The UAZ Patriot belongs to the SUV class, and it follows that all-wheel drive on all four wheels must be a mandatory addition. Indeed, the SUV is equipped with such a function that gives it the opportunity to get out of any puddles, swamps and other types of obstacles encountered off-road. It is this addition to the SUV that will be discussed in this material. Let's look at how all-wheel drive works and how to turn it on correctly so as not to harm the car's structure.

A real SUV

The principle of all-wheel drive on the UAZ Patriot

It is known that all-wheel drive on a car is a pleasant addition to mainly SUV vehicles, with the help of which you can get out of any swamp. But the downside of this phenomenon has always been considered to be greater fuel consumption when this system is turned on. The main advantages of this system are:

- better grip of the vehicle with the road;

- motor efficiency;

- fast start;

- increased power;

- cross-country ability increases;

- better handling parameters.

Among the disadvantages, in addition to the doubled fuel consumption, one can also note the complex design of this system, which entails a considerable cost of the device.

Transfer case lever

There are three types of systems for cars known in nature:

- Constant;

- With automatic connection;

- With manual connection.

UAZ Patriot has all-wheel drive of the third type, that is, which is activated manually. This has its advantages:

- fuel economy;

- turning on only when necessary;

- The cost of this design is lower than that of an automatic one.

So, the main driving device in the UAZ Patriot car is the rear cardan, that is, the SUV is driven using the rear axle. The front wheels are driven when the system is turned off.

- Transfer case UAZ “Loaf”: Design and principle of control of the transfer case

Do you want to reduce the consumption of your Patriot? To do this, read...

Also, this type is the best solution for powerful SUVs, which is facilitated by the distribution of torque in a ratio of 50 to 50.

Four-wheel drive works as follows:

- The motor transmits torque directly to the gearbox, and from it to the transfer case.

- The transfer case has a device called a center differential, which distributes torque between the front and rear axles.

- When the front-wheel drive lever is turned off, torque is distributed only to the rear axle. When turned on - on both.

- The torque is supplied to the cardan of the rear (and, if necessary, front) axle, then it is transmitted to the gears of the cross-axle differential.

- Torque is transmitted directly through the axle shafts to the rear wheels and, when the lever is engaged, to the front wheels.

The presence of a center differential lock is mandatory on systems with permanent all-wheel drive. The UAZ Patriot SUV has one drawback (if it can be considered one), which is that this system cannot be used for a long time. That is, all-wheel drive can be engaged only when absolutely necessary: when driving on a wet dirt road or in snow. If you use all-wheel drive on a UAZ Patriot SUV for a long time, this will lead to noise in the system, vibrations and, of course, increased fuel consumption.

The manual all-wheel drive of the UAZ Patriot SUV is controlled directly by first switching the hub clutches. There is a lever in the cabin that acts on the transfer case, thereby turning on the center differential. Let's take a closer look at how the switching occurs and the main features of this process.

Turning on all-wheel drive

So, having understood the important issues about what kind of all-wheel drive the UAZ Patriot has and how it functions, you should pay attention to the manual control of this system.

To correctly enable all-wheel drive on a UAZ Patriot SUV, you should know the procedure for these actions, which we will consider below. To properly activate the 4x4 system you must:

- UAZ Patriot has been updated and received a rear axle lock

- Initially, manually turn on the wheel couplings or hubs that we have already discussed earlier. These clutches are located on the front wheels and to turn them on, you need to move the pointer to the right on the left wheel, and on the right, on the contrary, to the left.

- At this stage, front-wheel drive can be considered engaged.

- Now the transfer case lever engages the four-wheel drive and movement begins. If it is necessary to increase cross-country ability, you should switch the transfer case lever, thereby engaging a lower gear.

- When the obstacle is already behind, and this is very simple using the 4x4 system, then you need to turn off the system in the same way. To do this, the transfer case lever returns to its original position and the hubs are turned off.

Designation of transfer case positions

In the interior of the UAZ Patriot SUV there is an additional lever located near the gear shift lever. Let's look at what the positions of this lever mean.

- Position when the lever is at the left rear . This position is basic and is determined by the following parameters: the front wheel drive is disabled, the transfer case is not in operation and the drive axle transmits torque to the rear wheels.

- Lever position - forward and right. In this position, the front wheels are engaged. In this case, the lower gear is disabled, and the front and rear drive axles rotate the wheels. This mode is applicable, in particular, for off-road use in mud or snow in small quantities. This mode is also used when driving on ice.

Updated transfer case - without lever

- The lever position is moved to the right and back up to half the stroke . In this position, the transfer case assumes the “neutral” position, in which the car is stationary.

- The position of the lever corresponds to the previous one, only all the way back . In this position, the SUV operates in all-wheel drive mode and the low gear is engaged. This mode is used in difficult conditions when it is necessary to get out of a swamp or snowdrifts. Used only in critical cases.

For your information! UAZ Patriot cars produced in 2015 are no longer equipped with a mechanical transfer case control lever, but with an electronic one. Therefore, in the cabin, instead of a second small lever, you can find a regulator that has similar functions. The photo below shows such a regulator.

Drive mode switch

At this stage, the short course in driving all-wheel drive on an SUV can be called complete. Knowing how the 4x4 system functions and the basic principles of its activation, you can freely go on any off-road routes and not worry that the SUV will not be able to handle them. UAZ Patriot is one of those cars that is not afraid of dirt and water.

SUVs are equipped with a 2-axle drive system, which allows you to drive on soft ground or in off-road conditions. The car owner needs to know how to enable all-wheel drive on a UAZ Patriot, which can be equipped with transfer gearboxes of several types (this depends on the year of manufacture of the vehicle). Depending on the gearbox model, a lever or a rotary washer is used to shift.

Washer or lever for switching the drive.

Transfer case for UAZ-452 cars

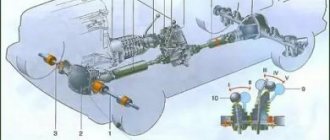

The transfer case (transfer case) of the UAZ-452 is designed to transmit torque to the front and rear axles and has two gears: direct with a gear ratio of 1.00 and a reduction gear with a gear ratio of 1.94.

Fig.1. Transfer case (transfer case) UAZ-452

1 — driven shaft of the gearbox; 2 — driven shaft bearing; 3 — gear for downshifting and rear axle; 4 and 7 — rear axle drive shaft bearings; 5— driven gear of the speedometer drive; 6 — speedometer drive gear; 8 - cover; 9 — rear propeller shaft flange; 10 — rear axle drive shaft; 11 and 24 - intermediate shaft bearings; 12 — intermediate shaft; 13 — front axle engagement gears; 14 — bridge cover; 15— front axle drive shaft; 16 — front shaft drive bearings, 17 — crankcase cover, 18 — crankcase gasket; 19 — transfer case housing, 20 — plug; 21 - cover; 22 — oil seal; 23 — front driveshaft flange; 25— plug; 26 — bearing cup; 27—box cover; 28—switching mechanism cover, 30—breather; 29 - upper crankcase hatch cover, 31 - oil filler plug The reduction gear allows you to significantly increase the traction force on the wheels under difficult operating conditions of the vehicle (off-road, deep snow, climbs). The UAZ-452 transfer case is shown in Fig. 1. The drive shaft of the transfer case is the driven shaft 1 of the gearbox included in it. The sliding gear 3 for engaging the rear axle and downshift is installed on the splines of this shaft. When this gear moves backward and connects it with the internal teeth of the rear axle drive shaft 10 gear, the rear axle will be engaged (gear ratio 1.00), and when it is moved forward and engaged with the intermediate shaft gear 12, a downshift will be engaged (gear ratio 1, 94). The intermediate shaft of the UAZ-452 transfer case, made integral with the reduction gear, rotates on two bearings, the front of which is roller, and the rear is ball. The sliding gear 13 for engaging the front axle moves along the splines of the transfer case shaft. When moving backward along the splines, this gear meshes with the gear of shaft 15 of the front axle drive. Both shafts are mounted on ball bearings. All UAZ-452 transfer case shafts are protected from axial movements by bearing caps and thrust rings installed in the grooves of the outer rings of ball bearings. The drive gear 6 for the speedometer drive is installed on the rear axle drive shaft. All gears of the UAZ-452 transfer case are straight-cut. When assembled at the factory, the gears are selected for noise. If for some reason during operation one of the gears is replaced with a new one, then such a transfer case may experience slightly increased noise during operation. Such noise is acceptable and is not dangerous for the transfer case. The bearings of the UAZ-452 transfer case do not require any adjustment in operation.

Fig.2. Transfer case control mechanism UAZ-452 1 — front axle engagement lever; 2 - lever for engaging the rear axle and downshifting in the transfer case; 3 — shaft for engaging the rear axle and downshift; 4 — front axle activation shaft; 5 - cracker; 6 — spherical bushing; 7 — spherical bushing body; 8 and 9 — intermediate levers; 10 — adjusting rods; 11 — front axle engagement rod; 12 — rod for engaging the rear axle and downshift in the transfer case; 13 - protective cuff Control of the transfer case of UAZ-452 vehicles, shown in Fig. 2, is remote. The control levers are located to the right of the driver, in front of the engine hood. The upper lever 1 is used to turn the front axle on and off and has two positions: forward when the front axle is turned on, and rear when the axle is turned off. Lower lever 2 is designed to change gears in the transfer case of the UAZ-452. It can be installed in three positions: forward when direct gear is engaged, neutral (middle) position in which the driven shaft does not rotate, and rear when downshift is engaged. Due to the presence of a locking device (lock) installed in the cover of the gearshift rods, a downshift can only be engaged after the front axle is turned on, and the front axle cannot be turned off when the downshift is engaged. Figure 3 shows the lock and the position of the rods when engaging the gears and the front axle.

Fig.3. Lock of the switching rods of the UAZ-452 transfer case a - position of the rods when engaging direct transmission (rear axle); b — position of the rods when downshifting and the front axle are engaged; 1 — front axle switch lever; 2—lever mounting pin; 3 — rod of the front axle activation lever; 4 — lever for downshift and rear axle; 5 — ball-lock; 6 — cover of the switching mechanism; 7—rod of the downshift lever and rear axle Figure 3a shows the position of the UAZ-452 transfer case rods when the rear axle is engaged (rod 7) and the front axle is disengaged (rod 3). At the position shown in Fig. 3b - the rods have moved to a position in which the front axle is engaged by rod 3, and downshift is engaged by rod 7. The locking ball 5 installed in the cover does not allow moving the rod 3 and disabling the front axle until the downshift is turned off by the rod 7. The lock is designed to prevent overloading of the driveshaft and rear axle parts. The front axle should be engaged when driving on a difficult road (mud, sand, snow, etc.). It is not allowed to engage the front drive axle when the front wheels are disabled. The position of the UAZ-452 transfer case shift levers is shown in Fig. 4.

Fig.4. Diagram of the position of the shift levers of the UAZ-452 transfer case a - front axle (upper lever); b — gear shift (lower lever); I—direct transmission; II - neutral position; III - reduction gear The spherical bushing 6 (see Fig. 3) of the upper shaft support and the bushing of the intermediate lever axis are made of plastic I and do not require lubrication. The lower ball joint is filled with graphite grease during assembly and additionally lubricated only during repairs or if squeaking occurs.

Front control rods 10 are adjusted in length using threaded forks. To adjust the position of levers 1 and 2, unpin and remove the finger from the rod fork connected to lever 1; set the rod (in the transfer case cover of the UAZ-452) to the rear axle engagement position, and lever 1 to the position corresponding to this gear.

Also interesting: Toyota Isis: modifications, features and equipment

By rotating the fork, set the required rod length, align the holes in the rod fork and the lever, insert a pin and pin it. The position of lever 2 is adjusted in the same way. During the first maintenance (TO-1), the UAZ-452 transfer case housing is checked by inspection; If traces of grease are found on it, check the oil level and eliminate the problem.

The oil level should be located at the lower edge of the filler hole. When refueling, do not rotate the shafts, as oil will stick to the gears and enter the crankcase in more quantities than required. This may cause oil to leak through the seal while the vehicle is running.

At TO-1, check the oil level in the transfer case housing and, if necessary, top up. During the second maintenance of the UAZ-452 transfer case (TO-2): - Inspect the tightness, condition and fastening of the UAZ-452 transfer case and its drive.

Remove the propeller shafts and tighten the nuts securing the flanges on the transfer case shafts (front and rear). Tighten the nuts and replace the driveshafts. When cottering, it is not allowed to unscrew the nut to ensure that the slot on it coincides with the hole on the shaft.

To do this, you just need to tighten the nut. Clean the breather from dust and dirt and blow it out. Change the oil in the crankcase. If the oil is heavily contaminated or there are metal particles in it, the crankcase should be flushed with kerosene before adding fresh oil. To do this, you need to pour 0.8-1.0 liters of kerosene into the crankcase, raise the wheels, start the engine and let it run for 2-3 minutes, after which the kerosene is drained and fresh oil is added.

______________________________________________________________________________

______________________________________________________________________________

- Clutch and gearbox UAZ Hunter

- Transfer case and driveshafts UAZ Hunter

- Drive axles UAZ Hunter

- Adjusting the steering mechanism of the UAZ Hunter

______________________________________________________________________________

______________________________________________________________________________

- Checkpoint UAZ-Patriot

- Razdatka UAZ-Patriot

- Drive axles UAZ-Patriot

- UAZ-Patriot suspension

- Steering UAZ-Patriot

- UAZ Patriot power steering faults and their elimination

- Components of the UAZ-Patriot hydraulic brake drive

- UAZ-469 engine and its main parts

- Gearbox UAZ-469

- Drive front and rear axles of UAZ-469

- Clutch of UAZ-469 cars

______________________________________________________________________________

- Cylinder block and timing belt for UAZ-31512, 31514 engines

- Front and rear suspensions UAZ-31512, 31514

- Operations for assembly and disassembly of UAZ-31512, 31514 bridges

- Steering UAZ-31512, 31514 and its parts

- Brake system UAZ-31512, 31514

- Gearbox UAZ-452

- UAZ-452 clutch and its parts

- Transfer case UAZ-452

- UAZ-452 bridges and its components

- Gearbox UAZ-3909, UAZ-2206

- Cardan transmission UAZ-3909, UAZ-2206

- Front axle UAZ-3909, UAZ-2206

- Brakes UAZ-3909, UAZ-2206

- Clutch UAZ-3303

- Transfer case UAZ-3303

- Rear axle UAZ-3303

- Steering of UAZ-3303

- Cylinder block and crankshaft ZMZ-409

- Timing belt and valves ZMZ-409

- Lubrication system ZMZ-409

- Cooling and power system ZMZ-409

- Parts of the UMZ-421, UMZ-4218 cylinder block

- Timing belt and valves UMZ-421, UMZ-4218

- Lubrication system UMZ-421, UMZ-4218

- Cooling system UMZ-421, UMZ-4218

- Fuel system UMZ-421, UMZ-4218

How the all-wheel drive system works

The Patriot's engine is connected to a 5-speed synchronized manual transmission. The secondary shaft of the box transmits torque to a 2-stage transfer gearbox, which is connected to the axles using cardan shafts with needle bearings and movable couplings. Splined couplings ensure the operation of the transmission when the axle moves on a suspension. The drive to the rear beam operates in continuous mode; the driver turns on the front axle when driving off-road.

The classic UAZ transfer gearbox is equipped with gears with straight teeth, which are switched using a lever. The gearbox housing parts are made of cast iron, the primary and secondary shafts are located inside, and there is an intermediate element with a movable carriage. The gearbox cover houses a switching mechanism equipped with two rods and forks. The mechanism is connected to a lever located inside the car.

The Dymos gearbox (with an aluminum crankcase), used since the summer of 2013, uses a chain to transmit power to the wheels, and the design includes a double synchronizer (when all-wheel drive is engaged in direct drive). The manufacturer claims a gearbox life of 200 thousand km, but with frequent use of the vehicle in severe off-road conditions, the unit fails earlier. To change gears, an electric servo drive is used, connected to a control puck.

The car's all-wheel drive distributes torque between the axles in a 50/50 ratio. There is no center differential in the transmission design. The rear axle is equipped with a differential; axle shafts installed inside the axle stockings are used to transmit torque to the wheels. To supply torque to the front wheels, axle shafts and steering knuckles with hinges are used. The units allow power to be transmitted to the steered wheels. The front axle housing also has a cross-axle differential.

- Transfer case UAZ Hunter: Design and switching

On cars manufactured before 2007, factory couplings (hubs) were installed in the front wheel hubs. The devices allow you to disconnect the hubs from the axle shafts and differential, which has a positive effect on fuel consumption. The products are equipped with splined couplings; a special rotary washer in the center of the hub is used to control the position. The plant refused to install hubs in order to simplify the design of the vehicle, but owners of Patriot vehicles can install the hubs themselves.

How the UAZ front axle works

The diagram of the UAZ loaf front axle allows us to determine that it consists of several components:

- Composite crankcase;

- Gearbox;

- Half shafts

Below is the structure of the components of the front axle of the UAZ loaf car.

Carter

The UAZ loaf axle housing consists of 2 parts. The parts are bolted together to form a gearbox housing. Parts of the crankcase are equipped with fastenings for installing springs and shock absorbers.

IMPORTANT: As the vehicle is used, the lubricant in the crankcase heats up and expands. At the same time, the pressure in the crankcase cavity increases. To prevent leakage of the axle housing, a breathing valve is provided. It is installed on the axle housing of the UAZ front axle and is necessary to communicate the crankcase cavity with the atmosphere.

There are turning mechanisms along the edges of the bridge. They are necessary to drive a car. The mechanisms are pivotally connected to the edges of the crankcase casing. Trunnions are installed on the rotating mechanisms. They are necessary for articulated connection with the vehicle hubs. To reduce the degree of friction, the hub is mounted on roller bearings.

Gearbox

The UAZ loaf front axle gearbox consists of a main gear and a cross-axle differential. When the front axle of the UAZ loaf is turned on, the torque from the gearbox is supplied through the driveshaft to the gearbox flange. It is mounted on the same shaft with the main gear drive gear.

As the drive gear rotates, it transmits torque to the driven gear. Compared to the drive gear, it has a large diameter. This allows you to reduce the torque transmitted from the transfer case.

REFERENCE: The teeth of the gears of the main gear of the UAZ vehicle gearbox are located at an angle. This prevents the gear teeth from hitting each other, thereby reducing the noise level when the vehicle is moving.

An interwheel differential is located inside the driven gear. It consists of conical satellites and their axes. The differential mechanism includes axle shaft splines. The differential allows, when turning a car, to achieve a difference in the speed of rotation of the wheels of one axle. You can also read about UAZ 390945.

Half shafts

The front axle of the UAZ loaf car is a shaft with splines on the edges. On the one hand, the splines are installed in the differential gearbox. The second side of the axle shaft drives the wheel hub. The transmission of torque from the front axle gearbox to the wheel mechanism is carried out using a CV joint. It allows you to transmit torque regardless of the angle of rotation of the wheel mechanisms.

A distinctive feature of the front axle of the UAZ Bukhanka is the ability to disconnect the wheel hubs from the axle shafts. This is necessary to prevent wear of the rotating parts of the gearbox during prolonged movement on good quality surfaces.

Turning on all-wheel drive on a UAZ Patriot

UAZ vehicles assembled before 2013 have a standard transfer case. To change operating modes, a separate lever is used, located on the tunnel between the front seats. The handle allows you to turn the drive to the front axle on or off, as well as select direct or reduced speed in the gearbox. A spherical plate is mounted on the handle, on which the gearbox switching algorithm is indicated.

After the introduction of the Hyundai Dymos transfer gearbox (developed in South Korea), a rotary washer mounted on the center console is used to switch transmission modes.

The use of electronics allows you to turn on the all-wheel drive mode on the go (at speeds up to 100 km/h). But to engage a downshift, you need to stop and move the main gearbox lever to the neutral position (with the clutch released). Then the washer is moved to the right, and the clutch is depressed until the indicator on the panel turns on.

Operating modes of the Dymos gearbox:

- Standard 2H, used when operating a vehicle on highways or dirt roads with hard surfaces (in summer and winter).

- All-wheel drive mode with direct 4H transmission, activated when driving on wet or slippery dirt or asphalt roads. When the drive is turned on, a control indicator on the instrument panel is activated. The factory recommends switching the mode only when driving in a straight line. Activation of the drive on 2 axles when moving in an arc leads to shock loads on the transmission units. If, when turning the washer, the drive to the front axle does not turn on, then you need to increase or decrease the speed and then try again.

- The lowered row 4L is used when driving in difficult road conditions or when moving a trailer through mud or deep snow (up to 400 mm or more). The mode provides an increase in torque at the wheels; a warning lamp lights up on the instrument cluster. When driving, it is forbidden to jerk the car sharply with the engine, since the chain mechanism does not tolerate shock loads and is destroyed.

Dymos transfer case with gear ratio 4.11.

When all-wheel drive is connected, the gearbox may produce extraneous sounds accompanied by body vibration. When operating a vehicle with front axle drive, controllability deteriorates (the angle of rotation of the wheels decreases), and vibrations occur when the steering wheel rotates. The use of the drive on dry roads leads to increased fuel consumption and additional noise, and also negatively affects the service life of tires and transmission components.

To return to rear-wheel drive mode, you need to release the gas pedal and then press the clutch. At the same time, the washer is rotated to the 2H position. After the 4H indicator goes out on the instrument cluster display, the clutch pedal is released. To shift from a lower gear to a direct gear, you need to stop the car, then press the clutch pedal, then move the washer from position 4L to position 4H, wait until the indicator turns off and release the clutch.

When operating machines with a Dymos gearbox, a malfunction occurs due to spontaneous activation of the all-wheel drive. The defect is associated with erroneous switching of the unit control unit.

To restore functionality, you will need to repair the controller or replace the part along with the rotary washer. The design of the gearbox provides a diagnostic system: when faults are detected, the 4WD Check indicator turns on in the instrument cluster with simultaneous activation of the indicator of the operating mode in which the problem was detected.

Dymos gearbox diagram.

Maintenance of transfer case UAZ Patriot

Regardless of the conditions of use of the vehicle, it is necessary to regularly inspect the UAZ Patriot transfer case for drips. For normal operation of the unit, maintenance is necessary.

When operating the machine, it is necessary to periodically change the oil in the crankcase. The oil change in the transfer case is carried out after a certain number of kilometers traveled. The manufacturer recommends changing the oil for the first time after the car has driven 5,000 kilometers. Subsequent times, the lubricant is changed every 25 - 30 thousand kilometers.

The interval between oil changes can be shortened depending on the operating conditions of the vehicle. When driving aggressively, the quality of the lubricant deteriorates, which negatively affects the operation of the unit.

WARNING: When wading, water may enter the transfer case through the breather valve. To prevent this, the outlet of the breathing valve is equipped with a flexible hose, the second edge of which is installed under the hood of the car.

Transfer case lever positions and their meanings

The classic transfer gearbox is controlled using a separate handle. The lever moves along a path in the shape of the letter P; there are a total of 4 handle positions. The position in which the lever is at the lower left point of the letter P is considered neutral.

When using a gearbox, you should take into account the presence of hubs in the front wheel hubs (installed at the factory until 2007, and then by the owners themselves). If there are elements on the machine, then it is necessary to first activate the drive by turning the handles on the hubs.

Positions of the gearbox control lever on the UAZ "Patriot":

- To disable the drive to the front axle, move the handle to the base position. In this case, torque is transmitted to the rear wheels. This operating mode is intended for operating the vehicle on paved roads in summer or winter. The plant recommends using the mode during everyday use of the Patriot car, since due to the reduced load on the engine, fuel consumption decreases. At the same time, there is a decrease in noise when the machine is moving.

- Moving the lever forward and to the right allows you to turn on the supply of torque to the front wheels (direct transmission is enabled in the transfer gearbox). The mode can be activated while moving (speed up to 60 km/h). When turning on the drive while the machine is standing, difficulties may arise due to the position of the gears in the gearbox; after moving the machine 20-30 cm forward, the drive turns on without jamming. The mode is used when driving along a wet country road and on snow-covered or icy paved roads.

- Moving the lever from position 2 to the right and back to the middle of the stroke allows you to engage the neutral position in the gearbox. In this case, the cardan shafts stop, the car remains motionless (regardless of the position of the lever in the main gearbox).

- Moving the lever to the right and all the way allows you to turn on the lower row in the transfer gearbox while maintaining the transmission of torque to the front and rear axles. The mode is used when driving in difficult road conditions (for example, in snow more than 400 mm deep or in mud reaching the center of the wheel hubs). A lower gear is used when driving in the mountains (including with a trailer) or when crossing swamps or streams.

The manufacturer prohibits the use of a 2-axle drive when driving on dry roads. When driving around curves in the highway or when making turns, the outer wheels travel a greater distance than the inner wheels. To compensate for this effect, a center differential is used, which is not provided on Patriot cars. As a result, the mechanical loads on the transmission components increase, which leads to the destruction of parts and abrasion of the tire treads.

Similar articles

UAZ Patriot rear driveshaft UAZ crosspiece UAZ Patriot instrument panel Do-it-yourself differential lock on UAZ

Since the UAZ Patriot is directly related to the cohort of SUVs, this should imply the mandatory presence of an all-wheel drive system in the design of this vehicle. The presence of 4 driving wheels allows the UAZ Patriot to confidently overcome the most difficult obstacles with which off-road terrain is strewn.

Our article will touch on the design features of the all-wheel drive Ulyanovsk SUV. We'll also look at how the system works and how to turn on all-wheel drive.

How the all-wheel drive system works

There is no doubt that all-wheel drive is a very pleasant bonus for the owner of any car. The advantages in cross-country ability and stability on slippery surfaces are obvious here. However, such a drive can present the owner of a UAZ Patriot with some unpleasant moments. The first of them is an increase in fuel consumption.

Let's talk about the advantages, since there are many more of them compared to the negative aspects.

So, the advantages:

- grip on the road surface is significantly increased;

- confident start, especially on slippery surfaces;

- cross-country ability is significantly improved;

- more predictable controllability and stability.

The disadvantages include the complexity of the design, although this is a purely subjective aspect, because for most technically savvy owners, the all-wheel drive UAZ Patriot does not seem like anything special in terms of design.

Let's look at what types of all-wheel drive systems are most common here.

There are three of them:

- When all-wheel drive is permanent.

- With the possibility of manual connection.

- Automatically connected.

In the UAZ Patriot, the developers used precisely the second type of system, that is, the all-wheel drive mode can be activated manually.

This scheme has a number of advantages, namely:

- the ability to save fuel;

- switching on when a need arises;

- the cost of the components is significantly lower compared to the option where all-wheel drive is connected automatically.

- It remains to figure out how to turn on all-wheel drive.

How does the device work? The main role in the all-wheel drive system of the UAZ Patriot is assigned to the cardan, with the help of which rotation is transmitted to the rear wheels directly through the rear axle. This is a single-wheel drive mode, because the front wheels are not yet connected and have the “status” of driven wheels. Below we will look at how to enable all-wheel drive.

Note that for energy-powered SUVs, this design approach is the optimal solution. Here the level of torque distribution between the axles is 50 to 50 (in percent).

The drive operation on axis 2 is carried out according to the kinematic diagram below.

- The torque from the engine flywheel is sent to the gearbox, and from it is transmitted to the transfer case.

- The transfer case contains a special mechanism - a center differential. It is necessary to redistribute the rotational force between the axes.

- When the front-wheel drive activation lever is disabled, torque is transmitted only to the rear axle.

- If the lever is turned on, the transfer case will begin to distribute torque between the two axles.

- As noted, the rotational force is transmitted to the driveshafts, not only rear-wheel drive, but also front-wheel drive.

- In order to drive the rear wheels, the designers installed an axle, which consists of a gearbox with a differential and axle shafts with hubs. Approximately similar units are used to transmit torque to the front wheels.

- A useful feature of the system is the presence of a differential lock. This function allows you to increase cross-country ability, as it synchronizes the rotation of the wheels on one axis when slipping, and this does not lead to a significant loss of torque.

The only drawback of the option is that it is not recommended to use the system for a long time, otherwise noise, vibration and other signs of malfunctions in the drive units may quickly appear.

Now let's talk about how to enable all-wheel drive in a UAZ Patriot.

Oil pressure sensor UAZ Patriot 409

Razdatka Daimos on UAZ Patriot scheme

Turning on all-wheel drive on a Patriot

Control of the system involves preliminary switching of the hub couplings. In order for the owner of a UAZ Patriot to ensure correct connection of the front axle drive, a number of simple manipulations will need to be performed. So, turning on the front axle occurs as follows:

- First, manually activate the wheel clutches. For this purpose, move the pointer to the right on the left wheel side, and to the left on the right wheel side.

If you need to activate a lower gear, then switch the transfer case lever to the appropriate position. This mode is necessary to increase the cross-country ability of an SUV. As you can see, engaging the front axle does not cause any difficulties.

If you need to disable the all-wheel drive mode, we proceed in the reverse order, that is, first return the lever to its original position, and then disconnect both clutches (hubs).

The front axle does not engage. | Topic author: Jakab

Guys, please tell me.

Vladimir (Telma) most likely hubs.

Evgeny (Shigeo) how to check them??

Viktor (Gilmour) Evgeniy, to check the hubs you need to, firstly, turn them on (I don’t want to be rude, but not everyone knows how to do this, especially in cases with old-style “ratchets”), secondly, first hang one, and then the other wheel (the front one, of course) and, turning on the front axle in the transfer case, try to turn the hanging wheel by hand. The new type of clutch may not turn on immediately, unlike a “ratchet”, and when it turns on, the wheel should have a small backlash (about 30*), but no more and not rotate. Both wheels are checked, because If one of the wheels does not connect, then there will be no front-wheel drive.

It happens that the front axle does not engage in the transfer case: the axle engagement lever seems to rest against something, in general, this is how it is. If everything is fine in the RK, then you can drive a little forward (or backward, or slip if you get stuck) and try to turn on the front axle again, you don’t need to make much effort.

Andrey (Abiel) look at the cardan in place

Alexander (Shifa) most likely one of the couplings is not engaging. When I bought mine, I didn’t immediately understand what was going on.

Viktor (Gilmour) start by simply changing the oil, maybe change the oil seals, preferably together with the flanges, maybe it will work.

Anton (Rastin) Yes, the bridge is not turned on only because of the hubs, the lack of a cardan or because of the rk, I don’t take into account the incorrect unconnected rods and all that kind of thing.

Andrey (Abiel) Guys, tell me, the front of my loaf stopped working. When turned on, the cardan spins, but the wheels stay in place, which could be the case. Military bridges

Transfer case lever positions and their meanings

- The lever is located at the left rear. This position is the main one and indicates that the front-wheel drive is deactivated. Here the transfer case does not function, and the transmission of torque is fully addressed to the rear axle.

- The lever moved forward and to the right. This position indicates that the front end drive is connected. Note that downshift still remains inactive. This mode is very effective on slippery surfaces or when overcoming light off-road conditions.

- The position when the lever is moved to the right and then back half the original stroke. This position is characterized by the neutral position of the dispensing unit, which indicates that the vehicle is stationary at a given moment.

- The lever is in a position almost identical to the previous one, but is brought back all the way. With this position, the “observer” understands that the SUV operates in an all-wheel drive system, and with an activated low gear. Such actions should be resorted to when overcoming significant obstacles off-road or if the UAZ Patriot is “stuck” in a swamp and needs to get out of there. That is, the mode is effective in critical situations and cannot be used continuously, otherwise there is a risk of harm to the system units.

Let's sum it up

In 2015, the Ulyanovsk SUV manufacturer made adjustments to the all-wheel drive system. Now the connection of the front wheels, that is, the control of the transfer unit, is carried out not using a lever, as we just looked at, but through electronics. In the cabin, the traditional lever has been replaced by a small regulator, which has similar functionality. If your car does not have a lever, then the front axle is engaged according to the scheme described

Sources used:

- https://prohodimets.ru/transmissiya/polnyj-privod-na-uaz-patriot.html

- https://myuazpatriot.ru/transmissija/vklyuchenie-polnogo-privoda-na-uaz-patriot

- https://uaz-patriot.info/obshhee/polnyj-privod.html