The gearbox is one of the most important components of a vehicle. Without the normal functioning of this element, driving a car will not only be difficult, but can also lead to various unforeseen situations that pose a threat to the life and health of the driver, passengers, and other road users. That is why it is important to identify a gearbox malfunction in a timely manner.

We will now talk about the main signs of wear of synchronizers in a manual transmission and other breakdowns of the unit.

Features of the mechanism

Before discussing the signs of a faulty transmission, you should understand how this unit functions in general. The purpose of the gearbox is to change torque and transmit it from the power unit to the wheels. With the help of a gearbox, these elements can be separated for an unlimited period of time.

In the case of a mechanical transmission, the torque changes gradually (the role of the stage is played by two interacting gears). Moreover, each stage has its own gear ratio. When the driver changes the position of the lever, the gears move along the shafts and then engage with each other. This is what makes it possible to change the operating modes of the vehicle. Malfunctions of the manual transmission lead to the fact that the car becomes unsuitable for use, or its use will be difficult.

Self-repair of manual transmission

The need to repair a manual transmission (with your own hands or at a service station) arises when all of the above reasons for which malfunctions in the operation of the unit may occur are excluded. In simple words, if the clutch and oil level are normal, and there are no problems with the gear selection and engagement mechanisms, then the gearbox itself needs to be repaired.

Certain signs also indicate problems with the gearbox (for example, gears do not change, only certain gears do not engage, problems are clearly expressed in a specific one or two gears, a gear “knocks out” while driving, etc.).

Such symptoms may indicate that gears, bearings, gearbox synchronizers, etc. are worn out. In any case, the box must be removed, disassembled, troubleshooted and subsequently repaired.

If you have a garage, tools and experience, it is quite possible to repair a manual transmission yourself. It is also advisable to carry out the work with an assistant, since the process of dismantling, as well as disassembling and assembling the gearbox is quite complex and labor-intensive. In outline:

- To remove a manual transmission from a car, you need to disconnect all elements connected to the unit (cables, strips, etc.);

- Then you will need to drain the oil from the gearbox;

- Next, wheel chocks are placed under the wheels and the battery terminals are disconnected;

- Now all elements that may interfere with the removal of the box are removed;

- Next, supports are placed under the internal combustion engine and gearbox so that heavy units do not fall off under their own weight during dismantling;

- On a car with front-wheel drive, you need to remove the wheels and then the CV joints. On rear-wheel drive vehicles, the driveshaft is removed;

- Next, the box is removed from the support pads and disconnected from the motor;

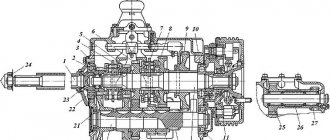

- After dismantling, the box must be cleaned of dirt, then the unit is disassembled. First, the “bell” is removed, the fifth gear cover is unscrewed;

- As part of the troubleshooting, you need to pay attention to the gear fork, since if there are noticeable signs of wear, the element needs to be replaced;

- The shafts, gears and splines are also removed and inspected for wear and damage. Worn parts require replacement;

- Often, replacing parts in a manual transmission is accompanied by the installation of new gears, bearings, shafts and a number of other elements, since it is difficult to visually determine their condition without obvious damage. All parts are checked for runout;

- After the bulkhead of the box is completed, the manual transmission is assembled and installed on the car. These actions are performed in the reverse order of removal. You also need to remember that during assembly, sealant is applied to the joints of parts and elements (for example, before closing the covers, when installing the gearbox pan, etc.).

Article on the topic: Engine life of a diesel engine - counting the “life” of a car

What causes node failure

As a rule, gearbox malfunctions occur in the following cases:

- improper operation of the vehicle (poor quality oil, abrupt shifting of the lever, aggressive driving);

- normal wear and tear;

- poor-quality repairs (including the use of non-original components);

- mechanical damage.

All this can lead to malfunctions of the manual transmission.

Gearbox noise

The most common symptom of a breakdown. As a rule, the problem leads to:

- low oil level. As a result, lubrication is not carried out properly, the elements of the assembly rub, which causes howling. If you hear noises after several hundred thousand kilometers, then this is a natural process, so just add oil;

- bearing failure (in this case, the sound appears when the clutch is pressed);

- gear wear. Here it is necessary to completely change the spare parts; the gears cannot be repaired;

- development of differential resource. You can understand this by the vibration of the gearbox at high speeds.

It is also worth noting that some VAZ models are produced with a defect, which leads to the appearance of extraneous sounds in the box.

How to check the gearbox yourself

I think it's obvious that before buying a car (no matter what: new or used), you need to check all the basic functions and mechanisms.

If we are talking about mechanics (manual gearbox), then in general everything is quite simple and clear. The buyer just needs to drive and change all gears one by one. In this case, you need to listen carefully to everything and understand tactilely whether everything is working correctly, whether there are any unnecessary noises or beats.

If you hear or feel something in your hand, it’s up to you to decide whether to buy this car or not. The repairs may be required (and they will be required if you heard something) are trivial, or you may have to replace half of the parts. In any case, if you decide to buy, the identified shortcomings can be discussed with the owner of the car in terms of reducing the actual price.

With an automatic transmission (automatic transmission), things are more complicated. This is understandable, because the mechanism of such a device is quite complex. The details are all fitted very, very precisely. And if you have doubts about the condition of the automatic transmission, you need to think carefully about it. After all, even after repair, such a box will not be even close in technical condition to a new box.

In general, automatic transmissions are quite durable and reliable. But with a fool you can break whatever you want. Automatic transmission is no exception. It’s worth skidding in a snowdrift or puddle for fifteen to twenty minutes - and hell! The box will be damaged.

Therefore, before purchasing, it is still worth checking the automatic transmission using available methods. The first step is to check the availability of a service book. If the car was imported from Europe, there should be one. There you can find out literally everything about your future purchase: technical condition, number of repairs, whether the car was in an accident and much more.

The next step is to check the oil level and its condition. Let's start the car and let the engine run. Let's measure the oil level with a special dipstick. Ideally, the level should be in the golden mean. Let's check the condition of the oil. Place a drop of oil from the dipstick onto your thumbnail. Tilt your finger thirty degrees. The drop should begin to slide very slowly.

Now consider the color and consistency. A good oil should be an amber-reddish color. If the oil is gray or black, if metallic inclusions are visible in the lubricant, it is best not to purchase such a car.

Check that the gears are shifted correctly during the trip. Make sure there is no slipping in the gearbox.

We buy thoughtfully

You need to understand that even if you really like a car, but there is even one questionable detail in it, it’s still not worth buying such a car. Don't give in to emotions and choose carefully. Then you will be proud of yourself.

Problems with gearbox switching

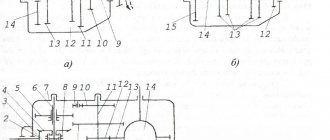

Such signs of a malfunction of a manual transmission indicate defects in the synchronizer. At the same time, you should not rush to repair the unit. First, you should check the serviceability of the gear selection mechanism, as well as the clutch. In addition, switching problems can result from:

- cable jamming;

- poorly adjusted speed selection mechanism;

- backlash of the lever link.

You may also be interested in: The best injector cleaner

If such malfunctions are detected, it is better to immediately go to a service center. If you continue to drive with a breakdown, very soon this will lead to the complete exhaustion of the synchronizers' service life.

In addition, when disassembling the unit, you should take a closer look at the gears, couplings and forks.

Gearbox Features

It is generally accepted that everything is simple with a “mechanics”, but an automatic transmission will require more effort. Even before the inspection, you need to find a qualified specialist.

The secret is in the features of the device. Classic “automation” is necessary only to make driving as easy as possible; accordingly, there are more features here, and their structure is more complex.

For example, if the mileage is not so significant, and the automatic transmission was not repaired every 50-60 thousand km, then the chances are different. That is, the possibility of establishing the serviceability of the transmission condition is more than high.

The main condition is the use of original transmission compounds. You also need to regularly replace the automatic transmission filter.

These details are easy to check on your own; this does not require excessive knowledge and effort, but attentiveness on the part of the inspector is still necessary.

Many people are confident that they can check it themselves. This is possible, but if you want the result to be high, it is better to take some measures. Alternatively, arrange for an inspection prior to purchase. This is an objective request; refusal would be suspicious.

Knocks out the transmission

If the coupling splines and teeth on the gears grind down, the transmission may spontaneously disengage when the accelerator pedal is released. In case of such a gearbox malfunction, you should check:

- correct installation of the intermediate shaft bearing;

- speed shift rod and forks;

- gearbox mount (if worn, it will move);

- cable;

- case fastening (it may have become loose).

Assembly and installation of manual transmission on a car

Assembly and installation of the manual transmission takes place in the reverse order of disassembly. Nuances worth paying attention to:

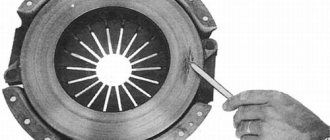

- When installing the coupling, do not forget about the stopper;

- Bearings are installed according to grooves and grooves;

- The box must be cleaned of dirt and the edges coated with sealant before closing the lid.

It will be useful: How to tension the chain of a VAZ 2107 carburetor

Repairing a manual transmission is a rather complicated procedure, but you need to remember that many garage craftsmen even repair automatic transmissions, which is much more difficult.