We set up the 4th generation HBO ourselves. Photo report, basics and basic setup tips.

Here I will show you how I do it.

I will describe the rules and actions. You can read the same below if something is not clear to you. Hi all ))). Let's start with how to properly start setting up a 4th generation gas car yourself. In principle, almost all, well, many, systems are identical and built on the same principle. The main difference is the Graphical interface. And there is a slight difference in additional options. In this article, the settings are suitable for LPG systems; STAG4-EKO, STAG4-+, STAG-300, STAG-GOFAST, STAG-QBOX, Zenit (pro), KME DIEGO, COMPACT, LPGTECH.

You need to start with: 1

.

We warm up the car until it is in full working order. > +60 2

. Completely turn off all load on the engine. (stove, fans, air blowers, heated seats - any device that consumes energy). The car remains idling without any load.

3

. We connect the cord, launch the block setup program ourselves, so to speak, on our own :).

4

. Using the STAG4 program as an example, open the page: Setting the number of cylinders in the car Correctly select the number of cylinders per coil (RPM revolutions must correspond to the revolutions of your car, be careful. There is an option in the figure on the right, the revolutions should be approximately in the range of 550-940)

We check whether everything matches our car correctly.

5 . Next we go to the tab

We set the switch-on temperature in SUMMER +35 (no less), WINTER +40 or +50 (no less) Cylinder shutdown from 250 (I set the value so that when switching from gasoline to gas and back, the engine does not twitch. That is, to achieve a smooth start and turning off the gas.) Pressure error time from 300 to 420 Type of gas injectors Must correspond to the type of injectors that you have. (if you can’t decide what to install, then most often the injectors are valtec typ 30 (3om), as a last resort, look at the injectors; any self-respecting company puts all the identification marks that are listed in the list of injectors in the program). Reducer pressure Operating from 1 to 1.3 bar (no more, later I will clarify what exactly the operating pressure should be in your field) and Minimum 0.50 (no less) Fuel type LPG - propane (put a mark) CNG - methane

The rest on this page, which is not so significant, can be left untouched. (this is intended for a more advanced master) My example:

We are waiting for the setup to complete. The program will notify us about this.

(Setting up can last from 40 seconds to 5 minutes. It all depends on the correct and correct operation of the machine on PETROL. If the machine is not working stably or the ignition system is faulty (plugs, wires, coils) and so on. The setup lasts more than 2 minutes.)

7. Next, go to the MAP

The orange line will take approximately the same bend as shown in mine. What is important now is not the bend itself, but from which number in the COEFFICIENT field the beginning of the orange line will be located. It is desirable and important that the line lies in the area of numbers 1 to 1.4 We will discuss how to achieve this in more detail.

The master’s task when installing an LPG system is to correctly select the power of the injectors themselves to match the power of your car. There is a type of injectors that are universal and can be mechanically matched to any car with different horsepower ratings. There are injectors produced by the factory that are not supplied mechanically, but are ready for a certain power with a small margin. For certain injectors, the PRESSURE adjusted by the REDUCER itself is important.

Remember, I wrote that it is desirable that the pressure be in the range from 1 to 1.3 atmospheres. Options tab

After starting AUTOCALIBRATION, the working and real pressures will be the same; the machine will do this for you during setup. But here an incident may arise with the line itself.

A

—

The line is higher than

COEFFICIENT 1 to 1.4 For example, you have a pressure from 1 to 1.3 bar and the orange line became higher after calibration. This means that the nozzles in your injectors are narrowed. This means that the throughput of the nozzles needs to be increased by drilling the nozzles to a wider diameter.

Always try to ensure that the line at a pressure of 1-1.3 bar is in the range of COEFFICIENT 1-1.4 This is due to the fact that you choose the correct gas supply coefficient to maintain the car’s acceleration, gas consumption (no more than 20% of gasoline in terms of consumption) and keep the engine in working condition without reducing its service life. ______________________________________________________________________________________________

Here, in principle, are the simplest instructions for setting up 4th generation gas units for many LPG systems. These basics are generally accepted almost everywhere. Since the algorithm is the same for everyone, it doesn’t matter that the programs themselves are not similar to each other. Many manufacturers have added their own features to the settings, but this may seem complicated to you. But if you are eager to know more, take training from official dealers and you will enjoy it.))

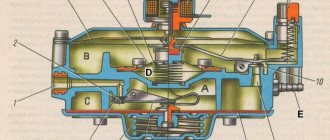

Gas reducer Lovato for injection system (4th generation LPG)

The advent of gas injection systems required the creation of a fundamentally different gearbox (see the section on the principle of operation of gas equipment). The main purpose remained heating and evaporation of the gas coming from the cylinder, as well as maintaining a stable differential pressure at the outlet of the reducer.

By differential pressure we mean the difference between the pressure at the output of the gearbox and the pressure in the intake manifold of the car engine. And when the driver presses the accelerator pedal, the gas pressure at the outlet of the gearbox will increase in proportion to the increase in pressure in the intake manifold, due to constant feedback from the manifold to the working diaphragm of the gearbox.

Injection gearboxes are usually single-stage. But, despite the apparent simplification of the design, choosing a good and suitable gas reducer for a given vehicle and gas electronics can be quite a difficult task.

The reducer must reliably heat the gas before supplying it to the gas injectors and provide stable pressure, as discussed above. The 4th generation Lovato gas reducer must efficiently handle some transitional moments during engine operation. For example, for many gearboxes, a very difficult mode is exiting the cut-off mode (engine braking); in this mode, many gearboxes strongly increase the differential pressure, which often leads to the engine trying to stall. The second critical point is a sharp increase in the load on the engine - many gearboxes, due to insufficient performance, first drop pressure, and only then begin to equalize it.

Thanks to a well-thought-out design, all Lovato gearboxes are practically free of the above-mentioned disadvantages. And minor pressure deviations are compensated electronically, because In the software of the electronic unit of the Lovato gas system, the company's engineers take into account all the behavioral features of their gearboxes.

At the time of writing, Lovato produces 3 models of 4th generation propane injection gearboxes:

- RGJ 3.2.L - for cars of low and medium power, allowing the Lovato gas system to operate confidently on engines up to 150 horsepower;

- RGJ UHP - for medium and high power vehicles, allows you to install Lovato LPG on engines up to 350 horsepower;

- RGJ 3.2.L-DD - for kits intended for cars with direct gasoline injection. With this reducer, the outlet pressure changes in a different ratio (increasingly) in relation to the pressure in the intake manifold, which allows it to provide more comfortable conditions for the Lovato gas control unit (ECU) when working with direct injection.

All Lovato propane reducers are designed and manufactured in strict accordance with European standards ECE 67R-01 and certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011).

Methane reducers differ from their propane counterparts by the presence of an additional stage to reduce the pressure from 200 Bar to 10 Bar. For methane gearboxes, heating is less important, since methane enters the gearbox in a gaseous state. Lovato methane reducers have high performance and reliability, which is confirmed by the frequent choice of these components by automakers when installing a gas system on a conveyor (OEM projects).

Lovato methane injection gearboxes

At the time of writing, Lovato produces 2 models of methane injection gearboxes:

- RMJ 3.2.S - for cars of low and medium power up to 190 horsepower;

- RMJ 3.2.HP – for medium and high power vehicles, allows the system to confidently operate on engines up to 272 horsepower.

All Lovato methane injection gearboxes are manufactured in accordance with the rules of ECE R110, ARAI, INMETRO and comply with ISO 15500 - 9 standards, certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011). Both gearbox models are equipped with an electric shut-off valve with an extended inlet filter. They are equipped with a pressure gauge with the ability to connect a level sensor with an indication of the gas reserve with output to the fuel type switch.

Lovato traditional methane reducers

Lovato produces 3 automotive gas reducers for traditional systems:

- RME 090 – for cars of low and medium power, designed for engines up to 122 horsepower;

- RME 140 – for cars up to 190 horsepower;

- RME 180 – high power gearbox for engines up to 245 horsepower.

All RME model gearboxes are a three-stage gearbox for carburetor (gas supply through a mixer) systems using compressed natural gas. Production is carried out in accordance with ECE R110, ARAI and INMETRO regulations, complies with ISO 15500 standards. Gearboxes are certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011). The gearboxes are equipped with a solenoid valve located between the second and third stages, and a mixture quality adjusting screw.

Safety of Lovato gas reducers

Traditionally, Lovato pays the closest attention to safety issues, and the gearboxes, of course, meet all the necessary safety standards for gas equipment. For example, Lovato injection gearboxes - in addition to the mandatory solenoid valve that shuts off the gas flow if the car does not use gas fuel or the engine is not running - are equipped with a separate additional safety valve. The safety valve is activated (reduces the pressure inside the reducer) if the pressure inside the reducer exceeds the norm (approximately 4.5-5 Bar). The presence of a safety valve guarantees the integrity of the reducer and also prevents rupture of the gas hose at the output of the reducer. This is just one example of why we think Lovato is ahead of the curve when it comes to HBO safety.

Authentication of Lovato gearboxes

Today, Lovato gearboxes have deservedly gained immense popularity among both gas equipment installers and ordinary users. The natural reaction of the market was the appearance of counterfeits. While their level is quite low - they are not difficult to distinguish visually, but Lovato is already taking active measures to protect its products. Each gearbox is marked with a special code, and for each product it is possible to determine not only when the part was produced, but also for which country and which supplier sold it.

The authenticity of Lovato gearboxes of any generation can be verified

Beware of fakes!

In gas-cylinder equipment, the gearbox is given the greatest importance among all components. Its task: to provide the driver with the opportunity to reduce the pressure coming from the cylinder. Repair, namely adjustment, on a car gearbox involves working with one or two regulators: this is the main difference.

In principle, a gas reducer is a primitive pressure regulator designed to independently maintain a standard pressure value based on fuel consumption. As practice shows, the device supports it with minor fluctuations. The pressure decreases slightly with increasing gas flow. This is not a very significant point, but requires attention.

Correct setting of Lovato LPG in Easy Fast

How to set up Lovato 4th generation HBO?

I decided to install gas equipment on my car and contacted a specialized office. They supplied me with Lovato equipment, but they couldn’t set it up correctly. My city is not large and the other companies that I could find did not install and service Lovato.

Main problems:

- the car barely pulled on the gas

- gigantic gas consumption

- Along with gas,

gasoline was consumed at the same time - after installing the gas system, the car started on gasoline with explosions in the exhaust system

After many attempts, I realized that they couldn’t adjust the gas for me like that and I would have to figure it out myself. Hopelessness is the engine of progress, we had to look for options. After googling a little, I found a huge number of manuals, but all of them were in one way or another incomplete and did not reveal the essence of the setup. I had to figure out a lot of things myself.

Features of installation and operation

Many car owners choose gas because it is much cheaper than gasoline or diesel fuel. In addition, gas fuel creates a better mixture when interacting with air, this is due to the fact that it has good chemical properties. As a result, it turns out that it burns better, and at the same time does not emit a large chemical residue, and also does not leave traces of soot.

The standard set includes the following components:

- a gearbox on which a valve is already installed;

- ramps;

- gas filter;

- temperature sensor;

- switch;

- wiring;

- detailed instructions;

- warranty card.

Due to the fact that Lovato’s products belong to the 4th generation of LPG, the principle of its operation is slightly different from its predecessors. Thus, gas fuel is supplied to the injectors while taking into account the readings of various sensors displayed on the electronic unit from which the system is controlled. Read more about Lovato gas injectors.

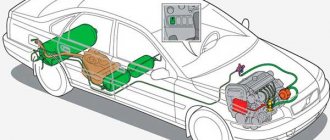

The system operates as follows:

- the gas is in a cylinder, which is installed either in the trunk or in the place of the spare tire;

- after the car warms up, the LPG system issues a notification to the panel that you can switch to gas;

- when switching to the use of gas fuel, gasoline stops flowing into the main transport systems;

- gas begins to flow through the open dampers into the gearbox, then into the injectors, and only then into the combustion system.

It is important that the entire process occurs in stages, and everything is distributed as much as possible, which ensures the normal functionality of the car.

Attention! The gas in the cylinder is under high pressure, and it must be reduced to supply it to the engine system. A reducer is used to reduce pressure.

The Lovato 4th generation HBO connection diagram consists of several parts. The first stage consists of installing the cylinder and gas lines; this process does not take much time and is also not very complicated. Most often, the gas cylinder is installed in the luggage compartment, but the filling hole can be installed in the bumper or near the gas tank. The lines themselves are laid under the bottom of the car.

The second stage is the most difficult - you need to install the fittings. Most often they are installed in close proximity to the injectors that supply gasoline fuel. If the work is not performed efficiently, this can lead to Lovato gas equipment malfunctioning, and new equipment installation work will be the way to eliminate this problem. At the next stage, it is necessary to install a gas reducer, which will monitor the decrease in pressure level in the system.

Important! The Lovato gearbox differs from all analogues in that it is practical and easy to use. In addition, most companies that specialize in the production of these products strive to achieve the same indicators and the same level of quality as the Lovato company.

After the gearbox is installed, all remaining components are connected to the system. At the final stage, the electronic unit is configured. This is a rather complicated process, and if done incorrectly, Lovato's LPG will not switch to gas.

Some drivers are wondering how to adjust Lovato's HBO. It is worth noting that adjusting the Lovato LPG is a rather complex process that can only be performed by a highly qualified technician. For this reason, it is not recommended to perform this procedure yourself, since not only the correct operation of the gas system, but also the safety of operation depends on this.

Lovato Easy Fast

Lovato Easy Fast is the official software for setting up Lovato LPG. To run the software, you do not need a license key, and it can work with both an original and a homemade cable. It is strange that the manufacturer does not distribute its product on the official website.

I used Lovato Easy Fast 1.7.4, it was easy to google and download.

Lovato Easy Fast - main menu

Main parameters of the “Configuration” section

Configuration Tab

- This tab contains the characteristics of your engine and gas system. Make sure all parameters are correct.

Switching

Lovato Easy Fast - “Switching” section

- Allow injectors to warm up - in this mode, in case of frost, the injectors will first turn on, work for a while, and only then gas will be supplied. This parameter will increase gasoline consumption.

- Idling Which fuel system will provide idle speed. Feel free to put on the gas.

- for switching : when decelerating, which corresponds to decreasing pressure on the gas pedal, and when accelerating, which corresponds to increasing pressure on the gas pedal. Most often, switching occurs without these actions, but sometimes in order to switch the car to gas, these conditions must be met.

- Reducer temperature for switching: Until the reducer warms up to the set temperature, the system will not switch to gas. If the gearbox is in good condition, we set as little as possible.

- Starting on gas with a warm engine after turning the ignition key, if the engine is warmer than the specified temperature, it will automatically switch to gas.

- Switching delay when the engine is hot: if the engine is hotter than the gearbox, but not hotter than the starting temperature on gas, then this rule works.

- Operation at high speeds.

- Gas In this menu you can configure the addition of gasoline when gas injectors cannot cope.

- Adding gasoline is a more detailed setting of the “Gas” option.

- Gasoline, everything is simple here, we exceeded the speed, turned off the gas, turned on gasoline.

Map

Lovato Easy Fast - “Map” section

- The Time/Rpm table is the most interesting part, this is where the settings will be made

- Sensitivity of additional injection - adding gasoline to the gas-air mixture during sudden acceleration.

Gear settings

Repair, namely adjustment, of the gearbox requires orientation in its settings. Propane analogues usually have two regulators, but there are also one. Methane type gearboxes are almost always characterized by one regulator. In their management, these settings are the most problematic.

Repair for the gas generation of gearboxes with one unique setting involves manipulation exclusively with the pressure of the transmitted gas. Vehicle owners with particular enthusiasm prefer to “tighten up” the pressure themselves. Having set the only correct and, what is very important, true pressure value, the fuel reducer alone will make it possible to limit gas consumption at operating power due to an element called the greed screw.

Repair has some difficulties when the screw is in the “closed” position. To maintain idle speed in this case, it is necessary to increase the pressure, the process of which involves:

- Checking the gearbox before tuning, namely, whether the “greed screw” is open.

- After the previous stage has been completed, adjustment work can begin.

Lovato gearbox design

Jet selection

There is a misconception that the jets are located at the end of the hose and are installed in the manifold; in fact, the jets are installed directly into the gas injectors.

Where can I find Lovato LPG jets?

Make sure you have the correct jets selected. Here is a table of diameters, depending on the power of one cylinder.

| Power per cylinder, hp | Diameter, mm |

| 13-20 | 1,6 |

| 20-26 | 1,8 |

| 26-29 | 2,0 |

| 29-34 | 2,2 |

| 34-39 | 2,4 |

| 39-45 | 2,6 |

If necessary, drill out the jets.

Method for adjusting gearboxes with two adjusting screws

The gearbox regulates two main parameters: the pressure in the second stage (hereinafter referred to as “sensitivity” - this is closer to the truth) and the amount of gas passing through the idle channel - the idle screw.

The engine must be started on gasoline and warmed up to operating temperature.

Initial adjustment position:

- the dispenser is turned to the maximum (maximum cross-section of the gas supply channel);

- screw the idle speed screw all the way and then unscrew it 3–5 turns;

- The sensitivity screw is set to the middle position.

Idle speed setting

Start the car on gas. If this fails, then start it on gasoline and switch to gas, maintaining the speed at about 2000 rpm. Reduce the speed to idle and turn the idle speed screw to find its position when the engine does not stall. If the engine stalls, repeat the operation until the idle speed is stable (idling speed). Then, turning the idle speed screw, you need to find the maximum speed. Next, gradually tighten the sensitivity screw; if the speed changes, then you need to adjust it with the idle speed screw to maximum. If that doesn’t work, turn the sensitivity screw 2 turns and repeat again. As a result, the sensitivity screw is turned almost all the way, the engine idles at maximum - somewhere around 1100–1200 rpm. Using the idle screw, turn it in to lower the speed slightly below the nominal speed and then turn it back, set it to 950–1000 rpm.

Self-tuning

Before tuning, it is recommended to drive a little on gasoline, this is necessary so that the gasoline brains “feel” the normal mode and correct the correction factors.

All self-tuning can do is accurately determine the timing of gas injection at idle. All other engine modes require manual adjustment. It’s a pity, most often gas workers limit themselves to only this mode.

We connect the cable to the car, turn on the Lovato Easy Fast program, initialization occurs, which takes some time. In the lower right corner the cable icon is displayed with a green check mark. From this moment you can start setting up.

Let's start setting up:

- Go to the Self-Configuration menu.

- Close the gas screw of the gearbox completely and open it a few turns. The gas pressure should be within 1.2

-

1.4

bar (indicator in the program at the top). - Click the auto-tune button.

Self-tuning start button

Self-tuning in progress

During tuning, the engine may stall or stall altogether, which indicates an incorrect injector diameter.

After successful completion of auto-tuning, press the “Gasoline” button (upper right corner), the car switches to gas, compare the “Gas time” and “Gasoline time” indicators, these 2 times should be approximately the same, as a rule, gasoline time is less than gas time by 1- 2 ms. The closer these indicators are, the better the engine will perform at high loads and at idle. If the gas time is too high, it is necessary to drill out the injector jets or increase the gas pressure; if it is too low, then reduce the gas pressure.

Self-configuration completed correctly

When switching from gasoline to gas and back, the engine should run smoothly, this indicates correct self-adjustment of the idle speed.

Gas equipment Lovato

Most domestic motorists choose Lovato brand LPG, as it belongs to the fourth generation. Also, this equipment is recommended to be installed by car service technicians, since installation does not require special knowledge, because the Lovato LPG setup is carried out using a simplified system.

It is important that the manufacturer provides a warranty on its components for a period of 3 years. This time is quite enough for a mileage of up to 300 thousand kilometers. This figure is one of the highest among 4th generation HBO. According to average data, this is enough for 5 years. When compared with similar companies in this field, their figure is much lower.

However, despite the high results, the driver should remember that it is necessary to promptly diagnose the 4th generation Lovato HBO. Because this will help not only to identify malfunctions, but to a greater extent the safety of operating the vehicle depends on it. Many masters claim that it is periodically necessary to adjust the control unit on the Lovato HBO.

Important! The Lovato company is a monobrand, since it produces all its equipment independently. When purchasing gas equipment from this company, consumers can be sure that all the parts included in the kit are made in Italy.

Lovato HBO must be installed only in specialized car repair shops, since poor installation can lead to malfunction and the system will not be able to function normally. If the installation is completed correctly, the system notifies you with a “Chicken Engin” signal.

Many drivers note that after switching to gas, engine power is greatly reduced. However, this problem is obvious, because during combustion gas has a temperature higher than liquid fuel. But this problem was solved with 4th generation equipment - at the moment, gas enters the engine system in the same way as gasoline. Therefore, the power reduction is only about 2%. Thus, the power of a vehicle is influenced by the quality of the fuel it fills.

You might be interested >> Gas injectors Barracuda

The essence of correct settings

The fourth generation of gas brains, unlike all previous ones, uses the native signal from gasoline injectors and adapts it into a signal for gas injectors, taking into account special coefficients that are stored in the fuel map. This allows you to take into account all the individual characteristics of any engines and install LPG on them without much effort. The whole point of good tuning comes down to the fact that you need to force the gasoline brains to work on gas and continue to think that they are running on normal gasoline.

Many people believe that using a fuel gas card you can “strangle” the engine and thereby save fuel, or add gas and make it more powerful. You need to understand one simple connection.

Problems, as with auto-tuning, arise from different adjustments throughout the fuel map. Somewhere the engine overfills, somewhere it underfills, and in the end this results in poor traction, high consumption and the gasoline brain gradually forgets how to work with gasoline correctly and when you switch to it, jerks, failures, and explosions occur in the exhaust system. It follows from this that there is only one correct throttle setting. If you want to tune your car, flash the petrol brain.

Repair and adjustment of gearboxes

Due to the fact that the gearboxes of modern gas equipment have different principles and construction schemes, the methods for setting them up are also multifaceted. The main differences are in the methods for setting up electronic and vacuum gearboxes, which we will consider. In any case, before adjusting the gear system of your LPG, the motorist needs to:

- In the case of using vacuum equipment, prepare a slotted screwdriver; when using an electronic gearbox, prepare diagnostic equipment (GBO cable, laptop and a special program for configuration);

- Find out the necessary settings for your type of equipment;

- Check out the adjustment methods below.

Fine tuning(Online tuning)

After successful completion of self-tuning, you can proceed to the precise configuration of the fuel map.

Fuel correction:

Install the ODB adapter in the car's diagnostic socket, connect to it via Bluetooth from your phone using Torque (or a similar program). Display graph information about long-term and short-term correction. The essence of these parameters is to adjust the fuel. If any situation arises when the engine is supplied with a mixture that is too lean or too rich, then the opening time of the injectors is compensated by this coefficient. For example, clogged injectors will make the mixture leaner and the correction factor will increase. As a rule, this parameter cannot go beyond ± 25%. If a mixture problem persists for too long, the short-term correction is included in the long-term correction.

When setting up LPG, we will need to check the fuel correction coefficients for gasoline and gas and “press” the gas correction to the gasoline one in different operating modes.

Setting algorithm:

Setting up is best done with two people. Driver and adjuster. A more or less flat section of the road is selected, on which the same engine speed can be maintained for a long time.

Each cell in the fuel map corresponds to an injector opening time of 20 ms. Each injector is 8-bit, which means it has 256 time levels. 0-minimum value means that the injector is closed, 255 maximum value means that the injector is open full time.

It makes sense to make adjustments only in operating modes; say, if you do not “turn” the engine more than 4500, then there is no point in adjusting the map higher. The setting is carried out in stages, at each stage the engine speed increases by 500 rpm. The car moves for a long time at an adjustable speed.

Let's start setting up:

In the Lovato Easy Fast program, go to the “Configuration” section in the “Map” tab.

- Gasoline supply is turned on (using a button in the program)

- The driver sets a constant engine speed and precisely maintains it during tuning.

- At these revolutions, correction factors are read out via ODB.

- The gas is turned on (by button in the program)

- The correction factors are read again.

- The cell under the point on the fuel map is configured. If the correction factor is too large, the cell value is reduced, if small it is increased. I recommend selecting the entire column and changing it by several units at once. (After highlighting, press the Enter key.)

HBO lovato fuel correction map

After setup, the card is inspected for sudden changes in modes. A well-tuned map is smooth, i.e. neighboring cells do not differ much in value. If there are uneven lunges, I recommend manually “straightening” the area around them.

If everything is configured correctly, you will get minimal gas consumption and maximum thrust.

How to set up and adjust

To correctly adjust the gearbox according to the instructions with your own hands, you need to understand the settings. Devices for propane systems have two or one regulator. Adjusting a methane device is a more complex process. Methane modifications are almost all equipped with one regulator.

Description of setting with 2 screws:

- the car is started with gasoline and warmed up until the temperature sensor shows the operating value;

- the dispenser should be at maximum,

- The idle speed screw is screwed in until it stops, then unscrew it 3 turns;

- the sensitivity screw is set to the average value at idle on gas fuel;

- reduce the number of revolutions by rotating the screw, while adjusting the position so that the car does not stall;

- reach the value where the speed reaches its maximum, then slowly tighten the sensitivity screw;

- when changing speed, an adjustment is made to the maximum value;

- achieve when the screw is screwed in almost all the way, and the car at idle shows a value of 1200 rpm. in a minute;

- reduce to 1000 rpm. in a minute.

Finalizing settings:

- slowly unscrew the screw until the speed parameters change;

- turn back again;

- perform a re-throttle, the motor should feel the pedal without any problems, otherwise repeat the operation.

Then comes the dispenser setup:

Final stage:

- sharply press the gas pedal, turning the sensitivity screw until you feel a failure;

- turn the regulator half a turn;

- repeat the dispenser settings.

Setting with 1st adjustment screw:

- The car should run on gas fuel, at idle speed, about 1100 rpm. in min.;

- tighten the screw, reduce the speed and set it to 1000 rpm. in a minute;

- adjust the dispenser, tighten it 1/2 turn and drive, as soon as the machine starts to work jerkily, adjust the screw until smooth.

On a note! The adjustment is made with a working idle speed control system (the resistance parameters between the contacts of the system are checked with a multimeter in car repair shops). Gas fuel consumption also depends on the correct operation of the MAP sensor; Lovato usually comes with it complete with the 4th generation gas equipment.

© Andrey Zelin (YMBR)

To begin with, we will divide all gearboxes of the 2nd (2+) generation into 3 groups.

Setting up HBO without an ODB adapter

It’s a shame, but it’s not always possible to read the correct values from ODB. Sometimes the adapter is not just not compatible with gasoline brains. Let's consider the option of setting up Lovato HBO, when for some reason it is not possible to read the correction coefficients.

This method is not accurate; you will not be able to set ideal fuel map coefficients, but the adjustment error will be within acceptable limits.

Setting up without ODB is very similar to setting up with an adapter, but in this case, we will not be checking the correction factor, but the gas supply time. This is perhaps the most unstable value and it changes several times per second, one way or another, this is the only thing we can work with now. You need to read the average value of this value, for example, the parameter jumps from 4.5 to 5.0, in this case the average value is 4.75. To correctly adjust the timing of gasoline, it is important to drive on the smoothest possible road, with extremely equal speeds; any deviation is critical.

Let's start setting up without ODB:

- Gasoline supply is turned on (using a button in the program)

- The driver sets a constant engine speed and precisely maintains it during tuning.

- At these speeds, the average value of the gasoline injection time is read from the Lovato Easy Fast program.

- The gas is turned on (by button in the program)

- The average gasoline injection time is read again.

- The cell under the point on the fuel map is configured. If the gasoline injection time when operating on gas is longer than on gasoline, the cell value increases, if less it decreases. I recommend selecting the entire column and changing it by several units at once. (After highlighting, press the Enter key.)

Gasoline injection time

Gas injection time

Correct connection diagram

The most common and also very effective is the parallel option. The connection technology is as follows:

- To connect the evaporator to the common line through which the coolant moves, use a duralumin tube. It connects the motor block to the stove.

- The tube is cut into several parts. A tee is installed between them and secured very tightly.

- A pipe is connected to the line, through which the antifreeze enters the evaporator (the lower fitting is used).

- The other pipe of the stove, connected to the water pump (pump), is also cut.

- The remaining tubes are connected using a tee.

- A hose is put on the side pipe, which is connected to the evaporator. To do this, use an outlet fitting designed to remove antifreeze or antifreeze.

Advantages of parallel circuit:

- fast warm-up;

- the connection does not have any effect on the operation of the internal combustion engine;

- HBO operation does not affect the functions of the interior heating system.

The disadvantages of such a connection, when several stoves operate simultaneously, include the formation of air. Sometimes too little coolant flows through the gearbox. As a result, the system does not warm up well and fuel consumption increases.

Gas reducers Lovato

This material talks about the evolution of automobile gas reducers produced by the Lovato company, but most of the following is also true for other brands represented on the Russian market.

Purpose of the gas reducer

The first task of any automotive propane reducer, regardless of the generation of gas equipment, is to transfer gas from a liquid to a gaseous state and maintain a stable gas temperature during engine operation.

The second task is to ensure gas pressure at the outlet of the reducer, in accordance with the current fuel demand of the car engine. The tasks, in general, are simple, but very important for the proper operation of the entire gas system of any generation of gas equipment.