What is a direct-flow exhaust system

To understand why to install a direct-flow muffler, you need to know how the car exhaust system works as a whole and what its tasks are.

Main goals:

- Filling the cylinders with a prepared fuel-air mixture, and in diesel cars - forming the fuel mixture in the combustion chamber;

- Ensuring the removal of spent fuel gases from the engine and passenger compartment outside the vehicle;

- Reducing the emission of toxic gases and harmful substances into the atmosphere thanks to the built-in catalytic converter;

- Reducing noise levels in the cabin and surrounding area.

The operating principle of the exhaust system is partly based on the law of inertia.

Thanks to the action of this law, a vacuum zone is formed behind the exhaust valve into which gases rush, and their place is immediately taken by a fresh portion of the fuel mixture.

This happens due to the fact that the phases of fuel intake and exhaust gases overlap each other, as is provided for in the design of modern engines.

After the exhaust valves are closed, next to the high-pressure zone formed as a result of exhaust gases escaping under pressure, another low-pressure zone is formed in the manifold, which moves along the exhaust pipe at the speed of sound.

Entering the muffler, the vacuum zone encounters resistance in the form of partitions, is reflected and goes in the opposite direction to the valves.

The ideal case is when this zone approaches the motor at the moment the valves open, but this depends on the frequency of the engine and the distance to the obstacle.

And since in modern cars such a distance is large, the vacuum zone from one cylinder, as a result, at the moment the valve opens, ends up in another, and not in the one from which it left.

Thanks to the design of the “spider” (exhaust manifold), where pipes of the same length are provided, the effect of vibration damping occurs, since the vacuum zones go from 4 pipes into one, where resistance is created at the junction of the latter, and they also partially dampen each other.

But the muffler plays a leading role in noise reduction, because the exhaust manifold and other elements are unable to greatly reduce noise.

But on many sports cars such a device may not be found; the role of a muffler there is played by a special turbine, which smoothes out vibrations and reduces the force of the exhaust by grinding the outgoing gas flow.

What is a muffler for?

Everyone knows that exhaust gases after the combustion chamber enter the exhaust manifold under pressure, and from there through the rear of the car in pipes they reach atmospheric air. At the same time, with direct flow a fairly loud process is created, but without it it will be quieter. In addition, a self-made forward flow adds up to 5 percent of the engine’s power. That is why many are trying to install this design in order to modernize the car. It is worth noting that the sound volume can reach 120 decibels (this is within the permitted range).

Types of devices

The standard exhaust system of a modern car includes a resonator (the first one comes from the engine) and the muffler itself.

The resonator cuts off low-frequency vibrations, and the muffler cuts both low-frequency and high-frequency vibrations, which together leads to a good result.

But the above scheme, both jointly and separately, may include the following types of mufflers:

- Made of aluminized steel;

- Stainless steel;

- Silencers, limiters, absorbers and reflectors;

- Resonator type;

- Direct-flow (sports) analogues.

Aluminized steel

Devices made of aluminized steel are characterized not only by a long service life, from 5 to 10 years, but also by a high price.

It will be difficult to choose such a muffler for your car, since only a few companies produce such devices, and making it yourself will be problematic.

Stainless steel

The devices are in the inexpensive segment, but their service life is only from 2 to 5 years. A big plus is that you can match the element to almost any car.

Limiters

They are usually used as an additional device installed in front of the main one.

The operating principle is based on creating low acoustic resistance.

Structurally, this is done like this: in the pipe, a large diameter turns into a small one, then there is a sharp increase in volume according to the principle of a large bottle with a narrow neck. The sound, entering a large space, decreases.

Reflectors

Used as a secondary muffler installed after the main one.

Exhaust gases entering the device encounter a group of acoustic mirrors on their way. Reflecting from them, the gases dissipate their energy one by one, and the output is a weak sound.

Absorbers

Can be used as a main muffler. The principle of operation is based on the absorption of vibrations by a porous material, usually glass wool, the fibers of which are heated by oscillating, thereby converting sound into thermal energy. Structurally close to direct-flow analogues.

They are considered ineffective because they absorb only high-frequency vibrations and transmit low-frequency ones.

Resonator type

As a rule, they are used first in exhaust systems as additional ones.

The principle of noise absorption is based on the presence of chambers of different sizes, through which the sound is effectively muffled.

Everything is arranged like this: a pipe with slots runs through the center of the resonator, which is surrounded by chambers of different volumes. Through the slots, exhaust gases penetrate into the chambers, where their energy is lost.

After this, the sounds enter the main device, where they are further reduced.

Direct flow

They are also called sports mufflers. As a rule, they are made of stainless steel. Installed on sports and tuned cars.

After installing a direct-flow muffler, the suction of the air-fuel mixture into the cylinders is improved, and the resistance in the exhaust system created by conventional analogues is reduced.

A direct-flow muffler is structurally somewhat similar to a resonator; there is the same pipe with holes and empty cavities separated by partitions. Only the cavities themselves are filled with basalt wool (or other material), which can withstand high temperatures.

Consisting of long mineral fibers, basalt wool absorbs sounds well, but only until it is blown out of the direct flow and even special protective metal mesh does not save the situation.

If the direct-flow muffler, when you tap on it, begins to sound like an empty metal container, then it needs to be filled again with cotton wool or replaced. And the sound produced by the exhaust system will be different.

Types of mufflers and their differences

There are 4 types of mufflers based on the method of absorbing acoustic waves:

The reflective circuit is reverse-flow, the rest are direct-flow.

Reflective

If one muffler is installed in a car, then a reflective version is used. It uses the principle of “breaking” the flow of exhaust gases by creating several partitions, expansion chambers and turns. Exhaust volume is reduced to standard levels. For this reason, the vast majority of factory vehicles are equipped with the reflective type.

The disadvantage of this type of muffler is the reduction in engine power due to the resistance of the exhaust system to the flow of exhaust gases.

Resonator

A resonator muffler is installed as the first stage in the exhaust system of powerful engines. It consists of a perforated pipe placed in a housing. The body is divided into two or three sections. The energy of the exhaust gases is weakened due to a stepwise reduction in pressure.

The part reduces the force of sound vibrations and maintains engine power with a free flow of exhaust gases.

Restrictive

In restrictive mufflers, the gas flow passes through a diaphragm or cone narrowing, which leads to a decrease in engine power. The acoustic protection of such devices is low, since the diaphragm does not interfere with the rectilinear movement of the sound wave.

Absorption

The damping function for sound vibrations in the absorption muffler is performed by a finely porous non-flammable material located in the space between the perforated pipe and the housing. The design is similar to the resonator type. This type has little effect on power reduction.

Sounds made and their features

After installing a direct-flow exhaust system, the sound emanating from the car immediately changes; as a rule, it is low-frequency “growling”, “bass” and “mumbling”.

This happens because mineral wool placed in the co-current cavities removes only the high frequencies, while leaving the low bass unchanged.

The resistance to exhaust gases is also greatly reduced, and this affects the increase in engine power (but only in combination with other measures).

But the nature of the sounds largely depends on the number of holes and their diameter in the central pipe, as well as the characteristics of the material embedded in the cavity.

As was noted, mineral wool does not support low frequencies, and in most cases the engine produces sounds in the low range.

Therefore, it is not surprising when a car with direct flow makes sounds of engine operation through the muffler, and the higher the frequency the latter operates, the more it clogs the ears.

This is felt especially well inside the car, when such sounds, coinciding in frequency with body vibrations (and they are close to the frequency of the engine), lead to resonant vibrations inside the car and the strength of the sound increases significantly.

Therefore, it is almost impossible to make a quiet direct-flow muffler.

How to make a straight-through muffler quieter

The PG becomes quieter as it is collected. And each craftsman does this differently, using mineral wool, metal shavings, brushes or asbestos. It is also recommended to arrange several compartments inside the homemade muffler, creating additional resonance.

The installation of direct flow in various ways involves the use of mineral wool, shavings and other fillers

A car with an exhaust louder than 96 dB does not pass inspection, does not cross the border, and does not drive around the city. This is the law. Sound today is limited even in motorsport, where it would seem there should be no restrictions or boundaries.

Having decided to suppress the GHG, you need to understand that this should in no way affect the effectiveness of the new system. None of the components of the GHG system should create resistance to exhaust gases.

Flute

The flute or silencer in the PG is a simplified design used by tuners. Its task is to “calm down” the SG, obtaining legitimate dB at the output.

Making a flute is not difficult. It will be enough to use as a muffler a piece of a perforated 20-centimeter tube with a diameter that is slightly larger than the exhaust (by 1/3). A disk or conical washer must be fixed to the pipe to act as a plug. Fastening is carried out using bolts at the air cut. The washer, in fact, creates a structure that resembles a flute.

The flute is used in PG to reduce noise

The cost of ready-made silencers in stores varies from $8 to $150. Chinese models are very cheap, but don’t expect quality from them. Original, good European-made flutes can be purchased for $100–$150.

You can assemble a flute for the PG yourself. Below is a diagram by which you can easily make such a model.

A homemade flute is easy to assemble

A homemade flute is easy to assemble:

- take a 20-centimeter steel pipe (it is recommended to use stainless steel) and a sheet of iron 1 mm thick;

- welding is carried out (preferably arc);

- Initially, a plug with holes for 8 bolts should be welded to the pipe.

It is recommended to fasten it with all 3 bolts, but you can do it with 1. It will be much faster.

Damper

A SG with a damper is a universal opportunity to simultaneously increase the power of an internal combustion engine and ensure quiet forward flow. A design of this type has been known to car enthusiasts for a long time; it is even found as standard on some BMW models.

The operation of the GHG damper is based on the following principle. When the engine operates at low speeds, gases exit through a standard, conventional muffler. At this time, the SG is closed by a damper. But as soon as the internal combustion engine reaches high speeds, the damper in the PG opens, and due to enhanced ventilation, optimal torque is produced.

The damper is controlled automatically, for example, on a BMW. But manual models are also known.

The price of a ready-made system with a damper can be high, especially for cars with automatic transmission. So, the cost of such a system, together with a titanium spider, is approximately 2-3 thousand dollars.

Analogue models, similar in capabilities to the original ones, are more moderately priced. However, a successful upgrade of this option may require the specific knowledge of an experienced minder.

Direct flow with a damper is considered the most effective option for increasing the power of an internal combustion engine

You can make a damper yourself, but it is impossible to predict the result of such an installation. It's better not to take risks.

Whatever option for manufacturing PGs is chosen, ready-made models and kits should not be excluded. In some cases, it will be much easier to buy them than to bother with pipes, a welding machine and fillers.

The muffler is an element of the engine exhaust system. Its presence does not depend on the type of fuel the engine runs on - gasoline, diesel fuel or methane. The muffler dampens sound vibrations, helps attenuate, subside and resonantly reduce sound waves from engine exhaust. Interlocutors will not be able to communicate around a running engine without a muffler. The noise of the engine will drown out their speech. Nevertheless, many car owners dream of remaking the exhaust system and making it forward-flowing. Some people can create it with their own hands.

Power and forward flow, three different opinions

Many owners of VAZ cars or, for example, Mitsubishi Lancer 10, Mazda 3, installing direct-flow exhaust systems on their vehicles pursue several goals, as a rule, there are two of them:

- Tuning your car;

- Increase the engine power, they say installing a sports analogue will leave many behind when starting at a traffic light.

The first opinion is that this is true. There is no debate about tuning; we are missing this point. But there is another opinion about increasing power, and it is the opposite.

The second opinion is that a sports muffler without deep tuning of the engine will not give an increase in power and partly it coincides with the opinion of experts.

The third opinion from professionals is that a noticeable increase in engine power is possible only after significant processing, and a direct-flow muffler is a secondary part of the issue.

The tuned power unit produces more exhaust gases, and, therefore, the standard exhaust system will not cope with its tasks, especially at high speeds.

Therefore, it will be necessary to increase the diameter of all pipes, install a tuned manifold, and only then a direct-flow muffler.

It is on sports cars that they install not simple engines, but ones that require special attention. And the direct-flow exhaust system fits into the overall picture of the tuning engine.

Making a direct-flow muffler with your own hands

If you want to manufacture and install direct flow on your car, then it is better to conduct such experiments with domestic cars, for example, VAZ.

It is better to tune the exhaust system of Mitsubishi Lancer 10, Mazda 3 and other foreign cars by contacting special companies that do this professionally.

We discussed the design of the direct flow above. The difference between a sports muffler and a regular muffler is shown below.

We will be tuning the exhaust system of a VAZ-2110 (8 valve 1.6 liter volume).

To do this you will need the following materials and tools:

- Metal pipe with a diameter of 52 millimeters (a little more than 2 inches);

- Grinder with a disc for cutting metal 1 (1.6) mm;

- Welding machine, preferably inverter;

- Metal sponges (brushes) for cleaning dishes - at least 50 pcs.

Work progress

Dismantle the old device or prepare a similar one taken, for example, from disassembly.

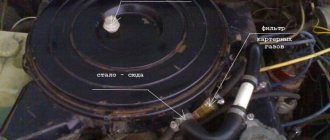

Cut out the gutter and all the insides as shown below.

Leave a 4 cm protrusion on both sides so that a new pipe can be welded into this area.

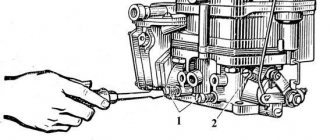

Prepare a new pipe by cutting it to size and drilling holes with a diameter of 6-8 mm in it at a distance of 1-2 cm from each other.

This is labor-intensive work, so you can use an alternative method - using a grinder with a 1.6 - 3.2 mm disc, cut holes in the pipe in the shape of a herringbone at a distance of 1-2 cm from each other.

Weld a pipe with holes to the sections in the muffler and fill the entire space with metal pipe cleaners.

On the reverse side, the electrode may be missing, no problem, the hole left will be additional to the rest drilled or sawn. But if you go by principle, you will have to cut out the other side of the muffler.

Weld the outer part back and, if necessary, update the pipe running from the forward flow towards the exhaust.

Completely clean the device, prime it with primer and paint, this will extend its service life.

It’s worth taking a closer look at the filler. In the example described above, a metal mesh was used, but still the best option would be expanded clay (in the middle), and put fire-resistant mineral wool on top.

What is forward flow?

If you don’t know how to make a direct flow with your own hands (photos of the work are presented in our article), then you should master the information from the very beginning of this simple process. Today, many workshops are engaged in the modernization of vehicles. And if in any city you can only change the oil, repaint your car and introduce other innovations, then in more professional workshops you can transform an ordinary car into a sports car. One of the modernization methods is to install direct flow.

Forward flow is the part that gives your vehicle sound. In this case, all operations can be performed independently. You just need to take a set of tools and materials. And if we talk about statistics, forward flow can be found more on domestic cars. Innovations are usually introduced by the owners of AvtoVAZ “nines”, “sixes” and other models. Making a direct flow on a VAZ with your own hands is quite simple. And even if the operation is performed incorrectly, you will not lose much money. If you do everything correctly, the effect will greatly please you.

We make direct flow from scratch

To do this you will need to use the services of a turner. We order two pipes:

- One made of steel 2 mm thick with a diameter of 130 mm and a length of 42 mm.

- The second is made of steel with a thickness of 2.5 mm, a diameter of 52 mm and a length of 42 mm with holes with a diameter of 8-10 mm, every 2 cm;

Two flanges with a diameter of 130 mm with an internal hole of 52 mm, metal thickness 2-2.5 mm can be ordered separately.

Prepared:

- Asbestos rope;

- Glass wool or mineral wool.

Asbestos rope is wrapped around the inner pipe. This is done in order to protect the mineral wool, which will be the top layer, from overheating.

We fill the top layer, assemble and scald the structure. We weld the fasteners and attach the forward flow to its regular place. For beauty, you can put a muffler attachment on it.

Another design of the device is shown below.

Blueprints

There are a lot of ways to make a direct-flow muffler; the main thing here is to understand the principle of operation of the device and use your imagination. And for car owners who find it difficult to do this, use the methods and drawings described above, they are simple and accessible to many.

Also tell us in the comments what type of forward flow is installed on your car and how you can do it yourself, this will help many people understand this topic.

How to make forward flow on a VAZ 2107 with your own hands

Making a direct flow for a “seven” is not much different in complexity from remaking a standard muffler. To make forward flow on a VAZ 2107 with your own hands, you should follow these steps:

- cut a piece of pipe with a diameter of 42 millimeters and a length equal to the length of the muffler;

- drill many holes in a thinner pipe, leaving only 5-7 centimeters intact from its edges;

- install and weld a pair of flanges on the edges of the pipe so that 5-6 centimeters of pipe protrude from each edge;

- wrap the surface of the workpiece between the flanges with mineral wool, asbestos cloth, then with mineral wool;

- put a larger diameter pipe on top of the mineral wool, cutting it so that its length coincides with the interflange distance;

- weld the edges of the thick pipe to the flanges, making a sealed seam;

- paint the direct flow with heat-resistant paint.

Tip: To enhance the sound of the exhaust, emphasizing its low-frequency characteristics, you need to cut a small piece of 130mm pipe and weld it to the end of the muffler.

When altering a standard exhaust system or making a direct flow yourself, you must pay close attention to the quality of the welds that ensure the tightness of the structure, and pay special attention to the anti-corrosion coating of the product. Otherwise, rainwater and salt solution from winter roads will lead to the rapid appearance of through corrosion.