What is a pump in a car and its purpose?

The liquid cannot move through the cooling system on its own, so the design of the liquid system includes a water pump, also known as a pump. Its main task is to ensure the circulation of coolant through the system, which ensures heat intake and removal.

The pump does nothing else, but the normal functioning of the motor depends on its operation. Without it, the power plant will overheat very quickly, since heat removal will not be provided.

Video: Why does a car need a water pump?

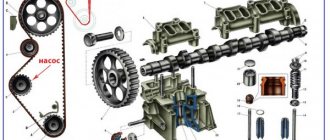

Cars currently use a centrifugal type water pump. This type of pump has become widespread due to its simplicity of design, and it copes with the task quite well. To drive it, the force obtained from the crankshaft is used, which is transmitted through a belt drive.

Liquid circulation throughout the system is ensured by an impeller. To ensure the movement of liquid in the cooling jacket, the pump is included in the design of the power unit. Moreover, its main part is located on its outer side, and only the impeller is located inside the jacket.

Do-it-yourself pump replacement on VAZ cars

As mentioned above, the replacement procedure will look different on different car models. This is due to the location of the unit in the engine compartment and the design of the car itself. The easiest way to perform the replacement is on VAZ cars.

To replace the pump you only need wrenches

The replacement procedure is as follows:

Wait until the engine cools down. It is prohibited to carry out work immediately after stopping the engine, as you may get burned.

Prepare a set of wrenches and a container to drain the old coolant. It is necessary to change the pump together with antifreeze (antifreeze), since the old liquid gradually loses its cooling properties during use.

Unscrew the antifreeze drain plug (the plug is located on the engine block). After this, unscrew the cap on the radiator to quickly get rid of the old fluid. Place containers under the drain points.

When the antifreeze (antifreeze) stops dripping, loosen the generator belt tension rack. After this, remove the belt, since otherwise it will be impossible to get close to the pump.

Remove the three pulley bolts.

Remove the alternator belt pulley.

Unscrew the nuts that secure the part to the motor housing.

What is a pump?

When we talk about this, we need to understand that when the car is running, it heats up quickly. It has an operating temperature, but if it starts to rise higher, then an additional fan should turn on and cool it down. If it does not work and the temperature is critically high, then the motor will “boil”.

To prevent this from happening, every car has a special cooling system. It consists of different elements, one of them is the pump. In general, this is a solid system in which antifreeze or antifreeze circulates, which cools the system. It absorbs some of the heat and removes it through the radiator. There, due to the large number of cells, the heat disappears. At this time, the liquid circulates through the system.

The role of the pump is to drive this liquid like a pump. She herself cannot move at the required speed, so there is a pump that drives her through the system. This is the pump's sole purpose. All cars have them, and if it breaks down in winter, then the car does not reach its maximum temperature so quickly, but in about 15 minutes. If it is a hot summer, then a few minutes is enough for this.

What is a pump in a car

Engineers know how to extract thermal energy from an internal combustion engine in several ways:

- air;

- liquid;

- combined.

Systems developed on the basis of air cooling are usually called open. They involve directed air flows that bypass the engine body from the outside. This design is becoming less and less common in modern cars, but is in demand in small motor vehicles.

Representatives of closed systems are liquid analogues. Heat is removed due to the circulation of antifreeze through the channels of the covering jacket of the cylinder block. The combined scheme involves the introduction of both air and liquid cooling for the car.

In the last two types of designs, a pump is a mandatory attribute; this is what a water pump is usually correctly called, as an integral part of the forced circulation of coolant in a car.

Important! Liquid-cooled systems are much quieter than their counterparts that use air to dissipate heat.

Water pumps in a car: which one to choose

Petr Nechiporenko, Marketing Director of LUZAR, talks about water pumps.

The water pump (pump) circulates coolant in the cooling system of a car engine. The water pump was used at the dawn of the automobile era and since then has consistently performed a vital function in maintaining the temperature balance of automobile engines.

History of water pumps in cars:

- 1885 - the appearance of the first cars with an internal combustion engine. Engine cooling is air, liquid cooling is not used;

- 1900 - appearance of liquid engine cooling.

Coolant circulation occurs “by gravity” - when heated, the hot liquid rises up, and the cold liquid flows to the engine cylinders; - 1910 - Liquid cooling system becomes "forced". Coolant circulation is provided by a water pump.

Structurally, the water pump is a relatively simple product consisting of five parts - a housing in which the bearing is pressed, an oil seal that protects the bearing from coolant, an impeller and a pulley.

Water pump parts:

- body (is the “basis” of the entire structure)

- bearing (pressed inside the housing; the impeller and pulley are “fitted” onto it)

- oil seal (seals the bearing from liquid)

- impeller (provides fluid supply)

- pulley (the pump rotates through it)

Simple flange. As an example, pump LWP 0823 for Hyundai Elantra XD

Simple flange. As an example, pump LWP 0823 for Hyundai Elantra XD

Simple flange. As an example, pump LWP 0823 for Hyundai Elantra XD

Let's look at the parts of the water pump individually.

Water pump housing

Two types of materials are widely used - cast iron and aluminum. Aluminum is a more modern material and allows you to create housings of complex shapes with strict adherence to dimensions, which makes it possible to install the bearing “pull-in”, and not use a screw that secures the bearing from turning. Cast iron pump casings are used, as a rule, on heavy-duty vehicles - where engine speeds are low, but a long service life of the part is required.

For reference: there are experiments using plastic housings for water pumps, but plastic has not received practical use.

Often the housings of modern pumps take very elaborate shapes. Another modern trend is that the pump body becomes part of the cylinder block.

"Belt" pulley. As an example, the LWP 1425 pump for Renault Koleos

"Belt" pulley. As an example, the LWP 1425 pump for Renault Koleos

"Belt" pulley. As an example, the LWP 1425 pump for Renault Koleos

Typically, two radial bearings are used, between which grease is placed. Outdated design - two open-type ball bearings are located separately on one shaft and are secured against rotation with screws; it is possible to additionally press grease between the bearings, for which a grease nipple is located on the pump body.

Modern design - double-row ball or ball-roller bearing of a closed type, rigidly pressed into the pump body; This bearing uses high-temperature grease, which does not require replacement for the entire service life of the bearing and pump.

"Toothed" pulley. - driven by a timing belt. As an example - pump LWP 0558 for Daewoo Matiz

"Toothed" pulley. - driven by a timing belt. As an example - pump LWP 0558 for Daewoo Matiz

The “toothed” pulley is driven by the timing belt. As an example - pump LWP 0558 for Daewoo Matiz

Designed to seal the bearing and protect it from liquid ingress. It is the most important part of a water pump - due to the “dynamic nature” of the pump’s operation, the sealing element is constantly under heavy load. A modern oil seal consists of two ceramic elements of the “flat spool” type, pressed against each other by springs.

“Toothed” pulley - driven by a timing chain. As an example - pump LWP 1435 for Nissan Teana

“Toothed” pulley - driven by a timing chain. As an example - pump LWP 1435 for Nissan Teana

The “toothed” pulley is driven by the timing chain. As an example, the LWP 1435 pump for Nissan Teana

Depending on the type, the drive can be “belt” (drive from a “simple” belt) and “gear” (drive from a timing belt or timing chain). The “belt” drive is often made removable - in this case, a flange is pressed onto the pump shaft, on which the drive pulley is subsequently installed.

In modern engines, electromagnetic clutches are gradually becoming widespread as pulleys, which allow you to regulate the speed of rotation of the pump (or even “turn off” the water pump).

Electromagnetic coupling. As an example, the LWP 18C4 pump for Volkswagen Golf VI

Electromagnetic coupling. As an example, the LWP 18C4 pump for Volkswagen Golf VI

Electromagnetic coupling. As an example, the LWP 18C4 pump for Volkswagen Golf VI

The pulley also indirectly affects the performance of the water pump - after all, the fluid supply depends on the speed of rotation of the shaft, and by changing the diameter of the pulley, you can increase (or decrease) the ratio of the speed of the crankshaft (from which the pump is driven) and the pump shaft. However, here you need to remember that the dependence of productivity on the speed of rotation of the pump shaft is “parabolic” in nature - productivity increases as the rotation speed increases, but when reaching a certain speed it begins to decrease.

Designers select a pulley diameter to ensure optimal pump performance at specific engine speeds. The main importance in terms of ensuring the performance of the pump is the impeller.

Impeller

It is the main “actuator” of the water pump, responsible for its performance. The flow characteristics of the water pump depend on the following impeller parameters:

- Diameter

- Distance from the impeller to the “mating part” (“cover”) of the pump

- Shape of the blades (must be “hydraulically correct”)

- Thickness of the blades (the thinner the blades, the greater the volume of “captured” liquid)

- Cleanliness of the blade surface (a “wave effect” may occur on a rough surface)

In an effort to create the “ideal” impeller, designers use various materials that have both advantages and disadvantages. Let us dwell in more detail on the most common materials from which water pump impellers are made.

Cast iron

As an example, the LWP 0101 pump for VAZ 2101–2107

As an example, the LWP 0101 pump for VAZ 2101–2107

As an example, the LWP 0101 pump for VAZ 2101–2107

It has been used in impellers since the very first water pumps. It is still in use, but is gradually ending its “career”. The manufacture of a cast iron impeller does not require high technology; Cast iron has high corrosion resistance. However, cast iron has a rough surface and heterogeneous structure; In addition, cast iron has certain limits on shaping. Cast iron impeller blades will, by definition, be thicker than blades made from other materials.

Plastic

As an example, the LWP 0226 pump for IZH “Oda” (the only pump with a plastic impeller produced by LUZAR)

As an example, the LWP 0226 pump for IZH “Oda” (the only pump with a plastic impeller produced by LUZAR)

As an example, the LWP 0226 pump for Izh Oda (the only pump with a plastic impeller produced by LUZAR)

Relatively modern material. Excellent forming properties and surface smoothness; thin blades. Disadvantage: poor corrosion resistance.

Now it is practically not used.

Aluminum

As an example - pump LWP 0190 for Lada Granta

As an example - pump LWP 0190 for Lada Granta

As an example - pump LWP 0190 for Lada Granta

It occupies a “middle” position between cast iron and plastic and has the advantages of both cast iron and plastic. Good forming properties, good surface smoothness; fairly thin shoulder blades; high corrosion resistance.

Sheet steel

As an example, pump LWP 0822 for Hyundai Solaris

As an example, pump LWP 0822 for Hyundai Solaris

As an example, pump LWP 0822 for Hyundai Solaris

Excellent “mirror” smoothness of the surface, the thinnest blades, high resistance to corrosion. Disadvantage: due to the properties of the material, the blades of such an impeller cannot be made rounded.

Today the most common material for water pump impellers.

Polyphenylene sulfide (PPS, "ceramic plastic")

As an example, the LWP 0982 pump for Renault Duster

As an example, the LWP 0982 pump for Renault Duster

As an example, the LWP 0982 pump for Renault Duster

Don't confuse it with regular plastic!

Polyphenylene sulfide has truly limitless possibilities - super-corrosion resistance (not afraid of any known solvent) and super-molding properties. The only drawback is the design complexity, which leads to high cost.

Also, quite exotic materials are rarely used in impellers. For example, for small production volumes - when it is not practical to invest in an injection mold - machined steel impellers are used. There are options for coating the impeller with “glaze”, which allows you to remove surface roughness, however, due to the low reliability of such a coating, impellers using this technology are produced only experimentally.

What is a pump for in a car and how does it work?

The engine cooling system of any car has its own pump (in jargon - a pump). The element is quite reliable in operation, but requires supervision, since it plays an important role in the operation of the power unit. If a part breaks, the car will not be able to continue its journey. Hence, the purpose of this publication is to explain to inexperienced car enthusiasts what a pump is and how it functions.

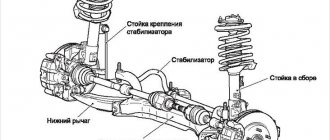

How to check the water pump on a car without removing the water pump

The water pump (water pump) of the engine cooling system is an important component that ensures constant circulation of coolant through the channels of the cooling jacket, pipes, lines, cooling radiator, etc. Even a slight decrease in the performance of a car pump can cause the engine to overheat, especially in the warm season.

Another reason to check whether the pump is working or not is possible extraneous noise in the water pump drive. In this case, the specified pump requires increased attention on some car models. The fact is that the pump can be driven by the timing belt. If the water pump jams, then the timing belt breaks, resulting in valve bending on most engines. Next, we will look at the available methods that allow you to check the water pump yourself.

How to check the serviceability of the pump on a car

Timely diagnostics of the pump allows you to avoid costly repairs or problems with constant overheating of the engine. To answer the question of how to check the pump’s performance yourself, let’s consider diagnostic methods using the example of domestic VAZ cars (model 2109, 2110).

Let's start with the fact that the pump is a kind of “consumable”, which on cars with a pump driven by a timing belt is recommended to be changed every 60 thousand kilometers traveled or 48 months, whichever comes first. These are the regulatory requirements of many automakers.

As practice shows, a high-quality pump on average lasts about 100 thousand km. For this reason, drivers usually do not change the water pump immediately (if there are no visible reasons for replacement), but in parallel with the second replacement of the timing belt (after 100-110 thousand km), trying to combine the replacement of the pump with the replacement of antifreeze.

In simple words, a good pump lasts as long as two timing belts last. It is also worth adding that using spare parts or low-quality antifreeze, mixing different types of coolant, etc. can lead to pump failure ahead of schedule. For this reason, it is advisable to check the pump regularly.

How to check the pump's operation

You should check the water pump on your car using a common method. For diagnostics on a VAZ and a large number of other cars, the engine should be warmed up until it reaches operating temperatures.

- After warming up, you need to hand pinch the upper pipe coming from the radiator. If the pump is working properly, then the coolant pressure created by the pump will be felt. This is the main answer to the question of how to check whether the pump is working or not without removing the pump from the car. During such a check, care must be taken, since the coolant in the system gets very hot. If the fluid pulsation is weak or absent, then you should proceed to a detailed inspection.

- To check, you need to remove the protective casing of the gas distribution mechanism, which will allow for a visual inspection. If the rubber seal (pump seal) in the area of the seat begins to leak, then drips of antifreeze or antifreeze will be visible. Also, leakage and problems with the pump will be indicated by deposits around the seat, which may have a reddish-brown or grayish color. If they are present, you need to drain the antifreeze and remove the pump for troubleshooting and replacement.

- If engine operation is accompanied by a characteristic “howling” sound, then the problem may be in the pump bearing. In this case, the pump is checked for play in the shaft area. To check by hand, you can rock the pump drive gear. In some cases, you can replace the worn bearing or immediately install a new pump.

What is better, change the pump or repair it?

Please note that if there are no external signs of problems with the water pump, but the pump has not been changed for a long time or low-quality coolant has been used, then an inspection of the device from the inside is necessary. The fact is that the pump blades can be made of metal. As a result, corrosion forms on the blades. Also, the blades can be made of plastic or other materials, which leads to mechanical failure.

As for repairing the pump, it is possible to carry out this procedure, but it is extremely impractical due to the affordable cost of this unit for most cars of domestic and foreign production. It is also not recommended to repair the coolant pump on cars where it is driven by a timing belt, since the repaired part may be less reliable than a new pump.

After all checks, repairs or purchasing a new pump, you need to install the pump back. Particular care will be required in installing the gasket, as well as tightening the mounting bolts. For greater reliability and insurance against leaks, some craftsmen use sealants. Note that this method is not always suitable, since the presence of sealant will not allow further loosening of the pump for mounting the timing belt on some cars when replacing it without replacing the pump.

You must also observe the recommended tightening torque for the pump mounting bolts. This is necessary in order not to damage the threads and not to compress the gasket. The completion of all work is considered to be filling with antifreeze. If a sealant was used, then you need to wait a couple of hours before adding coolant to the system so that the sealant has time to dry. Next, air pockets are removed from the cooling system, and the liquid is added according to the level. Some time after starting and warming up the internal combustion engine to operating temperatures, you should inspect the pump seat for possible leaks.

Source: https://krutimotor.ru/proverka-pompy-na-avtomobile/

What is the pump made of?

There are many different spare parts there. The entire structure is assembled in a metal case, which is most often made of aluminum. It also has a mount with which everything is screwed to the motor. There is a shaft installed inside the housing that rotates the fan and moves liquid through the system.

Photo: car-use.lv

In order for the shaft to rotate well, it was placed on bearings and an oil seal. There is no need to lubricate them, since they are closed and lubricant is immediately placed inside. In order for the impeller to rotate, the machines have a timing belt, which rotates the shaft, which transmits torque to the impeller.

Purpose of pumps: fluid dependence

There are quite a few models of water pumps, but all devices are distinguished by one more characteristic - the ability to work without problems with a particular liquid medium.

- Clean or slightly polluted water. Such equipment has a chance to pump almost uncontaminated liquid without damage to working units. It may contain solid inclusions up to 0.5-0.8 mm in size.

- The water is moderately polluted. Pumps designed to work with it are more powerful. In this case, the partings are able to cope with pumping liquid, the size of solid particles of which is a maximum of 15 mm. The first example is fire motor pumps, which are used not only for their intended purpose, but also for transporting water over long distances.

- Heavily contaminated liquid. This pumping equipment is characterized by high performance, the ability to create pressure, the maximum of which is 35 m of water column. Such pumps easily cope with inclusions whose diameter does not exceed 25 mm.

The most serious problem is sewage wastewater, which requires “professionals”. Such pump pumps are called fecal pumps. Their purpose is to pump wastewater containing large, fibrous, insoluble inclusions. The difference between fecal aggregates and all previous types is the presence of a special device - a cutting mechanism. Its task is to grind the solid inorganic components of the liquid.

How to determine if the pump is broken?

Although almost all elements of the device are made of metal, breakdowns still occur. They can vary, but most often this happens with the oil seal or bearings, which are more susceptible to failure.

To determine it you need to check:

- Is there any liquid outside, because if it is already starting to flow, then the oil seal is not holding it back well;

- Are there any additional sounds when the pump is running?

- Is there any play on the pump during its operation?

Photo: skladexpress.ru

These are the main breakdowns that can occur. But there are also others, sometimes the body cracks. This happens extremely rarely, but it still happens. Sometimes the impeller itself breaks inside - this happens due to chemical issues in the device itself.

The pump is usually not repaired, but completely replaced. Most often, the entire set is replaced at once, and not just the pump. After all, after several thousand km. You may have to change the roller, and after a few thousand more, the timing belt. Therefore, you changed everything immediately and you drive calmly. The pump itself is assembled at the factory, and after that the body is welded and it becomes solid. Therefore, you can still take it apart, but you can’t put it back together. To find the location of the pump in your car, you need to look at the technical documentation about the car and you will find it.

Signs of a pump malfunction

The simplicity of the water pump design provides it with excellent reliability and long service life. But malfunctions with this unit still occur, since the design uses elements that are the “weak” point of the pump. They are bearings and oil seal. During operation, bearings often wear out, which leads to the appearance of backlash. This immediately affects the seal tightness. But the rubber element itself can become damaged during operation.

Video: Signs of a pump malfunction. Choosing a VAZ pump. VAZ NIVA pump device

The main signs of pump wear:

- Coolant leakage from the water pump side.

- The appearance of extraneous noise when the motor is running.

- Visually noticeable play when the unit is running.

All these signs are caused by worn bearings and a damaged oil seal. There are other malfunctions that are much less common. Among them are damage to the impeller as a result of chemical processes occurring as a result of constant contact with antifreeze, the appearance of cracks in the housing, excessive wear of the working surfaces of the pulley or gear.

Note that the water pump is one of the components of the power plant that cannot be repaired. All components are seated into the body by pressing, so the unit is non-separable, and if signs of wear appear, the pump is simply replaced. In this case, the gasket must also be replaced. The only thing is that you can only change the pulley, and only if it is attached to the axle using a bolted connection.

Everything about the water pump (pump) of the cooling system

The cooling system is designed to create comfortable operating conditions for the engine: cooling to the optimal temperature, at which thermal damage to finely fitted parts does not occur. For the motor to work normally, all accompanying components, including cooling, must work normally.

Purpose, principle of operation

An automobile water pump, also known as a pump, is designed to ensure forced circulation of antifreeze in the cooling system - from the engine to the radiator and back. To ensure adequate cooling of the motor, not only artificial convection is used, but also additional cooling of the radiator using a fan. Stopping the water pump will slow down the movement of antifreeze to such an extent that the engine will overheat in a matter of minutes (especially if the breakdown occurs in hot weather).

The principle of operation of the water pump is pumping liquid through the use of centrifugal force: antifreeze enters the working chamber and a rotating impeller pumps it into the outlet pipe.

Engine cooling system

If we consider the flow diagram of the coolant, the water pump is located after the radiator in front of the engine. This solution allows you not to expose the pump mechanism to high temperatures: the antifreeze enters it already cooled.

Water pump device

The cooling system pump has a fairly simple design with a minimum of parts: on a shaft mounted on two bearings there is a metal or plastic impeller that pumps antifreeze in a circle. To seal the connection between the shaft and the working chamber, an oil seal is used, and gaskets made of special rubber are used to seal the joints of the pipes. The entire structure is enclosed in a durable metal case made of aluminum or cast iron, resistant to vibration and temperature changes.

The pump shaft is driven by the engine crankshaft through a pulley, that is, mechanically. Thus, the water pump begins to work simultaneously with the engine, and the higher the vehicle speed (the higher the shaft speed), the more active the antifreeze moves in the system.

The pump is installed on the engine housing on a special gasket that dampens vibration during operation of the mechanisms.

The weak points of the water pump can be considered parts that are subject to friction and stress: the oil seal and bearings. As a rule, pump failure is associated with them.

Most often, the oil seal fails: due to its wear, coolant enters the bearings and washes away the lubricant from them, after which they become unusable.

Schematic diagram of the end seal: 1. Rotating ring. 2. Stationary ring.

3. Sealing collar. 4. Pressure spring.

The spring in the oil seal performs an adjustment function: thanks to it, the friction rings are pressed tightly against each other, regardless of the degree of wear.

The service life of the water pump ranges from 60 to 160 thousand km (and in some cases more), and failure is due to mechanical wear.

There is no regulation for replacing the pump, but most often it is changed simultaneously with every second timing belt replacement, and at the same time a preventive check of the alternator belts is done.

As a rule, the water pump is not repaired: the fit of the parts is so precise that disassembly and reassembly are technically impractical. Therefore, in the event of a breakdown, it is easier and faster to install a new pump than to make labor-intensive and unreliable repairs.

Symptoms of a problem

- Antifreeze leaks. If the tightness of any part of the cooling system is broken, the antifreeze that is under pressure in it begins to leak. This can be detected when inspecting the car or after parking by looking at stains on the asphalt.

Drainage hole from which antifreeze leaks when the oil seal wears or leaks

- A decrease in antifreeze level is a direct consequence of a leak.

- The pump starts to run noisily - a sign of bearing wear.

- There is a smell of coolant in the cabin.

- When the engine is warm, the heater does not work - cold air blows.

- The engine overheats, as indicated by sensors and indicators. Engine overheating is one of the most serious problems that can render it unusable in a matter of minutes.

- Upon inspection, the pump shaft has play: it can be shaken with a noticeable amplitude. Such play is a clear sign of bearing wear, even if the pump is still running.

How often should I replace?

Don't wait for signs of a problem. The water pump is changed in advance. Mileage may vary. For domestic cars it is 60 thousand kilometers, for foreign cars - 120-150. The best option is replacement along with the timing belt or antifreeze. The manufacturer of the spare parts may vary. However, you need to pay attention to the quality of the part and the cost. A good substitute should not cost 3 times less than the original. By installing a high-quality pump, you can forget about problems in the next 3-5 years of operation.

water pump

water pump

, also known as a car engine water pump, is a pump that creates forced circulation of coolant in the internal combustion engine cooling system.

The water pump

is intended to organize the circulation of antifreeze or other composition in the cooling system. A malfunction of the pump leads to a serious disruption of the internal thermal regime of the engine, which is why it “boils” quite quickly.

This cannot be allowed to happen, so to make sure that the engine pump is working, you need to periodically listen and inspect the motor in order to repair or replace the failed unit in time.

Causes and consequences of water pump failure

Since the car pump is a fairly simple mechanism, it does not break down too often, especially with normal engine care. However, even the most reliable pump can fail. There may be several reasons for the breakdown, including:

- wear of device components, including aging of the oil seal;

- initially low quality pump;

- unprofessional repairs.

If the system remains sealed, but the pump does not initiate fluid circulation through it, this will lead to an increase in engine temperature, as indicated by the gauge on the dashboard. Driving for a short time in this mode will cause the radiator to boil or the engine to seize.

If a pump leak occurs, you need to take action to eliminate it as quickly as possible.

Another sign of a pump failure is an antifreeze leak in the area where it is installed. If the leak is not very severe, this is not so scary, since the liquid circulating in the system will still perform its functions normally, it just needs to be topped up regularly. But still, if such a breakdown is detected, it is best to eliminate it immediately, because leaks tend to increase in intensively used engines.