The UAZ Patriot and Hunter SUVs are equipped from the factory with two drive axles: front and rear. Thanks to the presence of two axles on the UAZ Patriot SUV, its cross-country ability is unparalleled. The front axle, unlike the rear, is steerable. This indicates that the front axle is engaged only when necessary. The bridge that is installed on the UAZ is called Spicer. It was developed back in the 90s, and every year it was improved and supplemented. Today there is such news that Spicer will soon displace the old designs of units that are installed on “loaves” and “goats”. Today we will pay attention to the Spicer front axle of the UAZ Patriot SUV. What it is, features, advantages and method of adjusting the product.

Front axle features

The Spicer axle housing consists of a cast material into which the axle shafts are pressed. The axle housing is closed using a crankcase cover. The transverse plane of the device does not have a connector, which increases reliability and adds rigidity to the structure. Also, the differential and main gear of the Spicer bridge are located in one housing, which determines the high precision of engagement and operation of the device. All these features lead to an increase in the performance of products. Now, in order to service the device, it is enough to remove the crankcase cover and carry out the necessary repairs or replacement of products. Periodic monitoring of the oil level in the system, timely replacement of seals and bearings, as well as elimination of play in gears and differentials - all this is the main criterion for servicing the unit. The Spicer bridge is equipped with new types of joints (CV joints), the feature of which is durability. These hinges require periodic lubrication of the structure, for which CV joint-4 material is used. It is unacceptable to use Litol-24 to lubricate joints. An equally important point is the gear ratio of the Spicer bridge. Devices are available with two front axle ratios for the UAZ Patriot: 4.11 and 4.62. Axles with a value of 4.11 are installed on a UAZ Patriot SUV with a ZMZ 409 gasoline engine, and 4.62 on ZMZ 514 diesel units.

Design and diagram of the Spicer front axle

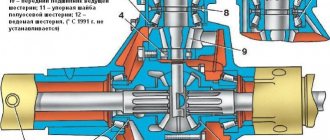

The photo below shows a diagram of the Spicer front axle with digital symbols. Let's look at the main mechanisms that make up the Spicer front axle.

1 - bolt; 2, 33 — spring washers; 3 - driven gear; 4, 24 — axle shafts; 5 — adjusting ring; 6, 22 — bearings; 7 — spacer sleeve; 8 — outer race of the outer roller bearing; 9 — roller bearing; 10 — thrust ring; 11 — oil seal; 12 — reflector; 13- flange; 14 — washer; 15 — nut; 16 — axle housing; 17 — adjusting ring of the drive gear; 18 — outer race of the internal roller bearing; 19 — internal roller bearing; 20 — oil deflector ring; 21 — shaft with drive gear; 23 — adjusting nut of differential bearings; 25, 39 — right and left parts of the differential housing; 26 - bolt; 27, 40 - support washers for axle gears; 28, 43 — axle gears; 29, 45 — differential satellite axes; 30, 41, 44, 46 — differential satellites; 31, 38 — differential bearing covers; 32 — retainer for the differential bearing adjusting nut; 34, 36, 37 — bolts; 35 — main gear housing cover; 42 — main gear housing cover gasket.

Device, design and maintenance features.

The UAZ Patriot cars , as well as all models based on them, are equipped with front and rear single-stage Spicer-type drive axles with a one-piece crankcase, named after the American engineer Clarence Spicer, author of more than thirty patents and owner of the Spicer Manufacturing Company, now Dana Corporation.

Front and rear axles of the Spicer type began to be installed on the UAZ-3160 and UAZ-3162 Simbir cars, instead of axles of the old design, and from them they were inherited by UAZ Patriot, UAZ Pickup, UAZ Cargo and UAZ Hunter.

Front and rear axles of the Spicer type on the UAZ Patriot, device.

The front axle is combined, simultaneously performing the functions of drive and steered, and is a rigid hollow beam, inside of which the main hypoid gear and differential are located. From the main gear, torque is transmitted to the front hubs through the axle shafts.

The axle shaft is a single part with constant velocity joints (CV joints) of the Rzepp-Birfield type, named after its inventor Alfred Rzepp and the American company Beerfield, which produced it under a patent.

It is more compact than the Bendix-Weiss joint on Timken axles, can operate at larger angles and transmit more torque. Front axle UAZ Patriot

Currently, front axles of the old Timken type design, which are still installed on UAZ cars of the passenger and utility-passenger model range, are also equipped with such hinges. For this reason, they got the name - hybrid bridges.

The rear axle is a rigid hollow beam, at the ends of which the hubs of the drive wheels are mounted on bearings, and the main hypoid gear and differential are located inside.

From the main gear, torque is transmitted through the axle shafts to the hub. The front and rear axles have main gears and differentials of similar design. Rear axle UAZ Patriot

Design features of the front and rear axles of the Spicer type.

Spicer-type axles are largely unified with single-stage axles of the old Timken type; they have the same differential bearings, rear axle axle shafts and almost all parts of the hub units.

The thickness of the driven gear substrate in the new axles was increased by 8 millimeters, this reduced noise and increased the reliability of the main gear. The new differential can be used on old single-stage axles with a split crankcase, provided that a compensator ring is installed on the cup stud.

Currently produced front and rear axles of the Spicer type have a final drive ratio of 4.111 or 4.625. The former are installed mainly on UAZ cars with gasoline engines, and the latter on cars with diesel engines, and all cars starting from the 2015 model year.

UAZ Hunter cars and all models based on it are equipped with so-called narrow axles with a track of 1445 mm, the catalog number of the front axle is 31605-2300011 - the final drive ratio is 4.111, or 31608-2300011 with a gear ratio of 4.625. Rear axle catalog number 31605-2400010-30 - gear ratio 4.111 or 31514-2400010-10 - from 4.625.

The UAZ Patriot, UAZ Pickup and UAZ Cargo vehicles are equipped with wide axles with a 1600 mm track, front axle catalog number 3163-2300011, 3163-2300011-10, 3163-2300011-10, gear ratio 4.111 or 4.625. Rear axle catalog number 3162-2400010-10, 3163-2400010, gear ratio 4.111 or 4.625.

Inspection and maintenance of the front and rear axles of the Spicer type on the UAZ.

Maintenance of the front and rear axles consists of maintaining the required level of transmission oil in their crankcase, it should be at the lower edge of the filler hole, and replacing it in a timely manner.

And also in checking seals, timely detection and elimination of axial gaps in the main gears, periodically cleaning the safety valve, tightening all fasteners and cleaning the magnetic plug from metal particles when changing transmission oil.

To lubricate Bierfield-type hinges, a special CV joint-4 lubricant is used, which should not be placed in the entire internal cavity of the steering knuckle, as before, but only in the hinge itself. The use of other types of grease, including traditional Litol-24, is unacceptable. During operation, adding lubricant to the joint is not required. The internal cavity of the steering knuckle is filled with Litol-24 lubricant.

Adjusting axial clearances in the front and rear axles of the UAZ.

Axial play in the bearings of the drive gear of the main gear is not allowed, since if it is present, rapid wear of the gear teeth occurs and the axle may jam. The presence of axial clearance is checked by rocking the drive gear by the driveshaft mounting flange.

To eliminate the axial play of the drive gear, it is necessary to tighten the flange nut. The nut is cored into the groove of the threaded part of the drive gear and when tightening it will require more force on the wrench. The nut is tightened carefully until the axial play of the drive gear is eliminated, without allowing it to be overtightened, after which it is cored again. If it is not possible to tighten the cored nut, then it should first be loosened by 0.5-1.0 turns, and then tightened until the axial gap is eliminated and cored.

Axial play in the final drive differential bearings is also not allowed. It is checked by rocking the driven gear with the crankcase cover removed. The axial play of the main gear driven gear is eliminated by tightening the differential bearing nut, after first removing the lock plate.

If you find an error, please select a piece of text and press Ctrl+Enter.

Advantages of the Spicer Bridge

The UAZ Patriot SUV is equipped with a wide type front device.

The advantages of this design are the following: • Increasing the track, which has a positive effect on the stability of the vehicle both on and off-road. The track was increased to 160 cm. • This also had a positive effect on the possibility of increasing the steering angle of the front wheels to 32 degrees. In this case, the SUV received better maneuverability on the road and abroad. • The strength class of the steering knuckles has been increased, thereby reducing the frequency of lubrication and repair work. • Thanks to the presence of a new suspension, the UAZ Patriot received better handling and stability.

Thus, these advantages indicate that the SUV has high off-road stability, as well as cross-country ability, which is important for such a unit.

Possible faults

Constant increased noise when the front axle is operating. 1

.

Worn or incorrectly adjusted differential bearings. 2

.

Incorrect adjustment. damage or wear of gears or bearings of the gearbox. 3

.

Insufficient amount of oil in the axle housing. 1.1

.

Replace worn parts, adjust differential bearing. 2.2

.

Determine the gearbox malfunction, repair or replace it. 3.3

.

Restore the oil level, check for oil leakage through the front axle crankcase seals. Noise during vehicle acceleration and engine braking 1

.

Incorrect adjustment of the main gear gear engagement. 2

.

Incorrect side clearance in the meshing of the final drive gears. 3

.

Increased clearance in the drive gear bearings due to a loose flange nut or worn bearings. 1.1

.

Adjust the engagement. 2.2

.

Adjust the gap. 3.3

.

Adjust the clearance and replace the bearings if necessary. Knock when the car starts moving 1

.

Wear of the hole for the pinion axle in the differential box 1.1

.

Replace the differential box and, if necessary, the pinion shaft.

Replacing the drive gear shaft seal of the front axle reducer

Replace the oil seal if oil leaks are detected from under the gearbox flange.

An oil leak can also be caused by excess oil in the crankcase or a clogged breather.

You will need

: a 27 socket socket, a wrench, a flat-blade screwdriver, a torque wrench.

1

.

Brake the car with the parking brake and place chocks under the rear wheels of the car. Raise and place the front of the car on supports. 2

.

While holding the bolts from turning, unscrew the four nuts securing the propeller shaft to the front axle gearbox flange, remove the bolts and move the shaft to the side. 3

.

Unscrew the nut securing the front axle drive shaft flange and remove the flange with the reflector. 4

.

Using a screwdriver, remove the oil seal from the axle housing. 5

. Using a suitable size mandrel, press the new oil seal into place.

You can use an old oil seal as a mandrel.

6

.

Install the parts in the reverse order of removal. 7

. Tighten the front axle drive shaft flange nut by turning the shaft past the flange until the bearings are seated.

Where is the front axle located and how is it arranged on the UAZ Patriot?

The front axle of the UAZ Patriot, mounted on a spring suspension with additional shock absorbers, is designed for the installation of steering knuckles. The beam design has a gearbox with a differential, which allows you to transmit and distribute torque between the front wheels.

Construction of the bridge and individual elements

The front axle is equipped with a monolithic cast gearbox housing (Spicer design), in which axle shaft stockings are installed. Due to the absence of a parting line, the rigidity of the structure is increased and the operating conditions of the gears are improved. A cover secured with bolts is used to access the gearbox and differential. The internal volume of the crankcase is used to store a supply of lubricant; drain and inspection holes with plugs are provided. The tension-mounted stockings are intended for installing the beam on the frame and for mounting the front wheel drive axle shafts.

To turn the front tires while simultaneously supplying torque, ball joints (CV joints) of the Birnfield design are used. The joint cavity contains a supply of special lubricant that does not need to be replenished during vehicle operation. The front wheels have a fixed installation angle in the vertical plane; in the horizontal direction, the toe-in angle is adjusted on the stand. The steering knuckles are of a pivot design, the pivot axis is inclined, ensuring the automatic return of the front tires to a neutral position.

Advantages of the Spicer front beam:

- increasing the track to 1600 mm, which increased the stability of the car;

- the angle of rotation of the steering wheels reaches 32°, which has a positive effect on the maneuverability of the vehicle;

- the use of the Spicer beam made it possible to abandon leaf springs in favor of a spring dependent suspension;

- the design of the steering knuckles does not require routine maintenance or replacement of lubricant;

- access to the mechanisms for repair is provided through a removable cover;

- increasing the rigidity of the structure and placing the gearbox and differential in a single housing made it possible to increase the service life of the unit;

- reduction of noise due to the installation of a modernized driven gear (the part can be installed in axles of an old design with a split housing).

Enabling and disabling the bridge

Torque is transmitted to the front axle gearbox using a cardan shaft with a splined coupling connected to a 2-stage transfer gearbox. There are 2 types of transfer cases on Patriot cars: mechanically controlled (Russian design) and electrically driven (Dymos gearbox, used since mid-2013).

To control the gearboxes, a lever or a rotary washer located on the central tunnel of the body is used.

Old-style transfer case control algorithm:

- Press the clutch pedal all the way.

- Move the gearbox control lever to the required position; the control algorithm is indicated on the plastic knob of the handle. The manufacturer allows the transition to torque transmission mode to 2 axles using direct transmission in the transfer case at speeds up to 60 km/h.

- Release the clutch pedal and continue driving with active all-wheel drive. To disengage the front axle, you must press the clutch pedal again, and then set the transfer gear lever to the neutral position.

To engage the front axle on machines with a Dymos gearbox, you must turn the washer to the required position. The design of the transmission allows all-wheel drive to be engaged while driving, but if low range is required, the vehicle must be stopped. Then it is necessary to move the main box to the neutral position, which will enable the lower row in the transfer gearbox.

Frequent malfunctions

The design of the front drive axle is highly reliable; possible malfunctions arise due to natural wear of rubbing parts or violation of operating conditions. Gearbox failures are associated with loss of crankcase sealing or damage to gears. The car owner can independently find the cause of the breakdown and carry out repairs in a garage.

High noise level

An increased noise level indicates a decrease in oil level and mechanical wear of the rolling bearings or gears of the main pair and differential. If adding lubricant does not reduce the operating noise, then it is necessary to disassemble the unit and replace worn elements.

After reassembly and restoration of the oil level, the functionality of the Patriot front axle is checked.

Noise during operation of the bridge occurs due to incorrect adjustment of the main gear gears. To restore normal operating conditions, the position of the parts is adjusted (using steel spacers), but if the teeth are damaged or worn, it is impossible to ensure the required contact patch. In this case, a complete replacement of gears is carried out; installing gears from different sets is strictly prohibited.

Oil leakage

Oil leakage from the Spicer UAZ Patriot axle occurs through the gasket between the cover and the gearbox housing, as well as through the sealing gland. The cause of the defect is wear of parts or damage to elements during installation or maintenance of the vehicle. To restore normal operating conditions, it is necessary to replace damaged parts; it is permissible to apply a sealant to the surface of the gasket. After repairs, it is necessary to restore the transmission oil level in the front axle gear housing.

Grease drying out

During operation of the machine, degradation of the lubricant located in the axle housing occurs. At high temperatures, the oil evaporates, and when overcoming water barriers, water enters the cavity. To check the lubricant level, use a control hole closed with a screw plug. If the owner regularly overcomes water obstacles, it is recommended to install extension hoses on the ventilation ducts. The lines are routed under the hood of the car, reducing the risk of water and dirt getting into the crankcases.

Node jamming

Jamming of the gearbox occurs in the case of increased axial clearance in the bearing supports on which the drive shaft of the main pair rotates. Due to the movement of the axis, the contact patch between the gears is disrupted, which leads to wear and destruction of the teeth.

During operation, it is necessary to periodically check the condition of the bearings by rocking the drive axle by the flange intended for attaching the propeller shaft.

Rules of service

Axle maintenance consists of periodically checking the level and changing the oil in the crankcase (every 45 thousand km). It is recommended to monitor the condition of the sealing elements and parts holding the beam to the vehicle. It is also necessary to promptly adjust the axial clearances, which change due to natural wear of gears and rolling bearings. Additionally, the gap in the steering knuckle pins is eliminated and the toe angle is adjusted.

The old oil is drained after the crankcase has warmed up while driving. The housing design includes a threaded plug; a container is placed under the hole to collect waste liquid. It is necessary to wipe the surface of the plug from particles formed when the gears wear out (a magnet is provided in the design of the part). Oil is filled through a control hole closed with a threaded plug. The normal level of lubricant is located near the bottom edge of the hole.

DIY repair

The design of the front beam allows for repair work to be carried out on one’s own, but some of the work is carried out under service conditions. For example, a car owner cannot correctly adjust the angle of deflection of the front wheels. The beam design includes a thrust bolt that does not allow the fist to be deflected by an angle greater than 31-32°, but determining the parameter is only possible on a bench.

Algorithm of actions when installing a new drive shaft oil seal:

- Place the vehicle on a level surface, then apply the parking brake and place chocks under the wheels.

- Using wrenches, unscrew the 4 bolts holding the propeller shaft flange to the counter pad located on the drive shaft shank. To make the procedure easier, it is recommended to treat the threads with WD40.

- Remove the bolts and move the drive shaft to the side.

- Unscrew the central nut holding the flange with the reflector on the drive axle of the front axle gearbox.

- Use a screwdriver or an awl to pry up the worn oil seal, and then remove the part from the mounting hole.

- Wipe the surface with a rag to remove any remaining oil and dust.

- Install a new oil seal in its original place, using the worn part as a mandrel.

- Mount the washer and flange on the shaft, and then tighten the fastening nut.

During self-service, it becomes necessary to adjust the alignment of the front discs and tires. To change the parameter, use a transverse steering rod, which is equipped with a coupling with lock nuts. Before tuning, the steering rod joints and wheel bearings are checked to ensure there is no play. To determine the angle, you need to measure the distances between the center lines on the sidewalls of the tires. When adjusted correctly, the clearance at the front is 0.5-1.5 mm greater than the distance between the tires at the rear.

Removing and installing the wheel release clutch

The wheel release clutch is removed to replace it or gain access to other units. You will need

: a 14mm wrench, a flat-blade screwdriver, and a puller for the outer retaining rings.

1

.

Remove the three mounting screws. 2

.

and remove the coupling cover. 3

.

Remove the six bolts securing the wheel release clutch and remove it. 4

.

Remove the three screws securing the coupling cover to the flange... 5

.

And remove the cover. 6

.

Using a puller for the outer retaining rings, loosen the retaining ring by prying it up with a screwdriver. 7

.

Remove the retaining ring and the washer installed underneath it. 8

.

And remove the spline bushing from the flange. 9

. Install the parts in the reverse order of removal.

Removing and installing the axle shaft

The axle shafts of the front wheels are removed for replacement in case of damage, failure of constant velocity joints (CV joints) or to gain access to other units. 1

.

Brake the car with the parking brake and place chocks under the rear wheels of the car. Raise and place the front of the car on supports and remove the wheel. 2

.

Remove the brake disc. 3

.

Remove the wheel speed sensor. 4

.

Remove the bolts securing the axle to the steering knuckle and remove the axle assembly with the hub and wheel release clutch. 5

.

Remove the axle shaft assembly with CV joint from the axle housing. 6

.

Before installing the axle shaft, apply clean CV joint-4 grease to the constant velocity joints. 7

.

Install the parts in the reverse order of removal. Replacing the front axle axle oil seal

Replace the oil seal if oil leakage is detected from the steering knuckle. You will need a flat blade screwdriver.

An oil leak can also be caused by excess oil in the crankcase or a clogged breather.

1

.

Brake the car with the parking brake and place chocks under the rear wheels of the car. Raise and place the front of the car on supports and remove the wheel. 2

.

Remove the steering knuckle and secure it in a vice. 3

.

Using a screwdriver, remove the oil seal from the steering knuckle ball joint. 4

. Install a new oil seal by carefully pressing it into the ball joint using a mandrel of suitable diameter, and lubricate the working edge of the oil seal with Litol-24 grease.

You can use an old oil seal as a mandrel.

5

. Install the parts in the reverse order of removal.

Enabling and disabling the bridge

Torque is transmitted to the front axle gearbox using a cardan shaft with a splined coupling connected to a 2-stage transfer gearbox. There are 2 types of transfer cases on Patriot cars: mechanically controlled (Russian design) and electrically driven (Dymos gearbox, used since mid-2013).

To control the gearboxes, a lever or a rotary washer located on the central tunnel of the body is used.

Old-style transfer case control algorithm:

- Press the clutch pedal all the way.

- Move the gearbox control lever to the required position; the control algorithm is indicated on the plastic knob of the handle. The manufacturer allows the transition to torque transmission mode to 2 axles using direct transmission in the transfer case at speeds up to 60 km/h.

- Release the clutch pedal and continue driving with active all-wheel drive. To disengage the front axle, you must press the clutch pedal again, and then set the transfer gear lever to the neutral position.

To engage the front axle on machines with a Dymos gearbox, you must turn the washer to the required position. The design of the transmission allows all-wheel drive to be engaged while driving, but if low range is required, the vehicle must be stopped. Then it is necessary to move the main box to the neutral position, which will enable the lower row in the transfer gearbox.

Removing and installing the front axle final drive

The main gear is removed for repair or replacement. You will need: “10” keys, “19”, “27” sockets. 1

.

Brake the car with the parking brake and place chocks under the rear wheels of the car. Raise and place the front of the car on supports, remove the wheels. 2

.

Remove the plug and drain the oil from the front axle. 3

.

Remove both axle shafts. 4

.

Disconnect the left tie rod end from the steering arm and move the tie rod to the side. 5

.

While holding the bolts from turning, unscrew the four nuts securing the propeller shaft to the front axle gearbox flange and move it to the side. 6

.

Remove the ten bolts securing the final drive housing cover. 7

.

And remove the cover. 8

.

Clean the mating surface from the old gasket. 9

.

Unscrew the nut securing the front axle drive shaft flange. 10

.

Remove the flange with the reflector. eleven

.

Remove two bolts securing the differential bearing caps, remove the caps and remove the differential assembly with the driven gear, and then the shaft with the drive gear assembled with the rear bearing. 12

.

Remove the flange seal. 13

.

Remove the front pinion shaft bearing from the front axle housing. 14

.

Press the outer races of the front and rear pinion shaft bearings out of the crankcase. 15

.

Install the parts in the reverse order of removal. 16

.

Adjust the main gear. 17

. Fill the front axle housing with oil.

Front axle UAZ Patriot: Construction and repair

The UAZ Patriot has high off-road performance thanks to all-wheel drive. The front axle of the UAZ Patriot is plug-in.

Torque is transmitted to the bridge using a transfer case.

Front axle structure of UAZ Patriot

The front axle of the UAZ Patriot car consists of:

- Gearbox;

- Housings;

- Two axle shafts;

- Axle shaft housings;

- Steering knuckles;

- Brackets for mounting springs and shock absorbers.

Gearbox

The front axle gearbox of a car consists of a main gear and a cross-axle differential. The main gear is made in the form of two gears. The drive gear is small and mounted on the drive shaft. The driven gear is increased in size, which reduces the torque transmitted to the wheel mechanisms. The gear teeth are angled. When the unit operates, the gear teeth do not hit each other. This reduces the noise level while the vehicle is moving.

An inter-axle differential is installed inside the driven gear of the front axle gearbox. When turning a car, it allows the wheels of the same axle to rotate at different speeds. The cross-wheel differential is made in the form of bevel gears mounted on two axles. The splined part of the axle shafts is included in the cross-axle differential mechanism.

Steering knuckles

A distinctive feature of the front axle is the presence of steering knuckles. They are necessary to drive a car. To transmit torque to the wheel mechanisms, regardless of their angle of rotation, the manufacturer equipped the axle shafts with CV joints.

REFERENCE: Unlike previous models of the Ulyanovsk Automobile Plant, the UAZ Patriot has a greater angle of rotation of the wheel mechanisms. This is achieved by installing ball joints instead of a pin mechanism.

Frame

The design of the front axle of the UAZ Patriot implies the presence of an all-metal housing that forms the gearbox housing. To ensure tightness, the gearbox housing is closed with a lid. It is installed with bolts. A gasket is installed at the junction of the cover and the gearbox housing. On the side of the wheel mechanisms, axle shaft housings are pressed into the gearbox housing.

ATTENTION: To avoid the occurrence of excess pressure in the front axle crankcase as a result of increased temperature, lubrication, the manufacturer has installed a breather valve. It communicates the axle housing with the atmosphere, preventing dust and contaminants from entering the mechanism.

How to turn on and off the front axle on a UAZ Patriot

The front axle on the UAZ Patriot is engaged by the transfer case. The manufacturer installed two types of transfer cases on the model. Older versions are equipped with mechanically controlled valves.

The front axle is engaged on a mechanically controlled transfer case using a lever installed in the car interior between the driver and passenger seats. The lever mechanically moves the transfer case rods.

Newer versions of the car are equipped with an electronically controlled transfer case.

The transfer case control unit turns on the electric motors. Electric motors move the rods to the required position.

To turn on the front axle on a UAZ Patriot you need to:

- disengage the clutch. To do this, depress the clutch pedal installed in the cabin;

- After disengaging the clutch, set the lever or regulator to the required position;

- After releasing the clutch pedal, the front axle of the car will be engaged. Disabling the axle drive should be done in reverse order.

ATTENTION: The manufacturer does not recommend turning on the front axle for long trips on good quality surfaces. Violation of this rule may lead to incorrect operation of the node.

Possible malfunctions and their causes

The design of the front axle is reliable and unpretentious to operating conditions. Most malfunctions that arise during the operation of a car can be fixed by a person with minimal technical knowledge. Below are the most common faults that require unit repair. You can also read about the Front Axle of the UAZ “Loaf”.

Oil leakage

The presence of grease drips indicates a violation of the crankcase seal. The cause of lubricant leakage may be a failure of the gaskets or wear of the seals. If a malfunction is detected, it is necessary to replace worn gaskets or seals.

When installing, the gaskets must be treated with sealant.

Increased noise

Loud noise during operation of the unit may indicate wear of the gears or bearings. To troubleshoot problems, you will need to disassemble the unit. Failed parts must be replaced with new ones.

Deterioration of lubricant quality

The cause of strong noise during operation of the unit may be poor quality of lubricant. It is necessary to regularly change the lubricant in the gearbox housing. Regular use of the vehicle for off-road driving or fording can cause water to enter the crankcase. Water prevents the rotating parts of the mechanism from being lubricated, which can lead to complete jamming.

To avoid failure of the entire assembly, it is necessary to regularly check the quality of the lubricant. When using a car to ford, the breathing valve is equipped with a rubber hose, the second end of which is led under the hood.

Repair and maintenance of the front axle of the UAZ Patriot

For normal operation of the unit, it is necessary to carry out regular maintenance. To do this, it is necessary to visually inspect the housing for lubricant leaks.

The manufacturer recommends changing the lubricant after every 30,000 km. When using the machine in extreme conditions, this figure is reduced.

If it is necessary to repair the front axle of the UAZ Patriot, the unit should be disassembled. You can disassemble the front axle without removing it from the car. Disassembly is carried out as follows:

- Install a car overpass, inspection hole or lift;

- Immobilize the vehicle by installing anti-roll devices under the wheels;

- Drain the used lubricant from the crankcase. To do this, you need to prepare a container with a wide neck;

- Jack up the front axle and install it on specialized supports;

- Remove the housing cover and the driveshaft;

- Where to mount the axle shafts;

- Unscrew the nut securing the drive shaft flange;

After completing these steps, the front axle gearbox components will be available for replacement. Assembly of the unit is carried out in reverse order. To facilitate the repair procedure, it is necessary to use the design diagram of the UAZ Patriot front axle.

From the above it follows that the front axle of the UAZ Patriot improves the vehicle’s off-road performance. The design of the unit makes it reliable and unpretentious to the conditions of use. For normal operation of the mechanism, regular maintenance is necessary.