Despite the fairly large number of varieties of suspension types, most modern cars use only those subcategories in which the main damping element is either powerful springs or hydraulic shock absorbers with a telescopic mechanism. Pneumatic devices have not yet become widespread. Their primary area of use is commercial vehicles or passenger cars, which belong to the premium class. It is not surprising that many motorists are simply not familiar with this type of suspension. Our task is to give the reader an idea of what it is, how it works, what advantages and disadvantages it has.

The purpose of air suspension in a car.

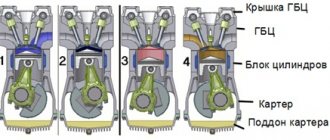

Air suspension diagram

Air suspension is used in two cases: to increase comfort and when there is a large difference between the curb and maximum vehicle weights. In trucks, it is built into a complex pneumatic circuit along with brakes ( ZR, 2012, No. 7 ). For passenger cars, the system includes body level sensors, a tank receiver for storing prepared air, a compressor with a dryer and a temperature sensor, an electronic control unit, solenoid valve blocks, as well as the pneumatic elastic elements themselves. The air movement pattern is simple. The compressor sucks it in from the atmosphere and, driving it through a dryer, fills a receiver with a capacity of 5–10 liters. Here it is stored under pressure, reaching 20–23 bar during operation. To get rid of moisture, absorbent granules are used.

Application of air suspension

The simplest pneumatic systems (which, by the way, does not mean cheap) can only be installed on the rear axle. Often such solutions can be found on station wagons and large crossovers. The system assumes periodic increased load on the rear axle, so it adjusts the ground clearance and suspension stiffness depending on the load. Basically, such schemes work in tandem with the Multilink multi-link, but can also be used with MacPherson struts. Moreover, such an air suspension allows you to “lower” the car as much as possible, which greatly simplifies loading and unloading.

Mercedes air suspension control buttons

However, most often pneumatics are installed on all four wheels. This makes it possible to more flexibly control clearance. This design is used not only on expensive crossovers, but also on sports cars, where every millimeter of ground clearance will affect aerodynamics and, as a result, speed and handling.

In recent years, the design of air suspension has become increasingly reliable, which makes it possible to install it not only on expensive cars in the premium segment. The use of air suspension allows you to make driving more dynamic, increase the smoothness of the ride and the level of comfort. This is achieved due to the ability to change the position of the body and the degree of damping of the shock absorbers.

Recommendations

- Often the first things to fail on cars with air suspension are the air struts. At the same time (especially if the cylinders are open), you can slightly increase the service life of the cushions by regularly washing the cylinders in a high-pressure washer. This statement is true for both cars and SUVs.

- If problems arise with the tightness of the cylinders, you should not delay replacing them, since the compressor will constantly turn on to maintain pressure and overheat.

If the air leak is severe, in this case the compressor will often turn off, since the system turns on overheating protection, and the body will not be able to return to its normal position. We also recommend reading the article about which shock absorbers are best to choose for a car. From this article you will learn about the features of selecting racks, as well as what parameters and characteristics need to be taken into account. - Taking into account the high cost of assembled air struts, some car owners carry out handicraft restoration of air suspension. This method seems attractive in terms of cost, but it also has a number of serious disadvantages. It must be remembered that during restoration the air spring is repaired (sealing), while the shock absorber often remains worn out.

- Today you can buy air suspension separately for different cars (for the purpose of modernization, tuning and modifications for specific tasks).

It is important to understand that high-quality installation of air suspension is a complex procedure and will often require the involvement of third-party specialists. For this reason, if you absolutely need air suspension, it is easier to immediately buy a car equipped with this type of suspension than to modify the car yourself. - Restoration of air struts does not allow us to talk about reliability; the air can still begin to “poison” a little over time. The result is insufficiently efficient operation of the air strut as a whole, changes in stability, deterioration in controllability, increased load on the compressor, difficulties with calibrating the body position, etc. For this reason, the best solution would be to replace the air struts with new original ones, in pairs on the same axis (similar to conventional shock absorbers). This method guarantees the normal operation of the entire system throughout the predicted service life of the part.

Malfunctions and repair of pneumatic air on a car

When operating a car on air, you need to pay attention to the main signs of air suspension malfunction. Symptoms of malfunctions include:

- the front and/or rear end lowers when the engine is off;

- when starting the engine, only the rear or front part of the car rises;

- after starting the engine, any side does not rise; a hissing sound may be heard from outside the car;

- the front part rises higher than the back part;

- during active driving, the front part lowers, but after stopping it rises higher than the rear part;

- the ground clearance constantly changes, the body cannot take the desired position;

- there is no way to change the ground clearance, it is not possible to turn on the service mode to repair the air, it is not possible to do a wheel alignment;

Often the air suspension fault icon lights up on the instrument panel. This notification informs the driver of problems and may also indicate that the air is operating in emergency mode.

As a rule, the main problems are associated with the following malfunctions:

- air leakage through air cylinders or connections;

- wear of compressor piston rings;

- malfunctions of sensors and control electronics.

Air suspension repair

Depending on the type of malfunction, the air suspension is repaired.

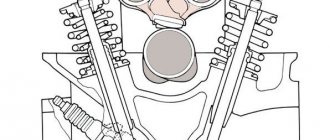

Often, air cylinders or air struts fail, since their official service life is about 100 thousand km, but in practice problems can arise already at 50-60 thousand km. This is especially true for open-type air springs. Simply put, a cushion or pneumatic chamber is a high-pressure rubber sleeve that stretches or collapses along a guide piston, which allows you to change the linear length of the shock absorber to change the ground clearance. Over time, the frame and then the rubber wear out, and the cylinder begins to leak air.

We also recommend reading the article on how to check the shock absorbers on a car with your own hands. From this article you will learn about the available ways to check struts on a car.

As a result, the car lowers, the struts do not hold pressure. By the way, the load on the compressor increases greatly, since it needs to constantly maintain pressure. In such a situation, the air cylinders need to be changed as soon as possible, since after a short period of time the expensive air compressor will additionally need to be repaired or replaced.

We also note that in addition to the cylinders and compressor, the pneumatic valve block, discharge valve or fitting may fail. There may also be problems with the height sensors, suspension control unit or highway.

Main advantages

Considering the air suspension design, we note the advantages of this system as a whole:

- Possibility of adjusting ground clearance. The main parameter for which motorists choose this suspension.

- Independence from the total vehicle load. The car does not sag on the cushions, even if there is a large load on board.

- Greater smoothness. Unlike springs with shock absorbers, cylinders completely absorb all shocks that occur when driving on uneven roads.

- Ease of management. The driver can adjust the desired ground clearance directly from the cabin, thanks to the control panel. On trucks, it has a coiled cord that allows the driver to control the raising and lowering of the axle on the street. This is especially important when hitching a semi-trailer.

- Easy to maintain. There are no complicated parts in the system that need to be periodically lubricated, changed or adjusted.

The air suspension design is such that the system can be fully adapted to road conditions and axle loads of the vehicle.

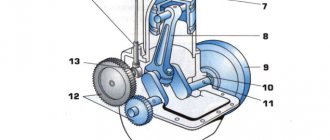

Air preparation unit

These are some devices with which you can supply compressed air to the air suspension and monitor the pressure in it. Single-circuit - pneumatic elements located in the system are connected to each other Double-circuit - pneumatic elements are separated into two circuits. If only one axis is pneumatized, then the division is made into a right and left circuit. This makes it possible to get a stiffer suspension or level the car with uneven loading. In the case of pneumatization of two axles, there are two circuits - the front and rear axle. (front and rear cannot be connected, since usually the pressure in these circuits is different) Four-circuit - only when the entire car is pneumatized. Each pneumatic element has its own pressure. Improved driving performance, the ability to level the vehicle with uneven loading. Possibility of building an active suspension with a controller. From simple to complex. — You can limit yourself to only a nipple for inflating pneumatics with a pump or compressor (what is a compressor?), but we must not forget that some systems operate at a pressure of more than 8 a](what is “Bar”?)[/anchor] and you (or your compressor) will have a hard time raising that pressure. If you mainly move around the city, then you can use the services of gas stations. You can carry a cylinder of compressed air with you - but where is the guarantee that you will have enough air for your trip? — A primitive pumping system - the compressor directly pumps into the air cylinders, and you can release the pressure through the air nipple. The kit includes a pressure gauge (what is a pressure gauge?) to display the pressure in the system. This is a cheap, convenient and small-sized system. It will allow you to fully enjoy the air suspension on your car and does not exclude the possibility of a subsequent upgrade. The number of circuits is unlimited. — Systems with a receiver are a preparation unit that works something like this: The compressor pumps compressed air into the receiver and automatically (only when the engine is running) maintains the specified pressure in the receiver. You use a pneumatic distributor (mechanical (pneumatic buttons) or electromagnetic) to distribute the pressure in the pneumatic elements. These systems can differ in the size of the receiver (the minimum air supply is calculated based on the type of pneumatic element used and the operating pressure, or based on the rule - there should be enough air in the receiver to rise from the minimum position to the working one). The volume of the receiver used dictates the type of compressor that needs to be installed. They all differ in performance, max pressure (10-14 Atm) and non-stop operating time. The larger the receiver, the larger the compressor and therefore the more expensive the system. Pneumatic distributors also differ in type and flow area, and to select the one you need, you must clearly formulate the tasks that you set for pneumatics. For example, a system with pneumatic distributors will consist of the following pneumatic elements: 1. Compressor 2. Check valve 3. Compressor relay 4. Receiver 5. Sensor for automatically maintaining pressure in the receiver 6. Pressure gauges and control keys (pneumatic key, electric key) 7. Pneumatic distributor block 8. Pneumatic line tubes