Engine vibration at idle, cold or warm engine: possible causes

Let us immediately note that there are many reasons for the appearance of internal combustion engine vibration, ranging from torn engine mounts (mounts) to misfires and tripping of the power unit. For a more accurate determination, first of all, you should pay attention to one or other symptoms.

The fact is that vibration can be either constant (regardless of warming up and loads on the unit), or manifest itself in a certain operating mode (idle or high speed, cold or hot). Engine vibration may also appear when the internal combustion engine is cold, but as it warms up it completely disappears. Let's figure it out.

- For example, if the engine has recently been disassembled for repair (perhaps a major overhaul), then there is a high probability that the crankshaft was not properly balanced after reassembly. The result is beating and increased vibrations.

- We also note that after repairing the engine, imbalance and vibrations can be caused by different weights of the parts of the cylinder-piston group. The greater the difference in weight, the stronger the vibrations will be. For this reason, experienced craftsmen weigh pistons, pins, etc. before assembly.

- Often the cause of vibrations is that the engine is misfiring, that is, one or more cylinders for some reason do not work or are malfunctioning. As a rule, eliminating the cause of tripping automatically eliminates the presence of vibrations in the power plant.

- Do not forget that an incorrectly aligned timing belt or chain also causes vibrations. The reason is that the engine is running unstable due to a violation of the valve timing.

- Many engines have special balancing shafts in their design, which are necessary in order to “dampen” vibrations. It is quite obvious that problems with these shafts will lead to increased vibration of the motor.

Engine mounts are one of the most common reasons why an engine vibrates. In fact, this is a damper, made of rubber on many cars to absorb vibrations. As you know, over time, rubber dries out and cracks, loses its properties as a result of the ingress of technical fluids, etc. The main thing is that an engine with a damaged mount cannot run smoothly.

- If you have recently moved from one car to another, you should consider that different engines may differ in vibration load. The number of cylinders, layout and a number of other features affect the level of vibration. In simple words, a regular 6-cylinder in-line engine can operate with less vibration than a 4-cylinder and, especially, a 3-cylinder engine. Moreover, in this case we are not talking about malfunctions, since for a particular internal combustion engine a certain level of vibration can be considered the norm.

- Let’s also add that in order to reduce vibrations, many engines have a so-called torsional vibration damper on the crankshaft. If there is a problem with the element, the motor will begin to vibrate more strongly.

As you can see, at the initial stage it is important to accurately determine the reason for the increase in vibrations. For example, in most cases it is enough to replace the engine mount or solve the problem that the engine is shaking. However, it also happens that the power unit itself needs to be disassembled and repaired.

Ways to eliminate vibrations

After competent, professional installation of the causes of engine vibrations, they must be eliminated as soon as possible. The methods of “treatment” are very diverse, it all depends on the “diagnosis”.

Low compression

One of the reasons for engine tripping is low compression levels in the cylinders. This may occur due to the failure of any part that is part of the cylinder-piston group. In order to fix this problem, you will have to resort to disassembling the engine itself.

The cause of low compression may be a worn piston, piston rings and/or valves. In this case, the most optimal and rational option for eliminating vibration will be only a complete professional replacement of defective parts.

If you replace it yourself or restore it, further, more significant breakdowns may occur, and therefore costly repairs of the entire power plant.

Uneven air flow

If air enters the combustion chamber disproportionately, this can be corrected by simply replacing the air filter. You should also carefully inspect the air supply system for cracks and chips. It is recommended to replace the mass air supply and throttle sensors.

Incorrect fuel supply

In this case, professional car mechanics advise performing the following algorithm of actions:

- carefully inspect and clean the injectors;

- if after this the problem has not been resolved, then the injectors must be completely replaced;

- carry out an inspection of the condition and operation of the fuel pump, if necessary, replace the assembly;

- identify and reset ECU errors

Ignition system

When diagnosing early or, conversely, later ignition timing in the system, you should pay attention to the condition and soot of the spark plugs, as well as the integrity of the high-voltage wires. If replacement is required, it is best to do this with the entire set.

Re: Vibration when starting a cold engine.

Andrey100

, If it’s not the gasoline that’s to blame, then with such an abstract statement of the problem, they won’t give you any other “smart” advice here (at most they’ll send you to the dealer) - it could be anything, including problems with the pistons, and you can talk about this for a very long time. Even the advanced luminaries of the forum are unlikely to have ever removed the cylinder head from a Suzuki! It’s just that until now all engine vibration issues were solved by the quality of gasoline.

When the engine starts cold, something starts to click.

Good day to all! When the engine is cold started, something starts to click; when warmed up, it works intermittently, sometimes it clicks, sometimes it doesn’t, it could be the nozzles or hydraulic compensators engine 603.912 124 300 d

These could be sprayers or hydraulic compensators

W124 three liters of gasoline. Friends gave it to me! Bunny!!

tel. 8 910 241 zero3 7 zero.

Strange. Well, why, as soon as something in a diesel engine “clacks”, then it’s the nozzles. I don't understand. Why would they do this and then suddenly stop “clicking” when heated and then start again.

There the spring is pressed out at a pressure of 120 atmospheres. so if they make a clicking noise, it’s as if it’s always clicking, and the fuel injection pump itself, even a broken-down one, produces under 300 atmospheres.

I really want to understand why people are talking about the injectors right away? What's this. such a “scam” from the service station like change the nozzles and everything will go away? but also with new ones it “clacks”.

The injector may either be pouring or working correctly. pouring, this means the needle is frozen in the “open” state. There, again, there is nothing to “clack” about.

Have you ever seen clattering injectors?

Have you ever seen clattering injectors?

I have heard and listened to the sound of a running tractor constantly for 7 years using different home diesel engines. but the fact that it’s the injectors rattling and I have to break out and run to change the nozzles is something that hasn’t crossed my mind for 7 years.

If they work great, why bother?

Even here the answer is already: “Both. Start with sprays.”

Does it work great or is it still clicking? These are mutually exclusive concepts.

Does it work great or is it still clicking? These are mutually exclusive concepts.

Well, what are the symptoms of a “flowing” injector?

The advice when it doesn’t smoke, runs smoothly, but there’s a “clicking” noise, going to the service station and unscrewing the injectors is of course good. but only for those who will receive money for this work.. Because they will check it, well, they will say that it’s like the norm or it’s set up. But as it clicked, it will click.

A lot of posts are replete with this. They replaced the nozzles, but the “clatter” remained.

You can negotiate this way until the engine is completely replaced.

I’m saying that I “fell” into this myself, like “knocked” and I still go change the nozzles. and there are no sprayers, but the piston is cracked, and now this head with all the three-piece components runs fine on a different engine.

No matter how much literature I have read, it is written everywhere that if the injector is leaking, the engine jerks at idle, smokes and does not run. The oil level in the engine rises due to unburned diesel fuel.

Well, if you are technically competent in repairing diesel equipment, then how can you adjust only the injectors on a used car with an in-line injection pump, setting them to a certain opening pressure. Then you also need to clearly regulate each injector with its plunger pair of injection pump for an equal amount of injected fuel.

And excuse me, it’s not 5 thousand for setup. and it’s unlikely that anyone can actually do this.

Does it work great or is it still clicking? These are mutually exclusive concepts.

I wrote about the entire engine as a whole, and not about the injectors. if there are no symptoms of a “flowing nozzle” but only a “clatter” of something.

If they work great, why bother?

The thing is that it smokes and runs unevenly, it consumes 3000 liters of oil, it starts at the drop of a hat. I didn’t check the compression; before buying the car, the previous owner changed the pistons in the kit. help where to dig

The thing is that it smokes and runs unevenly, it consumes 3000 liters of oil, it starts at the drop of a hat. I didn’t check the compression; before buying the car, the previous owner changed the pistons in the kit. help where to dig

Still, write clearly which symptoms of engine operation do not suit you

And so it turns out that: 1. It starts perfectly 2. It doesn’t consume oil at all. because for this tractor 300 grams per 1000 km is the norm, and you probably drive at 150 km per hour

Earlier you wrote that: “When it’s warm, it works intermittently, sometimes it makes a clicking sound, sometimes it doesn’t.” “Clattering noise and “Uneven operation” are different things. Is your engine running rough?

Well, write what year the engine is and approximately how long it has run.

Here are the main symptoms of malfunctions: https://dizelist.ru/i. ai-ix-simptomy

Still, write clearly which symptoms of engine operation do not suit you

And so it turns out that: 1. It starts perfectly 2. It doesn’t consume oil at all. because for this tractor 300 grams per 1000 km is the norm, and you probably drive at 150 km per hour

I'll take a video and then we'll see

Still, write clearly which symptoms of engine operation do not suit you

And so it turns out that: 1. It starts perfectly 2. It doesn’t consume oil at all. because for this tractor 300 grams per 1000 km is the norm, and you probably drive at 150 km per hour

. the light flashes. I changed the chocolate bar, it works smoothly but it only works for 1 month and then it flashes again, I figured it out

"The engine is shaking." I’m sitting in the car and when idling the car doesn’t make much noise, but it vibrates. Sadils in another gelding did not have this vibration (I changed the engine mounts last year)

“When warmed up, it works intermittently, sometimes it clicks, sometimes it doesn’t.” Sorry, it’s not like that, I was looking at it when it’s warmed up, it clicks, it doesn’t click

Smokes white only when cold (ERL does not work)

Light smoke may come from the exhaust pipe in the following cases:

Causes of automatic transmission vibration

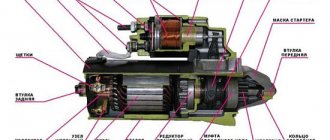

An automatic transmission is a complex device consisting of several interconnected components.

It contains bearings, valves, gears and other elements that are in motion and capable of producing vibration if there is a problem. Improper installation of an automatic transmission can cause similar symptoms. Schematic structure of a typical automatic transmission:

Box vibration manifests itself as a beating transmitted to the automatic transmission selector and body, felt by the driver. The beat can be of varying intensity and appear in different situations:

- idling;

- when accelerating a car;

- vibration when engaging reverse gear of the automatic transmission;

- when changing gears;

- when stopping or starting to move for a short time, if you press the brake in position D or “reverse”.

Important: vibration of the box is not always associated with problems with the automatic transmission itself; sometimes this phenomenon is associated with a malfunction of the chassis, engine, ignition, low-quality fuel, wheel imbalance, etc.

Diesel engine idling and vibration

After starting, a cold diesel or gasoline engine may vibrate slightly at idle, especially in winter. A diesel engine is more susceptible to vibrations initially due to a number of features. Idle speed (idle speed) is the operation of the engine when the clutch is disengaged and the gearbox is in the neutral position. In other words, torque is not transmitted from the engine to the car's wheels.

Idle speed for most diesel engines is around 680-780 rpm. Gasoline units may have a higher rate. Vibration at idle is noticeably felt in the steering wheel of a fully functional engine, especially while the car is warming up. After reaching operating temperature, the engine should start running absolutely smoothly. Also, vibration should decrease significantly or completely disappear with increasing speed on both a cold and warm engine.

Vibration appeared when starting the engine: what could be the reason?

As a rule, one of the most common engine malfunctions is vibration, which can only appear when the engine is cold or when starting the engine, be present constantly at idle or under load, intensify as the engine warms up, etc.

In any case, it is important to understand that vibrations in the engine, which are transmitted to the body, steering wheel or gearshift lever, indicate failure of certain elements and parts. In this article, we will look at the main reasons why engine vibration occurs, and also pay attention to why the engine vibrates strongly when starting.

POSSIBLE REASONS

- Uneven compression in the cylinders. Due to a decrease in compression, efficient combustion of the air-fuel mixture does not occur, as a result of which the piston in the problem cylinder does not receive proper acceleration. The reason for vibration at idle speed in this case is a decrease in the inertial movement of the piston during the power stroke.

- Misfire in 1 or several cylinders at once. As in the case of loss of compression, due to poor combustion of the fuel injection pump, the piston does not receive proper acceleration, which leads to uneven rotation of the crankshaft.

- Dual-mass flywheel malfunction. When in good condition, the torsional vibration damper can reduce the load on the crankshaft and transmission elements. In case of failure, engine vibrations are observed, accompanied by a characteristic rumble.

- Wear of engine mounts. The engine in the engine compartment is supported by several silent blocks. In case of cracks or tears in the rubber dampers, vibrations will be transmitted to the body and clearly felt in the cabin.

- Wear of the drive of the balance shafts and the balancers themselves. Bearing wear, chain stretching, and incorrect tensioner adjustment lead to increased noise and vibration.

Re: Vibration when starting a cold engine.

Andrey100

, still try to start by simply changing the gas station..... if the gas is not very good, then at idle I also have vibration.... on normal gasoline there are no vibrations..... And even on VR I once got caught on not very gasoline.....

We reached Berlin, we will reach Washington.

The soldier was tipsy, a tear rolled down, the captured Googlephone wheezed, and the medal “For the City of Washington” sparkled on his chest. The author thanks the alphabet for the kindly provided letters.

All of the above is just my personal opinion.

If you don't agree with him, well, that's your right. For example, I never remember evil, but I can burn down a hut. And an earnest request: do not let children on the Internet, they spoil it.....

Shaking at idle with a cold engine

clutch basket for replacement. Well, I also heard tales that people changed the oil in the box and everything got better)

Oh, I didn’t notice that it was only before warming up))) sorry I stepped

Check the injection pump and injectors. At what speeds does it shake, and at what speed does it stop shaking?

W201 1991 102910 5 manual transmission, ABS, ABD. GAZ69 OM616 4 manual transmission (under construction, but already moving)

Big fan of W123

It's just wrong with you, you need to check the injectors, I had the same problem, and do you also have an air filter - paper or oil? Clean it up. Change the oil in the filter, maybe it will get a little better, and check the injectors anyway. here such passions tell what happens to the engine, if the odds are pouring, so don’t put it off.

. our hands are not for boredom. " )))

check the temperature sensor for mixture enrichment (vacuum hoses, maybe they just fell off)

Hmm, troit? it seems to be working smoothly. but it shakes)))

Big fan of W123

Hmm, troit? it seems to be working smoothly. but it shakes)))

No, the shaking and vibration just gradually goes away. Does your Murzik run smoothly and without vibration during a cold start?

Big fan of W123

No, the shaking and vibration just gradually goes away. Does your Murzik run smoothly and without vibration during a cold start?

It’s best to check the fuel injection pump, I had the same problem, the pump supplied fuel with too much spread across the cylinders (the plungers were seated). After replacing the fuel injection pump, the engine was unrecognizable and began to run smoothly, picked up speed normally, and started much better.

Vibration in the car.

Any driver can be infuriated by the moment when his car begins to shake. Fortunately for motorists, in 75% of cases this cause can be corrected and eliminated, which will allow your car to return to its previous comfort. Each of us certainly wants the car to run smoothly and without vibrations. I especially want the car not to disappoint and to be as before - like new. But unfortunately, sooner or later any of the machines begins to break down due to their natural wear and tear. But this does not mean at all that it is time to buy yourself a new car. After all, uneven operation of the engine and the car itself can manifest itself not only on a fairly used car.

If the “check engine” light comes on, - 5 (five) most common reasons for the “Check engine” indication to turn on

If your car begins to shake due to vibrations that you do not understand, then the main thing here is not to panic. If the car is more than 3 - 5 years old, then most likely the following could happen: some components in the car have exhausted their service life. You could say that your car is starting to show its age. If you do not want to overpay for car diagnostics in order to find out and identify the cause of such shaking, then you can try to identify this malfunction (in our case, shaking) yourself.