What is Bendix, and in what cases is it required to be replaced?

Bendix is a clutch used to engage the starting electric motor and flywheel when starting the engine.

Externally, the element is an oblique gear and is located on the starter shaft. At the moment it is triggered, it moves forward with the help of a solenoid and connects to the flywheel. When the power supply stops, the gear returns to its place, disconnecting from the flywheel. The amplitude of movement of the clutch is about 10 cm. The bendix is protected from excessive displacement by locking rings.

Be sure to read

What is Bendix and how does it work?

Signs of a malfunctioning clutch are clearly visible, so the question of how to check the starter bendix usually does not arise. The “symptoms” of a malfunction include:

- a grinding noise in the flywheel area when trying to start the engine;

- the starter rotates idle, without transmitting torque to the flywheel;

- a characteristic knocking sound at the moment the solenoid relay is activated, after which the shaft does not rotate.

A faulty gear is usually not repaired, but replaced. Repairing the element is possible, but such actions are not justified in terms of financial and time costs. Therefore, if the coupling breaks, it must be replaced. If you still want to repair it, a detailed video will be at the end of the article.

This method is not a repair method, but it allows you to start the engine and get to your home or auto repair shop.

Starter solenoid relay: fault diagnosis and repair

Let's start with the fact that the starter solenoid relay of a VAZ or any other foreign car can often fail for the same reasons. Considering that this element is reliable and durable, its breakdowns are the result of wear or high loads.

Typically, the driver may encounter that the relay clicks, but the starter does not turn the engine, the retractor relay does not make any sounds after turning the ignition key, the relay clicks every other time, etc.

One way or another, in such a situation, the starter retractor may be damaged. This is not surprising, since the starter relay operates with high voltages of up to several hundred amperes. As a result:

- the power contacts of the starter relay on the side of the contact disk burn out;

- the holding or retracting winding breaks;

- the return spring is deformed;

- a short circuit occurs in the windings;

- mechanical damage to parts in the solenoid relay device;

To accurately determine the cause of the malfunction, you need to diagnose the relay

Considering that the relay operates on the principle of an electromagnet after voltage is applied to the starter windings, it is important to find the problematic element

To begin with, you can pay attention to external signs.

In the case when the starter does not turn, it is quite possible:

- the retractor relay works, but the starter does not start to rotate;

- the solenoid relay and starter do not work;

So, the fact that the relay has been activated is indicated by a click that can be heard at the moment the armature is pulled inward. It turns out that by turning the key in the lock and noticing a click, we can assume that the relay is working properly.

Otherwise, that is, when the starter relay does not click, either electricity is not supplied to it, or the relay itself has failed. By the way, it also happens that the solenoid relay works, but the starter does not turn. In this case, the reason is burnt relay contacts.

To check this, you need to take a screwdriver and close the protruding parts of the contacts with it. If after a short circuit the starter starts to turn, then the reason is burnt contacts. If the short circuit does not help, then the fault is related to the starter itself.

The same thing happens when the starter and relay do not work at the same time. In this case, there may be several problems, starting with a break in the switching circuit or failure of elements in the ignition switch and ending with breaks in the winding of the solenoid relay, loss of contact with the ground of the coil, and others.

It also happens that the solenoid relay is activated, but at the same time extraneous sounds are heard (knocking, something rattling, etc.). Usually the reason is that the contact of the windings is poor. You can check it by measuring the resistance with a multimeter. Normally, the resistance of the pull-in winding should be about 0.55 Ohm, and the holding winding 0.75 Ohm.

If the readings are lower, then this indicates a short circuit within the winding, while a high resistance will indicate poor contact with ground and/or terminals. If you suspect a winding break, you can check using test lamps and a battery.

By connecting a light bulb to the winding, check whether it lights up. If it lights up, then everything is in order with the winding, but if it doesn’t light up, this indicates a break. The only thing is that this method does not allow identifying a short circuit due to the fact that minor deviations in resistance do not affect the brightness of the control lamp.

In any case, if a problem is detected, the solenoid relay is either repaired (collapsible type) or replaced (non-dismountable). The collapsible relay is removed from the starter, after which it is often necessary to solder the winding terminals. Then all contacts are checked, and if they burn, they are cleaned with fine sandpaper.

In a situation where the winding leads fall away from the housing, they are soldered in place. Also, during disassembly, parts of the relay that are worn out are identified and replaced. As a result, repairing the solenoid relay allows you to restore the functionality of the part. However, if this is possible, it is better to immediately replace the starter relay with a new one, especially considering its quite affordable price.

Starter operating principle

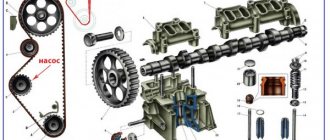

Bendix VAZ 2114 is one of the main elements of the electric starter, which is an overrunning clutch with a gear, through which rotational motion is transmitted to the engine at the moment of starting.

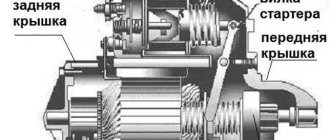

Starter device

The entire process of the starter operation looks like this:

- after turning on the ignition, power begins to flow from the battery to the starter and its solenoid relay;

- the relay moves the bendix forward and puts its gear in contact with the engine flywheel gear;

- at the moment of engagement, the starter’s electrical circuit is turned on, its electric motor begins to rotate and thus spins the crankshaft flywheel. This sets the engine pistons in motion, the working mixture begins to ignite, and the engine starts;

- after the engine starts running, the power to the starter and retractor relay is turned off, and the bendix, under the force of the return spring, returns to its original position, leaving the clutch with the flywheel.

After completing the work, you should check how the engine starts. The starting engine should run smoothly, without knocking and grinding noises characteristic of a faulty overrunning clutch. This is a sign of a high-quality replacement of the Bendix on VAZ-2109-2115 cars.

In some cases, changing the bendix is not enough. Prolonged operation of a faulty clutch leads to wear and damage to the flywheel teeth. In this case, the symptoms of failure that existed before replacing the gear may become weaker, but do not disappear completely. In such cases, it is necessary to replace the flywheel.

Do-it-yourself Bendix starter repair (photos and videos).

What is a Bendix (overrunning clutch)?

Replacing the Bendix on a VAZ starter or do-it-yourself repair

In modern cars, the engine is started using an electric starter. The starter is a DC electric motor that transmits rotation to the engine flywheel through a special clutch.

This is what the starter looks like:

This is what the flywheel looks like:

Typically, the gear on the starter has 10-12 teeth, and the flange on the flywheel, with which the starter engages and starts the engine, has more than a hundred teeth.

If you exclude the overrunning clutch, then after the engine starts, even at idle, the starter will spin up to an incredible 100,000-200,000 rpm! Naturally, it will collapse.

To prevent this from happening, a special overrunning clutch is used, colloquially called a bendix.

It works on the principle of the rear hub of a bicycle, i.e. torque is transmitted only in one direction - from the starter to the engine.

Causes of Bendix malfunctions.

All malfunctions manifest themselves in the same way - the bendix fires every once in a while or does not work at all, while the starter spins.

Visually, a Bendix malfunction appears like this:

To repair a Bendix, you will need a screwdriver that can withstand blows from a hammer, a hammer, a yew, or a rag.

It is difficult to buy spare parts for Bendix, since Bendix is usually sold assembled. But there is one life hack - we buy a Bendix from a VAZ-2101 (the cheapest) and disassemble it for spare parts. The diameter of the rollers is almost always the same; if you don’t find the right diameter or if you have a large hole, you can cut it with a drill; springs are almost always suitable. The author of this article repaired the bendix on the Chery Amulet starter by replacing the rollers and springs with similar ones from VAZ.

The causes of failure are listed in order of likelihood, from most common to least common.

Loss of spring elasticity.

In the picture above, you can see that the rollers are pressed by springs. When the springs lose their elasticity, the bendix begins to slip, and the starter itself fires every other time.

Repair - we flare the starter bendix, carefully remove the inner part, replace or stretch the old springs, assemble without lubrication; if the bendix is lubricated, it will slip, and flare it.

Roller wear.

This is the second most common reason: the rollers do not spin during their operation and therefore only wear out on one side, sometimes they flatten and become oval.

Repair - we flare the bendix, carefully remove the inner part, turn the rollers over on the other side or replace them, assemble them without lubrication, and roll them.

Oiling.

This problem is relevant only for gear starters. Sometimes gear lubricant gets into the bendix, in which case it begins to slip constantly.

Repair - we flare the bendix, carefully remove the inner part, wipe all the rollers with gasoline or acetone, assemble without lubricant, and roll it. It is advisable to replace the lubricant in the starter gearbox with a more refractory one, or reduce its quantity.

If you prefer to watch a video, below is a detailed video on how to repair a starter bendix with your own hands:

That's all for me today. After reading the article, repairing the Bendix starter should not cause you any difficulties.

It is important to understand that Bendix is not such an expensive part and it costs 200-300 rubles, therefore, it is advisable to repair it only if there are no spare parts, or if the car is very expensive

Algorithm for repairing a VAZ 2114 starter

- Disconnect the negative terminal from the battery.

- Using a “13” key, remove the 2 upper mounting screws connecting it to the clutch housing. Usually there is no third bolt, but if there is one, you will need an inspection hole to remove it.

- Moving the starter forward, remove wiring No. 1 from the connector on the starting relay.

VAZ 2114 starter repair. Do-it-yourself Bendix replacement

- Using a “13” wrench, remove the fastening nut of the wire, which is the connector of the starter traction relay output to the “ ” battery terminal.

- Assess the condition of the flywheel teeth.

- Use a Phillips screwdriver to remove the 2 starter cover mounting screws.

- Unscrew the nut that secures the output of the starter winding to the solenoid relay. Use the key to “13”.

- Remove the washer-bracket.