08/21/2021 13 213 VAZ 2109

Author: Ivan Baranov

Modern cars are mostly equipped with an internal combustion engine. In order to cope with various unforeseen situations on the road, you need to know the structure of the machine. The article describes the operating procedure of the VAZ 2109 cylinders, as well as possible malfunctions in the operation of the power unit.

[Hide]

The principle of operation of a four-stroke power plant

You can understand why it is important to connect high-voltage wires correctly if you study the principle of operation of the power plant. The carburetor or injector of the VAZ-2109 operates on approximately the same principle, since both power plants are four-stroke.

- First, the cylinder volume is filled with the fuel mixture and exhaust gases. This process is called "inlet".

- The engine then goes into compression. With it, the valves are closed, and the crankshaft and connecting rod move the piston upward. The mixture of fuel and air is transferred to the combustion chamber.

- During the expansion stage, the ignition is switched on and a spark appears. It ignites the fuel mixture, resulting in the formation of gases. They put pressure on the piston, causing it to move down. This force is transmitted through the connecting rod to the crankshaft.

- The process is completed by the “release” of exhaust gases through the exhaust system.

In order for the engine to operate smoothly and without jerking, the processes must take place in a certain order. This, first of all, concerns the order in which the cylinders are put into operation.

Video “Visual aid for adjusting SOP”

Find out how to configure the system correctly and avoid mistakes in the process from the video below (author: Nail Poroshin).

The operating order of the VAZ 2108 2109 cylinders is clearly indicated by the manufacturer in the technical documentation of the engines of the listed cars. These units of the VAZ 2109 and VAZ 2108 cars are internal combustion heat engines and are used in passenger cars in which the ignition and combustion of the air-fuel mixture occurs directly in the cylinder. Continuing the topic of internal combustion engines, it is worth adding that they come in two types. The first is units with external mixture formation, these include gasoline carburetor units, and gas units, in which the fuel is flammable gas. Second, these are units operating on diesel fuel, and the formation of a combustible mixture in these engines is called internal.

In order for the engine to properly perform its functions, it must observe a strict sequence, or the order of operation of the cylinders of the VAZ 2108 2109. In these brands of cars it is as follows: first cylinder 1 fires, then 3, after 4, and last 2. To ensure clear During engine operation, its cylinders, at strict intervals, must be cleaned of exhaust gases and receive a “fresh portion” of the air-fuel mixture. For this purpose, the engine gas distribution mechanism with exhaust and intake valves is provided.

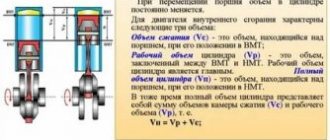

This mechanism, or rather its shaft, is directly connected, through a timing belt drive, to the engine crankshaft. When a combustible mixture ignites in the cylinder of a VAZ 2108 2109 car, it burns and expands, which puts pressure on the piston, which, moving down, imparts rotational motion to the engine crankshaft, and then, through the flywheel, to transmission parts. Thanks to the given energy from the flywheel, the piston moves upward and the process of burning the mixture is repeated. This ensures uninterrupted rotation of the engine crankshaft, which actually sets the car in motion. The critical positions of the pistons, upper and lower, are called “dead” points, respectively, top (TDC) and bottom (BDC).

Engine workflow through cylinders

The cylinders are activated as follows:

- In the first there is an upward movement. The gases expand and the mixture of air and fuel burns.

- In the third, to carry out the compression procedure, the piston rises.

- In the fourth, “injection” occurs - the piston moves down and at the same time a mixture of air and gasoline enters the cylinder.

- In the second cylinder, the piston rises and takes the upper position so that gases escape through the valve system. After which the exhaust gases are removed from the power unit.

Based on the principle of operation of the cylinders, their activation diagram looks like this: 1-3-4-2. It is important to connect them correctly so that the cylinders work in that order.

How to connect wires correctly

When replacing high-voltage conductors, they are first connected to the ignition distributor. The distributor cover is convenient in that it is always installed in one position. There is a special mark on it, thanks to which it will not be difficult to place the part in place. Before connecting the wires, inspect the cover. It must be intact, since if cracks appear, the performance of this unit is not guaranteed.

The mark on the distributor cover is located next to the wire socket of the first cylinder. The firing order of the cylinders is slightly out of order (1-3-4-2) due to the ignition slider. It moves around the circle (distributor) counterclockwise. It is precisely by this principle of movement of the slider that it is easy to remember the order of the wires. They need to be connected to carburetor and injection VAZ-2109 according to the same principle. On the distributor cover, connect the wires according to the principle of movement of the slider, this is the only way you can set the ignition correctly:

- the socket of the first cylinder is located at the mark;

- the third one is connected at the very bottom;

- on the same line with the socket of the first, there is a place for the wire to the 4th cylinder;

- at the top point the second cylinder is connected.

On the engine itself, the cylinder numbering goes from the location of the timing belt to the starter, that is, from left to right. The fourth cylinder is closest to the starter, and the first is closest to the timing belt. When connecting, it is important to look at which socket of the distributor cover the wire comes from, if you confuse their location, the car will not start.

If you have connected the wires correctly, but the car still does not start, then the problem may be in them. Check high-voltage conductors for integrity. If you haven't changed them in a while, it's worth buying a new set. The peculiarity of these wires is that over time microcracks can form on their surface. They lead to a lack of spark when the ignition distribution system is working. Moisture and dust get into these cracks, which damages the wire from the inside, although it appears intact from the outside.

Car enthusiasts recommend purchasing sets of high-voltage wires from foreign manufacturers, as they last much longer than stock or domestic ones. It is advisable to replace the spark plugs along with the wires, especially if cracks or carbon deposits appear on their surface. This is necessary so that after repair you definitely do not have problems with ignition.

Actions with the crankshaft when adjusting the valves of VAZ 2109, 2108

Work on the crankshaft to adjust the valves of VAZ 2109, 2108 is carried out without problems. To make it convenient to work, you need to unscrew the spark plugs. This will make it easier to manipulate the shafts and other mechanisms involved in the process. Use the figure below to understand the essence of the process.

And the sequence is:

- The crankshaft must be rotated so that the mark on the camshaft pulley coincides with the mark on the gear shaft cover. Other marks must be placed strictly in their places. You need to focus on the fact that the piston of cylinder No. 1 should be in the top dead center position.

- After this, the crankshaft is rotated 40-50 degrees to move the cams away from the pushers. The technician measures the gaps in 1, 2, 3, 5 valves. The gaps on valve 2 and 3 should be 0.2+-0.05 mm. And on valves 1 and 5 is 0.35+-0.05 mm, respectively If the gaps do not meet the required values, they must be adjusted.

- After this, the crankshaft is rotated 360 degrees, and similar clearance values are checked, only in relation to 4, 6, 7, 8 valves. In the event that there are deviations in the gaps, they also need to be adjusted using a replaceable set of washers.

Valve adjustment diagram for VAZ 2109, 2108

As practice shows, there is no need to carry out repairs yourself. In this case, this can lead to the fact that even with savings, there is no likelihood that installing washers will lead to a positive result. A significant amount of effort and time will be spent.

Service center specialists will perform all work promptly. This will save you time and resources, and provide you with ideal conditions for operating the vehicle.

IMPORTANT! Be sure to keep in mind that the equipment is first diagnosed, after which the need to adjust the gaps is determined. Take advantage of this offer, which will guarantee you the best working conditions.

The operating order of the VAZ 2109 cylinders

Very often, during repairs, high-voltage wires are removed from the ignition distributor or spark plugs. The only problem is that few people remember how they were connected before. To avoid confusion, you need to know the sequence of connecting the high-voltage wires of the VAZ 2109, first to the ignition distributor, and then to the spark plugs of each cylinder.

Connecting wires to the ignition distributor

The ignition distributor cover is placed on it only in one position; it cannot be put on in another way.

The distributor cap has a mark; this mark indicates the socket of the high-voltage wire of the first cylinder of the VAZ 2109 engine. The operating sequence of the engine cylinders is as follows: 1-3-4-2. The ignition distributor slider rotates counterclockwise when viewed from the cover. Therefore, the lower socket corresponds to the high voltage wire of cylinder No. 3. The next socket, going counterclockwise, corresponds to cylinder #4, and the top socket corresponds to cylinder #2. All this is depicted in the picture below. The numbering of engine cylinders starts from the timing belt and goes from left to right.

Cylinder arrangement VAZ 2109

That is, the cylinder closest to the timing belt is the first, the cylinder closest to the starter is the fourth. If the wires from the ignition distributor are mixed up, the car will not start. Therefore, if you remove high-voltage wires, then you need to connect them back as they were before. And then there are comrades who remove the wires, mix them up and then start a panic that the car has stopped starting.

The operating order of the VAZ 2109 cylinders

Thus, the working cycle of the VAZ 2109 internal combustion engine is represented by the following sequential actions: 1. In the 1st cylinder, a downward movement occurs, the working stroke, that is, the combustion of the working mixture and the expansion of gases. 2. “Compression” occurs in the 3rd cylinder, the piston moves up. 3. In the 4th cylinder there is an “intake”, the piston moves down, and the working mixture is pumped into the cavity. 4. “Exhaust” is carried out in the 2nd cylinder; exhaust gases leave the cavity through the exhaust valves.

Now let's look at several cases of malfunctions in the operation of the VAZ 2109 engine. In order to find out the cause of the breakdown, you should use the following algorithm of actions:

• Start the engine and go to idle speed. Listen to the sounds of exhaust. If uniform, periodic popping noises are observed, then most likely the cylinder is not working due to suction, a faulty spark plug, reduced compression or lack of spark. • Inspect the spark plugs; there should be no traces of soot, oxidation or moisture. The gap between the electrodes should average 0.8-0.9 mm. • Replace the spark plug set. • Check the condition of the high-voltage wires of the ignition system. The insulation must be intact, and the contacts must not be oxidized or burnt. If the wires are damaged, they must be replaced. • Inspect the rotor and distributor cap. The lid must be intact, without cracks and clean, without traces of soot. The carbon contact must not be worn or damaged. The rotor must also be intact and have no signs of burnout. All faulty elements must be replaced. • If, after the actions taken, interruptions in the operation of the cylinders continue, then you should contact a service station for a full diagnosis and adjustment of the ignition system, which should be carried out on a stand. • It should be noted that normally the compression should be above 1.1 MPa. If fluctuations within 0.1 MPa are observed in one of the cylinders, then it is necessary to urgently repair the engine itself.

Thus, it is quite obvious that knowledge of engine operation will allow timely repair work and avoid serious breakdowns.

interruptions in the operation of the engine of a VAZ 2108, VAZ 2109, VAZ 21099

During interruptions, the car engine idles unevenly, the engine does not develop sufficient power, and it consumes gasoline more. Engine failures on a VAZ 2108, VAZ 2109, VAZ 21099 are usually explained by incorrect carburetor adjustment, a faulty spark plug or one of the cylinders, or air leaks into one of the cylinders. It is necessary to find the fault and, if possible, eliminate it.

1. Start the engine of a VAZ 2108, VAZ 2109, VAZ 21099 car and leave the engine idling. Go to the exhaust pipe and listen to the sound of the exhaust. The sound should be even, “soft”, of the same tone. Popping sounds from the exhaust pipe at regular intervals indicate that one cylinder is not firing due to a failed spark plug, lack of spark at the plug, excessive air leakage into one cylinder, or a significant reduction in compression in the cylinder. Popping noises occur at irregular intervals due to improper carburetor adjustment, ignition, severe wear or dirty spark plugs. If popping noises occur at regular intervals, you can try to replace the entire set of spark plugs yourself, regardless of the mileage and appearance of the spark plugs, but it is better to do this after contacting a car service center to diagnose and adjust the carburetor and ignition system.

2. If the popping sounds are irregular, stop the engine and open the hood. Check the condition of the ignition system wires. High-voltage wires must not have insulation damage, and their tips must not be oxidized. If there is damage to the high-voltage wires, replace the faulty wire.

What is the order of operation of the cylinders in the VAZ 2109 engine?

Operating procedure

Often when repairing an engine, it becomes necessary to disconnect high-voltage wires. Some drivers, after disconnecting the wires, do not remember the order in which they were installed. As a result, there may be confusion with the wires, and if they are connected incorrectly, the car will not start. To avoid an unpleasant situation, you need to know how the internal combustion engine operates.

Connecting wires to a VAZ 2109

The principle of operation of the power unit is based on such a property of gases as the ability to expand when heated. A standard four-cylinder engine operates in 4 strokes:

- During the first stroke, the air-fuel mixture and part of the exhaust gases are “injected”. This mixture completely occupies the volume of the cylinder.

- In the second cycle, the “compression” process occurs. In this case, the valves are closed, and the piston moves upward due to the movement of the crankshaft and connecting rod. The working mixture fills the combustion chamber.

- On the third stroke, called “expansion,” a spark appears thanks to the spark plugs, which ignites the working mixture. The expanding gases exert pressure on the piston and force it to move downward. Then, thanks to the connecting rod, the crankshaft begins to move.

- On the fourth stroke, the process of “release” of exhaust gases is carried out. Through the exhaust valves they enter the exhaust system of the VAZ 2109.

In order for the operation of a multi-cylinder engine to be smooth and the crankshaft not to experience uneven loads, it is necessary that the work processes be carried out in a certain order.

There are different schemes that determine in what sequence the cylinders will function. The VAZ 2109 uses the following scheme: 1-3-4-2. The cylinders are numbered starting from the front cover of the power unit.

Cylinder numbering on the VAZ 2109

If we imagine the working process of the engine through the cylinders, then the order of operation is as follows:

- In the first cylinder, an upward movement occurs, the working process takes place: the air-fuel mixture burns, the gases expand.

- In the third, a “compression” process is carried out, in which the piston moves upward.

- The fourth receives the working mixture as the piston moves downwards, thus carrying out the “injection” process.

- In the second, the piston moves upward, while the exhaust gases exit through the exhaust valves.

Possible causes of failure

During the operation of the internal combustion engine, various malfunctions are possible. To detect them, you should perform the following sequence of actions:

- First you need to start the car. The engine should idle. At this time, you should listen to what sounds are coming from the exhaust pipe. If you hear regular popping noises, then one of the cylinders is faulty. The cause may be faulty spark plugs and lack of spark. The malfunction can also be caused by a large amount of incoming air or insufficient compression in the cylinder.

- It is necessary to inspect the candles. If there is carbon deposits, moisture or oxidation, you need to clean it. Check the gap between the electrodes, which should be 0.8 - 0.9 mm.

- Replace all spark plugs, regardless of their appearance and vehicle mileage.

- If there are irregular emissions, you need to inspect the high-voltage wires. There should be no traces of oxidation on their tips, and the insulation should not be damaged. If defects are found, the wire should be replaced.

Wires connecting to the coil - The gas distributor cap should be inspected. There should be no soot or cracks on it. The carbon contact should be checked for damage and wear.

- The rotor needs to be inspected. It must be solid and have no signs of burnout. All parts with defects must be replaced.

- The pressure in the cylinders is allowed to be no lower than 1.1 MPa, and the compression difference should not exceed 0.1 MPa. If the indicators do not correspond, engine repair is necessary.

If after the above steps the problems remain, then you need to contact a service station to undergo a more accurate diagnosis of the VAZ 2109 engine and adjust the ignition system on the stand.

Sources

- avtozam.com/vaz/2109/poryadok-raboty-tsilindrov/

- navaze.ru/108-poryadok-raboty-cilindrov-vaz-2109.html

- vaz2109.net/ekspluatatsiya-avtomobilya/poryadok-raboti-cilindrov-vaz-2109.html

- ladaautos.ru/vaz-2109/kakoj-poryadok-raboty-cilindrov-vaz-2109.html

What are the advantages of VAZ 2107 injection models?

• Thanks to electronic speed control, the engine runs more reliably at idle, stalls less when starting, and starts well at low ambient temperatures.

• Compared to a carburetor engine, an injection engine does not require frequent adjustments to the ignition and fuel supply systems.

• The air-fuel mixture that enters the cylinders has the most favorable composition. And the existing catalyst controls the minimum amount of harmful exhaust gases. This plays a big role in preserving the environment and taking care of health.

• There is no need to manually adjust the mechanism, since this is done by the hydraulic chain tensioner and hydraulic valve clearance compensators. They also guarantee less noise (noise insulation) when the engine is running.

• Torque graphics are “smooth”, a larger rpm range allows high torque to be achieved.

• Problematic access to some components due to the location of the engine and other mechanisms under the hood in the same format as in older models. Although at the same time, the system providing fuel injection is reliable and does not require frequent maintenance during operation.

Photo of VAZ 2107 under the hood

• The injection VAZ 2107 is equipped with a catalyst, which is very easy to damage when driving on a bad road with large bumps and obstacles. In such cases, of course, you need to be careful when driving on problematic roads.

Photo of VAZ 2107 catalyst

• The presence of an injection engine increases the requirements for fuel quality, in contrast to the carburetor version. If you use low-quality gasoline, you cannot avoid clogging the fuel system. This leads to unplanned vehicle maintenance.

• If the injection system breaks down, it is not possible to repair it yourself in a garage. Here you only need to contact professionals at a specialized service station.