Operating principle of the evaporator reducer

Let's take a closer look at the work of gearboxes from three different companies - the Novogrudok plant (Belarus), Italian and Lowato (Fig. 14). They all work according to the same principle, as shown in the figure. And if you take a dozen more gearboxes from different companies, it turns out that the operation of each of them is based on the same single principle.

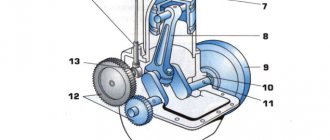

Rice. 14. Diagrams of NZGA (a), “Bedini” (b) and “Lowato” (c) gearboxes: 1 – second stage valve seat; 2 – adjusting screw for the idle speed system; 3 – idle valve assembly with diaphragm; 4 – idle speed valve spring; 5 – vacuum channel fitting; 6 – second stage valve; 7, 12 – coolant inlet and outlet pipes; 8 – first stage spring; 9 – adjusting washer; 10 – first stage diaphragm; 11 – first stage valve lever; 13 – first stage valve; 14 – valve seat; 15 – diaphragm of the unloading device; 16 – gas outlet channel; 17 – spring of the unloading device; 18 – second stage valve lever; 19 – second stage diaphragm; 20 – pressure adjustment screw in the second stage; 21 – second stage adjusting spring; 22 – valve; 23 – electromagnetic starting device; A – cavity for coolant in the evaporator; B – cavity of the first stage; B – cavity of the second stage; G – cavity of the unloading device; D, E – atmospheric pressure cavities.

The engine is not running yet, the ignition is on, the gas solenoid valve is open.

Gas entering the reducer through the main line through the open valve (13) fills the cavity (B) of the first stage, in which excess pressure is created.

As a result of the pressure difference in cavities (B) and (E) (cavity (E) is always connected to the atmosphere), a force appears on the diaphragm (10) that balances the force of the spring (8) and the gas pressure entering through the valve (13) from the main line .

The diaphragm (10) begins to move upward, overcoming the force of the spring (8), and closes the valve (13) connected to it through a lever transmission, tightly pressing it to the seat. Tightness is ensured by the annular protrusion of the seat and the rubber seal of the valve. Further flow of gas into cavity (B) stops. In this case, the RND performs the function of an automatic valve.

When the pressure in the cavity (B) decreases to a certain value, the gas pressure on the diaphragm (10) becomes insufficient to hold the valve (13) in the closed position. Under the action of the total force from the spring (8) and the gas pressure in the inlet gas line, the valve (13) opens and the pressure in the cavity (B) increases. The diaphragm (10) rises again, overcoming the force of the compressed spring (8), and the valve (13) closes - a constant excess pressure is established in the cavity (B).

The pressure in the first stage of the gearbox can be adjusted using an adjusting shim (9), which changes the force of the spring (8).

The pressure in cavities (G) and (G) is equal to atmospheric pressure, the idle valve (3) is closed under the action of the spring (4). The unloading device holds the second stage valve (6) under the action of the spring (17) in the closed position, and the valve is tightly pressed to the seat (1) by the additional spring (21) of the adjusting screw (20).

Before starting the engine.

The starting valve (22) opens under the action of an electromagnetic starting device (23), controlled by a fuel type switch. After this, the gas enters cavity B of the second stage and is supplied to the mixer through the outlet pipe (16).

When starting the engine.

In the engine intake system, the vacuum increases, which is transmitted through the vacuum fitting (5). The diaphragm bends, overcoming the force of the spring (4), and opens the valve (3) of the idle air system. Gas enters cavity B of the second stage, which ensures the engine starts (this applies only to gearboxes with an idle speed system; later models of gearboxes do not have this system). At the same time, vacuum is also transmitted to the cavity (D) of the unloading device. The lever (18), carried by the thrust disk, is raised, partially opening the valve (6) of the second stage, as a result of which gas begins to flow little by little through cavity B to the outlet to the mixer built into the carburetor.

The secret of 2nd generation gearboxes

Well, it's time for you to reveal a little secret!!! This is what our colleagues don’t tell you or simply don’t know about the secret of second-generation gearboxes. An example of what the gearbox looks like can be seen in the photo.

This is practically the most common gearbox that is installed on cars with second-generation gas equipment installed.

Tomasetto Model AT So someone suggested or told you (this is not so important) that you should replace or repair your gearbox. Let me remind you that we are talking only about 2nd generation gearboxes!!!!! Not to be confused with gearboxes for the HBO generation 4!!! There's a different story!!! Naturally, you will most likely decide to repair your gearbox because it is cheaper than buying and installing a new one. This decision is quite natural for any person with average income. But as a rule, unfortunately, you are not given all the information about what happens after the gearbox is repaired.

As I already reminded you, this depends on the decency and competence of both the master and the seller.

The point is this!!! For example, there is a gearbox and a new repair kit for it. It would seem that what else is needed, we dismantled the old membranes, threw them out, and installed new ones.

Repair kits look approximately like this, look at the photo:

In the photo we see two membranes that they give us and a lot of rubber bands. But the most important thing, as always, is missing!!!! In any gearbox, when we disassemble it, there is a main spring; let’s call it “power spring”.

she looks like this, look at the photo:

The role of this spring in the gearbox is almost the most important. It is made of the simplest metal, not hardened. It is responsible for the throughput in the outlet channel, giving, for example, the pressure necessary for the car to operate. Over time, this same spring makes itself known to us when we begin to think about gas consumption in our favorite car. All or many who have installed HBO 2 sooner or later start the car on a “cold engine”!!!!!! Well, in the summer it’s not so bad, but at other times of the year it’s very bad. I will try to explain what happens when starting a car on gas when the engine is NOT warmed up!!! In the cylinder, the gas is in the liquid phase, entering the reducer, which is already heated, the liquid phase turns into a vapor phase and is supplied warm to the engine itself.

During this time the gearbox has already warmed up the spring!!!! ours is also warmed up and has taken on a natural shape for running on gas, the new membranes are also ready to work under load. The gas enters the reducer through the filter in the liquid phase and the process of converting the liquid phase into vapor begins.

Here's the opposite situation.

The liquid phase of the gas entered the cold, NOT heated reducer. A spring, like that bottle of champagne that was forgotten in the freezer, begins to change its characteristics that were laid down when it was manufactured at the factory; it contracts!!!! and bends in different directions. New membranes also suffer from this, since the rubber, interacting with the liquid phase of the gas, begins to “stiffen” - it becomes inelastic and rigid. Micro cracks appear and so on. At first, this effect does not greatly affect the operation of a newly purchased or made gearbox. But later everything will fall into place. The car works, sneezes a little)))) And here the most interesting thing is that the antifreeze that is supplied to our gearbox begins to warm up the gearbox operating at maximum load. And our internal parts begin to return to a seemingly normal state. But it was not there!!!! The unfortunate spring is so loaded with temperature differences that it once again begins to change its technical characteristics laid down by the manufacturer. And it simply loses its properties.

This also applies to membranes.

Having described to you what and how, it becomes interesting to me whether it is worth repairing the gearbox now after reading it or buying a new one and not fooling yourself and us. Gearbox repair costs an average of 350. A new gearbox with work costs 750.

Almost half the cost of the gearbox itself)))))

And so is the moral!!!!! It is cheaper to warm up the car a little on gasoline and extend the operating time of the gearbox.

Or make repairs with new membranes but with an old, worn and terribly damaged spring and continue to be surprised that the consumption is terrible.

I hope you found it interesting and useful to learn something that I’m sure you didn’t know. By clicking the play button on the player below, you will hear my commentary in the audio recording.

I would like to remind you that this is purely my personal opinion on this problem.

Author: Voronsoft

Gas reducer Lovato

In gas-cylinder equipment, the gearbox is given the greatest importance among all components. Its task: to provide the driver with the opportunity to reduce the pressure coming from the cylinder. Repair, namely adjustment, on a car gearbox involves working with one or two regulators: this is the main difference.

In principle, a gas reducer is a primitive pressure regulator designed to independently maintain a standard pressure value based on fuel consumption. As practice shows, the device supports it with minor fluctuations. The pressure decreases slightly with increasing gas flow. This is not a very significant point, but requires attention.

Manufacturer's offer

The Lovato gearbox design is characterized by versatility, simplicity and reliability. For Turkish artisanal producers, the manufacturer is a role model. Almost all generations of Turkish gearboxes have adopted the design of a flattened “drum”, at the ends of which there are two stamped covers. belongs to a family-type enterprise that was founded in the post-war period in conditions of acute fuel shortages. In modern conditions, Lovato is one of the leaders in the global gas cylinder system market. Repair, namely adjustment, of Lovato analogues depends on the following factors:

- mechanism generation;

- number of regulators;

- fuel system.

Manufacturer product range:

- Lovato propane vacuum reducer for 90 and 140 kW. The device is intended for 1st generation LPG systems on carburetor-type cars with a power of up to 123 horsepower. The reducer is intended exclusively for conversion to propane.

- Lovato electronic propane reducer 90, 140, 170 kW. The device is intended for 1st, 2nd and 3rd generation HBO systems on cars of injection, mono-injection and carburetor types with engine power up to 123 horsepower. The reducer is designed for propane-butane.

- Lovato methane gearbox. The 2nd generation device is used for converting cars and buses to methane fuel.

Gear settings

Repair, namely adjustment, of the gearbox requires orientation in its settings. Propane analogues usually have two regulators, but there are also one. Methane type gearboxes are almost always characterized by one regulator. In their management, these settings are the most problematic.

Repair for the gas generation of gearboxes with one unique setting involves manipulation exclusively with the pressure of the transmitted gas. Vehicle owners with particular enthusiasm prefer to “tighten up” the pressure themselves. Having set the only correct and, what is very important, true pressure value, the fuel reducer alone will make it possible to limit gas consumption at operating power due to an element called the greed screw.

Repair has some difficulties when the screw is in the “closed” position. To maintain idle speed in this case, it is necessary to increase the pressure, the process of which involves:

- Checking the gearbox before tuning, namely, whether the “greed screw” is open.

- After the previous stage has been completed, adjustment work can begin.

Lovato gearbox design

A few words about the design of the LPG gearbox

The understanding of the essence of gear systems with which gas equipment is equipped lies through consideration of its general concept. Everyone knows that gas, represented by propane or methane, is in a gas cylinder under high pressure and in a liquefied state. In its standard form, supplying such fuel to the internal combustion engine chambers is not possible, because for its operation it is necessary to prepare a fuel-air mixture. It is the preparation of the latter that is carried out by a standard gas equipment reducer.

Please note that not all generations of gas equipment are equipped with gearbox systems. So, for example, the last two generations of gas equipment, numbers 5 and 6, do not have this equipment, because the supply of gas to them is liquefied. However, on gas equipment of 1-4 generations, the gearbox is an integral part of the system. In many ways, the correct functioning of gas installations depends on the stable operation and configuration of gear equipment, which should not be forgotten.

Structurally, LPG gas reducers of any generation are evaporator units that convert liquefied propane or methane into evaporated gas, which is already sent to the intake tract for mixing with air, and then to the combustion chambers of the engine. The design of the unit involves a system of several sequential chambers separated by valves. The operating principles of the GBO 2-4 and partial first generation gearbox are as follows:

- Gas in liquefied format is supplied to the inlet tract of the reducer, called the unloading valve;

- The latter produces dosage and proper distribution of fuel, which is carried out either mechanically (on vacuum gearboxes) or electronically (on gearboxes with solenoid valves and their control unit);

- After this, the gas evaporates and it enters directly into the engine through its manifold, where it is mixed with air.

Note that any gearbox, similar to a carburetor, has an idle channel through which fuel enters the internal combustion engine chambers at idle speed, as well as various adjustment elements.

In any operating mode of the engine, it does not require liquefied gas, but a fuel-air mixture, prepared in the order noted above through evaporation. To achieve the latter, special evaporation elements and their chambers are used. Depending on the number of chambers the gas passes through until complete evaporation, there are single-stage, two-stage and three-stage LPG reducers. Regardless of the method of organizing evaporation, the pressure in the chambers invariably changes during its process, usually downward. Today, the most popular are gear systems with two evaporation chambers, which are used on LPG from Lovato, LPG on methane and equipment.

Adjustment process

The Lovato gas regulator itself is presented in the form of a screw compressing a spring. In order to install it, you should consider:

- when tightening, the gas supply will be reduced by the reducer;

- when unscrewing, it will grow.

Sometimes screws are found with left-hand threads, most often they are right-hand threads. This moment depends on the designer’s imagination of the manufacturer. To simplify this task slightly, it is necessary to take into account: with any rotation it is characterized by the above characteristics of changes in gas pressure.

Adjusting the idle speed on vehicles is explained by the degree of engine shaking. His calm work indicates that the gearbox repair was carried out competently and efficiently.

So, start the engine and hold the throttle open. Then we smoothly release it and slow down until the power unit stalls. At the same time, do not forget the condition: the gas reducer of the car engine must continue to work. For “dummies”, an explanation: the engine will not stall completely if you start twisting the throttle valve in an arbitrary direction. If worse motor performance is observed, you will have to change the direction of rotation of the gearbox and restore its stable operation.

Equipment setup

As an example, consider the configuration option for a popular gearbox from Tomasetto (Tomasetto AT-07 electronic). Adjustment of 2nd generation Lovato gearboxes and its full analogues, such as Atiker and Torelli, is performed in a similar manner.

Before starting work, make sure that all engine systems are in good condition. The air filter has been changed, the ignition has been adjusted, and the coolant level is normal. Drain the condensate from the gearbox, if it is not new, make sure it is in good condition.

In order to adjust second-generation gas equipment with your own hands, you need to warm up the engine to operating temperature on gasoline, switch to gas and turn off the engine. From now on, we will separate the tuning options for different types of engines.

Correct adjustment of 2nd generation HBO on a carburetor with your own hands

- Using a flat-head screwdriver, tighten the screws of the gearbox and dispenser until they stop (without much effort), and then unscrew:

- membrane sensitivity 2-3 turns;

- “greed screw” of the first chamber until fully open, the second by 1 turn.

- Start the engine on gas. Gradually tighten the sensitivity screw to find the moment the speed drops at a lean mixture. Attention! A drop may occur when the mixture is enriched. Therefore, if, when unscrewing the screw, the speed increases, and then falls again, it means that this is working on a rich mixture. Now, by screwing the screw back in clockwise, you need to set the peak of increased engine speed - this way the idle speed will be found (800-850 rpm). If higher, adjust the quantity screw on the carburetor itself to the desired readings.

- Use the accelerator to increase engine performance around 3000 rpm. Use the “greed screw” of the first chamber to set the moment when, when it is tightened, the drop begins, and when unscrewed, the speed increases. Release the accelerator and revoke the throttle; if the internal combustion engine develops low speed (there is a dip), unscrew the screw of the first chamber of the power register by 1/8. At the same time, adjust the sensitivity screw as indicated in point No. 2. Check by re-gasping again.

- The second chamber of the carburetor operates at increased engine speeds from 3000 rpm (depending on the engine brand). Therefore, the “greed screw” of the second camera must be set to approximately the same position as the first.

- Next, you need to carry out control tests on the move under different loads (lifts, sudden accelerations).

Setting up 2nd generation HBO on an injector

- Unscrew the screw of the power register and membrane by 2-3 turns, tighten it until it stops.

- Start the engine. Raise the engine speed to 3000-3500 rpm, by tightening and unscrewing the dispenser, find the peak of maximum engine speed. From this position, screw in the register screw 0.5 turns.

- Release the accelerator and revise the throttle. If the engine starts to choke, unscrew the metering bolt 1/8. And so on until finding the optimal speed set.

- Then, gradually tightening the membrane sensitivity screw, find the moment the speed drops, loosen the screw by 1/8.

In this case, it is convenient to use a lambda probe emulator. The setting can be considered correct when the indication on it (LED) glows red at idle. If this condition is not met, you can unscrew the x/x screw until the engine speed stabilizes. Also, if you have a device (gas analyzer), you can use it to adjust the gas equipment even more accurately.

5. Make further adjustments during sea trials. If the car does not develop enough power, slightly release the gas supply with the register screw.

Gas reducer, what is it?

This article will talk about what a gas reducer is.

A gas reducer is a device designed to reduce the gas pressure in a gas cylinder and maintain this pressure optimal. The gas reducer in the LPG kit (gas equipment for a car) performs exactly these functions: it maintains the pressure value in the gas cylinder that is optimal for correct operation of the system, regardless of the pressure, for example, in the gas pipeline.

The use of gas reducers, however, is not limited exclusively to gas-cylinder equipment in cars. They are used both in household gas cylinders (for example, in the absence of a central gas pipeline in summer cottages), and in industry (when transitioning from a large central gas pipeline to a local network), etc.

Types of gearboxes:

- injection;

- vacuum;

- electronic.

Unit technical characteristics

It is important to add that such a unit is ideal for automotive systems not only of the second, but also of the first generation. This is explained by the fact that the gearbox is distinguished by the presence of a dual control system, which will increase the productivity of the unit as a whole.

Moreover, some devices of this brand may contain not one, but several stages of gas pressure reduction. In addition, there are models containing so-called auxiliary valves, designed to relieve the gas flow at the moment when the pressure in the device begins to increase.

In addition to all that has been said, there are also products on sale that are capable of functioning in those cars that are equipped with a powerful engine.

Operating principle of the gas reducer

First of all, we note that for proper operation of the LPG kit in general, and the gas reducer in particular, the car should be warmed up, especially in autumn and winter.

Gas from the gas cylinder first enters the reducer, and then into the carburetor or injector. There is a special membrane at the gas inlet and outlet. If the gas pressure is low, the reducer diaphragm keeps the valve open and gas flows into the cylinder until the pressure rises. The valve then closes and no gas can flow. These are both the regulating and control functions of the gas reducer.

Adjusting the gas reducer

Adjusting the gas valve is a responsible matter.

And you should only take on it yourself if you are an HBO specialist and confident in your abilities. Otherwise, we advise you to contact a professional service center. Moreover, more and more such services have begun to appear in recent years. Remember that improper adjustment of the gas reducer can lead to gas leakage and uncontrolled increase and/or drop in pressure in the gas cylinder. There is no need to talk about how dangerous this can be.

As a rule, if problems occur in the gas reducer, they can be eliminated by replacing one or another part of the reducer, if the reducer is dismountable. If it is non-separable, then you will need to buy a new gearbox.

If you take on the task of adjusting the gas reducer yourself, then start by setting the idle speed. Then, after each throttle release, unscrew the sensitivity screw a quarter turn until you get the correct response to a sharp throttle opening.

After this you need to adjust the feed. Use the throttle to increase engine speed to 3000 rpm, then tighten the gas supply metering screw (screw) until the speed begins to decrease. Then you can try it out for a drive and see how responsive the equipment is to your actions.

Gearbox components. Peculiarities

If we consider the 2nd generation Tomasetto gas equipment, it should be noted that it is famous not only for its simplicity of design, but also for such serious advantages as the ability to independently configure, safety and reliability. In general, Tomasetto Arctic was specially designed for all those car owners who value efficiency.

All those who wished to install such equipment were personally convinced that it was truly worth it. After all, the equipment can operate not only on methane, but also on propane, while showing good results.

Moreover, such products are equipped with a durable metal body, as well as a modern built-in valve. It should be added that this option is ideal for those vehicles on which specialized pipelines with high gas throughput are installed.

If you want to know how to adjust the 2nd generation Tomasetto gas reducer, you should definitely seek help from experienced specialists. After all, only in this case will this operation be performed thoroughly.

By contacting specialists for advice, you can find out how to set up the 2nd generation Tomasetto gas reducer.

Installation of a gas reducer

It is better to entrust the installation of the gas reducer, as well as the adjustment, to specialists in service centers.

However, we can describe the general installation layout. The gearbox should be securely secured vertically at three points on the body. It should be installed above the top level of the radiator, as close to the mixer as possible. Gas is supplied to the gearbox through a solenoid valve, which should not come into contact with the body. The adjusting screw and drain fitting must be freely accessible.

The cooling system is connected through conductors and tees. Then install the solenoid valve (it is through it that gas will flow into the cylinder when filling), it must also be securely fastened. After all these steps, a gas line is supplied, it is secured under the bottom of the car using self-tapping screws and brackets away from the heating and moving parts of the car and in no case should it come into contact with the road surface.

The final stages of installing the gas reducer is wiring. You will find the diagram to follow in the instructions for your LPG kit.