Connecting the engine to the gearbox: how to do it correctly

Let's start with the fact that the need to “mate” a car engine and gearbox usually arises after the power unit has been removed for overhaul. Also, quite often you have to remove the box itself, since this unit in some cases requires reassembly or replacement (especially in the case of an automatic transmission or manual transmission, better known as an “automatic” or a robotic gearbox).

As a rule, after repairing units, certain difficulties may arise at the stage of reassembly, namely when trying to connect the engine to the gearbox. In this article we will talk about how to attach a manual or automatic transmission to a car engine.

Advantages of contract engines

Contract engines have only two advantages: saving money and time. But the advantages of a contract engine can only be discussed using the word “if”.

That is, a contract engine will have advantages if it:

- It is cheap and its purchase is economically justified.

- It will quickly and easily install in the car and “go away”.

- Before purchase it was used normally and did not overheat.

- It has a relatively short mileage and sufficient resource reserve.

- Worked on high-quality gasoline and oil.

- Timely and high-quality technical maintenance.

- Before purchase, it was stored in good conditions, and not outside in the open air or in a damp garage. A long period of idle time without work is also not good for the engine.

- Once was not seriously injured in the accident.

- Legally clean and has all the necessary documents and guarantees.

It will be useful: How to replace the outer CV joint on a VAZ 2109

If the contract engine meets the conditions listed above, then it will undoubtedly have advantages and disadvantages. Otherwise, the buyer of the “contractor” will receive shortcomings and problems.

Connecting the gearbox to the engine: features and nuances

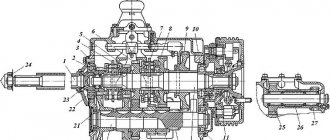

Let us immediately note that the connection of a manual transmission, as well as a robotic transmission, is somewhat different from a similar operation with another type of transmission, that is, an automatic torque converter automatic transmission. Otherwise, the usual mechanics and the “robot” (especially the single-disc one) are very similar in design.

This means that such boxes are connected to the motor in almost the same way. However, if we talk about an automatic transmission, the installation of this unit involves a number of individual differences.

To solve the problem, you need to raise the front axle of the car by placing wooden blocks, etc. It is also advisable to invite an assistant before starting work, but in extreme cases you can do it yourself.

Having raised the car, it is necessary to first remove the intermediate steering rod, since the element will complicate the process of connecting the engine and gearbox, taking into account the installation at an angle relative to the body.

Even before removing the lever, you need to engage fourth gear. Let us add that in the case when the clutch assembly was removed from the engine, it is imperative to center the driven disk in relation to the support bearing. This is done using a special mandrel or by removing the input shaft from the box.

If this is not done, the input shaft will not fit into the specified place during installation, that is, it will not be possible to install the gearbox. Next, loosen the bolts on the engine mounts, loosening the nuts that secure the upper metal brackets. This is necessary so that the engine has the opportunity to position itself at a certain angle, without the risk of damaging the cushions themselves.

In this case, it is important to prepare in advance all the necessary tools, fasteners, etc., and also arrange them so as to gain easy access. We are talking about the head, spanners, bolts securing the box to the engine and other elements. Now you can proceed to the installation stage. If you have not previously practiced this operation and do not know how to connect the engine to the gearbox, carefully study the following recommendations:

Contract automatic transmission: subtleties and nuances

First of all, the basis for unit replacements are usually serious breakdowns, when repair of a particular unit is simply impossible or the feasibility of repair is called into question, it is extremely unprofitable to carry out repair operations economically, it is difficult, etc.

Also, units are changed for the purpose of modernization, tuning the car, as part of various complex modifications (for example, replacing the engine with a more powerful one, replacing a manual gearbox with an automatic one and vice versa, etc.).

So, contract automatic transmissions are used automatic transmissions that were removed from various cars for one reason or another. Often we are talking about units that come to the territory of the CIS countries from Europe, Japan or the USA.

Typically, such boxes are much cheaper than new automatic transmissions. Also, often the cost of such units is comparable to the cost of high-quality repair of an automatic transmission, which makes this solution quite popular among car enthusiasts.

Moreover, replacing an automatic transmission with a contract automatic transmission in some cases is faster and easier than repairing an automatic transmission.

Let's start with the fact that large sellers who sell contract spare parts usually value their reputation by purchasing used spare parts only from trusted suppliers abroad. As a rule, the accompanying documents contain information about the mileage of the car from which the unit was removed.

Then the automatic transmission is carefully checked by the dealer himself, after which it is sold officially, since all the accompanying documents (customs declarations, etc.) are available. A warranty is also provided (especially in the case of installation in a service that is a dealer, that is, a partner).

As a rule, such parts usually have a fairly large residual life and can work properly and efficiently for more than tens of thousands of kilometers, which is especially important in the case of automatic transmissions.

Moreover, often such boxes have not been repaired and consist 100% of original spare parts, which is an advantage compared to automatic transmission repair, when some parts can be replaced with analogues from third-party manufacturers (not always of high quality).

- Now about the nuances, since there are also disadvantages to buying a contract automatic transmission. First of all, even thorough checks may not reveal hidden defects, which means there is still a possibility of the box failing.

However, this is not even important. Please note that when purchasing contract spare parts, you should not chase the lowest price, and you also need to pay increased attention to the integrity and professionalism of the dealer who selects and sells contract units.

You will also need to separately clarify details regarding the warranty policy, conditions for return or repair under warranty, replacement in case of serious defects, etc. The fact is that a situation often occurs when the automatic transmission was initially incorrectly selected, since the type of automatic transmission was incorrectly determined.

Another problem can arise as a result of the fact that when trying to install a contract automatic transmission, mistakes are made due to the unprofessionalism of the installer, which leads to breakdowns and malfunctions of the unit.

Also, unscrupulous dealers can sell a reconditioned automatic transmission, that is, such a transmission was first repaired (not always efficiently), after which it is sold as a contract one in excellent condition at a bargain price.

Often units with high mileage are sold at a low cost, the resource of which is almost exhausted, that is, expensive repairs will soon be required. The main advantage of such automatic transmissions is their affordable price. Remember, a contract transmission with a guarantee in good condition cannot cost much less than a major overhaul of an automatic transmission.

Let us also add that in pursuit of profit, unscrupulous suppliers who do not have their own spare parts warehouses may quote short selection and delivery times. However, in reality, delivery in this case takes 1.5 - 2 months or more.

It will be useful: How to remove a generator from a Priora with air conditioning

Main tasks

Absolutely any car has a gearbox, regardless of its make, model and year of manufacture. This is not surprising, because the role of the gearbox in a car is really difficult to underestimate, and without it, connecting the wheel drive and the engine would be very problematic.

To understand why a transmission is needed, it is worth remembering the diagram by which the car’s wheel drive system works and what the principle of its operation is based on. Of course, the main link, which is the source of mechanical energy, is the engine, the operation of which is usually based on the combustion of a certain type of fuel.

The operating scheme is such that the translational movement of the piston is converted into rotational movement, which is carried out by the crankshaft. Using a gearbox, this shaft is connected to a wheel reducer, which rotates the axle shafts and makes the car move.

At this point, many people have a completely logical question: why do we need such a complex circuit, which is based on connecting the wheel drive to the engine shaft through a gearbox? Is it possible to connect directly?

The fact is that the system, which has the principle of connecting the wheels through the gearbox, has several important advantages that allow the engine and all other components of the car to work more efficiently.

So, it is worth remembering that a system such as a gearbox functions by transferring torque from the engine to the wheels. If this moment in the system were transmitted directly, then with this operating principle, the rotation speed of the crankshaft and propeller shaft, which connects the gearbox to the wheel gearbox, should be the same. The direct transfer of torque will result in the wheel speed having to have a constant relationship with the shaft speed.

With this principle of operation without a gearbox, the car will be very limited in its characteristics, so it is necessary to change the torque, depending on the speed. It is the gearbox that carries out this work, and it determines with what torque the engine energy will be transmitted and how it will be used.

Contract motor with gearbox: all the pros and cons

In practice, the situation is as follows: first, the owner delivers the faulty vehicle to the service center, specialists disassemble and troubleshoot the units, after which the possibility of repair is determined and a preliminary estimate is drawn up. It is not difficult to guess that even if a major overhaul of the engine or repair of the gearbox (especially an “automatic” or “variator”) is possible in a particular case, the final amount is often quite impressive.

Naturally, in such a situation, purchasing a contract unit may be a way out. At the same time, it is possible to install a new engine or gearbox quite quickly, which means the vehicle can be put into operation as soon as possible. We also note that quite often a contract engine and automatic/manual transmission become a subject of interest among tuning enthusiasts. These units are usually used as part of tuning and boosting a car.

One way or another, the sale of contract used units usually means that such units are supplied from car dismantling yards in Europe, Japan, Korea, the USA, etc. Then the unit undergoes customs clearance, after which it is officially sold on the territory of the Russian Federation. In this case, it is necessary to highlight both the pros and cons of such a purchase. We have already described some advantages above, now we should add a few more points.

- First of all, contract engines, gearboxes and automatic transmissions are usually removed from cars that have been in an accident. This means that it is possible to buy a used motor or gearbox, which at the same time has quite a decent resource. Normally, the documents for the unit contain information about which vehicle it was removed from, and the mileage of the vehicle is also indicated.

- Often, a contract motor or gearbox will consist of original spare parts, since in developed countries the cost of repairs is very high. In fact, no one there will carry out major repairs of the internal combustion engine or gearbox, since the practice is to replace a unit or unit with a completely new unit or a used unit.

- If you compare the overhaul of an engine or gearbox, the contract option looks better precisely because the contract unit contains original parts. If you repair an existing engine at a service center, most of the new items purchased in stores will be non-original. Using only original spare parts from the catalog is also not a guarantee of 100% quality, since factory-installed items are usually better than those sold at retail in the form of spare parts. At the same time, the cost of repairs using the “original” increases significantly.

- Also, as part of the overhaul, not all parts are changed, but only worn ones. In other words, overhaul does not mean that the owner will receive a completely new engine with maximum service life. Another advantage of a contract unit is its assembly at the factory, since service specialists often make mistakes during repairs, and the quality of the assembly suffers. All this affects reliability.

- Finally, an old engine or gearbox can always be sold for spare parts, which allows you to gain a certain amount of money and partially offset the costs of the contract unit and its installation.

Now let's move on to the disadvantages of purchasing and using contract units, since there are quite a lot of nuances.

- First, before replacing the engine, you need to take into account that this unit is numbered. This means that the new internal combustion engine is subject to registration with the traffic police. However, such problems do not arise with the checkpoint.

- Although you can often buy a contract motor or gearbox in a few hours, in some cases you still have to wait quite a long time for one or another component. Typically, spare parts suppliers do not keep engines and boxes in stock, but simply collect orders and promise the shortest delivery times to attract customers. However, in practice the process is usually delayed.

- Often suppliers of contract spare parts directly cooperate with car services. At the same time, it is easier, faster and more profitable for the service to simply remove the old one and install a contract unit, after which it will also receive its additional percentage from the supplier of used spare parts.

Also, often an old unit, if a “contractor” is used, can be bought cheaply from the owner in the same car service center, after which it is successfully restored and subsequently resold. Conclusion - you should only have a motor or gearbox defective from trusted specialists whom you really trust.

- It is better to participate in the process of purchasing a contract engine or gearbox yourself, without relying solely on intermediaries or car service employees. It happens that a contract motor or gearbox turns out not to be a part brought from abroad, but a unit removed from a car that has always been operated in the Russian Federation.

In this case, many of the advantages of the “contract” may disappear, since the general condition of the unit may in reality be unsatisfactory, the engine or transmission may have previously been opened and repaired by domestic “craftsmen”, etc. It is quite obvious that such a purchase will soon require repairs again and may have a small residual life.

- Another important detail is that the contract unit must be exactly the same as it was before. It is important to understand that selection errors can lead to the fact that the motor does not mate with the gearbox, the mounting points do not match, electronic control units do not fit, etc. In the case of an internal combustion engine, swap the engine for a more powerful one, install a different type of power plant, etc. may lead to the fact that the traffic police simply will not register the new engine.

It will be useful: How to check battery density at home

We also note that when purchasing a used engine, the unit must have all the necessary documents confirming the legality of its sale. These documents will be necessary in order to officially register the engine, which is a numbered unit, and to make appropriate changes to the title.

Main principle

So, the main task of a car’s gearbox is to connect the engine and wheels in such a way that the torque remains optimal, and even at extreme speeds, the engine speed always remains within the normal range.

To do this, firstly, it is necessary to connect the gearbox to the engine and the driveshaft leading to the wheels. In the simplest case, two shafts are used for this - the primary and intermediate. The primary shaft of the gearbox is connected to the engine crankshaft, and the intermediate shaft is connected to the driveshaft of the car.

These gearbox shafts have sets of gears of different sizes and configurations. In order for the torque to change, a lever with a rocker is used, with which the shafts can be shifted and connected using different gears.

CONTROL OF A CAR WITH A MANUAL TRANSMISSION AT START

At the initial stages of training in driving schools, many students enthusiastically get behind the wheel, turn on the ignition, take the car off the handbrake, engage first gear and... The engine stalls and the car stalls. What causes this error? Yes, indeed, the algorithm of actions when you intend to move the car away is as follows: in a car with the ignition already turned on, the manual transmission knob must switch from neutral to first gear, having first fully pressed the clutch pedal - this way the fuel supply is activated, and the car has the opportunity to move from places. Then the clutch is released and the gas pedal accelerates the car.

But the problem is that it is to start that the engine needs to overcome the greatest amount of force, and if the clutch is released too quickly, the box cannot process the torque, and the engine, accordingly, cannot continue to function, which is why it stops. To properly move off a car with a manual transmission, you need to maintain a precise balance between the clutch and gas pedals. Having pressed the clutch with first gear engaged, you must then slowly and smoothly press the gas. As the car moves, you need to gradually accelerate it, at the same time pressing the accelerator pedal harder, and slowly, carefully remove your foot from the clutch until it is completely released. When the car starts moving, it is recommended to use exclusively first gear for maximum efficiency. It is with its help that the maximum torque is given to the wheels, which will be enough to move the huge mass of the car, and the possibility of stopping the engine when working correctly with the pedals is minimized. The gear is engaged using a smooth movement of the selector, as already mentioned, with the clutch fully depressed. You need to start releasing the clutch only when the manual transmission handle is firmly in place of the gear that is used in the current mode. If, when trying to move, the selector begins to shake so much that vibrations are sent into the driver’s hand, and an unpleasant grinding sound comes from the gearbox itself, the gear was not engaged completely, and you should immediately stop the car by fully squeezing the brake, then pressing the clutch and moving the gearbox handle gears to neutral position. After stopping, you can try again.

Connection of automatic transmission with engine

Taking into account the fact that an automatic transmission does not have a classic clutch and differs in design from manual and manual transmissions, the connection of the automatic transmission has its own characteristics.

First of all, you need to attach a torque converter to the engine (it will perform the clutch function), and this part must fit exactly into its seat. To check this, after installation it is necessary to separately measure the distance from the rear end of the cylinder block to the plane of the drive plate. It is with this plate that the torque converter is mated. (a)

It will be useful: Work on the Cherry Tiggo with gasoline engines 2.0 and 2.4. cost of routine maintenance for Chery Tigo

Please note that the indicated gap is leveled after the torque converter is completely pulled to the drive plate, however, such a gap must be present during installation. If there is no clearance, then there is a risk of damage to the drive plate, as well as damage to the oil pump. The parts are quite expensive, so extra care must be taken.

Let's move on. At the moment when the box is lifted for installation, you need to pay attention to ensure that the torque converter does not fall out. To prevent it from falling, the box should be lifted at an angle. Then the mounting holes on the torque converter (CT) are aligned with the matching holes, which are made on the drive plate itself.

Further assembly is carried out by tightening all the bolts with the required torque, which fit into the centering sleeves. Then the drives, hoses, etc. are connected. Upon completion, you should check that the GT does not experience any difficulties during rotation (the part rotates freely).

Regular machine

When choosing a vehicle with one of the types of automatic transmission, you need to know what an automatic and a robot are and what each of them consists of.

Attention! Automatic transmission was first released in the 30s of the twentieth century. But they began to produce it en masse only in the sixties of the same century. Vehicles with an automatic transmission are considered more reliable than those with a CVT or robot

Vehicles with an automatic transmission are considered more reliable than those with a CVT or robot.

Automatic transmission design

The automatic transmission consists of a torque converter, a planetary gearbox, and a valve body.

| Automatic element | What is he responsible for? |

| The torque converter consists of a turbine and reactor wheel, a centrifugal pump, an overrunning and locking clutch | Responsible for smooth gear shifting and acts as a clutch |

| The planetary gearbox consists of gearboxes and friction discs, a brake band | Transmits force through a system of different gear engagement options, switches speeds |

The structure of the automatic transmission, as can be seen from the table, is simpler than that of a robot. Another difference from the robotic one is the large number of gear ratio steps. Thanks to them, vehicle fuel consumption is reduced.

The difference between a robot and an automatic transmission lies in the operating principle of the automatic transmission. Gear shifting occurs without interruption when the engine reaches maximum speed in one of the gears and pressure is built up in the oil system to change speed.

And the hydraulic cylinders, which ensure the operation of the processes described above, are controlled by an electronic unit.

As already described, an automatic transmission can be distinguished from a robot by the following positions of the handle on the selector:

Positives and negatives

Like all devices, the machine has its positive sides and negative features. The advantages of an automatic transmission include:

The machine also has negative features, which consist of the following parameters:

The main subtleties of replacing an automatic transmission with a manual transmission

Replacing an automatic transmission with a similar one does not require a lot of money. But installing an automatic transmission instead of a manual transmission is accompanied by impressive investments. In this case, it is customary to be guided by the following principle: the older the car, the cheaper it is to modernize it.

The conversion of the transmission unit is carried out according to the following algorithm:

First, you need to drive the car onto an overpass or pit. Individual parts of the automatic transmission are heavy, so you need to use a lifting mechanism or call a partner, or better yet, a team of friends. If you have never had to disassemble an automatic transmission, use the help of specialists. Then you need to disconnect the battery pack to protect yourself and the electronic components from possible electric shock. The next step will require removing the instrument panel and powertrain components, which may create inconvenience when removing and installing a new box. After this, you need to disconnect all the wires that are connected to the automatic transmission, remove the cable and the selector lever drive. Next, drain the oil and remove the pan from the automatic transmission.

Key points for replacing an automatic with a manual

To install a manual transmission on an automatic machine, you don’t have to spend a lot of money. But installing an automatic transmission instead of a manual transmission will force the vehicle owner to fork out a fair amount. Also, remember that the older the car, the cheaper the replacement will cost.

Converting an automatic transmission to a manual transmission will take less time. Here are some steps of the procedure for converting the box:

- Drive the vehicle onto a pit or overpass. Some parts of the machine are heavy. Therefore, prepare a lifting mechanism in advance or call a partner, or better yet, a couple of people. If you have never disassembled an automatic machine, then find an experienced mechanic among your friends.

- First, disconnect the battery. This way you will protect yourself and your car equipment from electric shock.

- Remove the instrument panel and engine components that will interfere with the removal and installation of the old and new gearbox.

- Remove all wires that are routed to the transmission. Remove the cable, selector lever drive, speedometer cable.

- Drain the oil and remove the pan from the automatic transmission. Disconnect the machine from the cooling radiator. Remove the hoses.

- Unscrew the bolts that connect the automatic transmission to the engine. Separate them.

- Remove the intermediate shaft, as well as the supports and brackets that secure the machine.

- Remove the torque converter and disconnect the engine from the automatic transmission.

Next, you will need to install a manual transmission.

- Place the flywheel on the crankshaft.

- Connect the mechanical drive cables.

- Replace the automatic transmission selector with a manual transmission.

- Install the third pedal and clutch cylinder tubes.

- Now do the mechanical installation.

- Reflash the control unit (ECU).

It will be useful: Do-it-yourself tuning of Gili Atlas: improving the appearance and interior of the car, modification options to improve technical characteristics and power

That seems to be all. But in reality, it is not so easy to change an automatic transmission to a manual transmission. Since each vehicle has its own features that you may not know about. And I won’t be able to write everything about each car model. Therefore, I recommend not starting to replace the box if you do not understand the principle of operation of an automatic or manual transmission.

Attention! It rarely happens that an electronic control unit is completely identical to a mechanical one. Therefore, if you cannot reflash the unit, then it is better to buy a new one that is suitable for modifying the mechanics.

Practical implementation of a two-speed electric motor connection diagram

In practice, I only came across circuits on PKP-25-2 switches. This is a universal miracle of Soviet switching, which can have a million possible combinations of contacts. There is a cam inside (there are also several variations in shape) that can be rearranged.

This is a real puzzle and rebus that requires high concentration of consciousness. It’s good that each contact is visible through a small slot, and you can see when it is closed or open. In addition, contacts can be cleaned through these slots in the housing.

There can be several positions, their number is limited by the stops shown in the photo:

Batch switch PKP-25-2

PKP switch 25. A puzzle for everyone.

Batch switch PKP-25-2 – contacts

Why is an automatic transmission replaced with a manual transmission?

The box is replaced in the following cases:

In most cases, manual transmissions are installed instead of automatic transmissions by people who are already over 40. Since young people are accustomed to automatic transmissions and many young people do not want to give up automatic transmissions.

Repairing a manual transmission will cost the car owner less than repairing an automatic transmission. But on the other hand, automatic transmission cannot compare with manual transmission in terms of convenience and ease of driving. And the city mode on a manual transmission turns driving a car into torture. Constant traffic lights and traffic jams make the driver nervous and twitch the gear selector.

Therefore, it’s up to you to decide whether to replace the automatic machine with a manual one or not.

What is better - manual or automatic?

As many may have already noticed, most Russian motorists prefer manual transmission. Some experts believe that this is due to the mentality of the nation, others – with established negative stereotypes.

It's a different matter for Americans, 95% of whom cannot imagine driving a car without an automatic transmission. But this is not at all surprising, because the automatic transmission was invented by American engineers who wanted to simplify the lives of drivers.

The situation is the same in Europe. If 15-20 years ago everyone used mechanics, now it has almost been squeezed out of the market.

In Russia, there is also an increase in the popularity of automatic transmissions, but, according to experts and analysts, Russians do not know how to use an automatic transmission correctly. Every day, a lot of car enthusiasts come to auto repair shops with malfunctions, the main cause of which is precisely improper operation.

Manual or automatic: what to choose for a novice driver

There is no consensus on when a manual is better than an automatic or vice versa. Each gearbox option will have its fans, which means there will be different opinions. When choosing between an automatic transmission and a manual transmission, a beginner needs to pay attention to the following points:

You also need to take into account what gearbox the training car was equipped with at the time of training at the driving school. If it was a car with an automatic transmission, then the driver’s license will have a corresponding mark in the form of the letters “AT”. It means that the driver has the right to drive cars only with an automatic transmission; the question of choosing between an automatic transmission and a manual transmission is not relevant for him.

Mechanical transmission device

It is worth understanding that any gearbox itself will not be able to function separately from other equally important components of the car. One of them is clutch. This unit disconnects the engine and transmission at the required time

This allows you to change gears without consequences for the car while maintaining engine speed. The presence of a clutch and the need for its use is due to the fact that the manual transmission passes a large torque through its gears. It is also important to know that any gearbox, subject to the classical design, has axles shafts on which gears are strung. We mentioned them earlier

The housing is usually called the “crankcase”. And the most common configurations are three- and two-shaft.

The first are located:

The drive shaft is usually connected to the clutch, and a special disk is moved along it (it is called the clutch disk)

Next, the rotation goes to the intermediate shaft, which is firmly connected to the input shaft gear. When considering the design features of a manual transmission, the special location of the driven shaft should be taken into account. Often it is coaxial with the drive axle, and they are connected by means of a bearing located inside the drive shaft

This device ensures the independence of their rotations. The gear blocks from the driven shaft are not fixed, and the gears themselves are limited by special couplings. They can also shift along the axis. When neutral gear is engaged, free rotation of the gears is ensured. Then the couplings acquire an open position. After the driver has depressed the clutch and the gear has been shifted to, say, first, a special fork in the gearbox will move the clutch so that it engages the required pair of gears. This is how rotation and force directed from the engine are transmitted.

Mechanical transmission device

From the driven axle, torque and engine speed are transmitted via a driveshaft (in the case of rear-wheel drive) to the drive wheels. At the moment the synchronizer engages the drive and driven shafts, provided that the gears are not involved in the process, the highest efficiency is achieved. To perform reverse movement, the mechanics are equipped with a “parasitic” gear, by activating which the driver can change the path of rotation to the reverse. Many of the boxes mechanical type gears are equipped with helical gears. This is due to their ability to cope with greater forces and at the same time create less mechanical noise. As for the 2-shaft gearbox, the drive shaft is connected to the clutch in the same way. The difference between biaxial and triaxial is the presence of a gear block on the drive shaft. And, of course, there is no intermediate shaft. On the driven axle there is a rigidly fixed main gear gear. Other gears are equipped with synchronizing clutches.

Types of gearboxes

Main types of gearboxes:

- Mechanical , equipped with coaxial shafts (2 or 3, additional shafts are introduced on tractor units) with gears having straight or oblique teeth (in the last century there were small-scale designs with planetary gears). There are boxes with shafts installed at an angle, designed for use in tractors and four-wheel drive machines.

- Automatic or hydromechanical , planetary mechanisms are used to convert torque.

- Robotic , built on the basis of a mechanical gearbox with additional drives that control gear switching. The category of robots includes preselective automatic transmissions with dual clutch (for example, DSG), which have automatic control.

- CVTs equipped with a hydraulic coupling to transmit torque from the engine.

Manual transmission (Mechanics)

A manual transmission with manual gear selection is equipped with a clutch that opens by pressing the clutch pedal. Due to the use of synchronizers, switching occurs without extraneous noise and shock loads on the teeth. The shift lever is located on the tunnel between the driver and front passenger seats. Until the 60s. of the last century, cars were produced with a handle mounted on the steering column.

Automatic transmission (Automatic)

Automatic transmissions became widespread on cars of American concerns in the early 50s. last century, and then began to be used by European and Japanese companies. The unit includes a hydraulic transformer that transmits torque from the engine crankshaft. The stages are by a hydraulic unit with spool valves and an electronic control unit. The driver selects the required operating mode using a selector located on the tunnel or steering column.

The automatic operating mode prevents erroneous gear selection with subsequent twisting of the engine crankshaft. Some automatic transmission models support a manual speed selection algorithm (using a lever or paddles located under the steering wheel).

Special operating modes are provided

Robotic gearbox

There are 2 types of robotic transmissions on cars:

- A mechanical unit with electrical or hydraulic mechanisms that allows you to control a dry clutch and change gears without driver intervention. A similar scheme is used on equipment manufactured by Lada or Opel , it is low cost, but requires frequent maintenance and adjustment, and also does not provide smooth gear shifting.

- A design with 2 clutches responsible for engaging even or odd speeds, first put into mass production by the Volkswagen under the designation DSG. Later, similar robots appeared in the production programs of Ford, Hyundai-KIA and several others. By using a double clutch, fast and smooth gear shifting is achieved, and support for manual control is implemented.

CVT gearbox

The design provides 2 conical surfaces along which a metal belt moves, ensuring a smooth change in the speed of rotation of the output shaft. A number of manufacturers provide fixed belt positions, which are necessary to simulate steps during manual control.

Some manufacturers (for example, Nissan ) install an additional 2-speed hydromechanical unit, which reduces the load on the surfaces of the cones and the belt when driving at speeds above 100 km/h .

Types of manual transmissions

In addition to the number of shafts and stages, gearboxes are classified depending on the presence or absence of synchronizers. If they are not there, switching gears requires a certain time, which is reduced by adjusting the box and manipulating the gas and clutch pedals. Such manual transmissions are more reliable under high loads, therefore they are installed on motorcycles, sports cars, agricultural machinery, and heavy trucks, in which synchronization cannot be used for technical reasons.

Robotic boxes are also classified as mechanical. Their design is the same, including the presence of a clutch disc, but the control is carried out by electronics that perform the functions of a pedal. The switching pattern is also no different.