Gas reducers Lovato

This material talks about the evolution of automobile gas reducers produced by the Lovato company, but most of the following is also true for other brands represented on the Russian market.

Purpose of the gas reducer

The first task of any automotive propane reducer, regardless of the generation of gas equipment, is to transfer gas from a liquid to a gaseous state and maintain a stable gas temperature during engine operation.

The second task is to ensure gas pressure at the outlet of the reducer, in accordance with the current fuel demand of the car engine. The tasks, in general, are simple, but very important for the proper operation of the entire gas system of any generation of gas equipment.

The result of this task depends not only on the quality of the Lovato gearbox, but also on the competent and honest fulfillment by the LPG installer of several conditions:

- It is important to connect to the engine cooling system so that the circulation of coolant through the gearbox is effective in all operating modes of the internal combustion engine, and at the same time, this connection should not affect the operation of the heater or other vehicle devices. Simply put, the gas reducer should not cool down during operation, and all devices that worked in the car before and after the installation of gas equipment should work without changes.

- The maximum power of the Lovato gearbox must match or exceed the engine power (in the case of 1st and 2nd generation systems, installing a gearbox larger than the required power is not recommended). This is important not only for efficient gas evaporation, but also for the ability of the reducer to maintain a stable differential pressure, which is extremely important for Lovato 4th generation LPG systems.

If the vehicle is equipped with a gearbox of less power than the required power, this will not allow the Lovato gas system to operate normally and safely under high engine load conditions (there may be interruptions in operation, expressed in jerks, or a noticeable loss of power compared to gasoline, and In some cases, during sudden acceleration, a gas smell may appear).

For long and trouble-free operation of any Lovato gas reducer, the absence of dirt and deposits on the working mechanical parts of the system is of great importance. To achieve this, most gearboxes are equipped with Lovato gas purification filters at the inlet. It is very important to change the filter elements in a timely manner (in accordance with the service book), since their contamination directly affects the performance (power) of the gearbox.

Vacuum reducer Lovato (1st generation of gas equipment)

This is a completely mechanical device, created and intended only for carburetor cars. The Lovato vacuum reducer has a built-in mechanical function “Car Safety” - “Safe Car” (when the engine is turned off, the gas supply is shut off regardless of the position of the ignition key).

The reducer consists of 2 stages: the first serves to evaporate the gas and reduce the pressure to 0.45 - 0.65 bar, the second chamber is connected to the mixer, depending on the pressure in the intake manifold of the car, it increases or decreases the amount of gas supplied by the Lovato vacuum reducer into the engine. In the product line, Lovato's first generation gearbox is called RGV and is available in two versions for engines up to 122 hp. (RGV90) and up to 160 hp. (RGV140).

HBO 4th generation

The engine is idling erratically

— Gas injectors are faulty; — The ignition system is faulty; — Incorrect adjustment of the gas injection system; — The lambda probe is faulty; — Reduced engine compression; — The engine gas distribution mechanism is faulty; — The adjustment of the thermal clearances of the timing valves is disrupted.

The engine does not develop full power

— Gas injectors are faulty; — Reduced gas pressure in the reducer; — Incorrect adjustment of the gas injection system; — The lambda probe is faulty; — Poor heating of the gearbox with coolant; — The gas filter is clogged; — Gas lines are clogged; — The fine gas filter is clogged

The engine does not switch to gas power after reaching the “transition” temperature designated by the software

— The gearbox temperature sensor is faulty; — There is no engine speed signal (tachometer), — The gas temperature sensor is faulty; — The gas pressure sensor is faulty; — The gearbox is not heated (the gearbox heating system is aired); — Battery voltage is below 9 volts

Increased gas consumption

— The air filter is clogged; — The ignition system is faulty; — The gearbox adjustment is broken; — Reduced engine compression; — The gearbox is faulty; — Poor heating of the gearbox with coolant; — Gas injectors are not working properly; — The lambda probe is faulty; — The adjustment of the gas injection system is disrupted; — Increased pressure of the reducer; — Incorrectly selected injector calibration fittings.

Failure when opening the throttle suddenly

— Incorrectly selected injector calibration fittings; — Low gas pressure in the reducer; — The gas filter is clogged; — Gas lines are clogged; — The fine gas filter is clogged; — Gas injectors are not working properly; — The ignition system is faulty; — Reduced engine compression; — The engine gas distribution mechanism is faulty; — The adjustment of the thermal clearances of the timing valves is disrupted.

The gas injection system spontaneously returns to gasoline power

— The gearbox temperature sensor is faulty; — There is no engine speed signal (tachometer), — The gas temperature sensor is faulty; — The gas pressure sensor is faulty; — The gearbox is not heated (the gearbox heating system is aired); — Battery voltage is below 9 volts. — Low gas temperature due to low power of the reducer (incorrectly selected reducer)

Modern gas equipment, if selected and installed properly, as a rule, does not give rise to complaints. Experienced installers can even boast that they have successfully introduced gas equipment into cars that are theoretically not suitable for gas. Then where can problems come from?

The fact is that even the best installation wears out after several years of operation, and adapting a car to run on gas, due to its complexity and the need for serious intervention in the equipment, creates a high risk of installation errors. It is the combination of these two factors that leads to the fact that the operation of gas cars is not as carefree as it seems. Improperly operating equipment not only irritates the driver, but also leads to premature wear of the engine and its attachments. If problems arise, there is no need to delay repairs.

Typical installation errors most often appear during the first month after installing LPG. Symptoms will include: problems with gas filling (the valve closes too early), incorrect gas level readings, anomalies in the operation of the cooling and heating system, the “Check” indicator lights up, a drop in power, automatic switching to gasoline if there is a decent supply of gas. However, some problems may not appear until several years later. Then you will have to deal with wear and tear on the fuel injectors, pressure sensor and pressure reducer.

Read also: Willson body glass guard

Electronic gearbox Lovato (2nd generation LPG)

The 2nd generation Lovato electronic gearbox was created with the advent of injection cars on the market, since the vacuum one could not provide comfortable switching from gasoline to gas and back on this type of car.

Its design is almost identical to the vacuum reducer, but the vacuum membrane, which provides the “Car Safety” function, is removed from it. Instead, an electric valve is installed, controlled by a switch. The latter is obliged to de-energize (close) the valve if the engine is not running. Lovato's 2nd generation electronic gearbox in the Lovato product line is called RGE and is available in three versions for engines up to 122 hp. (RGE90), 160 hp (RGE140) and up to 300 hp. (RGE220).

Gas reducer Lovato for injection system (4th generation LPG)

The advent of gas injection systems required the creation of a fundamentally different gearbox (see the section on the principle of operation of gas equipment). The main purpose remained heating and evaporation of the gas coming from the cylinder, as well as maintaining a stable differential pressure at the outlet of the reducer.

By differential pressure we mean the difference between the pressure at the output of the gearbox and the pressure in the intake manifold of the car engine. And when the driver presses the accelerator pedal, the gas pressure at the outlet of the gearbox will increase in proportion to the increase in pressure in the intake manifold, due to constant feedback from the manifold to the working diaphragm of the gearbox.

Injection gearboxes are usually single-stage. But, despite the apparent simplification of the design, choosing a good and suitable gas reducer for a given vehicle and gas electronics can be quite a difficult task.

The reducer must reliably heat the gas before supplying it to the gas injectors and provide stable pressure, as discussed above. The 4th generation Lovato gas reducer must efficiently handle some transitional moments during engine operation. For example, for many gearboxes, a very difficult mode is exiting the cut-off mode (engine braking); in this mode, many gearboxes strongly increase the differential pressure, which often leads to the engine trying to stall. The second critical point is a sharp increase in the load on the engine - many gearboxes, due to insufficient performance, first drop pressure, and only then begin to equalize it.

Symptoms and costs

During the operation of a car with HBO, 18 characteristic malfunctions most often occur. Some of them are malfunctions in the operation of the gas installation itself, and the other part are typical problems that should be expected from a car powered by gas for a long time.

1. Loss of coolant.

Signs: The coolant level in the reservoir drops below normal. Topping up doesn't help. The situation repeats itself again and again. Puddles (drops) may appear under the car.

Reason: when installing HBO, you have to cut into the cooling system. Coolant is used to warm up the gearbox. Leaks most often appear in “tie-in” areas. The gearbox itself may leak. It is possible for both coolant to enter the intake manifold and gas to enter the cooling system.

Repair cost: 1000-6000 rubles.

2. Engine overheating.

Signs: the temperature gauge needle enters the red zone, the antifreeze is boiling.

Reason: during installation, the circulation of liquid in the system was disrupted, the system became airy.

Repair cost: up to 1000 rubles. It is necessary to remove air from the system, and in some cases replace pipes and clamps.

3. The car jerks when running on gas.

Signs: when running on gas, power increases unevenly, the car jerks, the engine has difficulty maintaining idle speed. At the same time, the engine works perfectly on gasoline.

Reason: It might just be running out of gas. In the case of mechanical gas equipment (I and II generations), the gearbox is probably malfunctioning, or there are leaks in the intake system. In addition, the stepper motor for controlling gas dosing could fail. Injectors (if multipoint injection is available) can also be the culprit.

Repair cost: it all depends on the cause of the problem. A set of LPG injectors including replacement will cost 4,000-9,000 rubles.

4. The gas reserve indicator does not work.

Symptoms: regardless of the amount of gas filled, the indicator shows a value different from the actual one.

Reason: The gas level sensor works on a principle similar to the float in the toilet tank. A stuck float is the most common cause of incorrect readings. Perhaps the reason lies in an electrical fault: no contact, short circuit, etc. and so on.

Cost of repair: most often you can get away with tapping the gas cylinder. If the float comes to life, consider yourself lucky. If not, you will have to prepare from 800 to 2000 rubles.

5. The heating does not work.

Symptoms: Regardless of the position of the set temperature control knob, cold or barely warm air blows from the vents.

Cause: The cooling system became airy during installation. It is possible that the cause of the anomaly is the incorrect installation of the LPG reducer.

Repair cost: removing air from the system will cost no more than 1000 rubles. To change the location of the gearbox you will have to spend up to 3,000 rubles.

6. The gas cylinder cannot be filled completely.

Signs: The gun fires too early.

Reason: Sometimes the gun itself is to blame. However, much more often the cause lies in a faulty filling device valve. It can be replaced or removed and cleaned. Before going to the service center, you should try to fill up with gas at another station, just in case.

Repair cost: a new valve costs from 600 to 1000 rubles. The cost of replacement work is about 500 rubles. But most often you can get away with cleaning the valve - from 500 to 1000 rubles.

7. Power loss.

Signs: in this case we are talking about a situation in which the dynamic performance of the car worsens from month to month, although initially everything was in order. On gasoline the engine runs properly.

Reason: HBO filters may be the culprit, but not only. In old-type mechanical systems (I and II generations), the reason may lie in wear of the gearbox, and in the presence of a multipoint injection system, in malfunctions in the operation of the LPG control electronics or faulty injectors.

Repair cost: replacing the filter will cost 500-1000 rubles. In other cases, costs depend on the specific case.

Signs: You can smell gas in or near the car.

Reason: The gas has a pungent odor, so even a small amount is immediately noticeable. The cause may be either small leaks or a leaky exhaust system. In old-type systems, due to loss of tightness of the intake duct, gas can enter the air intake system for the passenger compartment.

Cost of repairs: everything is assessed individually in each specific case. The repair begins with a classic check of the tightness of the connections, which will cost approximately 500 rubles. In some situations, the cost of elimination can reach up to 3,000 rubles.

9. The engine does not develop speed.

Signs: The engine runs perfectly at low speeds, but is reluctant to increase speed.

Reason: the reasons can be different, ranging from the prosaic clogging of the gas filter and a faulty gearbox (or its too low performance), and ending with problems with the software.

Read also: 740 1109560 02 Me

Repair cost: to replace the filter you will need from 500 to 1000 rubles. To replace the gearbox you will have to pay 10 times more. Diagnostics and tuning are assessed individually, depending on the type of installation and engine.

10. The engine suddenly stalls.

Signs: the engine stalls at the most unexpected moment: at an intersection, when releasing the gas, when braking, etc.

Cause: In older type systems, the cause lies in incorrect adjustment or improper modification of the intake system. Sometimes it turns out that the gearbox is installed incorrectly. In systems with multipoint injection, such problems are not observed, and if something similar happens, then the cause must be sought in the electronic control system.

Cost of repair: repair involves painstaking diagnosis and precise adjustment. Costs will range from 800 to 2000 rubles.

11. The Check Engine light comes on.

Symptoms: The check engine light stays on all the time or only comes on under certain repeating conditions and goes off after a few days.

Reason: for some reason, the composition of the mixture does not correspond to the parameters provided by the car manufacturer. You can drive the car, but ignoring the problem risks burning out the valve seats or damaging the catalyst.

Cost of repair: for diagnostics you will have to pay from 800 to 2000 rubles. Further costs depend on the scope of work.

12. The engine “shoots”.

Symptoms: applies to vehicles with mechanical type LPG for distributed injection. When starting or accelerating from low speeds, the mixture explodes in the intake manifold.

Reason: failure of the ignition system, incorrect adjustment of the mixture composition, installation errors, very large volume of the intake manifold.

Repair cost: replacement of high-voltage wires and spark plugs, and sometimes filters, will be required. For everything you will have to pay about 5,000 rubles. Additional costs will be required for re-adjustment and repair of damage caused by the explosion. The final cost may exceed 15,000 rubles.

13. Worn fuel pump.

Signs: a characteristic hum is heard in the rear of the car. When driving on gasoline, sometimes there is not enough power, the engine runs intermittently and is difficult to start.

Reason: In some cars with LPG, the fuel pump wears out faster than usual. Much depends on the type of equipment and how it is installed.

Repair cost: depends on the model and type of pump. The cost of a new pump is from 2500 to 8000 rubles.

14. Worn valve seats.

Signs: The engine loses power or runs rough. The valve clearance cannot be adjusted correctly.

Reason: wear of valve seats is accelerated not by the gas itself, but by a lean mixture - the result of incorrect adjustment of the gas equipment. It is worth noting that the composition of the mixture must be correct not only in steady-state conditions, but also in transient conditions, for example, during acceleration.

Repair cost: the repair is very serious and consists of dismantling the head and regenerating it. The cost of restoration ranges from 13,000 to 25,000 rubles.

15. Wear of the ignition system.

Signs: an engine with an old type LPG does not work correctly - it “shoots” and stalls. For HBO with multipoint injection, this problem is not typical, or at least has less acute symptoms.

Reason: Creating a spark in a mixture of propane, butane and air requires a higher voltage than in a mixture of air and gasoline. For this reason, the ignition system is more stressed and wears out faster.

Repair cost: for a new spark plug you will have to pay from 150 to 1000 rubles. The cost of new high-voltage wires is from 2,000 to 20,000 rubles. A regular old-style ignition coil will cost about 1,000 rubles, and a cassette – 10,000 rubles.

16. Body corrosion.

Signs: corrosion occurs wherever the LPG installer intervened: near the remote filling device, under the screws securing the LPG wiring to the body, under the screws holding the gearbox, and also in the trunk - in the area where the gas tank is attached.

Reason: installation requires drilling holes in the body necessary for fastening the LPG elements. The holes are protected by simple methods - usually treated with aerosols, which do not always perform their role well.

Cost of repair: sometimes it is enough to clean the damaged areas of rust and re-treat them. In extreme cases, it is necessary to move the attachment points to other places.

17. Exhaust system corrosion.

Signs: the engine is noisy, you smell gas, and the exhaust system resonates when changing speed.

Reason: The combustion of liquefied gas produces more water vapor than the combustion of gasoline. As a result, the exhaust system corrodes faster and mainly on the inside. The exhaust system may "ring" and resonate, although upon inspection it appears to be in good working order and sealed.

Repair cost: in the case of popular cars, replacement will be cheaper: from 5,000 to 10,000 rubles.

18. Damage to the intake manifold.

Signs: the engine runs unevenly, stalls, and does not idle.

Reason: after installing the HBO, depressurization of the manifold may occur at the places where the injectors are installed. In cars with LPG for distributed injection, the gas destroys the manifold and other elements of the intake system, for example, the flow meter.

Cost of repair: It is very rarely possible to restore the manifold or other elements of the intake system. Repair consists of replacing damaged elements with serviceable ones (new or used). It is necessary to prepare for expenses in the amount of 3,000 to 20,000 rubles.

Manufacturer's offer

The Lovato gearbox design is characterized by versatility, simplicity and reliability. For Turkish artisanal producers, the manufacturer is a role model. Almost all generations of Turkish gearboxes have adopted the design of a flattened “drum”, at the ends of which there are two stamped covers. belongs to a family-type enterprise that was founded in the post-war period in conditions of acute fuel shortages. In modern conditions, Lovato is one of the leaders in the global gas cylinder system market. Repair, namely adjustment, of Lovato analogues depends on the following factors:

- mechanism generation;

- number of regulators;

- fuel system.

Gear settings

Repair, namely adjustment, of the gearbox requires orientation in its settings. Propane analogues usually have two regulators, but there are also one. Methane type gearboxes are almost always characterized by one regulator. In their management, these settings are the most problematic.

Repair for the gas generation of gearboxes with one unique setting involves manipulation exclusively with the pressure of the transmitted gas. Vehicle owners with particular enthusiasm prefer to “tighten up” the pressure themselves. Having set the only correct and, what is very important, true pressure value, the fuel reducer alone will make it possible to limit gas consumption at operating power due to an element called the greed screw.

Repair has some difficulties when the screw is in the “closed” position. To maintain idle speed in this case, it is necessary to increase the pressure, the process of which involves:

- Checking the gearbox before tuning, namely, whether the “greed screw” is open.

- After the previous stage has been completed, adjustment work can begin.

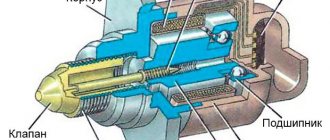

Lovato gearbox design

Adjustment process

The Lovato gas regulator itself is presented in the form of a screw compressing a spring. In order to install it, you should consider:

- when tightening, the gas supply will be reduced by the reducer;

- when unscrewing, it will grow.

Sometimes screws are found with left-hand threads, most often they are right-hand threads. This moment depends on the designer’s imagination of the manufacturer. To simplify this task slightly, it is necessary to take into account: with any rotation it is characterized by the above characteristics of changes in gas pressure.

Adjusting the idle speed on vehicles is explained by the degree of engine shaking. His calm work indicates that the gearbox repair was carried out competently and efficiently.

So, start the engine and hold the throttle open. Then we smoothly release it and slow down until the power unit stalls. At the same time, do not forget the condition: the gas reducer of the car engine must continue to work. For “dummies”, an explanation: the engine will not stall completely if you start twisting the throttle valve in an arbitrary direction. If worse motor performance is observed, you will have to change the direction of rotation of the gearbox and restore its stable operation.

Widely used gas equipment consists of a considerable number of elements. Perhaps one of the main ones is the gearbox, which plays the role of an injector or carburetor in this equipment. Of course, the operating principles and design of the unit are slightly different from the noted fuel distribution mechanisms, but in general they are quite similar. We will talk in more detail about the LPG reducer, methods for setting it up and other information about the part in the material presented below.

A few words about the design of the LPG gearbox

The understanding of the essence of gear systems with which gas equipment is equipped lies through consideration of its general concept. Everyone knows that gas, represented by propane or methane, is in a gas cylinder under high pressure and in a liquefied state. In its standard form, supplying such fuel to the internal combustion engine chambers is not possible, because for its operation it is necessary to prepare a fuel-air mixture. It is the preparation of the latter that is carried out by a standard gas equipment reducer.

Please note that not all generations of gas equipment are equipped with gearbox systems. So, for example, the last two generations of gas equipment, numbers 5 and 6, do not have this equipment, because the supply of gas to them is liquefied. However, on gas equipment of 1-4 generations, the gearbox is an integral part of the system. In many ways, the correct functioning of gas installations depends on the stable operation and configuration of gear equipment, which should not be forgotten.

Structurally, LPG gas reducers of any generation are evaporator units that convert liquefied propane or methane into evaporated gas, which is already sent to the intake tract for mixing with air, and then to the combustion chambers of the engine. The design of the unit involves a system of several sequential chambers separated by valves. The operating principles of the GBO 2-4 and partial first generation gearbox are as follows:

- Gas in liquefied format is supplied to the inlet tract of the reducer, called the unloading valve;

- The latter produces dosage and proper distribution of fuel, which is carried out either mechanically (on vacuum gearboxes) or electronically (on gearboxes with solenoid valves and their control unit);

- After this, the gas evaporates and it enters directly into the engine through its manifold, where it is mixed with air.

Note that any gearbox, similar to a carburetor, has an idle channel through which fuel enters the internal combustion engine chambers at idle speed, as well as various adjustment elements.

In any operating mode of the engine, it does not require liquefied gas, but a fuel-air mixture, prepared in the order noted above through evaporation. To achieve the latter, special evaporation elements and their chambers are used. Depending on the number of chambers the gas passes through until complete evaporation, there are single-stage, two-stage and three-stage LPG reducers. Regardless of the method of organizing evaporation, the pressure in the chambers invariably changes during its process, usually downward. Today, the most popular are gear systems with two evaporation chambers, which are used on LPG from Lovato, LPG on methane and equipment.

HBO 1st – 2nd generation

Gas does not enter the engine

— Not fully opening the flow valve; — Operation of the high-speed valve; — Clogged filter elements; — Clogging of pipelines; — Sticking of the high-speed valve in the closed position; — EMC gas does not work

Gas enters the stopped engine

— The gas EMC is not sealed; — The gearbox is faulty; — The switch is faulty.

Difficulty starting the engine

Read also: Is Plato needed for special equipment?

— Simultaneous supply of two types of fuel; — Incorrect gearbox adjustment; — The gearbox is faulty.

Reducer freezing, increased gas consumption

— Low coolant level; — The cooling system is air-filled; — The diaphragms in the gearbox are not sealed.

The smell of gas in the car interior

— Gas leakage from gas main connections; — Gas leak from the gearbox housing; — The EMC of the gearbox is not sealed; — The exhaust system is not sealed

The engine idles, but does not develop speed

— The gas filter is clogged; — Gas lines are clogged; — The gearbox is faulty.

Increased gas consumption

— The air filter is clogged; — The ignition system is faulty; — The gearbox adjustment is broken; — Reduced engine compression; — The gearbox is faulty; — Poor heating of the gearbox with coolant;

Features of gear systems

It would seem that the structure of the LPG gearbox is quite simple, and there are no difficulties in understanding the principles of its operation. So why is this unit arousing keen interest among motorists? Perhaps the main reason for close attention to gear systems installed on gas equipment lies in the features they have. To be more precise, there are only two of them:

- “Frozenness” of the gearbox. Probably every motorist has heard at least once that gearbox equipment for gas equipment often freezes. Is it true? And this phenomenon is connected with the fact that gas compressed to 16 or, as in the case of methane, 100-200 atmospheres, actively evaporates and loses pressure to 1.8-2 atmospheres, which is accompanied by the intake of energy (heat) from the environment. As a result, the gearbox freezes, sometimes to such an extent that it simply ceases to efficiently perform its main functions. To neutralize such a sensitive feature of gas “carburetors,” it is recommended to install them close to heating elements and, in winter, to warm up the car not on gas, but on gasoline;

- Types of equipment used. By the way, HBO gearboxes can be either vacuum, which are used on carburetor engines, or electronic, used on injection engines. How it needs to be configured depends on the configuration of the selected equipment. If, in the case of adjusting a gearbox with a vacuum operating principle, you will have to use all the skills of setting up carburetors, “shamanizing” the adjusting screws, then when using an electronic unit, it is enough to adjust its operation by using a special program on a computer connected to the LPG control unit. Of course, both tuning options are good, but the best way to adjust electronic gearboxes is definitely the best one. So, for example, on electronic systems it is possible to flexibly adjust the pressure in the chambers, which is simply unrealistic in the case of “vacuum systems”.

Having understood in detail each feature of the LPG gearbox, it is quite possible to avoid problems with this unit during its operation and configuration. Otherwise, you should be prepared for them.

Pros and cons of HBO Lovato

Why do car enthusiasts choose this Italian brand?

- Reasonable price plus the highest quality. Since the beginning of its journey (since 1922), the company has been focused on the mass consumer.

- A large network of importers around the world, Lovato products can be purchased in any city. Replacing the repair kit is not difficult.

- Car service technicians undertake the installation of equipment from the Italian brand, so installation instructions, operating manuals, and diagnostics are simple and available to auto repairmen.

- All Lovato equipment has a manufacturer’s warranty of up to three years (approximately 250 thousand kilometers, which is an excellent indicator for the 4th generation LPG).

- The issue of servicing a car with Lovato 4th generation LPG is not difficult; the instructions for setting up the ECU are not complicated.

- The company produces absolutely all gas equipment components, that is, it is a monobrand, which is very convenient for consumers.

- Lovato's equipment doesn't take up much space. The compact LOVATO JLP4 EP injector rail for 4 cylinders is not difficult to install in such a way that it does not interfere with wiring and gas lines.

- Lovato gearboxes are standards in power and pressure stability.

- Installation is carried out very quickly (in half a day).

- Gas tank 45 l. enough for a range of 400 to 500 kilometers.

- In liters, gas consumption is higher than gasoline consumption, but the difference in prices shows that switching to gas is much more profitable.

- The life of the piston group increases due to the fact that gas fuel is of higher quality. It cannot be “diluted” (can be seen from gas-burning oil, which is lighter than usual).

- If the Lovato 4 HBO connection is carried out normally, then it pays for itself in six months.

- Clear switching from one type of fuel to another.

- Car owners note that a gas-fueled engine runs the smoothest.

- Diagnosis of HBO Lovato 4th generation with your own hands is available, the instructions are clear to a beginner.

- An “advanced” microprocessor with the latest control options for gas and gasoline injectors allows you to effectively manage the system.

- Lovato's electronic brains are equipped with a diagnostic function for each component of the gas system, this makes it easier to find errors before they cause problems for the engine, and thereby facilitates vehicle maintenance.

Read more: What systems does the engine consist of?

Disadvantages that are identified when installing HBO:

- small indicators for reducing engine power when switching to gas, on average 5%;

- there is a loss in dynamics, an increase in acceleration time;

- on long trips, it may become a problem to find gas filling stations (mainly methane ones);

- the engine compartment space is reduced;

- a lot of space is given over in the luggage compartment for a gas tank;

- the likelihood of spontaneous popping noises in the injector (breakdown of spark plugs), the issue can be resolved by installing a computer.

These disadvantages are inherent in any gas equipment. As for the reduction in engine life. This statement is associated with the combustion temperature of the gas mixture. But in the latest developments of the 4th generation, fuel injection into the injectors occurs in the same way, both on gasoline and on gas.

The resource of the power plant depends most of all on the quality characteristics of the fuel and on how professionally the equipment is connected. It is strictly not recommended to do this yourself, but only in trusted centers.

On a note! Installing LPG is a responsible process. They install gas equipment to save on the budget. To achieve this, it is not advisable to save at the installation stage. You should carefully consider the recommendations of fellow car enthusiasts and get acquainted with reviews of the work of car services.