Many drivers, especially beginners, wonder whether it is possible to effectively flush the injector with their own hands or whether it is necessary to contact a service station, that is, to knowledgeable specialists. The answer to this question depends on many factors, but in most cases, cleaning the injectors yourself is not a particular problem.

- Self-cleaning of injectors, video:

To work independently, some preparation is required. You need to know your car well enough to avoid making fatal mistakes.

You also need to stock up on the appropriate equipment, tools and chemicals, get advice from specialists, and carefully study the instructions for both the machine and the flushing fluid. After this, you can start cleaning.

It should be noted that cleaning injectors yourself is quite popular. The main incentive for the demand for this method of self-care for your own vehicle is the fairly high cost of the work.

A justified desire to save money leads to a search for other ways to solve the problem than going to a service station.

But here we need to pay attention to the other side of the issue. Improper cleaning may result in the need to purchase a new set of nozzles, which can cost tens of thousands of rubles.

When is it necessary to clean injectors?

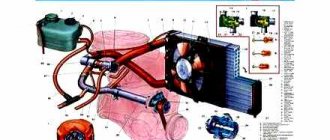

The injector is a fuel injection system. This is a rather complex unit. Depending on the specific case, in addition to the electric fuel pump, it includes a control system, pressure regulators, as well as many different sensors for measuring the parameters of fuel, intake air and other objects.

A significant disadvantage of the injector is that when using low-quality fuel, it becomes clogged quite quickly and does not work efficiently. Then the question arises about cleaning the injector.

Depending on the characteristics of the injection system and the fuel used, it is recommended to clean it after every 20 thousand kilometers or more.

But there are a number of signs that indicate that cleaning the injector is already necessary. These are the signs:

- fuel consumption has increased;

- the engine fails to achieve full power;

- smoky air comes out of the muffler;

- engine idling is uneven;

- The engine starts harder than usual;

- spark plugs are dirty.

Of course, there can be many reasons for engine performance deterioration. If in doubt, it is natural that it is better to contact specialists, a service station.

Causes

The reasons for the deterioration of the injectors are deposits on them. The result is incorrect atomization of gasoline, since the injector no longer closes completely. The filter cannot retain the entire volume of harmful substances. Therefore, the injector becomes dirty gradually. And before the driver realizes the complexity of engine failures, cleaning is already necessary.

If the engine is difficult to start, and problems are already diagnosed in idle mode, then problems with the injectors are obvious. Additionally, the gas pedal may fail. The engine is not as powerful, and the car accelerates much worse.

The injectors are exposed to high temperatures. As a result, resins are formed that contaminate the injector. It should be borne in mind that any gasoline leads to a similar outcome, since heavy hydrocarbons are contained in all its brands. The only difference is that when using gasoline of poorer quality, flushing will have to be done much earlier.

There are the following stages in injector malfunctions:

- with low contamination of up to 10%, the injector performance deteriorates. And although several liters more fuel is consumed, the engine continues to operate normally.

- With average pollution, the deterioration of indicators increases to 20%. Fuel consumption continues to increase, and interruptions in engine operation are already noticeable. The car is difficult to accelerate, and there is an unpleasant smell coming from the exhaust pipe.

- If the contamination is severe, the injector works half as bad. Several cylinders stop functioning. Popping sounds appear due to problems with the air filter.

Most car enthusiasts prefer to wash their injectors after 100 thousand km. However, a more optimal solution would be to carry out this procedure after 20-30 thousand km. It is especially recommended to do washing on the eve of winter.

Injector cleaning products

The liquid for flushing injectors should be selected carefully and accurately. If the choice is made incorrectly, then, as mentioned above, you will have to buy new injectors, and all attempts to save on the cost of work will be in vain.

The most commonly used injector flush fluid is Wynn's. The product, which is commonly called Vince, is considered potent.

It is most suitable for cases where the injector is very dirty and carbon deposits have formed on the valves and combustion chambers. Experts recommend using this drug for fairly old cars.

For new cars, Vince is undesirable, and in many cases it can be not only harmful, it can cause large unplanned costs. In any case, the spark plugs will definitely have to be changed.

On the contrary, LIQUI MOLY will save candles and you won’t have to change them. But this injector cleaning fluid is completely unsuitable for removing carbon deposits from the valves.

What's great about LIQUI MOLY is its versatility. It is not harmful to injectors.

Laurel flushing fluid resembles Wynn's in its effect on the injection system. But its main drawback is the cost. Due to its high price, laurel is rarely used by both professionals and amateurs.

The market offers a huge number of brands of flushing fluids for injection systems. It should be remembered that careful selection is especially important.

White spirit as an injector flush

One day, an uncle advised us to flush the entire fuel system (VAZ 2109) with white spirit.

He claimed that he even washed away carbon deposits from pistons (he checked). We washed it and bought a 0.5 bottle for two supply and return hoses, and it threshes at idle. The main thing is not to gas. when it devours everything, that means everything. After this procedure, the car became more lively! The actual question is how 402 will behave. And yet, is it possible to do this or will it ruin the engine? You can also remove carbon deposits on crab with water.

Well, the engine will probably run poorly on water :) I mean flushing the fuel without removing and disassembling it.

You don’t understand. Take a bottle of water. With the engine running, pour small doses into the crab and add gas at the same time. Carbon deposits are removed from the valves and piston steam.

White spirit is practically no different from kerosene. Naturally, it is not suitable as a fuel for gasoline engines; the octane number is very low. And the cleaning properties are high. So is penetration. IMHO, you can wash it without load, at low speeds. But the oil will have to be changed.

What we have is that after washing, immediately replace the oil and spark plugs. But is it worth it?

Added after 2 minutes 0 seconds You don’t understand. Take a bottle of water. With the engine running, pour small doses into the crab and add gas at the same time. Carbon deposits are removed from the valves and piston steam. Got it. got it!! THOSE. Then we also change the oil.

What we have is that after washing, immediately replace the oil and spark plugs. But is it worth it?

Added after 2 minutes 0 seconds

Got it. got it!! THOSE. Then we also change the oil.

No, there is no need to change the oil. After this flushing, the engine starts to run more smoothly. An old man in a taxi company taught me this method. I didn’t believe it either, and after removing the cylinder head, the valves were like new.

You don’t understand. Take a bottle of water. With the engine running, pour small doses into the crab and add gas at the same time. Carbon deposits are removed from the valves and piston steam.

be careful, otherwise it can lead to water hammer, and the neighbor in the garage permanently installed such a feature in the carb. and went. It even says gas savings!

Added after 7 minutes 4 seconds There is a valve cleaner for liquimol, fill the tank with 1 bottle for 40-70 liters of gasoline. It also smelled like white spirit, but the smell can’t be deceptive; you can’t analyze it; maybe there are some other chemical additives in there. In any case, a pre-tested item by the manufacturer. other than good, it won't do any harm. If it’s an injector, it’s better to combine cleaning and flush the throttle valve at the same time. After the tank rolls back, disconnect the battery terminal for a few hours or 2. From a cold engine, initialize the engine, auto-tuning with a new breath, the process lasts until the coolant fan is turned on/off, you absolutely cannot press the pedal.

Source

Equipment for self-cleaning the injector

It makes the most sense to use a stand for washing injectors . It is difficult to say whether it makes sense to buy factory-made equipment. It is quite expensive; for periodic work such a purchase is hardly justified.

But equipment for washing the injector without removing the injectors can be made independently, mostly from scrap materials. For this you will need:

- an ordinary two-liter mineral water bottle;

- two meters of rubber hose;

- two nipples, such as those found in tubeless tires;

- four clamps for fastening the hose;

- liquid pump with pressure gauge;

- terminals, wires and other accessories.

Of course, the installation of such components will be too simple, but it works, in some cases no less effectively than industrial equipment.

You can purchase a ready-made system, or borrow it from friends. Once you have decided how to clean the injector nozzles at home, you should begin the cleaning process.

Do-it-yourself injector washing, video:

Instructions on how to wash injectors yourself

The number of drivers is growing every year, as is the income of numerous services and workshops. Unfortunately, many of them are simply “riders” who do not have the slightest idea about the functioning of their car.

Proper and timely maintenance of your car is a guarantee of safe, accident-free driving. Following the advice of experienced specialists, any car owner can wash the injectors without any problems.

With the engine running

This method allows you to clean not only the injectors, but also has a beneficial effect on the piston rings, freeing them from coke.

Flushing is carried out only with the engine running:

- For an effective procedure, you will need a plastic two-liter bottle, in the lid and bottom of which holes with a diameter of 12.5 mm are drilled.

- Two nipples for tubeless tires are inserted there.

- The car's fuel hose is connected to the upper one, and the compressor hose is put on the lower one to build up pressure.

- An injector cleaning agent is poured into the bottle and air is pumped to a pressure of 2-2.5 atmospheres.

- This design is attached to the hood with the neck down.

After this, the engine starts and continues to run until the flushing fluid is completely used up.

With removal of injectors

This method is relatively complex, since it requires dismantling all the injectors and wires. This method, using a car battery, a 9-volt battery, wires, and a thin syringe needle, simulates the operation of each individual injector.

For this procedure, an injector cleaner is used. The results of such a point method are characterized by efficiency and quality.

Chemical cleaning of the injector

Methods for chemically cleaning an injector include not only the use of the liquids described above. There are, for example, special fuel additives that to some extent clean the injectors and remove carbon deposits from the valves. But this is more of a preventive remedy; in case of severe contamination, it is not very effective.

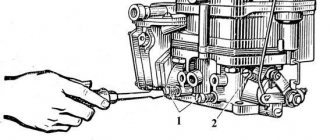

Washing injectors without removing them from the engine consists of a number of steps.

- First of all, you need to turn off the fuel pump. To do this, it is enough to wait until the engine stalls on its own while the engine is running. The pressure in the fuel system will be relieved, you can begin to perform the main stages of work.

- Next, you need to connect the homemade installation hose and tighten the connection with a clamp. The clamp should fit securely enough so that there is no rupture during operation. The pressure in the system will reach approximately three atmospheres, so you should be careful.

- Return overlap. If this is not done, injector cleaning fluid may enter the tank, which is undesirable.

- Filling the flushing liquid into the container intended for it.

- Connecting the liquid pump to the power supply.

- Main stage. Before flushing the injectors, you should once again make sure that all connections are secure. At this stage, an assistant is needed to start the engine. Now you should start the liquid pump, bringing the pressure to three atmospheres. That's it, the cleaning process has begun. Depending on the amount of flushing fluid used, cleaning the injectors will last from ten to twenty minutes. The standard amount of Vince per car is 500 milliliters. You just need to wait for it to end.

- Visually check the exhaust. If cleaning is effective, there should be no smoke at the end of the injector flushing process.

- Replace spark plugs if necessary.

- Finally, you need to turn off the homemade injector washing device and restore the system, that is, connect all the hoses, connect the fuel pump fuse, and the like.

- Check engine operation after flushing. If previously detected problems no longer appear in any way, then the flushing was carried out effectively.

Experts say that high-quality injector flushing can significantly reduce fuel consumption. It would probably be more correct to consider bringing fuel consumption back to normal. In any case, there is the possibility of significant savings on gasoline or diesel fuel.

Self-cleaning of diesel injectors is carried out in exactly the same way as flushing gasoline injectors. The homemade installation described above is quite suitable, and so is the operating algorithm. Of course, cleaning diesel injectors requires careful selection of flushing fluid and a certain amount of accuracy in work.

You can also wash the injectors yourself by removing them from the engine. There is a special spray for this, and the cleaning installation is different from the one described above.

You can wash the injector with your own hands this way, and quite effectively, but it is a longer and more complex process.

Self-cleaning of injectors, video:

Washing methods

To flush the injector, there are two solutions for cleaning the injectors:

- ultrasound procedure on a special stand;

- use of liquid.

In the first option, ceramic, old and very dirty injectors are excluded, since there is a risk of damage. Separately, after such a procedure, it is worth replacing the microfilter and sealing rings. Such parts are not cheap.

The second option involves washing the injectors without removing them from the engine. This method helps save money.

Flushing procedure

To carry out high-quality washing, you should have a second fuel pump, a container for cleaning fluid, a hose and the actual injector cleaner.

Adding rinse directly to the tank is not effective enough. Carefully remove the hoses and prepare a temporary power supply system.

Such a system, when supplying liquid to the injectors, acts as a fuel pump, but instead of gasoline it supplies the prepared solution. To create the system, a cleaner is poured into a plastic bottle. The calculation of the required quantity is related to the engine size. The template is a 2.5 liter unit, for which a liter of liquid is used. For larger volumes, the amount of solution is increased by 100 grams for every 0.5 liter of unit.

Gasoline is poured into the wash. It is taken in half the total volume of liquid. A hose is put on the bottle and secured with a clamp. The prepared fuel pump is inserted into it. The engine starts and warms up to operating condition. Next, remove the fuse from the fuel pump.

The engine is restarted. This relieves pressure from the fuel system. Then the hose is removed, through which gasoline is supplied to the injector. It is in its place that the fuel system bottle is fixed. When the fuel pump is turned on, it pumps fluid.

After running the engine for five minutes, it is allowed to rest. This time is enough to dissolve deposits on the injectors. At the next stage, the motor runs for half an hour. After disassembling the system, the engine should run for another 10 minutes. The remaining liquid burns off.

The selection of cleaning fluid should be approached very carefully. There is a demand for various brands in the market.

The optimal fluid for many types of engines is LIQUI MOLY. It is well suited for cleaning injectors without removing the engine. A soft effect has the disadvantage of leaving carbon deposits on the valves.

Wynn's can remove any carbon deposits and resin deposits. It is quite caustic and suitable for cars made in the 2000s. But to use it, it is necessary to check the characteristics for a particular car so as not to harm the injector.

Gentle and high-quality cleaning is provided by the less popular Carbon Clean brand.

But Laurel repeats Wynn's in its characteristics, but due to the high price it is used much less often, only it costs much more, so it is used less often.

Cleaning nozzles in ultrasonic baths

An ultrasonic bath for cleaning injectors is quite expensive equipment; it is used only at service stations.

The injectors must be removed from the engine and placed in such a bath. There they are cleaned using the cavitation effect. The cleaning process itself is multi-stage. After the first stage, the quality of the cut and the level of productivity are checked on a special stand.

Then another wash follows, followed by another check, and so on until the required result is achieved. One of the criteria for the readiness of injectors for further operation is a slight difference in their performance. It should be no more than one to three percent.

After the washing in the ultrasonic bath has been successfully completed, the sealing filters and rings must be replaced, if necessary.

Like all processes, ultrasonic injector cleaning has its pros and cons.

One of the main advantages of this method of cleaning the injector is the ability to remove very strong contaminants. Where liquid flushing simply won’t help, ultrasonic flushing can do the job.

But this method is far from omnipotent either. It happens that it is impossible to wash the injectors. This happens especially often if water gets into the fuel tank or the car has not been used for a long time. In this case, the service station will offer to check the injectors on a stand to determine whether they can still be used or should be replaced.

Reviews about ultrasonic cleaning of injectors are often negative. There are reasons for this when the service station employees incorrectly determined the method of cleaning the injector. It may well be that washing injectors from a car that was produced quite a long time ago in an ultrasonic bath can be effective.

At the same time, the use of such a potent agent on relatively new products can lead to disastrous results. The injectors may simply fall apart.

The quality of ultrasonic cleaning of injectors depends on many factors. This is the selection of equipment, the more modern it is, the better. This is also the selection of liquid with which ultrasonic baths are filled.

But the main thing remains the human factor. The qualifications of the service station employees, as well as their conscientious work, will determine the quality of ultrasonic cleaning of the injector.

Flushing frequency

The atomizer for direct injection of fuel into the cylinder is a fairly reliable device and, when using high-quality gasoline, reliably serves about 100-120 thousand kilometers. But since there have always been problems with fuel quality in the post-Soviet space, signs of contamination of small holes in the injectors appear much earlier:

Here are the clear signs that it is time to urgently clean the injectors due to a high degree of contamination. But flushing after a long interval (more than 50 thousand km) can lead to a negative result and the replacement of these parts, which you need to be prepared for.

Premature wear of nozzles occurs like this: due to dirt that has accumulated under the valve for a long time, a hole forms in its parts . After removing this dirt, which acts as a kind of seal, the injectors lose their tightness and begin to leak when the engine is turned off, although they behave well while driving. Because of this, the engine is difficult to start (especially in hot weather), and the oil in the crankcase is diluted by gasoline flowing there, that is, one “disease” is replaced by another. There is only one way out - change the nozzles.

Preventative flushing of the injector, performed once every 5-20 thousand kilometers, will protect you from getting into such a situation. But if the above symptoms appear, be sure to undergo diagnostics at a service station. You should make sure that it is the injectors that are acting up and that some sensor has not failed.

What are the signs that indicate a problem with the injectors?

- car engine has difficulty starting

- The engine may run unevenly at idle

- when you press the gas pedal sharply, a sharp decrease in speed is possible

- the car takes longer to accelerate

- increase in the level of exhaust toxicity (checked at a service station)

- noticeable increase in fuel consumption

These problems are especially pronounced in the winter season. Low temperature additionally affects the fuel, making it more viscous, which reduces the throughput of the injectors.

Stages of work:

- Run the engine until it reaches operating temperature

- Disconnect the fuel pump fuse

- Start the engine several times to reduce the pressure in the system

- Connect the external fuel pump to the fuel supply pipe, hang the return hose on the pressure regulator and lower it into the container with the fuel pump.

- Pour washing liquid into the container

- Turn on the fuel pump to check the tightness of the connections

- Run the engine for half an hour.

- Upon completion of work, remove the system for flushing and restore standard equipment

- Connect the fuel pump fuse.

- Change spark plugs

- It is recommended to change the engine oil after flushing. Injector cleaning fluid can get through the oil scraper rings and drain into the pan.

To make work easier, you can periodically use special engine additives as a preventive measure.