Design Features

Despite its simple design, the pump of any car, including the VAZ 2110, is a fairly loaded element, all due to the same drive, so it can easily fail. The culprit is usually the pump bearing.

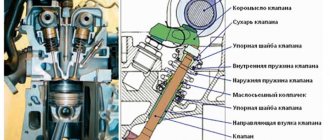

Essentially, the pump consists of:

- shaft;

- housings;

- bearing;

- oil seals;

- gear and impeller.

Advertisements

Everything is simple - a gear is mounted on the shaft on one side, and an impeller on the other. Between them on the shaft there are a bearing and seals, which are located inside the housing.

This housing attaches the pump to the cylinder block. In this case, the impeller is located inside the cooling jacket, and the gear is outside it. The timing drive causes the gear to rotate, and along with it the impeller, since they are mounted on the same shaft.

In this case, the gear does not contact the drive with its entire working surface, but only half.

And since the timing belt must be constantly tensioned, the pump bearing constantly experiences a one-sided load, which ultimately leads to its failure.

This, in general, is the main reason for the breakdown of the water pump in the VAZ-2110 and not only.

DIY pump repair VAZ 2110/2112

The driver does not always have the opportunity to replace a faulty pump. In some cases, it is possible to repair the device by restoring the operating functions of the pump. If the pump has not yet exhausted its service life (50 thousand kilometers), then you can repair it. However, the pump cannot be repaired without using a special repair kit. This is a set of rubber gaskets and parts that most often fail and need to be replaced.

Repair kits for pumps may vary in composition, depending on which spare parts need to be replaced

In addition, you will have to thoroughly prepare for repairs: the place for disassembling and repairing the pump must be clean and level.

How to disassemble a water pump

Once the pump is removed from the machine, it will need to be disassembled. Only after disassembly and thorough cleaning will it be possible to replace the leaked parts of the pump.

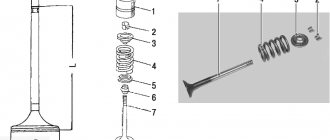

To disassemble the pump, it is recommended to follow the following diagram:

- Wipe the product with a dry cloth.

- Unscrew the pump pulley.

- Pull out the thrust ring.

- Use a hammer to knock out the bearings from the shaft.

- Pull the shaft itself out of the housing.

- Unfasten the impeller.

- If something remains from the oil seal, then remove the remaining rubber from the housing.

The procedure for disassembling the water pump is intuitive: until you remove the pulley, it is impossible to get to the shaft and impeller

After this, the cavity of the pump itself must be thoroughly cleaned of dirt and old deposits - you can wash the pump with the same gasoline that is usually filled into the VAZ 2110/2112 tank.

A visual inspection of the pump parts will show which element needs to be replaced. Typically, a pump leak is caused by rotting of the oil seal, and a whistle when the engine is running or a grinding noise at high speeds is caused by wear of the shaft.

Video: disassembling the pump

Replacing the oil seal

An oil seal is a gasket made of rubber and metal inserts. During normal pump repairs, changing the oil seal is included in the list of mandatory procedures, since the gasket is a rubber product in its structure, and therefore wears out quickly.

Replacing the oil seal is not difficult:

- The old gasket is removed from the shaft.

- The landing site is cleared of dirt.

- A new oil seal is installed.

The rubber-metal product that ensures the tightness of the pump is called an oil seal.

Before installing the rubber seal, you can lubricate it with antifreeze so that the oil seal quickly “grinds” to the shaft.

Changing the shaft with bearings

Most often, it is the bearings that have become loose that need to be replaced. But knocking them out of the shaft is a very tedious task. In addition, a hydraulic vice is required, which not every driver has. Therefore, it is easier to replace the bearings along with the shaft.

Again, the procedure for replacing the shaft is not associated with difficulties: a new one is driven in in place of the old shaft.

It is not possible to knock out the old bearings from the pump, so it is easier to replace the shaft along with them

How to replace a pipe on a pump

Sometimes, due to unstable pressure in the cooling system, the antifreeze supply or discharge hoses may become deformed. New pipes cost pennies, and new metal mounting clamps are not difficult to buy.

If the pipe is swollen, this is a clear sign that the rubber will soon burst. Cracks and dents in the tube also indicate the need for prompt replacement.

To make a replacement, you must:

- Use a screwdriver to loosen the clamp.

- Remove the clamp.

- Disconnect the pipe from the pump.

- Loosen the clamp on the back of the pipe and remove the fastener.

- Remove the pipe from under the hood.

The clamp, when compressing the pipe, can severely damage the rubber, which can cause antifreeze leaks

Pump location

On the VAZ 2110/11/12 the water pump is located on the cylinder block on the right side. This is due to the design features of the gas distribution mechanism, since the impeller begins to rotate only after the engine and timing belt are started. That is, the design of the gas distribution mechanism initially involves the use of a pump.

The water pump is part of the timing mechanism and is installed on the right side of the cylinder block

Pump installation

The new pump is installed in its place, after which its plastic casing is mounted and the camshaft pulleys are secured. Next, the timing belt is put on - experienced motorists use the marks previously applied to the camshaft for correct installation. By turning the engine, the belt tension is corrected. After installing the pump, it is necessary to add the required amount of antifreeze to the system.

Why do you need a pump in a car?

If we talk about the operation of a car engine, then we immediately touch upon the topic of its cooling. Indeed, without high-quality cooling, the engine will not be able to work for a long time and will definitely “boil”. Thanks to the circulation of coolant, it becomes possible to operate the engine at any time of the year under any external conditions.

The power component on the VAZ of the tenth family has a rather complex structure. During the working cycle, the pistons rub strongly against each other, which invariably leads to strong heating of the surfaces. The only way to prevent engine overheating is to constantly maintain the desired temperature in the friction zone through the circulation of coolant and. It is for this purpose that the VAZ design includes a cooling system.

The design and operating features of the VAZ 2110 engine cooling system are described in detail in this material: https://vazweb.ru/desyatka/dvigatel/sistema-ohlazhdeniya-dvigatelya.html

Coolant (antifreeze or antifreeze) is poured by the driver into the expansion tank of the car. From it, the liquid is transferred through pipes to the water pump, and from there it goes to the radiator and cylinder block. The water pump (or pump) is designed to pump antifreeze through the system while the engine is running. That is, the pump starts together with the engine and turns off after the driver turns off the car. Without a pump, the entire cooling system can be considered ineffective, since only the pump can create rapid circulation of liquid throughout all parts of the system.

The pump is designed to create the necessary pressure in the cooling system to move the liquid.

The device in a metal case ensures continuous circulation of antifreeze through the cooling system

Installation of an additional pump on a VAZ 2110/11/12

The interior heating system in VAZ 2110/11/12 cars often fails to cope with its responsibilities in the cold season. This problem can be solved by installing an additional pump in the cooling system.

To heat the interior of the VAZ 2110/11/12, an additional electric pump from GAZelle is installed

The VAZ 2110/11/12 stove functions normally only at speeds of at least 2 thousand rpm. At idle, slightly warm air enters the cabin. The fact is that to increase the air temperature, the coolant must circulate faster. The problem is solved by installing an additional pump and accelerating the circulation of antifreeze through the stove. As a result, the temperature in the cabin ceases to depend on engine speed. For these purposes, an electric pump from a GAZelle is installed.

Installation of an additional pump

To install an additional pump, you need to do the following:

- Coolant is drained from the cooling system.

- A part of the outlet pipe of the stove is cut out, equal to the length of the pump without taking into account the fittings.

- The fittings are coated with sealant, the hoses are put on and secured with clamps.

- To attach the pump to the body, use a special bracket that wraps around the pump and is attached to the body with two self-tapping screws. You can make such fasteners yourself or purchase them in a store. The bracket can also be attached to suitable studs on vehicle components.

- To control the pump, a button is installed in the cabin that supplies power from the positive terminal of the battery. In this case, it is advisable to supply voltage through a relay.

The additional pump fits into the return pipe of the stove and is secured using a special bracket

After installing the additional pump, antifreeze is poured into the system. After starting the engine, check the pump and pipes for leaks and test the operation of the new device.

Video: installing an electric pump

Thus, replacing the water pump on VAZ 2110/11/12 cars is not very difficult. Timely replacement and periodic maintenance of the pump will save you from much more serious problems.

Resource

The pump does not seem to be a consumable, but still it is also subject to periodic replacement. But unlike consumables, it does not have a specific resource.

One pump can run 100 thousand km, but the other won’t reach 20 thousand km. It all depends on the quality of manufacture of the part itself, as well as on the correctness and frequency of maintenance, namely, checking and adjusting the tension of the timing belt.

An overtightened belt can shorten the life of the pump, significantly.

What will happen if you don't replace your pump in a timely manner?

But if you do not replace the VAZ-2110 pump (8-valve injector) in a timely manner, you can get the following consequences:

- Broken or damaged timing belt. More serious repairs will have to be carried out, since very often the integrity of the valves or even the cylinder head is compromised. Sometimes even the pistons become unusable.

- The engine heats up excessively, the integrity of the rubber elements - pipes, gaskets - is damaged, the cylinder head gasket, valve cover, and piston group components are destroyed.

The price for replacing a pump on a VAZ-2110 (8 valves) in workshops is about 1500-2000 rubles. The more complex the repair, the more expensive it is. If the timing roller and belt need to be replaced, the cost increases.

It is worth noting that you can replace the pump on the “ten” yourself, this will not cause any difficulties.

Signs of a pump malfunction

Thanks to the rotation of the pump driven by the timing belt, the impeller circulates a special fluid (antifreeze, antifreeze) through the small and large circuits of the cooling system. A damaged pump can cause the engine to overheat or cause the timing belt to break. To avoid an emergency on the road, you should do preventive repairs on time. On a VAZ 2110 with an 8-valve engine, the omen of replacing the pump can be recognized by the symptoms described below.

How to check the pump on a VAZ 2110/2112

The driver, if there is a suspicion of a malfunction of the water pump, can check this unit without going to a car repair shop. In this case, there is no need to remove the pump from the car; the entire verification procedure is completed within 10 minutes:

- Warm up the engine to normal operating temperature (on a VAZ of the tenth family - 91 degrees).

- Put a glove on your right hand.

- Pinch the fluid supply pipe that comes from the radiator with your hand. If the pump is working normally, you will immediately be able to feel the pressure of the antifreeze inside the pipe. If, when pressed, the hose easily compresses, then the circulation of coolant is severely inhibited, which indicates a breakdown of the pump.

To identify pump malfunctions, it is enough to squeeze the antifreeze supply pipe - if the hose resists compression, then the pressure in the system is stable

When performing the check, you must be careful, since the antifreeze gets very hot during engine operation: you can get burned on the hot pipes and surfaces of the engine.

Symptoms of malfunction

There are several signs of a pump breakdown, and they can be obvious, or the fault can only be determined after diagnosis.

Signals that the water pump has become unusable are:

- Increased noise when the engine is running from the timing belt side, a squeak is possible;

- A constant and significant decrease in the coolant level in the expansion tank and traces of coolant leaks from the crankshaft drive pulley;

- Strong pump play.

As can be seen from the list, all these signs are caused by severe wear of the bearing and seals.

Some argue that a pump malfunction leads to an increase in temperature during operation of the power plant.

But this happens in very rare cases when, due to corrosion, the impeller blades are almost completely destroyed. Because of this, the pump simply physically cannot impart movement to the liquid.

But such a malfunction is an isolated case; in general, the pump cannot affect the temperature regime due to the fact that it is constantly in motion.

But ignoring the problem with the pump’s operation will also not lead to anything good.

In the best case, the bearing and seals will wear out so much that they will not prevent the coolant from flowing out at all.

And since there is a drainage hole in the pump body, the antifreeze will drain through it quickly, and this can actually lead to overheating of the engine.

It is much worse if the bearing collapses due to severe wear and leads to jamming of the pump.

The result of this is a belt rupture and possible collision of the valves with the pistons. And this is already a major expensive repair of the power plant.

Recommended.

Check the pump every time the drive belt is replaced. Well, if any of the signs of malfunction appear, you should immediately check the condition of the pump and, if necessary, replace it.

Let us note here that increased hum and squeaking can be caused not only by the pump, but also by the tension roller, so the pump is not necessarily the cause of the noise.

But if a faulty element is identified, it is worth checking both of these details. Fortunately, they are located nearby, so it is not difficult to determine whether the pump or the roller caused the increased noise.

How to check the cooling system pump?

By checking the pump without removing it from the engine, we can only indirectly assess its performance. When the volume of pumped coolant decreases, the stove begins to heat poorly. But before removing the water pump to inspect the impeller, we recommend checking the thermostat and also making sure that there is no air lock in the cooling system.

After removal, pay attention not only to the integrity of the blades and where the impeller fits on the drive shaft, but also to the shape of the blades. For example, on the VAZ 2121 over many years of production, impellers were installed that differed in the diameter of the pump wheel, the number and profile of the blades. Installing a less efficient pump on a more heat-loaded engine modification will result in the cooling system fan turning on more frequently and an increased risk of overheating.

Be sure to inspect the engine block where the housing fits and the pump itself. Fogging or a slight leak of coolant from the drain hole does not mean that the pump should be replaced. If a significant leak is detected, try to pinpoint the location of the leak. If the leak is only at the junction of the housing and the engine block, most likely the problem can be eliminated without replacing the pump. It will be enough to apply sealant and install a new gasket.

Risk of timing belt breakage

The danger with a misaligned water pump timing belt is that there are no obvious signs of failure. First of all, you need to pay attention to the timing belt. If it is pulled to any side, uneven production is observed, it is necessary to check the pump and rollers. The cause of the misalignment may be a manufacturing defect, bearing wear, or uneven fit of the housing to the engine block (dirty, rusty mating planes). Sometimes the malfunction begins to manifest itself after an accident, when elements of the body or attachments hit the pump pulley.

Choosing a pump for your car

So, you have decided to replace the pump. Now you need to go to the auto store and buy the required element. However, sellers offer a huge assortment of different water pumps for the VAZ 2110/2112 - which pump to choose so as not to go wrong with the price and quality?

The price of a pump for an 8-valve VAZ 2110/2112 engine is from 800 rubles, for a 16-valve engine - from 1 thousand rubles. However, regardless of the cost and brightness of the packaging, when purchasing, you must pay attention to the following details:

- manufacturer (take products only from companies that you know well);

- the pump has its own catalog number (for example, the standard VAZ pump in all catalogs in car stores and on Internet sites is numbered 21081307010);

- the pump is sold in clean, uncreased packaging;

- The kit includes a gasket;

- A factory quality guarantee is provided with the pump.

Car enthusiasts prefer a pump produced by TZA. A water pump from a domestic manufacturer is easy to install, lasts a long time and is inexpensive. However, there is a risk of purchasing a defective product.

The Russian-made product is characterized by affordable cost and high quality work

What to look for when buying a pump

When buying a liquid pump, you need to focus on the following points:

- Who is the manufacturer of the spare part? If the brand is unfamiliar to you, then it is better to refuse the purchase.

- What is the product catalog number? The stock pump for 8-valve VAZ-2110 engines has catalog number 2108-1307010.

- Is factory packaging present?

- Does the fluid pump come with a gasket?

- Is there a warranty card included?

Only if all these points are taken into account can you purchase the product. A high-quality pump will last the entire guaranteed period if it is installed correctly.

Step by step operating procedure

The water pump is replaced in an inspection pit or overpass. A regular jack will do, but you should make sure in advance that the body is lifted from the front right side and securely secured with additional stops.

The procedure for replacing the pump is identical for VAZ 2110/2112 with engines with 8 and 16 valves.

Replacing the pump involves removing the timing belt and tension pulley

After the initial preparation, you can begin the main work:

- Open the hood and remove the wire from the negative terminal on the battery.

- Unscrew the cap from the expansion tank.

- Get down under the car and place a container under the cylinder block.

- Unscrew the antifreeze drain plug and pour it into a container.

- After draining, install the plug back.

- Next, remove the front right wheel from the VAZ.

- The timing block will open under it - use a 10mm wrench to unscrew the three casing bolts.

- Remove the casing from the machine.

- After this, fix the crankshaft at the highest point of the first cylinder: engage the gear and turn the bolt that secures the pulley with a 19mm wrench. You need to turn it until the mark on the shaft gear matches the mark on the rear casing of the gas distribution mechanism.

- It is better to insert a large screwdriver or a long bolt between the crankshaft teeth to ensure it is static.

- Next, use a 17 key to loosen the tensioner roller, which will entail loosening the timing belt.

- First remove the belt, then the roller itself.

- Remove the five bolts that secure the bottom of the pump to the timing belt.

- Then unscrew the three bolts securing the top of the pump.

- It is easy to pry the pump housing with a screwdriver and pull it out of the socket.

- It is recommended to immediately clean the planting site from dust and old antifreeze. The remains of the old gasket must be removed.

- It is recommended to lubricate the new pump gasket with sealant on both sides and carefully place it in the landing zone.

- Install a new pump onto the gasket.

- Assembly work is carried out in reverse order.

Is it necessary to drain all the antifreeze from the system?

Drivers, when independently changing the pump on a VAZ, often wonder about draining antifreeze from the system. How much is it necessary to drain the coolant at all and if drained, how many liters?

There are specific answers to these questions:

- It is necessary to drain the antifreeze when performing any work on the elements of the cooling system. Draining the antifreeze ensures that pressure in the system is relieved and reduces the risk of injury. In addition, when dismantling and installing the pump, antifreeze will constantly leak from the landing zone, which will create a lot of inconvenience and ultimately lead to incorrect replacement.

- Regarding the question of how much antifreeze needs to be drained, there are two solutions. The first is based on caring for the car. As a rule, it is customary to change the coolant along with the pump, so it is better to drain the antifreeze from the system completely. The second option is suitable for those drivers who have only recently replaced antifreeze. In this case, you can drain only part of the liquid from the system (about 2-3 liters) in order to relieve the residual pressure in the pipes.

Accordingly, after replacing the pump, you need to fill in the same amount of coolant that was drained before dismantling.

Features of replacement on a 16-valve engine

The difference in replacing a pump on a 16-valve engine comes down only to the fact that this engine has two camshafts, and therefore two drive gears.

Therefore, when disassembling, it is necessary to align the marks on both gears.

And then, during the disassembly process, make sure that the camshafts do not move and their position is not disturbed.

After installing a new pump and belt and then tensioning it, be sure to check that the marks match. That is, the crankshaft is rotated several times, then the marks are set on the camshafts and their alignment on the flywheel is checked.

This is the whole difference between the replacement process on 8- and 16-valve VAZ-2110 engines.

In general, the described process for replacing the water pump is suitable for almost all cars whose engine is equipped with a timing belt drive.

Of course, there will be a difference at some points in the disassembly, but it is not significant.

Therefore, the described sequence of action is almost universal, especially for VAZ cars, starting with model 2108.

DIY pump repair VAZ 2110/2112

The driver does not always have the opportunity to replace a faulty pump. In some cases, it is possible to repair the device by restoring the operating functions of the pump. If the pump has not yet exhausted its service life (50 thousand kilometers), then you can repair it. However, the pump cannot be repaired without using a special repair kit. This is a set of rubber gaskets and parts that most often fail and need to be replaced.

Repair kits for pumps may vary in composition, depending on which spare parts need to be replaced

In addition, you will have to thoroughly prepare for repairs: the place for disassembling and repairing the pump must be clean and level.

Disassembling the pump

The pump is disassembled in the following sequence:

- The removed pump is wiped with a dry cloth.

- Using a special puller, the pulley is removed.

- The bearings are knocked off the shaft with a hammer.

- The shaft is removed from the pump housing.

- The impeller is removed.

- The oil seal or what is left of it is removed.

- The insides are thoroughly washed and cleaned.

If the pump is leaking, the seal must be replaced. The cause of a whistle at high speeds is usually a strong shaft wear.

Features of replacing the pipe on the pump

Due to the fact that the pressure is unstable, the hoses in the cooling system often become deformed for the flow or removal of fluid. If the pipe is swollen or cracks appear on it, then the rubber may “shoot out”.

To change the pipes on the pump, you should:

- loosen the clamp clamp;

- remove clamps and pipes;

- remove fasteners;

- remove the engine compartment pipe;

- remove the pipes.

On most modern cars, pump No. 2 is installed in the factory workshops, so the engine is easily cooled under increased loads. On the X generation VAZ, an additional unit is installed in order to optimize the operation of the stove in winter.

Replacing the oil seal

The oil seal is a rubber seal consisting of a metal rim, a spring and rubber. In any case, when disassembling the pump, the oil seal should be replaced, since the rubber wears out quickly. The procedure for replacing the oil seal is as follows:

- The old seal is removed from the shaft.

- The seat is cleaned of dirt.

- A new seal is installed.

Pump leaks are usually caused by worn out seal.

Replacement of shaft and bearings

Often, due to high production, bearings have to be replaced. They can only be knocked out using special tools (a puller or a hydraulic vice). Therefore, a new shaft with bearings already mounted on it is usually installed in the pump.

The pump shaft is replaced along with the bearings

Pump lubrication

Periodically replacing the water pump lubricant will significantly increase its service life. Some pump designs have special holes for lubrication. If there is no such hole, the water pump will need to be disassembled.

Some water pumps have special holes for lubrication.

Removing the old pump

Before installing a new water pump for the Lada VAZ-2110, you need to remove the old one. Carry out all work on a cooled engine, as the likelihood of getting burned is very high.

Dismantling sequence:

- Install the machine on an inspection hole or overpass.

- Open the hood and turn off the power. To do this, disconnect the negative terminal from the battery.

- Unscrew the cap on the expansion tank.

- Now you need to perform several manipulations from below the car. Drain the liquid from the cooling system - first from the radiator, then from the engine block.

- Using a “10” key, you need to unscrew the three bolts that secure the timing belt protection cover.

- After this, remove the casing.

- Now you need to position the crankshaft so that the piston of the first cylinder is at TDC. To make this easier, you need to turn the gear into neutral and turn the generator pulley to “19” using a key. The mark on the camshaft gear should align with the plate on the timing drive.

- Check if the marks located on the flywheel match - to do this, open the plug on the clutch housing.

- Now you need to fix the crankshaft - install a strong flat-head screwdriver into the flywheel teeth.

- Using a 17" wrench, loosen the nut that secures the timing pulley.

- Remove the roller and timing belt.

- On cars of the tenth family, you need to unscrew the bolts securing the timing case located at the bottom. The pump is secured with three bolts to the engine block.

- The liquid pump housing must be pulled out carefully by slightly prying it with a flat screwdriver.

After dismantling the pump, it is necessary to get rid of the remnants of the old paronite gasket. Do not use sharp objects or sandpaper.