The idea that the planet’s reservoirs are literally overflowing with the most impeccable fuel from an environmental point of view - hydrogen - has long been in the minds of scientists.

Over the years, many solutions have been proposed that make it possible to obtain this gas in its pure form.

As it turns out, each of us can extract fuel from water using a simple process called electrolysis. Next, we will learn how to make a hydrogen generator with your own hands for heating.

Features of a hydrogen generator

The exception is technological processes in which gas is formed as a by-product, but such production is still in scanty volumes.

It is much easier to separate hydrogen from water by passing an electric current through it - this process is called electrolysis. First, the H2O molecule breaks down into a hydrogen atom H and a hydroxo group OH, then the final separation of oxygen and hydrogen occurs.

The first, having a negative charge, rushes to the anode, the second - to the cathode. The elements accumulate in the form of bubbles, which, having reached a certain size, break away from the electrode and float up. Next, oxygen and hydrogen, without any separation (this mixture is called “Brown’s gas”), enter the burner, where, during the combustion process, they are again converted into water. To ensure that the finished product is supplied without difficulty, hydrogen generators are often equipped with air drainage.

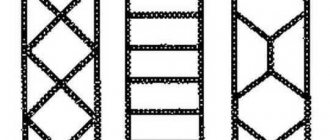

It is obvious that the productivity of the installation will increase with increasing contact area between water and electrodes. For this reason, the latter are made in the form of plates. They are assembled into structures reminiscent of steel finned heating radiators.

In order to increase productivity, cylindrical electrodes are used today, as well as those having a more complex shape.

The rate of hydrogen evolution also depends on the material of the electrodes.

Instead of copper or stainless steel, modern “advanced” generators use special alloys that are quite expensive.

Another condition is that the water must pass current. Note that in distilled form it is a dielectric. This liquid is a conductor of electricity due to the ions into which the substances dissolved in it, primarily salts, break down. The cooler the solution is, the better it will pass current.

As the size of the electrode increases, the power of heat generation decreases when an electric current is passed through it. This is a very important point, since when heated above 65 degrees, the plates become intensively coated with plaque, which will have to be constantly cleaned off.

Benefits of use

The main advantage of hydrogen as a fuel is its absolute harmlessness: when this substance is burned, pure water vapor is formed.

No other type of fuel can boast of this quality.

Even natural gas, when burned, produces carbon dioxide, which, as is commonly believed today, leads to the greenhouse effect.

The second advantage is accessibility. Hydrogen is the most abundant substance in the Universe, and it can be extracted directly from water, the reserves of which on our planet can be considered inexhaustible. True, as we will see later, this accessibility is still only apparent.

An important advantage is that to switch to hydrogen fuel, a gas boiler, like an internal combustion engine, almost does not need to be altered.

Required performance

In order to truly save fuel, a hydrogen generator for a car must produce gas every minute at the rate of 1 liter per 1000 engine displacement. Based on these requirements, the number of plates for the reactor is selected.

To increase the surface of the electrodes, it is necessary to treat the surface with sandpaper in a perpendicular direction. This treatment is extremely important - it will increase the working area and avoid “sticking” of gas bubbles to the surface.

The latter leads to isolation of the electrode from the liquid and prevents normal electrolysis. Do not also forget that for normal operation of the electrolyzer, the water must be alkaline. Regular soda can serve as a catalyst.

Negative aspects of hydrogen heating of buildings

In discussions on the feasibility of using hydrogen fuel for heating systems, skeptics provide compelling arguments:

- High cost: even in the most efficient electrolysis plants created today, to produce hydrogen it is necessary to spend 2 times more energy than its subsequent combustion.

- Explosiveness: people became convinced of the ability of hydrogen to easily explode during the crash of the Hindenburg airship, the cylinder of which was filled with this particular gas.

- The complexity of the preparatory process: getting hydrogen from water is half the battle. To be used effectively in heat generators, it must be supplied at a stable pressure, which requires a compressor and an additional tank with a reducer. In addition, you will need to get rid of water vapor, which will require the use of a dehumidifier.

Thus, the installation for producing hydrogen turns into a whole plant, which not every homeowner will be able to purchase and host.

Making your own hydrogen generator

The installation for separating hydrogen from water is quite simple to make yourself. In terms of its characteristics, it will not be much inferior to the purchased one, but it will cost much less. Let's consider the stages of creation sequentially.

Project (drawing)

To make the generator, you will need a hermetically sealed container, which will be filled with water before starting hydrogen production.

The electrodes located inside will look like a set of plates (16 pieces will be needed), installed with a gap of 1 mm.

To ensure this, nylon spacers must be placed between the plates (any other dielectric is allowed).

A distance of 1 mm is optimal: if you increase it, you will have to increase the current strength; When the gap is reduced, the escape of gas bubbles will be difficult. The plates will be alternately connected to the anode and cathode of a 12-volt power supply. In this case, they must be put on an axis, also made of dielectric material.

Once the electrodes are attached to the holder, it will need to be attached to the housing cover from below.

To select the gas mixture, a tube from a conventional dropper is cut into the housing cover. In addition, it is necessary to drill two more holes through which the wires will be passed. After assembling the installation, all holes in the cover will need to be sealed using silicone sealant or glue.

An important component of the generator is the water seal. To make it, you will need a small container (a regular bottle will do) into which you will need to pour water before using the device. In the hermetically sealed lid, you need to drill two holes: into one we pass the tube from the generator (it must be lowered to the very bottom), and into the second - another tube through which the gas mixture will flow to the burner. The holes in the water seal cover must also be sealed. Water should be poured into the bottle to ¾ of its volume.

In order for the water poured into the generator housing to have better conductivity, you need to add a couple of tablespoons of table salt or caustic soda (sodium hydroxide) to it.

Selection of electrodes

If the second requirement is not met, a chemical reaction will take place with the participation of the electrodes connected to the cathode pole, as a result of which the solution will become saturated with foreign substances.

This is why copper, one of the best conductors, cannot be used in an aqueous solution. It is recommended to use stainless steel instead. The optimal thickness for electrode plates made of this material is 2 mm.

Container

Taking into account the risk of explosion, the generator housing should be made of durable and plastic material that is resistant to high temperatures. Steel best meets these requirements. It is only necessary to completely exclude contact of wires or electrodes with the housing, which will result in a short circuit.

In residential and commercial buildings, polyvinyl chloride pipes are widely used to organize water supply. Using PVC pipes for water supply: advantages, disadvantages, installation features and technical characteristics.

You can find out the characteristics of the Slavaqua septic tank here.

Metal-plastic pipes are distinguished not only by their positive characteristics during operation, they are also easy to install. Here https://aquacomm.ru/vodosnabzenie/zagorodnyie-doma-v/avtonomnoe-vodosnabzhenie/trubyi/plastikovyie/montazh/metalloplastikovyih-trub.html you will find useful information on installing pipes with your own hands.

DIY hydrogen generator for a car (drawings)

Enriching the fuel-air mixture with hydrogen helps reduce fuel consumption. According to some car enthusiasts, fuel savings can be up to 30%.

The basis for an automobile hydrogen generator is the device that was described in the previous section. The difference is the absence of a water seal (the resulting hydrogen is immediately sent to the intake manifold) and the presence of a control unit. The latter will regulate the current between the electrodes depending on the engine speed.

Self-manufacturing of such a unit is only possible for those who are fluent in radio electronics, so we recommend using a purchased option. Moreover, the factory-made units take on all the work of regulating the performance of the hydrogen generator, without requiring user participation.

System elements for a car generator

All that is needed is for the very first time to manually select the current value (optimal) for the “idling” and “maximum load” modes, and then the control unit itself will vary the performance of the installation within the specified limits.

It is necessary to seal all connections very carefully: hydrogen leakage can lead to a fire.

It is best to check the tightness of the structure with soap foam: leaks, if any, will manifest themselves as constantly appearing and growing bubbles.

The body of a car hydrogen generator can be made from a water filter, which is quite durable. Its volume is small and so that the installation does not have to be refilled too often, it can be additionally equipped with a tank for storing a supply of solution. It is connected to the working container by two tubes.

Self-regulating thermal cable is excellent for anti-icing applications. In the next topic, we will consider in more detail the use of a heat cable with automatic thermoregulation and the features of its installation.

Why you need an air valve in a sewer system, read this material.

Video on the topic

AutoNews / Reviews / Tests

How to Make a Hydrogen Engine with Your Own Hands

DIY hydrogen engine

Hydrogen generators for passenger cars - Make your own hydrogen generator

Do you want to make a hydrogen generator for a car? Thousands of people who are developing their own hydrogen generators are installing them in cars to run on water due to the ever-increasing prices of fuel. If you are one of the many people who want to save money, or are trying to find ways to reduce consumption, you have probably already heard discussions about hydrogen for cars and methods for building your own generator.

The first time I heard about hydrogen for cars was several months ago, and although I was very skeptical, I still decided to find out about it and did some research. It turned out that Brown's gas is not only easy to obtain by electrolysis, but also that it has been in the USA for a long time simple installations are sold that help save from 30% to 50% of fuel

So how does a hydrogen generator work?

These hydrogen fuel cells for cars consist of a small container or vessel with water located under the hood, pour ordinary tap water into the vessel, throw in a teaspoon of catalyst, soda and immerse several stainless steel plates. We connect these plates to the battery and when the ignition is turned on, gas begins to be produced. We install a hose with hydrogen in the air duct after the filter.

Once all of this is properly established, hydrogen and oxygen (HHO) can be extracted from water using electrolysis (a process where electrical energy is used to break water molecules into HHO). DIY hydrogen generator. Hydrogen engine how to make an engine. This mixture of hydrogen and oxygen is then drawn into your car's intake manifold, where it is mixed with regular gasoline from the fuel tank and burned in the engine as usual.

In this mixture of gasoline and HHO, combustion occurs more efficiently, which significantly improves engine performance, thereby saving fuel. In some cases up to 50%. It also increases the power of your motor.

It turns out that making your own hydrogen generator for a car is not only quite easy, but also inexpensive. It cost us less than 100. There are a huge number of tutorials on the Internet, if you want to see the details, write a hydrogen generator on YouTube. The supply of hydrogen bound in water is virtually inexhaustible. Breaking atomic bonds allows hydrogen to be created and then used as fuel. Numerous processes have been developed to break down water into its constituent elements.

Short story

Hydrogen internal combustion engines appeared during the same period when the internal combustion engine principle was being developed and improved. The French engineer and inventor designed his own version of the internal combustion engine. The fuel he used in his development was hydrogen, which appeared as a result of the electrolysis of H2O. In 1807, the first hydrogen car appeared.

Isaac De Rivaz filed a patent in 1807 to develop a tractor for military equipment. He proposed using hydrogen as one of the power units.

The power unit was a piston, and ignition in it occurred due to the formation of a spark in the cylinder. True, the inventor’s first creation required manual generation of a spark. Just two years later, he finalized his work, and the first self-propelled hydrogen vehicle was born.

However, at that time, the development was not given importance, because gas is not as easy to obtain and store as gasoline. Hydrogen engines were put into practical use in Leningrad during the siege in the second half of 1941. Although, it is worth recognizing that these were not exclusively hydrogen units. These were ordinary internal combustion engines GAZ, only there was no fuel for them, but at that time there was plenty of gas, since they were fueled by balloons.

In the first half of the 80s, many countries, not only European, but also America, Russia and Japan, began experimenting with this type of installation. So, in 1982, through joint work with the RAF automobile enterprise, a combined engine appeared that ran on a mixture of hydrogen and air, and a 5 kW/h battery was used as an energy source.