The starter overrunning clutch or simply the starter bendix is an element through which torque from the starter is transmitted to the crankshaft of the car engine. During the operation of the car, wear occurs on the bendix springs and other components.

For this reason, it is necessary to promptly identify signs of a Bendix malfunction (the crankshaft does not spin, a creaking and grinding noise is heard when starting the engine). If signs of problems are detected, the Bendix should be checked:

- The starter is being dismantled;

- Bendix is being troubleshooted;

- a decision is made to repair/replace the overrunning clutch.

Read more about the causes of the breakdown, checking the Bendix on the starter, and how to replace the starter overrunning clutch in our article.

How does bendix work on the starter?

The starter Bendix is a relatively simple part and has a long service life. Structurally, Bendix includes:

- drive race (outer ring);

- driven clip;

The drive cage with rollers and pressure springs has characteristic wedge channels with a large width on one side. Spring-loaded rollers rotate in such channels.

When the rollers reach the narrow part of the channel, they are locked between the driving and driven cages. The springs actually “push” the rollers into the narrow part of the channel.

What is a starter

The starter is a DC electric motor combined with a retractor relay, which ensures its start and rotation of the crankshaft. In order to turn the crankshaft at a rotation speed that ensures the start of the working cycle, it is equipped with a motor of sufficiently high power, measured in kilowatts, and the required current for its operation can reach hundreds of amperes. Therefore, like any electromechanical device, the starter is subject to both electrical and mechanical failures.

Bendix operating principle

The operation of the Bendix is based on the inertial effect on the gear coupling until it engages with the flywheel. It turns out that if the starter is turned off or the car engine is running, the Bendix clutch does not engage with the flywheel crown. Bendix also protects the starter from damage after the engine starts.

The mechanism works as follows:

- when the driver turns the key in the ignition, current from the battery is supplied to the starter motor, the armature rotates;

- due to the presence of helical grooves on the inside of the coupling and the rotational movement, the coupling begins to slide under its weight along the splines until the moment of engagement with the flywheel;

- due to the influence of the drive gear, the driven cage with the gear also begins to rotate;

If the teeth of the clutch and flywheel do not match, a slight rotation is performed to obtain a rigid engagement. - the presence of a buffer spring allows you to “soften” the moment the engine starts and prevent breakage of the teeth as a result of an impact that occurs at the moment when the gears mesh;

It is important to consider that after starting the engine, the flywheel begins to rotate faster than its previous rotation speed from the starter. When the flywheel speed increases, the clutch twists back and slides along the splines of the armature or gearbox (when using a geared bendix). This is how the bendix disengages from the flywheel and at the same time protects the starter, which is not designed for high speeds.

Why does the starter bendix skip?

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

The starter bendix (real name is overrunning clutch ) is a part designed to transmit torque from the starter to the car engine, as well as to protect it from the high operating speeds at which the engine operates. The starter Bendix is a reliable part, and it rarely breaks. As a rule, the cause of failure is natural wear and tear of its internal parts or springs. To identify malfunctions, let’s first understand the device and operating principle of the Bendix.

Design and principle of operation

Most overrunning clutches (let's call them the more popular word among motorists - bendix) consist of a driving race (or outer ring) containing rollers and pressure springs, as well as a driven race . The leading holder has wedge channels, which on one side have a significant width. It is in them that the spring-loaded rollers rotate. In the narrow part of the channel, the rollers are locked between the driving and driven clips. As is clear from the above, the role of the springs is to drive the rollers into the narrow part of the channels.

The principle of Bendix operation is the inertial effect on the gear coupling that is part of it until it engages with the engine flywheel. While the starter is inoperative (the engine is turned off or running in constant mode), the Bendix clutch is not engaged with the flywheel crown.

Bendix works according to the following algorithm:

Bendix interior

- The ignition key is turned and current from the battery is supplied to the starter motor, driving its armature.

- Thanks to the helical grooves on the inside of the coupling and the rotational movement, the coupling, under its own weight, slides along the splines until it engages with the flywheel.

- Under the action of the drive gear, the driven cage with the gear begins to rotate.

- If the teeth of the clutch and the flywheel do not coincide, it rotates slightly until they are firmly engaged with each other.

- The buffer spring included in the design serves to soften the starting moment of the engine. In addition, it is needed to prevent tooth breakage from impact when the gears engage.

- When the engine starts, it begins to rotate the flywheel at a higher angular speed than the starter previously rotated. Therefore, the coupling twists in the opposite direction and slides along the splines of the armature or gearbox (in the case of using a geared bendix) and disengages with the flywheel. This saves the starter, which is not designed to operate at high speeds.

How to check starter bendix

If the starter bendix does not turn, then you can check its operation in two ways - visually , by removing it from the car, and “by ear” . Let's start the description with the latter, as it is simpler.

As stated above, the main function of the bendix is to engage the flywheel and spin the engine. Therefore, if at the moment of starting the engine you hear that the starter motor is spinning, and characteristic metallic clanging sounds - this is the first sign of a Bendix malfunction .

So then it is necessary to dismantle the starter and disassemble the bendix in order to inspect it in detail and determine the damage. The removal and replacement procedure is described below.

And so, the bendix was removed, it is necessary to inspect it. In particular, check whether it rotates only in one direction (if it turns in both, it means it needs to be replaced) and whether the teeth are eaten. Also check to see if the spring is loose. You should also remove the fork from the Bendix, check its integrity, signs of wear, and if necessary, replace it. In addition, be sure to check if there is any play on the armature shaft. If this occurs, then the bendix should be replaced.

Possible causes of failure

As mentioned above, gear rotation is only possible in the direction of rotation of the starter armature. If rotation in the opposite direction is possible, this is an obvious malfunction, that is, the bendix must be repaired or replaced. There may be several reasons for this:

- Reduction in the diameter of the working rollers in the cage due to natural wear. The way out is to select and purchase balls of a similar diameter. Some car enthusiasts use other metal objects, such as pieces of a drill, instead of balls. However, we still do not recommend doing it yourself, but buying balls of the required diameter.

- The presence on one side of the roller of flat surfaces formed due to natural wear. Repair recommendations are similar to the previous paragraph.

- Grinding the working surfaces of the driving or driven race in those places where they come into contact with the rollers. In this case, repair is hardly possible, since such excavation cannot be removed. That is, it is necessary to replace the bendix.

Starter overrunning clutch: signs of malfunction

As a rule, drivers are usually faced with the fact that after applying power to the starter, the bendix does not engage with the flywheel, the bendix may not turn the engine, etc. Often, engagement problems can be detected early on by hearing.

The main function of the bendix is to engage with the flywheel and turn the engine.

Problems with engagement will result in metallic clanging, crunching and grinding sounds when the engine starts. At the same time, the starter motor is running. If such a symptom of a Bendix malfunction appears, it is necessary to check the overrunning clutch.

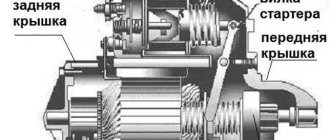

The principle of operation of the starter and its design

If everything is in order electrically and the circuit is without damage, then it is worth dismantling the spare part for disassembly and detailed inspection in order to identify defects. But before doing this, you need to study the structure and principle of operation of a car starter.

Car starter device: 1. front cover; 2. bendix; 3. gearbox; 4. anchor; 5. stator housing assembly; 6. fork; 7. solenoid relay; 8. brush assembly; 9. brushes; 10. rear cover of the car starter.

When you turn the key and start the engine, the following processes occur:

Z

The lock contacts are closed and through the starter relay, power is supplied to the windings (traction and holding) of the solenoid relay.

M

the magnetic field in the windings forcefully pulls the armature inside the housing (compressing the return spring).

The principle of operation of the starter

Then

it begins to push the rod with the contact plate, which closes the contacts of the retractor relay, as a result of which the starter motor begins to rotate. And at the same time, the bendix moves forward from the armature, bringing its gear into engagement with the engine flywheel. Which consequently leads to the launch.

IN

the moment when the flywheel begins to rotate faster, is it not the bendix gear, the overrunning clutch

prevents the transmission of torque

and the bendix is pulled back by a lever, and thanks to the return spring returns to its position.

TO

The key in the ignition switch returns to its original position and the voltage at the control terminal disappears.

Based on the considered diagram, we can make assumptions about possible problems at the appropriate stages.

Causes of Bendix failure

The main reasons for bendix failure:

- the diameter of the working rollers in the cage decreases as a result of wear (in this case, you can select balls of suitable diameter and replace them);

- the roller on one side has worn out due to wear (the solution is to replace the balls);

- the working surfaces of the driving or driven race are ground down at the points of contact with the rollers (wearing out means the need to replace the bendix).

- wear of the gear teeth (you can replace the gear or bendix assembly).

Replacing the bendix itself is not often required, since this part is reliable and has a long service life. However, natural wear and tear during vehicle operation is inevitable, which leads to malfunctions.

The starter also experiences heavy loads and is open to contact with the external environment (moisture and dust, dirt, oil, etc.). Deposits also accumulate in the grooves and rollers of the Bendix. As a result, the armature makes noise, but the crankshaft does not rotate.

First of all, the rotation of the gear should be carried out only in the direction of rotation of the starter armature. Rotation in the opposite direction clearly indicates a breakdown and the need to repair the bendix or completely replace it.

In practice, experts recommend changing the bendix even if repairs are possible. The fact is that the individual parts of the coupling wear out approximately equally. This indicates the rapid failure of other elements after replacing one worn part.

Other reasons

Another reason for poor performance may be a faulty relay. It is almost always located in the mounting block and switches the voltage supply to the solenoid relay. If it malfunctions, the starter will not show signs of life if all other components are in full working order. To check, just listen to his work. When triggered, it always clearly clicks (the contacts inside it close). If it is silent, it means it needs to be replaced.

The operation can be blocked by an immobilizer or a security alarm installed on the car. They can be connected to the ignition or starter circuits and, when arming, simply open the starting circuit so that the starter does not respond to turning the key. To check, you should try to bypass it by connecting it directly to the battery. If it works, then the reason may be precisely these security systems.

Thus, there are quite a few reasons why the starter does not respond to the ignition key or clicks, but all of them can be diagnosed and identified using a comprehensive and consistent approach.

Sometimes the vehicle does not want to start. And, what’s worst, this very often happens at the most inopportune and inconvenient moment. This situation is familiar to many motorists. Of course, we have to do something about it. And, if the car's electrical system is in perfect order and charged, then the problem may lie in the starter, namely in its peripheral devices. It is likely that the starter traction (retractor) relay is faulty. You can't do without repairs here, so you'll have to prepare for it. After all, it will be much easier for a trained person to overcome any difficulties, including repairing the starter solenoid relay.

How to check the starter solenoid relay?

The starter, in its essence, is very simple in its design. And, if there are instructions for this automotive component, then even the most inexperienced motorist can deal with its repair. It is important to remember that the most difficult thing is to dismantle it and then mount it back. Other work is done once or twice. But before you start repairing the starter, you need to figure out what the breakdown is and what place needs to be repaired. The first thing to do is check the battery charge, as problems can also arise from it. If you change the battery and this does not give any results, then you will have to repair the starter.

It is likely that the ignition switch or the starter switch located under the car hood on the mudguard is faulty. Their malfunction can be determined by characteristic sounds. If the starter makes absolutely no sounds, then most likely the ignition switch and starter relay are in order, and the causes of the malfunction lie in a completely different place. First, let's look at the principle of operation of the starter.

So, the starter, like its solenoid relay, works based on the principles of electromagnetism. When voltage is applied to the windings, it attracts the armature. This anchor moves the Bendix gear until it engages with the splines on the flywheel ring. In parallel with this, the contacts are closed, through which voltage is transmitted to the starter winding. After all contacts have closed, the coil of the solenoid relay stops receiving power, although the armature will continue to be held inside due to the created magnetic field. When the engine starts, the armature is pulled into place by the return spring and the bendix is released.

All described processes are completely interdependent and occur almost simultaneously. If at least one connection is broken, the car will not start. This means that you will have to look for the breakdown and try with all your might to eliminate it. Often starter breakdowns are caused by breakdowns of its retractor relay.

The most common causes of breakdowns of the car starter solenoid relay:

1.

Burnt starter winding or relay.

2.

Combustion of contact plates (popularly called nickels) inside the relay.

3.

Gradual destruction of the materials from which the device is made (including from old age).

Before you start checking the functionality of the starter solenoid relay, you should check the starter itself. To do this, you just need to turn the ignition key and listen. If the starter does not work, but some clicks are heard, this means that the starter is not working, but its solenoid relay is in order and the cause of the breakdown lies in something else.

Signs of malfunction of the car starter solenoid relay:

1.

The starter does not turn off after starting the engine and continues to rotate at a very high speed, as evidenced by the buzzing sound.

2.

After turning the key in the lock, you hear a click, which means the device is turned on, but the starter does not start.

3.

When you turn the key in the lock, you hear that the starter rotates idle, but the engine itself does not start to work.

How can you know for sure that the cause of the malfunction lies precisely in the solenoid relay?

In fact, you can accurately check the serviceability of the retractor relay even before removing the starter from the car. This is very convenient as it saves a lot of time and resources.

To check the solenoid relay, you need to do the following:

1.

Using a metal object or a piece of wire, close the contact bolts located on the back of the starter. This way the voltage will go directly to the starter windings without passing through the solenoid relay windings.

2.

If after turning the ignition key the starter starts to rotate, then it is working properly, and the breakdown really lies in the solenoid relay.

3.

If, after turning the ignition key, you hear the retractor relay clicking, but the starter itself does not work, then the relay is working properly, and the causes of the malfunction will need to be looked for elsewhere.

If you were unable to get to the contacts of the solenoid relay, you will need to dismantle it. When you check or repair any starter parts with your own hands, be extremely careful and attentive, since any incorrect movements can lead not only to breakdowns of car components, but also to injuries. Particular care should be taken when checking a dismantled relay (the rotation of the mechanisms is very strong and they can simply break out and cause injury to the motorist)

Repair of starter solenoid relay.

If you determine that the causes of starter malfunctions lie in its solenoid relay, then you will have to repair the starter solenoid relay. As practice shows, such repairs often end with a complete replacement of the solenoid relay. What is this connected with? The fact is that some manufacturers of automotive components produce retractor relays that are completely non-separable, thus trying to achieve greater reliability of this element. And, if you have a non-separable solenoid relay installed in your starter, then there is no other option but replacement.

But it also happens that the solenoid relay is disassembled. In this case, you can try to restore its functionality. As already noted, the causes of malfunction of the solenoid relay are the combustion of its contacts, short circuits in its winding, or simple wear and tear of its components. After disassembling the solenoid relay, problems with diagnosing the causes of failure should not arise, since any breakdown will be noticeable to the naked eye. But to check the serviceability of the winding, you will need an ohmmeter that is connected to the starter relay.

If the resistance value is no less than 10 ohms, then everything is in order with the winding.

And, if this indicator is lower, this indicates a short circuit in the windings and you will have to buy and install a completely new relay, since replacing the winding is extremely difficult. But to repair the starter solenoid relay, it must first be completely removed from the car.

The process of dismantling the starter solenoid relay consists of the following steps:

1.

Completely disconnect the battery from the power supply (otherwise, this may result in a short circuit and fire in all vehicle wiring).

2.

Remove the starter from the vehicle.

3.

Clean the starter from dirt and dust. This must be done carefully to prevent dirt from getting inside the unit.

4.

Unscrew the corresponding nuts from the brush assembly and remove the contact from the solenoid relay bolt.

5.

Unscrew the screws that secure the relay to ground.

6.

Remove the solenoid relay from the starter.

After the relay has been removed, it is either replaced with a new one or repaired. If you have a collapsible mechanism and you decide to repair it, then you should do the following:

1.

Unscrew the nuts on the ends of the solenoid relay and divide it into parts.

2.

Remove the old core and replace it with a new one.

3.

Reassemble all elements in reverse order.

The solenoid relay is installed back into the starter in the opposite order to removing this component. To avoid confusion, we recommend marking the terminals when removing the relay. This way there will be no issues during re-installation. It is also important to remember that before reinstallation, all contacts should be cleaned and thoroughly degreased. After installation, be sure to check all parts for functionality and make sure that the work done is correct.

A starter is an electromechanical device that starts the engine by creating primary torque of the crankshaft at the required speed to create a compression ratio to ignite the combustible mixture.

And when the starter does not work or works intermittently, starting the engine is very problematic and sometimes impossible. But before you start looking for the reasons why the starter does not turn, you need to remember that this unit works in tandem with other systems

vehicle in the common starting-charging circuit (battery-starting control mechanism-starter). Therefore, there can be both mechanical and electrical breakdowns, which have their own distinctive features.

How to check bendix on the starter

Checking the Bendix involves removing the part and then troubleshooting the overrunning clutch. As part of the diagnostics, you also need to know how to check the starter bendix:

- First, the starter is dismantled;

- Next, the bendix is removed and disassembled;

- then a visual inspection is carried out, damage is detected;

Bendix inspection begins with checking whether the clutch rotates in one direction or in both directions. If rotation is noticed in both directions, replacement is necessary. You also need to check the condition of the teeth and spring. Do not grind down the teeth or weaken the spring.

You also need to separately remove and inspect the Bendix fork for integrity and wear. If defects are detected, the plug can be replaced. At the same time, you should check for play on the armature shaft (if there is play, the bendix needs to be replaced).

Replacing the starter bendix

To change the bendix, the starter must be removed and disassembled. On different car models, removing the starter may be accompanied by certain difficulties and nuances. After removing the starter, it is necessary to disassemble the housing to check/repair/replace the bendix;

Before you start checking and/or replacing the overrunning clutch, it is important to understand what a starter bendix is in general and how this solution works. If the bendix has not been removed before, but signs of its malfunction have been identified, you can immediately buy a starter bendix and begin replacing it.

However, experienced specialists recommend first removing the starter and checking the existing bendix, since the reason is not always there. In any case, before starting work, you need to learn in advance how to change the bendix on the starter.

We also recommend reading the article about where the solenoid relay is located and how to check it. From this article you will learn about the location of the solenoid relay and how to check it.

The general steps are as follows:

- unscrew the tightening bolts and open the housing;

- Unscrew the bolts securing the solenoid relay;

- remove the bendix from the axle by removing the washer and removing the restrictive ring;

- carefully remove dirt and deposits on internal elements and surfaces;

- Before installing a new/repaired Bendix, the axle must be lubricated with high-temperature grease

- We install the locking ring and washer (the procedure is complicated, the ring needs to be opened using an open-end wrench, a clamp, pliers, etc.).

- after installing the Bendix, the rubbing parts of the starter must be lubricated with high-temperature lubricant (do not allow excess to get on the parts);

The final step before installing the starter on the car is to check it. To do this, supply power directly from the battery to the starter. Using a wire, “+” is connected to the control contact of the starter solenoid relay, “-” is connected to the starter housing.

Normally, you should hear a click when connecting, and the bendix moves forward. If the bendix does not extend, it is necessary to check and replace the solenoid relay.

Bendix starter - functions, malfunctions, checking and replacing bendix on the starter

Bendix starter

The starter bendix (real name is overrunning clutch ) is a part designed to transmit torque from the starter to the car engine, as well as to protect it from the high operating speeds at which the engine operates. The starter Bendix is a reliable part, and it rarely breaks. As a rule, the cause of failure is natural wear and tear of its internal parts or springs. To identify malfunctions, let’s first understand the device and operating principle of the Bendix.

How to change bendix on the starter

As a rule, in order to change the bendix, you need to remove the starter and disassemble it. Depending on the machine model, the procedure may have its own characteristics. We will describe the algorithm from the moment when the starter has already been removed and to replace the bendix it is necessary to disassemble its housing:

Bendix repair

- Unscrew the tightening bolts and open the housing.

- Unscrew the bolts securing the solenoid relay, and then remove the latter. When repairing, it is advisable to clean and wash all the insides.

- Remove the bendix directly from the axle. To do this, you need to knock down the washer and pick out the restrictive ring.

- Before installing a new bendix, the axle must be lubricated with temperature grease (but without excess).

- Typically, the most difficult procedure involves installing the retaining ring and washer. To solve this problem, craftsmen use different methods - they open the ring with open-end wrenches, use special clamps, sliding pliers, and so on.

- After the bendix is installed, lubricate all rubbing parts of the starter with high-temperature grease. However, do not overdo it with the amount, because excess will only interfere with the operation of the mechanism.

- Check the starter before installation. To do this, use wires to “light” the car in winter. With their help, supply voltage directly from the battery. Connect the “minus” to the starter housing, and the “plus” to the control contact of the solenoid relay. If the system is working properly, you should hear a click and the bendix should move forward. If this does not happen, it is necessary to replace the retractor.

Bendix repair

Replacing the bendix on the starter

Some tips from experienced drivers

Here are some tips from experienced motorists that will help you avoid possible problems and inconveniences when repairing or replacing a Bendix:

- Before installing a new or repaired bendix, always check its operation and the drive of the unit.

- All plastic washers must be intact.

- When buying a new Bendix, it is advisable to have the old one with you in order to verify their identity. Often similar parts have minor differences that are not visually memorable.

- If you are disassembling a Bendix for the first time, it is advisable to write down the process on paper or put the individual parts in the order in which they are dismantled. Or use the manual with photographs, video instructions above, and so on.

Tips and tricks

Checking and replacing the bendix is not a complicated procedure. If necessary, a car owner without experience in performing such work can replace the bendix on the starter with his own hands. The main thing is to take into account the following nuances:

- a new or repaired bendix must be checked before installation on the car; all plastic washers must be intact;

- when choosing a new Bendix, it is advisable to have the old element on hand to check full compliance;

- in case of complete lack of experience, it is advisable to have a manual;

Also note that Bendix is not an expensive part. For example, a Bendix starter for a VAZ, depending on the car model, can cost from 5 to 12 US dollars; a Bendix for a foreign car will cost 15-20 USD.

We also recommend reading the article about why the starter clicks but does not turn the engine. From this article you will learn about the main causes of starter malfunction, as well as failures when trying to start the car engine.

Given this price, it is not recommended to repair the Bendix. It is more rational to immediately carry out a complete replacement, after which you can count on a fairly long service life of the new part.