Troit carburetor engine, reasons

— The engine “troubles” - twitches at idle. Popping noises are heard from the muffler;

— When starting the engine, on “choke”, the speed is stable, without “chuck” on a warm engine, the idle speed is unstable until it stops.

Often, unstable engine idle speed is accompanied by increased fuel consumption and loss of power and throttle response.

Causes of "triple" - unstable idling of the engine of VAZ 2108, 2109, 21099

Let's look at the reasons for unstable engine idling (engine troits) on VAZ 2108, 21081, 21083, 2109, 21091, 21093, 21099 cars with carburetors 2108, 21081, 21083. Here is a list of reasons for the vehicle systems, a more detailed analysis of each of the reasons is given in individual articles available via links in the article.

The carburetor is faulty or not adjusted

— The idle speed adjustment with the “quantity” and “quality” screws of the fuel mixture is broken

Adjust the idle speed using these screws. By rotating the screws clockwise we increase the fuel supply to the cylinders, counterclockwise we decrease it. Normal idle speed for engines 2108, 21081, 21083 of VAZ 2108, 2109, 21099 cars is 750-850 rpm.

Dints of quality and quantity

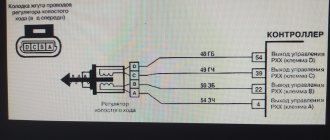

— The carburetor solenoid valve is faulty

We check its serviceability for a “click”. We remove the wire tip from the valve terminal and put it on again; a “click” should be heard. This shut-off needle is pulled into the valve body and opens the hole for fuel to pass through. There is no click - the valve is faulty, or there is no current flowing through the wire.

Carburetor solenoid valve (EMV)

— Foreign air is “sucked” into the carburetor, excessively leaning the fuel mixture

The culprits may be - a hose from the vacuum brake booster to the intake manifold (1), rubber sealing rings on the “quality” screw (8) and the solenoid valve (4), a slipped or burst tube to the housing of the vacuum ignition timing regulator on the distributor (2), leaky housing or damaged diaphragm of the vacuum regulator housing (6), deformation of the carburetor seating surface (5), or wear of its gaskets, crankcase ventilation tube (3), gasket under the intake manifold (7).

Air suction points

— The channels and jets of the carburetor idle system are clogged

— Low fuel level in the carburetor float chamber

— The air filter element is clogged

The degree of contamination should be quite high. Replace it with a new one.

The power system before entering the carburetor is faulty

— Fuel pump is faulty

— Filters in the power system are clogged

This is a filter on the fuel intake in the gas tank, a fine fuel filter and a mesh filter in the carburetor.

— Damaged elements of the power system

Ignition system is faulty

— Spark plugs are faulty

— The distributor (cover, slider) is faulty

— High-voltage wires are faulty

— The ignition timing is not set correctly

The power supply system is faulty

— Short circuit in the wiring

Engine faulty

— Thermal clearances in the valve mechanism are broken

— Marks in the timing system are shifted

— Wear of the piston group (breakage or sticking of rings, wear of cylinders)

— Burnout of valves

Notes and additions

— Before you begin to identify the causes of engine “triple” at idle, it is necessary to conduct a visual inspection of its engine compartment. A loose wire, a chip not fully inserted, a kinked hose, etc. will not allow the engine to work normally, and will take away the time and effort of the car owner spent on troubleshooting.

Source

Carrying out fault diagnosis work

Remove the central wire of the distributor and secure it at a distance of 3–5 mm from ground. Unscrew the spark plugs and inspect them. Remember which particular candle has black soot.

Insert the compression gauge one by one into the spark plug hole of the cylinder. The assistant turns on the starter and cranks the engine. Keep the gas pedal pressed. This makes it easier for air to be sucked in.

After measuring compression in all cylinders, we analyze the data obtained. A boiler with a compression different from others, more than 1 atm, is the cause of engine tripping. Moreover, the pressure can be either lower than on other cylinders or higher. Measuring compression can also show that it is equal in all “boilers” of the internal combustion engine of the VAZ 2106 car. Now, one by one.

- Case one: compression in one cylinder is noticeable, more than 1 atm. , lower than others. This case is the most common. Let's pour about 15 ml of oil into this cylinder and check the compression again. There can be two results.

Compression levels have increased significantly: piston rings are stuck or broken.

Compression does not change. We carry out diagnostics to determine exactly why the engine is running unstable. We install the piston of the problem cylinder at TDC. To determine TDC, insert a clean wooden stick into the spark plug hole and slowly turn the crankshaft until the stick rises the most.

This is interesting: Scheduled maintenance for Mitsubishi Lancer X: regulations, cost, maintenance schedule

The piston at this moment will be at the highest point. Use a compressor to supply compressed air to the cylinder (2–3 atm). If you don't have a compressor, use a well-inflated car tire and a piece of rubber hose. Place the car in gear first.

Listen to where the air is coming from. If it hisses from the spark plug hole of another boiler, the gasket under the block head is damaged. Air breaks into the carburetor - the intake valve does not fit well to the seat. If air escapes from the oil filler neck (remove its cap first), the piston is damaged. You can hear air noise from the muffler - it's burnt out, the exhaust valve is not sealing tightly.

2. Case two: the compression of one of the engine boilers is much higher than the others. Did a spark plug made from it have black growths on the electrodes? This means that oil is getting into the cylinder: the oil scraper rings are broken, there is some defect in the valve-guide sleeve pair, there is a defect in the oil seals of a particular cylinder.

3. Case three: compression is almost equal everywhere, the difference is no more than 1 atm. This indicates that there is uneven wear in the CPG. Happens on an engine with a mileage of 50,000 km or more. In this case, look for the cause not in the engine, but return to the ignition, carburetor.

Symptoms of a problem

If you know about the main signs and symptoms of a motor malfunction leading to tripling, it will be much easier for you to solve the problems that arise.

There are several signs in total.

To understand why the engine stalls at idle or in gear, you need to understand the possible reasons for this phenomenon.

Causes

The reasons for engine tripping are different. But they are most often caused due to the failure of one of the following units:

Now let’s take a closer look at the reasons and actions you can take in a given situation.

Cause

Your actions

The ignition was set incorrectly

It’s not uncommon for an engine to misfire because the ignition was set incorrectly. The problem is determined by skipping a beat, the appearance of popping noises, and bouncing of the engine. Listen to how the motor works. If the tripping occurs at idle, but when you start driving and increase the speed, the problem goes away, then the ignition is too early. It needs to be adjusted.

Vacuum booster problem

It may be damaged, the tightness of the diaphragm or valve may be compromised. This leads to the appearance of air inside the system, the mixture becomes “leaner” and does not ignite properly. As soon as there are literally 2 omissions, the candle will get wet and will not be able to work. If there are problems with the amplifier, the engine will fluctuate at idle, when the engine is hot and cold

Another common problem is engine tripping, accounting for about 50 percent of all cases. To solve the problem, periodically inspect the spark plugs, clean them and change them. Moreover, it is recommended to perform the replacement as a complete set, and not just each candle individually

If breakdowns occur in one of the high-voltage circuits, the spark will not be able to reach its spark plug. As a result, the motor stalls and does not work properly. To check, turn off the lights, start the engine and watch the area from the distribution coil to the spark plugs. If a spark appears in the gap, this indicates the presence of a hole in the capacitor or wire insulation. A temporary solution is electrical tape, but then the wire must be replaced

BB wires

If the engine stalls at idle, the problem may be related to the operation of the ignition system. The culprit is the armored wires, which most often fail. If the wire is damaged, then the spark will break through and, naturally, there will be no spark at the spark plug. The fuel mixture in the cylinder will not ignite. It is best to check the wires with a multimeter.

View gallery

Among the malfunctions of the wires, one can identify problems with the contacts at the points of connection with the spark plugs or with the coil. Also, the conductor may have various damages. If the insulation is destroyed, this will be accompanied by breakdowns and current leakage. In addition, increased wire resistance is also considered a malfunction. This also negatively affects sparking and the operation of the ignition system.

Manifestation of tripping at idle speed

The first sign is shaking at low speeds, which is transmitted to the steering wheel, gear knob, clutch and brake pedals. The main feature is that the engine revs at idle speed, and not under load. That is, when you press the gas pedal, the car drives smoothly without failures and accelerates well. As soon as you stand at a traffic light, the engine vibrates.

The second sign is the floating speed. The arrow on the instrument panel swings back and forth. The speed cannot reach 800 rpm.

The third common symptom is a freezing speed. The engine hums and buzzes at 1200 rpm and above.

How can you tell if the engine is actually stalling?

The very first and main task of the driver when such a problem is detected is to accurately determine that one of the cylinders is not working.

To do this, you can use the diagnostic tools built into the car. If the engine is old, then the search for a non-functioning cylinder will be discussed below. View gallery

In general, the indicators of engine “triple” are as follows. You will feel rattling and vibration in the cabin, which disappear when you press the gas. Also one of the symptoms is the car taking a long time to warm up at low temperatures. You can hear this problem - the operation of the motor will be irregular, and one beat can be heard missing.

If the Priora engine adjusts 16 valves at idle, this will be accompanied by loss of power and increased fuel consumption. If the “Check Engine” light comes on on the instrument panel, and there are also other symptoms from the list above, then the engine is definitely faulty.

Possible reasons

There could be a huge number of reasons. Let’s figure out how to diagnose this malfunction, what actions need to be taken, what to know so as not to buy unnecessary spare parts, not to pay all the diagnosticians in the city for saying: “everything is fine with you” or vice versa: “let’s change this, and this.”

Mechanical engine failure

First of all, you need to measure the pressure in the cylinders with a compression gauge. The compression value of a standard engine should be within 13 atm. Deviations of 1 atm are permissible, but no more. With such an insignificant difference, check the thermal clearances of the valves and hydraulic compensators, depending on what type of adjustment is installed on the engine. Hydraulic compensators are a mechanism of plungers and oil channels. Due to oil pressure, the hydraulic tappet compensates for the thermal gap between the camshaft cam and the valve stem. If the mechanism is broken, worn out, or no oil is supplied, the gap will not be selected and the engine will stall at idle speed. It does not appear under load, that is, at high speeds.

Having released Grant's car, AvtoVAZ replaced the cylinder head seats with metal-ceramic ones. Before this, the heads 21083 and 1118 Kalinovsky had cast iron seats. In connection with this simple replacement of one with the other, the thermal gaps need to be set 0.05 mm larger. This is what it says in the manual and letters from the factory. Many people don’t know this and do it as before, deliberately clamping the valves. The consequences of such an adjustment make themselves felt after some time, in the form of valve burnout and engine tripping at low speeds.

In practice, there are cases when the valve cracks, but at the same time the compression shows good. Such nuances are rare, but they do occur. How to check? For this there is a pneumatic tester, the operating principle of which is very simple. Air is pumped into the engine at a certain pressure and the difference in readings from two pressure gauges on the tester is observed. You can also tell by ear where the air is coming from. Through the intake, exhaust valves, engine crankcase or coolant expansion tank. In this professional way, the presence or absence of tightness at the contact point of the valve seat, piston rings, and head gasket is determined.

Car spark plugs

The main source of the engine trimming at idle speed is the spark plugs. If one of them does not work correctly, the engine will shake - one of the cylinders does not work.

View gallery

To find out which candle is not working, you can use the old method. Despite the fact that this diagnostic method is ancient, it can be used to very quickly and effectively find a broken spark plug.

You need to start the engine and then remove the spark plug cap from each cylinder in turn. If, when you pull the wire from the spark plug, the engine tries to stall, then the spark plug is in full working order. If the motor does not react in any way to pulling off the cap, then the spark plug in this cylinder is not working.

There is another method. After the engine is running at idle, you can unscrew the spark plugs and inspect them visually. Usually you can identify a non-working spark plug even with the naked eye. It will be filled with fuel. There will also be no characteristic soot on it. The faulty spark plug needs to be replaced and then engine operation will return to normal.

The engine stalls at idle: common causes and quick diagnosis

It is quite obvious that with such a malfunction it becomes difficult to operate the vehicle, since you have to constantly increase the speed to maintain normal operation of the internal combustion engine. As a result, fuel consumption increases noticeably, cold starting of the engine can also be very difficult, etc.

At the very beginning, you need to determine which cylinder is not working. To do this, start the internal combustion engine, and then disconnect the high-voltage wires from the spark plugs one by one. If after disconnecting the power the engine operation changes, this means that the cylinder is working. Turning off the power from the non-working cylinder, on the contrary, will not lead to a change in the sound and nature of the operation of the power unit.

In some cases, replacing the spark plug or cleaning it allows you to normalize engine operation and get rid of “triple”. It should be remembered that although spark plugs can be designed for 30-80 or even 100 thousand km. mileage, when driving on domestic fuel, it is often necessary to change these elements already at 20-25 thousand.

It is also important to consider that when checking high-voltage equipment, you need to follow safety precautions. If you have no experience, then it is advisable to put a wooden block, rubber mat, etc. under your feet. Also, when disconnecting the wires from the spark plug, do not hold onto the cap. You need to grab a high-voltage wire. In this case, you should try not to touch the engine and car body.

At the same time, it should be understood that armored wires can also be damaged and penetrated. By the way, if the spark “goes somewhere”, in the dark it is enough to look under the hood to detect a breakdown.

Please note that when a diesel engine is running, to check it is necessary to alternately turn off the supply of diesel fuel to the injectors. To do this, unscrew the fittings on the high-pressure lines.

Now let’s imagine that the required cylinder has been found, the spark plug gives a spark, the armored wire is in perfect order, and the engine still runs rough. In this case, you need to unscrew the spark plug again and inspect the tip, determining whether it is wet or dry. As a rule, this will indicate problems with mixture formation.

If the spark plug is wet, then the air/fuel mixture may be too rich. A dry spark plug indicates that the mixture is too lean. In both the first and second cases, the cylinder will not work on such a mixture, even if the ignition system is working. The cause may be contamination or damage to the injectors, as well as the leakage of excess air.

As part of the diagnostics, you can perform a quick check of the injectors by disconnecting the power plugs from them. If when you turn off the power from any injector the engine operation does not change, then this is a faulty element. To confirm or refute this, swap this injector with the one in the adjacent cylinder. If the cylinder operates normally, then the problem is not the injector.

Finally, it should be remembered that an injection engine also fails in many cases due to damage or failure of coils, commutators, ECM sensors, incorrectly set timing marks, etc. In some cases there may be no spark, in others there is a spark and everything is fine with the fuel supply, but tripping is still present.

In such situations, it will be extremely difficult to solve the problem yourself, especially on the road. It is better to immediately go for computer diagnostics. For example, a failure or incorrect signal from the mass air flow sensor (mass air flow sensor) is often the reason why the engine runs unevenly and idles.

Troubleshooting methods

The piston system is quite reliable, it rarely fails, but if this happens, you will have to start replacing the piston or rings. Fixing problems with the cylinder head may involve adjusting or replacing valves, worn rockers or valve stem seals, or cylinder head gaskets. Additional signs may indicate a gasket: unstable operation of two adjacent cylinders, overheating of the power unit, a decrease in the coolant level.

Bottom line: some of the problems that cause the VAZ 2106 engine to “trouble” can be solved in a garage even by a car enthusiast who is not particularly knowledgeable in these matters. But with malfunctions of the piston system, cylinder head, and in some cases the carburetor, it is better to contact specialists.

Spark generator

The first place where motorists usually look for a problem is the spark plugs. On old domestic cars this is done simply - using the old-fashioned method. The spark plug is unscrewed from the cylinder block.

Next, it is inserted into the tip and leans against the car body. Turn the ignition key for 1-2 seconds and you will see if there is a spark. This procedure should be repeated with all four candles. Of course, if there is a stand for checking spark plugs, then it is recommended to use it.

To check the high-voltage wires, you need to remove them from the vehicle and measure the resistance using a multimeter. The indicator should be about 5 ohm. For Zhiguli cars with a carburetor engine, it is recommended to use high-voltage wires manufactured by Tesla.

The VAZ 2106 engine uses a standard Zhiguli ignition coil, which can also fail. Therefore, it is recommended to diagnose this element as well. In case of failure, replace it.

Fuel supply

Fuel supply is one of the important elements in the formation of the air-fuel mixture. Let's consider where a malfunction can occur. The following elements should be diagnosed: carburetor, fuel pump, fuel filter and intake manifold.

Let's start with the most common cause of tripping - the carburetor. It has a float chamber where the float can break, blocking the normal supply of fuel. Because of this, a lean mixture is obtained, which actually leads to triplication.

To fix the problem, you will have to disassemble and rebuild the carburetor. To carry out restoration and repair operations, a repair kit is usually used, which can be purchased at any car market.

The fuel pump, or rather its malfunction, can lead to poor fuel supply. Of course, to fix the problem, you can buy a repair kit and rebuild the unit. But, as practice shows, the repair will not last long, and it is recommended to replace the unit. Also, it is worth replacing the fuel filter, which is located near the gasoline pump.

A crack in the intake manifold can lead to air leaks, which will lean the mixture and lead to the effect of a throttled power unit.

In order to inspect the part, you will need a pit or a lift, since the lower part of the collector can only be seen from the side of the car pan. If it is determined that the part has a crack, it must be removed from the machine and welded using argon welding.

Air intake

Another component where a malfunction may be hidden is the air supply, and in the case of Zhiguli, an air filter that is simply clogged. The recommended service life of the filter element is 20,000 km. But this indicator also depends on the region of operation of the vehicle, as well as the time of year.

This is interesting: How to make a beautiful interior of a VAZ 2107: how to remove door trim, recommendations and tips