is present.

- Engine oil enters the coolant circuit. This is assessed visually: the coolant looks darker and dirtier.

- Oil leaks from the cylinder head (often along with coolant).

- Increased coolant consumption over a short period of time

Signs of cracks

Damage to the cylinder head housing can be identified according to the symptoms. Let us consider in detail the symptoms that will allow you to check and determine the presence of microcracks.

Oil system

The first sign is mixing of engine and coolant fluids. As a result, an emulsion is formed in the power unit. Foam with a white tint appears on the surface of the oil. A film of lubricant forms in the coolant expansion tank. The same signs indicate damage to the cylinder head gasket.

Inlet channel

When cracks appear in the cylinder head, coolant will leak into the inlet channel. Because of this, the pistons of the power unit will be washed almost to a shine. You can see them by looking through the spark plug hole. If antifreeze gets into the intake channel, white smoke will come out of the muffler. But this sign is not always observed.

Release channel

If a crack appears in the exhaust duct, the refrigerant will pass through the pipe in the form of vapor. After warming up and before, the power unit will release steam, but you won’t be able to see it visually. Consumables leave the expansion tank. There will be no smell from exhaust gases.

The combustion chamber

Through the defect that appears, part of the consumable material will enter the combustion chamber, but its volume is usually insignificant. This is due to the large difference in pressure. During engine operation, the air-fuel mixture burns. This contributes to high blood pressure. Because of this, exhaust gases will enter the cooling system. As a result, the pressure will be higher.

This will lead to an increase in the volume of cooling system lines. And the smell of exhaust gases will begin to come from the expansion tank. While there is high pressure in the cooling system, consumables can enter the combustion chamber. There will be a vacuum and air intake here. As a result of the large pressure difference, coolant enters the combustion chamber. The main symptom is cleaned pistons, a smell in the expansion tank, and an increase in the volume of hoses. In this case, the radiator of the heating system will be cold due to the appearance of an air plug in it.

How to check the cylinder head gasket yourself

If the symptoms are not persistent, the cylinder head gasket is checked by the vehicle holder using a professional engine wash. When flushing the engine, mainly the oily dirt film that adheres to the engine is removed. If after washing, smudges form again, it is suspected that oil vapors are escaping and the cylinder head gasket is leaking.

Flush the engine thoroughly and, if possible, have a specialist do it. If this is done incorrectly, cables, control units and other parts may be damaged. In addition, modern engines are often installed in such a way that testing in this way is hardly possible.

Purpose of the cylinder head

In internal combustion engines, the cylinder head (cylinder head), (often called simply the head) is installed and secured to the cylinder block.

The cylinder head seals the cylinders, creating closed combustion chambers. A cylinder head gasket is installed between the cylinder head and the cylinder blocks. The design of the cylinder head can be different and vary significantly depending on the type of engine. Valves with springs, spark plugs and injectors are mounted in the block head.

Camshaft drive cylinder head

To drive the camshafts, the torque of the engine crankshaft is used. Types of drives in the picture.

(1) – Chain. Installed on Kia Rio or Hyundai Solaris of the previous generation.

(2) – Gear timing drive for V-engines.

(3) – Belt drive, installed on modern cars.

(4) – Toothed belt, manufacturers guarantee a mileage of at least 100,000 km.

What to look for when buying a cylinder head

Exact compatibility. Even with the same number of cylinders, the Opel Corsa D cylinder head is unlikely to be compatible with the head of the Audi A5 or Toyota Auris. The fit must be precise, especially since the required mounting screws and spacers will not match.

In addition, consider one more point when purchasing a cylinder head: specify your request using the original spare part code. Look carefully at the package, often the cylinder head is supplied without internals.

The cylinder head will serve you for the rest of the life of the car if you provide proper maintenance and care. Maintain coolant and lubricant. Cylinder head problems are associated with overheating and, as a result, gasket rupture. And this is not the worst option if you notice the danger in time. Well, you already know the signs of a damaged gasket.

Cylinder head: types of breakdowns, causes of their occurrence, solutions

advice for the driver and non-driver » How to properly operate a car

cylinder head: types of breakdowns, causes of their occurrence, methods of elimination

Main cylinder head malfunctions and methods for eliminating themIf you have special skills in repairing engines, in particular cylinder head, and can handle the work yourself, you should carefully consider all possible causes of malfunctioning of the unit and ways to eliminate them:

It should be remembered that any malfunction of the cylinder head will lead to disruption of the engine and provoke additional breakdowns. | |

| Category: Operating a car correctly | |

| Views: 19514 Date of publication: 03/10/16 |

Continue reading our auto magazine:

— What is a fuel card, which one to choose — Legal assistance in case of an accident — qualified protection for drivers — We properly care for the car’s bumper — We repair a broken tire on the road — The charming city of Sudak — How to organize the transportation of oversized cargo — Types of car rental: with or without a driver? — Motor oil Mobile 10w-40 – description, advantages, types — Road aggression — Spunbond will help preserve and increase the yield in the garden beds — OSAGO or what is motor vehicle liability? — Plastic plinth and all its advantages — How to get a microloan from a microfinance organization — How to accurately determine when it’s time to change the engine oil? — Choosing the right set of hubcaps for the car — Which electric bicycle to buy — More information about truck turbines and their repair — A profitable purchase of spare parts for the Volkswagen Passat: what’s the secret? — The best welder for the garage