In 2013, AVTOVAZ decided to modify the manual transmission (manual transmission 2180). A cable replaced the gear shift drive with rods. The design of the box was modernized, and the following serial number was added to the name (manual transmission 2181). Let's look at the features of a cable gearbox.

Which models were equipped with a cable gearbox?

As soon as the new gearbox model was introduced in 2012-2013, it began to be installed on cars:

- Granta (sedan);

- Priora (hatchback, sedan, station wagon);

- Kalina (sedan, hatchback, station wagon);

- Kalina 2 (station wagon, hatchback, sedan).

"Lada Granta" (sedan, 2013)

In 2014, a new transmission appeared on the Kalina 2 Cross and Granta liftback. Starting from 2021 and up to the present time, they began to install it on the new Granta (Cross, hatchback, station wagon).

Design of a cable gearbox on the Lada Granta

Among the innovations:

- New and improved synchronizers have appeared in the first two gears. They make shifting easier and crisper. The cable gearbox in the Granta has a reduced noise level.

- The switching mechanism has also been updated, which now acts as a separate part and is not located below. Thanks to this, it does not sit among the hardening oil in the parking lot and lives longer.

- Now you won't be able to turn the car into reverse by accident - a lock has appeared. The shift forks are now cast from aluminum, rather than steel, as was the case in the 2180. They are supplied by the German brand Schaeffler.

The most interesting new feature of this box is the transition to cable drives, unlike the old 2180. Rods cost less and are actually more reliable, but manufacturers are massively refusing to use them. The cables eliminated unnecessary noise, knocks and vibrations. The clutch drive was originally supposed to be hydraulic, but due to the price this idea was abandoned. This is bad because the hydraulic one has better characteristics.

Principle of operation

Compared to a box with rods, a cable transmission definitely wins:

- When switching, the cables dampen vibrations.

- The lever sticks in smoothly, without clicks or knocks.

- By switching to cables, the oil fill level was reduced by approximately 25-30%.

- Cable transmissions are not afraid of temperature changes and freezing in cold winter.

- The cable gearbox on the Grant has a new clutch with an increased disc diameter (215 versus 200 mm).

Cable gearbox "Lada Grants"

Cable gearboxes are great for cars with powerful engines. Thus, the longitudinal movement was reduced to 13 cm, and the transverse movement to 9 cm. The adhesion moment increased due to an increase in its area.

Volume and type of oil, replacement frequency

The transmission itself has an oil volume of 2.2 liters. The oil in the Grants gearbox with a cable drive must be selected according to viscosity. If it is too viscous and the temperature outside exceeds the specified values, the transmission may bite. For hot regions, you need to select a thinner oil, and for cold regions, a viscous one. The recommended replacement frequency is 70 thousand km.

With a cable drive, Lukoil TM4 is poured. Viscosity depends on the location where the machine will be used. Viscosity grades:

- 80W-90;

- 80W-85;

- 75W-90;

- 75W-85;

- 75W-80.

The company recommends filling in the brands of oils "Lukoil", "Rosneft Kinetik", "Trans" KP-2, TNK "Trans" KP and KP "Super", "Novoil Trans" KP. The viscosity of all oils is different; it should be selected according to operating conditions. For all AvtoVAZ cars, they recommend the same oil manufacturers.

Design features

The optimal level of acceleration is ensured by the transmission system. In particular, on the version of the car that develops 87 horsepower, the car accelerates to 100 km/h in approximately 12.5 seconds (manual transmission). This indicator is higher only on a car where an automatic transmission is installed. As for fuel consumption, the basic configuration consumes approximately 8 liters per 100 km. This indicator is optimal for cars of this class.

The Kalina 2 gearbox includes a block of drive gears, driven bearings and synchronizers are installed. There is an oil sump near the front bearing. This element is responsible for supplying oil. The mechanical housing on the Lada includes, in addition to the clutch housing, the rear crankcase cover. They are cast from aluminum alloy.

A distinctive feature of the Kalina gearbox is that there is a magnet in the existing drain plug. The need for this is explained by the fact that it directly attracts metal debris that can get into the system.

The solenoid is effective. It is necessary to block accidental reverse gear. The solenoid is located in the gearbox housing. If the solenoid breaks down, reverse gear will no longer engage. However, the occurrence of this malfunction may be due to an electrical circuit break.

Thus, Lada Kalina can be equipped with a manual or automatic transmission. The service life of the machine depends on how often the device can be serviced. It is recommended to periodically check the oil level in the Lada Kalina box.

Advantages and disadvantages of cable gearboxes

Advantages:

- The first advantage of the cable transmission in the Grant is the switching mechanism. Now it is not immersed in oil, so it is easier to use in severe frost.

- The overall reliability of gearbox components has increased, since the gearbox has become more compact.

- Improved grip on the Grant with a cable gearbox. Due to the increased diameter, the torque also increased.

- Overall comfort has increased. The gears fit in more pleasantly, there are much fewer knocks, howls and vibrations.

The main disadvantage of the manual transmission 2181 is its manufacturing technology. The metal on the gears is bad, it gets licked off quickly. The cable drive fails. The good news is that recently the box has been improved and it has become more reliable.

Grants box shift mechanism

Many important elements of the old manual transmission were located at the bottom and were bathed in an oil bath - the shift mechanism, the rod clamps and reverse forks, the gear set seal, the reverse light switch. All of these elements were potential sources of leakage. Many people solved the problem with sealant, but moving the elements upstairs solved the problem once and for all.

The new gear shift module on Grant is a separate mechanism that, if necessary, can be removed without disassembling the box. The mechanism has a selector grille that clearly follows the gear shift pattern and prevents accidental engagement of reverse gear.

The center detent now rides on the center plate and transfers force to the lever without sliding bearings. This solution made it possible to eliminate all mechanical losses and increase the information content of switching.

Service

The only way to maintain the 2181 gearbox on a Grant is to change the oil in a timely manner. The replacement interval is 70 thousand km.

Manual transmission service

The oil change procedure looks like this:

- Find a place where you can access the bottom of the car - an overpass, a lift, a hole in the garage.

- Drive the car, secure the car with the handbrake.

- Prepare a container of at least 3 liters and gloves. Waste oil is harmful to the skin.

- Open the drain cap and wait until all the oil drains into the container. You also need to open the filler plug, so the oil will come out faster and more evenly.

- Fill in 0.5 liters of mineral oil to flush (a little more is possible), put the gearbox in neutral and idle for five minutes, then turn it off.

- Drain off what you washed with and add fresh oil.

Oil change for Lada Granta

For “mechanics” it is very advisable to wash the box when changing the oil, this way it will live longer.

Clutch Drive Maintenance

The clutch drive does not need to be serviced; it is simply easy to maintain. Chafing of the cable and damage to the drive itself can lead to increased noise when the clutch is disengaged and to its incomplete engagement.

It is very advisable to lubricate the cable, and if it is worn out, replace it. Periodically, the clutch needs to be adjusted and the pedal travel monitored.

Maintenance and adjustment of the cable drive (gear selection system)

It also needs lubrication and supervision. There is no way to adjust the cable drive on the Grant purely technically, because the engineers did not provide for such a possibility. Craftsmen try to simply tighten the cables or move the fastening ears, but the method is not very effective.

If the cable drive is worn out, it must be replaced. According to the plan, they are replaced every 100 thousand km. If the car is still under warranty, the easiest way is to contact the authorities. The Granta gearbox cable repair kit will also help you.

Troubleshooting cable boxes

Let's look at typical faults for a cable gearbox.

Noises

Many owners notice that the cable gearbox in the Grant is noisy. The reason for this may be a badly worn control cable. The howling of the gearbox, especially when braking the engine, occurs due to poor metalworking of the gears.

Oil

You need to pay attention to the oil in the transmission and change it in a timely manner. The factory one is not of the proper quality.

The oil on this gearbox model often leaks, despite changes in the crankcase design. You should not increase the lubricant level in order to get rid of the howling of the gearbox, this will only add problems. Try to fill in high-quality oil. It slightly compensates for noise and allows the gearbox to work longer.

Gear shifting problems

If the gears stop shifting at a certain moment, the reasons may be bent forks or broken plastic bushings of the rocker. Sometimes synchronizers fail.

ROPE DRIVE

Despite the simplicity and low price, almost all manufacturers abandoned the rod drive, like on the old box. Today, designs of several rods with complex scenes are used to dampen vibrations on the lever, or a more expensive and convenient cable drive. AVTOVAZ experimented with the latter back at Samara, purchasing parts from. But with the switching mechanism located at the bottom, the performance of such a circuit is problematic, and the price of components was scary at that time. Work on the cable-driven gearbox continued as part of other projects, but the production model could only be realized now.

Cable box repair

Let's look at the repairs one by one.

Preparation

First you need to drive the car onto a pit or lift and secure it securely. Remove the battery, engine mudguards, air filter. It is advisable to prepare all the tools at once and place them within walking distance. After this, the old oil from the box must be drained. The oil container must be at least 3 liters.

Set of tools

To disassemble the gearbox you will need quite a lot of tools. The main thing is to have a set of keys (10, 12, 14, 17, etc.) and heads. You will also need pliers and a flathead screwdriver.

Removal

After preparation is completed, proceed to dismantling:

- Remove the clutch housing cover by unscrewing the three bolts.

- Unscrew the two bolts securing the clutch housing to the gearbox and remove the torque rod from the box.

- Remove the front wheel drives.

- Loosen the two bolts securing the top of the gearbox to the cylinder block and the ignition coil nut.

- Similarly, loosen the nut securing the box to the block from below. Secure the box with bars.

- Unscrew the 5 screws of the left engine support to the gearbox, and then remove the bracket itself.

- Remove all transmission mounting bolts and nuts. Carefully move the gearbox away from the engine.

Repair of Lada Granta with cable drive

Be careful with the diaphragm spring petals - do not rest the input shaft on them, as there is a risk of damage.

Disassembly

As soon as you remove the box, you need to wash it to make it easier and more pleasant to work with. Then:

- Remove the bracket to which the clutch cable is attached. To do this, you need to turn the box on its side and unscrew the bolt.

- Install the transmission vertically. The back cover is secured with 6 nuts, they need to be unscrewed.

- Then remove the back cover. It will go hard, you can speed up the process by lightly hitting it with something soft, a rubber hammer handle will do. Don't forget to remove the gasket.

- Put it in fourth or third gear. Then unscrew the bolt securing the fifth-speed fork and turn it on.

- Unscrew the nuts on the secondary and input shafts and remove the fifth gear assembly.

- In fifth gear, remove the locking ring so that the gear can be removed.

- Remove the rings, the needle bearing itself and the fifth speed drive gear.

- Remove the plate on which the bearings are attached. She needs to be hooked with something.

- From the secondary shaft, remove the needle bearing sleeve from the fifth speed and the thrust washer, remove the retaining ring of the primary shaft bearing, and then the secondary shaft.

- Remove the plug and three retainer balls. Repeat the same with the reverse lock.

- Disconnect the gearbox housing from the clutch housing by unscrewing all the nuts and mounting bolt. Then the box housing must be removed.

- Remove the first and second gear shift fork by unscrewing the bolt. Do the same with third and fourth gear. Remove their stem.

- For fifth gear, remove the rod, retaining ring and reverse fork. Then remove the gear along with the axle.

- Remove both shafts - primary and secondary, and the main gear with differential.

- To remove the shift mechanism, unscrew the three mounting bolts. Also remove the sealing gasket.

- There is a bearing in the clutch housing. It must be carefully removed with a handy tool. It's pressed in there.

- After this, remove the speedometer sensor, the magnet from the clutch housing and the driven gear.

- Remove the reverse limit switch and the gear shift rod.

When the entire box is disassembled, you need to wash all its parts. It is strictly not recommended to install it in an uncleaned state. During operation, tiny metal shavings accumulate in the transmission oil, which gradually kills the entire mechanism.

Repair

Once you clean the box, start troubleshooting it. Carefully inspect all parts. Initially, the box was made for classic engines - 70 horsepower. Now the power has exceeded a hundred, but the structure has not been strengthened properly. The use of low quality metal has a worse effect on the reliability of all moving elements.

Pay special attention to gear teeth, bearings, and seals. Remember all the places during disassembly where oil was leaking. It is also necessary to inspect the clutch housings and boxes for mechanical damage.

Don't forget about forks and stems. There should be no deformations, cracks, etc. anywhere.

Assembly

Reassemble in the reverse order of disassembly. However, there are also subtleties here:

- Lubricate all moving parts with transmission oil. At the moment the engine starts, even a completely filled oil without moving the mechanism will not fall into all the cracks.

- Replace all gaskets.

- When installing the shafts, the gear teeth must be in mesh.

- Don't forget to install and clean the magnet. Examine it. If it is damaged or not magnetic, install a new one.

Cable gearbox

If the gearbox is leaking, all seals must be replaced. Or at least the drive seals.

Installation

The gearbox is heavy and uncomfortable to hold; it is best to do this work with an assistant. Installing the transmission into the car is done in the reverse order. Lubricate all moving parts that you connect to each other. On drives, replace the locking rings to prevent them from coming off while driving.

When you assemble the box, fill it with fresh oil. It will take a little more because the mechanism inside is almost dry.

Schemes and design of manual transmission 2181

Main elements of the VAZ-2181 gearbox:

1 – main gear drive gear; 2 – secondary shaft; 3 – input shaft; 4 – fifth gear fork; 5 – fork for selecting third and fourth gears; 6 – reverse light switch; 7 – clutch housing; 8 – gear shift mechanism; 9 – central lock.

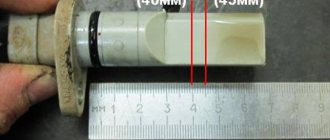

Device of synchronizers of VAZ-2110 (A) and -2181 (B) boxes:

1 – first gear gear; 2 – intermediate rings; 3 – blocking ring; 4 – synchronizer clutch; 5 – synchronizer clutch hub; 6 – clamp; 7 – second gear gear.

Gear selection mechanism:

1 – gear selector levers; 2 – selector grid pin; 3 – selector grid; 4 – reverse locking mechanism; 5 – central three-dimensional plate.

Results of the modernization of the gearbox on the Lada Granta

The box turned out to be ambiguous. On the one hand, the transition to cables made it more reliable, quiet, and clear in switching. Most automakers are now switching to cable-based transmission designs.

However, the first revision of these boxes was a failure. Many owners have them break. The vibrations became much quieter, but the box began to howl. Bad metal also made itself felt in the form of licked gears. The design of the gearbox was promptly modified at the factory, and everything is fine on modern cars, but the owners were left with an unpleasant aftertaste.