Node purpose

The UAZ 469 transfer case is used to engage all-wheel drive. The mechanism is two-stage. This allows you to double the speed range for forward and reverse movement. Reducing torque when driving off-road reduces wheel slip.

UAZ 469 has a constantly engaged rear axle. The front axle is pluggable. Its inclusion is provided by the manufacturer for driving on low-quality surfaces.

IMPORTANT: It is prohibited to use the vehicle with the front axle constantly engaged when driving on high-quality road surfaces. Failure to comply with this rule will result in damage to transfer case components or jamming of rotating parts.

UAZ HELICAL TRANSFER CASE, APPLICABILITY, SHIFTING MECHANISM, FEATURES.

The helical transfer case began to be serially installed on UAZ-3162 Simbir cars. It is 80 percent unified with a spur transfer case, but at the same time contains eleven original parts. The main difference between a helical transfer case and a spur transfer case is the presence of helical gears instead of spur ones to transmit torque to the front axle of the car.

The use of helical gears in the design of the transfer case made it possible to reduce its overall noise level by 8-10 dBA compared to spur gears, but only in the front axle engagement mode. In low gear mode, the noise remained almost the same, since the drive gear for direct and downshift engagement and the reduction gear of the intermediate shaft remained spur-cut.

UAZ 469 transfer case

The transfer case is rigidly mounted on the rear of the gearbox housing. The rear of the transfer case is equipped with a parking brake. It is made in the form of a drum and pads with friction linings.

When the parking brake is applied, the release device presses the shoes against the drum, blocking the rotation of the rear axle driveshaft. After releasing the parking brake lever, the pads move in the opposite direction under the action of power springs. You can also read about UAZ “Cargo”.

The device of the UAZ “Bukhanka” transfer case

The UAZ Bukhanka transfer case is a two-stage design without a differential between the axles. The mechanism is also equipped with a neutral message and switchable front wheels. The components are placed in a tray made of cast iron and equipped with a plug. The pallet is attached to the back of the box through the holes of the plates. In addition, the components of the handbrake are also attached here. The main and transition shafts of the box, the drives of the front and rear wheels, are secured by bearings. Between the supports that facilitate the rotation of the shaft, a gear is placed that drives the speed measuring device. The top of the box has an inspection hatch protected by a shutter.

Dymos transfer case for UAZ (finishing):

The control contains two rods with forks attached to a plug. The fork-shaped rods work in tandem with the drive gear and the activation gear for the front pair of wheels. Two control rods are connected to the forks by means of movable pins. There is also a blocking sphere that prevents the activation of low gear when the front wheels are not working.

By activating direct transmission, the UAZ Bukhanka transfer case acts in a similar way so that the main gear moves into the slot of the gear shaft of the rear pair of wheels, transporting the impulse directly. Activating the low gear shifts the main gear so that the impulse is transported to the intermediate shaft and to the gears that drive the axle. Activation of the low stage is only possible after the machine has come to a complete stop.

UAZ Bukhanka transfer case diagram:

RK Corps

The transfer case housing consists of two parts. To prevent lubricant leakage at the joint, the parts are sealed with gaskets. Oil seals are installed on the shafts coming out of the sealed housing. They prevent lubricant from leaking out when the car is moving.

REFERENCE: Under load, the lubricant and parts of the lubricant heat up. To avoid breaking the seal of the housing, the manufacturer equipped it with a breathing valve. The device provides communication between the device cavity and the atmosphere.

Drive mechanism

The RK mechanism consists of:

Control mechanism

The unit is made in the form of a metal cover. It is bolted to the transfer case housing. Two levers are installed in the cover. One serves to connect the front axle, the second to reduce the torque transmitted from the gearbox.

REFERENCE: The UAZ 469 transfer case diagram shown above is distinguished by its reliability and high service life. With normal maintenance, the unit can be used for a long time, regardless of operating conditions.

Transfer case housing

The transfer case housing for the UAZ 469 car is cast from cast iron. In the plane of the housing there is a connector perpendicular to the axes of the shafts. Two tubular pins determine the relative position of the body halves. The crankcase assembly and cover are processed mechanically. Because of this, they are not individually interchangeable.

There is a hatch on top of the crankcase. It is closed with a lid. If necessary, a power take-off mechanism is installed here. The gearbox is centered on the gearbox along a double-row angular contact bearing through an intermediate cup. Between the two boxes are a suspension plate and sealing gaskets.

Carter RK is assembled from two halves. To prevent the leakage of oil circulating in the cavities of the transfer case during its operation, a sealing gasket is installed between them. In the places where the shafts are installed, which extend outward from the housing, oil seals are placed. They reliably hold lubricants inside the unit while the vehicle is moving.

The operation of the transfer case, gears and shafts is associated with increased loads. When overcoming obstacles, when all mechanisms are involved, metal parts heat up. The oily substance inside the housing evaporates and gases accumulate in the cavities.

In order to avoid depressurization, in order to remove harmful accumulations from the crankcase to the outside, the manufacturer has provided for installing a special breathing valve - a breather - on top of the transfer case housing. This device ensures communication between the internal cavities of the crankcase and the atmosphere.

Transfer case switching diagram for UAZ 469

The transfer mechanism is controlled remotely from inside the car. downshift or front axle engagement is forced. This is done using levers installed next to the manual gearbox control.

The front axle drive is controlled by the right lever (in the direction of travel of the vehicle). To turn on the drive, the driver moves the lever to the extreme forward position. To turn off, the lever moves in the opposite direction. The front axle is controlled when the clutch is disengaged.

The left lever is used to reduce torque transmission. The control has three fixed positions:

ATTENTION: The UAZ 469 transfer case switching diagram, which is shown above, is equipped with a lock against involuntary downshifting. The lock is made in the form of a ball retainer, which does not allow engaging a lower gear without the front axle drive.

Types of UAZ Patriot transfer cases, their purpose and design

Until 2014, the manufacturer equipped the car with a mechanically driven transfer case. The transfer case is controlled by a lever located in the cabin. Since 2014, the manufacturer has been installing a Dymos device on cars. The UAZ Patriot dymos transfer case is electronically controlled.

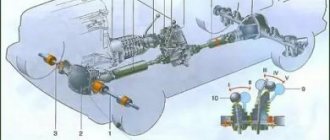

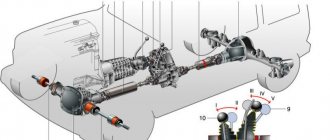

The transfer case is designed to distribute torque between the vehicle's drive axles. The rear axle of the model has permanent drive. The front axle is connected using a transfer case. The transmission of torque from the transfer case to the axles is carried out by cardan shafts.

To improve off-road performance, the transfer case is equipped with a low gear. It reduces the torque transmitted from the gearbox. The transfer case is rigidly fixed to the gearbox housing.

The device is driven by the secondary shaft of the gearbox. A gear block is located inside the mechanically controlled product. They are mounted on shafts. The gears are brought into engagement by two rods. One rod connects the front axle, the second engages a lower gear.

REFERENCE: The gear teeth are located at an angle. This eliminates the beating of gear teeth against each other, reducing the noise level during operation of the unit.

The Dymos product is structurally different. The transmission of torque between the shafts is carried out using a metal chain.

This reduces noise when the vehicle is moving. The device is controlled electronically, in the form of a switch installed in the cabin.

When you turn the handle, the UAZ Patriot transfer case control unit supplies power to the built-in electric motors. They move the rods to the required position. Electric motors are installed on the transfer case housing.

Transfer case service

When operating a vehicle, it is necessary to regularly service the unit. For this:

The oil in the transfer case and gearbox is changed at the same time. Each car owner determines the frequency of replacement independently. The manufacturer recommends changing the oil every 35 - 45 thousand mileage.

REFERENCE: When regularly driving a car off-road, it is necessary to change the transmission oil more often. This is due to high loads and the possibility of water entering the crankcase of the mechanism when fording.

Transfer case on a UAZ car - features and principle of operation

Administrator SpetsTuningUAZ

The cars of the Ulyanovsk Automobile Plant are valued by their owners for their reliability and cross-country ability, the ability to overcome almost any road conditions, and for comfortable and safe off-road driving, motorists should be well aware of the structure and operating features of the transfer case on a UAZ car.

Why do you need a transfer case on SUVs?

The transfer case of a UAZ and any other SUV is needed to provide the vehicle with the ability to effectively drive off-road, rough terrain and on poor country roads and dirt roads.

With the help of the RK, the driver can reduce wheel torque when overcoming particularly difficult sections. Such actions can significantly reduce the level of slippage even in the most difficult conditions, including when stuck in a wetland.

The UAZ transfer case is a functional product, the value of which is clear to almost all car owners. This item:

- increases cross-country ability;

- improves vehicle handling;

- increases maneuverability;

- makes the car universal, capable of performing well on any trip.

Typically, an SUV drives on the rear axle (it is the drive axle), and no torque is transmitted from the engine to the front. However, if the driver has to overcome a difficult section, he can make both axles driven.

The design of the UAZ transfer case is such that it can only be used when driving on difficult roads; you won’t be able to drive on asphalt on two bridges if you don’t want to pay for the repair of the transfer case.

How does the device work?

In principle, the operation of the transfer case is quite simple. In general, it is only needed to connect/disconnect vehicle axles. By means of a center differential, it is possible to change the torque and transmit it to the front and rear axles with uniform or divided force to different wheels.

The operation of the UAZ “Bukhanka” transfer case can be schematically depicted as follows:

- Rotation comes from the gearbox to the drive shaft, which is transmitted through gears to the intermediate shaft. In the transfer case design, one of the intermediate shaft gears is locked with the drive shaft, so the rotational effect is transmitted immediately.

- The intermediate shaft has a movable gear that transmits rotation to the vehicle axle through a control mechanism.

- There is also a center differential, which is necessary to improve transmission and vary torque. It is used to relieve shifting load and smooth rotation transition.

Features of the transfer case on a UAZ

The distribution box for the UAZ “Bukhanka” and other models from the Ulyanovsk plant includes several elements. It consists of:

- drive shaft;

- differential;

- differential locks;

- rear/front axle drives;

- gear and reduction gears;

To control the transfer case, special levers are placed inside the car, allowing you to control the axles without going outside: turn the front axle on or off, turn both on at the same time, etc.

An important design element is the crankcase with a cover, which is fixed to the rear wall of the gearbox. For centering, the device uses a ball bearing of the UAZ transfer case.

The crankcase and cover are connected to each other with pins and small bolts. The handbrake mechanism is located behind the transfer case. The bearings contain: drive, intermediate shafts and shafts necessary for simultaneous drive of both axles.

Which transfer case is better for a UAZ?

Different UAZs (models and years of production) are equipped with different transfer cases. At the same time, motorists often argue which is better: a helical transfer case on an UAZ or a straight-cut, single-lever or double-lever?

The Ulyanovsk plant predominantly uses helical transfer gears, which, due to the larger number of teeth in engagement, are capable of transmitting greater torque. As for the spur tooth, it experiences only radial loads, without axial ones, which in theory should provide it with a longer shelf life.

However, in practice they are both good.

Transfer case maintenance

With constant use of the vehicle, the transfer case of the UAZ “Patriot” and any other model requires careful maintenance.

The standard part care process includes:

- visual inspection for the presence of lubricant leaks in places where rubber seals and gaskets are located;

- checking the fasteners that attach the gearbox to the gearbox and tightening the propeller shaft bolts;

- Changing the oil in the UAZ transfer case.

Car maintenance requires simultaneously changing the oil in the gearbox and transfer case of the UAZ Patriot. The frequency of replacement is determined independently, taking into account the manufacturer’s recommendations. Regardless of which transfer case is installed on the UAZ, the Ulyanovsk Automobile Plant recommends changing the oil every 35-40 thousand kilometers.

When regularly operating a vehicle in off-road conditions, the oil must be changed more often, since the transfer case and the entire transmission of such a vehicle are subject to increased loads.

Without careful maintenance and care, the transfer case may fail, after which the driver will have to replace the UAZ RK with a new one.

Controlling the transfer case on a UAZ car

For convenient and efficient control of the transfer case, the cabin has levers located to the right of the driver:

- Upper. Used to turn the drive axle on and off. It works only in two positions: in the upper position it turns the bridge on, in the lower position it turns it off.

- Lower. Used in design to change gears. Can be set to 1 of 3 different positions: forward, neutral and low.

When operating the transfer case, you need to take into account that the front axle is used only for operating the machine in difficult off-road conditions, if you need to overcome mud, snow or sand. It cannot be used on a good road, otherwise you will soon need to buy a new one and install a UAZ transfer case.

If for some reason the device fails, you can buy an inexpensive RK assembly or spare parts for the UAZ transfer case in our store.

Contact us, we will help you solve any problem with your car.

Source: https://spectuninguaz.ru/news/ustroystvo-razdatki-na-avtomobile-uaz/

Transfer case of UAZ-452 car

Device

The transfer case is designed to transmit torque to the front and rear axles and has two gears: direct with a gear ratio of 1.00 and a reduction gear with a gear ratio of 1.94.

The process of changing the oil in the transfer case of UAZ 469

Before starting work, it is necessary to warm up the transmission. To do this, drive a car for 2 to 4 kilometers. When heated, the viscosity of the oil decreases and it will be easier to drain it from the crankcase.

Changing the oil in the UAZ 469 transfer case is carried out in a certain sequence:

REFERENCE: When carrying out the oil change procedure on a UAZ 469, it is recommended to check the functionality of the breathing valve (breather). Malfunction of the product can lead to depressurization of the crankcase.

After replacement, it is necessary to eliminate oil leaks formed during the work. A rag is used for this.

Transfer case for UAZ

You can already write textbooks about the cross-country ability of the UAZ (Ulyanovsk Automobile Plant) bestsellers. The owners of such cars know very well how this is achieved. For those who are just considering the prospect of purchasing a car of this brand or want to understand the reasons for its vulnerabilities, the first thing to do is to find out about the design of its transfer case.

Maintenance

During operation, check the oil level and replace it within the time limits specified in the lubrication table. Check all fastenings periodically. If a leak is detected, find out the cause and replace the faulty parts (gaskets, cuffs, plugs, etc.).

During vehicle operation, it is possible to lower the oil level in the gearbox to 8 mm relative to the lower edge of the filler hole and simultaneously increase it in the transfer case. In this case, it is not necessary to equalize the oil levels in the gearbox and transfer case, since the total volume of oil ensures the normal operation of both units.

When changing the oil in the transfer case housing or topping it up, it is necessary to simultaneously bring the oil level in the gearbox to the lower edge of the filler hole.

On vehicles of the UAZ-31512 family, lubricate the shift lever axle through a grease nipple. Access to it is from below.

On vehicles of the UAZ-3741 family, when disassembling the control mechanism, lubricate the shafts and lower support, and also adjust the front linkages of the mechanism. The transfer box has no adjustments.

Transfer case maintenance

Like any other vehicle device, for stable operation the UAZ Patriot transfer case requires systematic maintenance, since the SUV is often operated in difficult conditions and its components are subject to increased loads. It is necessary to regularly check the transmission oil level and replace it on time.

The manufacturer's instructions on the frequency of replacing the UAZ Patriot transmission are contained in the user manual supplied with the vehicle. For new cars that have recently left the assembly line, the procedure for the initial change of transmission fluid is prescribed no later than after 5 thousand km. mileage Such a short interval is due to the fact that during the grinding of new parts to each other, which occurs during the running-in of the car, there is a high probability of the appearance of metal particles that can negatively affect the durability of the mechanisms.

Further rotation of the transmission oil is recommended after every 30 thousand km (about 2 years of driving) + checking every 15 thousand. However, you need to understand that the duration of the intervals between changes may depend on the operating conditions of the vehicle and the quality of the product poured into the transmission.

Which oil is better to use?

Using a high quality product, recommended by the manufacturer or equivalent, is essential to ensure proper vehicle performance and long life of its parts. The UAZ Patriot operating manual recommends the use of oils with different performance indicators for certain transmission components. However, in practice, it is not very advisable to purchase three types of liquid at once, especially since it is sold in containers of 1 liter or more. and you will have significant balances.

What experts recommend pouring into all transmission units

| Oil |

For what

The volume of oil required for the UAZ Patriot transfer case, as indicated in the manual, is 0.7 liters, for axles - 2.7 liters (1.4 for the front and 1.3 for the rear) and 2.5 liters for the gearbox. Accordingly, if you decide to use the same transmission for all components, you will need 6 liters of oil.

The oil in the transfer case must be filled to the bottom edge of the filler hole.

The level is checked with a dipstick that should be equipped on the car. It should be taken into account that active use of the car can lead to a decrease in the oil level to 8 mm relative to the specified level. In this case, there is no need to level the oil level, since its total volume will ensure proper operation of all components.

Oil change procedure

Before this, you need to drive about 10 km so that the liquid in the system liquefies when heated and quickly drains. Having driven the car into the pit, we find the drain and filler holes, and install a container under the drain into which the waste will flow. We clean the surface adjacent to the indicated holes from dirt. Then unscrew the filler plug with a wrench to relieve pressure.

Unscrew the drain plug, being careful not to get burned by the hot oil. We wait until the waste has completely drained, after which we tightly tighten the drain plug and fill in fresh oil using a technical syringe until it begins to flow back. Don't forget to tighten the filler cap at the end.

Along with changing the oil in the transfer case of the UAZ Patriot, it is recommended to replace it in the gearbox. After changing the oil, you need to drive the car for several kilometers, then drive it back into a pit or overpass and inspect the transmission for leaks. Having discovered an oil leak, you need to identify the cause and eliminate it by tightening fasteners or replacing faulty oil seals, cuffs and plugs. All key transmission mounts should be checked regularly and tightened if necessary.

UAZ Patriot transfer case parts are designed for operation in aggressive conditions. Therefore, they are characterized by increased strength. However, its proper service life ultimately depends on how carefully the owner follows the maintenance instructions.

Untimely oil changes or ignoring signs of a transfer case malfunction can lead to a decrease in the vehicle's maneuverability, controllability and safety, as well as to serious breakdowns that will entail expensive repairs.

Disassembling the transfer case

Disassemble the transfer case in the following order: 1. Unscrew the nuts and bolts securing the transfer case to the gearbox and disconnect the components. Remove the transmission intermediate shaft thrust ring from its socket. Remove the gaskets from the mating ends. 2. Remove the power take-off hatch cover. 3. Remove the cover of the switching mechanism with rods and levers. 4. Turn out the screws and remove the parking brake drum. 5. Unscrew the rear axle drive shaft flange nut and remove the flange. 6. Unscrew the bolts securing the brake mechanism to the transfer case and remove it. 7. Remove the flange from the front axle drive shaft and the front bearing cover of this shaft with a cuff. 8. Unscrew the bolts connecting the crankcase parts and disconnect the crankcase so that all internal parts remain on the cover. Do not remove the plugs and bearing cup unless absolutely necessary.

Rice. 3.50. Knocking out rods and removing forks

9. Remove the locking plate of the shift rods and knock out the rods (Fig. 3.50) with a copper hammer, while simultaneously removing the shift forks from them. At the same time, keep the balls and springs of the clamps located in the fork sockets from falling out.

Rice. 3.51. Removing the speedometer gear

10. Remove the stopper of the driven gear fitting (Fig. 3.51) of the speedometer and remove the gear together with the fitting.

Rice. 3.52. Removing bearing retaining rings

Rice. 3.53. Pressing out transfer case shafts

11. Remove the bearing caps for the intermediate shaft and the front axle drive shaft. Remove the retaining rings (Fig. 3.52) of the bearings and knock out the shafts (Fig. 3.53).

Rice. 3.54. Removing the bearing from the rear axle drive shaft

12. Remove the bearings (Fig. 3.54) from the shafts with a puller. 13. Press out the rear axle drive shaft. Remove the oil deflector, the speedometer drive gear and remove the bearing with a puller. 14. Remove the rear bearing cover of the rear axle drive shaft and remove the bearing. 15.* Unscrew the nut of the lever axles, press out and remove the levers. 16.* Remove the arm bracket. * On vehicles of the UAZ-3741 family, instead of work according to paragraphs. 15, 16 it is necessary to remove the control shafts

Rice. 3.55. Disassembling the switching mechanism

17. Knock out five plugs from the switching mechanism cover. Knock out the pins (Fig. 3.55) from the levers towards the removed plugs. 18. Remove the front axle engagement rod, the lock ball through the side hole, and the forward and downshift engagement rod.

Rice. 3.56. Removing the inner ring of the intermediate shaft roller bearing

Note Until March 1993, the inner ring of the roller bearing was pressed onto the intermediate shaft of the transfer case (Fig. 3.56), and until July 1994, a shaft fastening nut was installed.

Transfer case repair

Bearings are checked for defects, chips, cracks, track spalling, play and, if necessary, replaced. Oil seals have a rather short nominal service life, a little more than 30 thousand kilometers. But the indicator for replacement is not the mileage, but the leakage of oil protruding in the places where the shafts are located. Accordingly, if a leak is detected, the seal must be changed. Even if the leak is not obvious, but the wear of the working edge of the oil seal is more than 1 mm, or there are chips and microcracks, the oil seal requires replacement.

Gears need to be replaced when they become noticeably worn or crumbled. If you do not promptly replace the UAZ Patriot transfer case gears, the load on the engine will increase or even jam. A particular shaft on which wear of the working surface, threaded connection or splines is detected also requires replacement. The width of the spline cavity on the shaft flange must be at least 4.645 mm, otherwise the flange will need to be replaced. It is also preferable to replace a flange with noticeable damage.

Shift forks should be checked for wear, chips, cracks, bent and replaced if necessary. Dents, cracks and chips on the covers and crankcase are a significant reason for its replacement. However, for minor damage, you can get by by simply cleaning the problem area with a file.

To eliminate excess noise from the UAZ Patriot transfer case, you must first inspect the bearings and seals. Check the suspension bearing and crosspiece (by injection), since a loose cardan can break the transfer case parts over time. Inspect the mounting of the transfer case and engine. If the noise that disappeared after the repair reappears after some time, you need to check the driveshafts. Also, the source of noise in the transfer case when the front axle is disconnected can be a gear operating in idle mode, transmitting rotation to the front axle. Loose nuts should be tightened until they stop, installing missing bushings if necessary.

Upon completion of the repair, it is recommended to replace the oil with fresh one, even if the mileage has not exceeded 30 thousand km.

Dismantling the transfer case

In order to repair the UAZ Patriot transfer case, it is necessary to dismantle and disassemble the device. For dismantling, you will need keys 10, 12 and 17, as well as a flat-blade screwdriver and a syringe screwdriver. Removing the UAZ Patriot transfer case is carried out in the following order.

First you need to install the car on a viewing hole or a lift, thereby ensuring free access to all the necessary parts. Before removing the device, be sure to lower the parking brake lever and set the gearbox and transfer case levers to the neutral position. Next, drain the oil from the transfer case. Disconnect the driveshafts. Before doing this, it makes sense to make notches on the flanges with a chisel, so that the position does not get mixed up during assembly.

Inside the car, you need to remove the right floor panel by unscrewing the screws and sliding it along the direction of the car (1). Remove the decorative cover of the transfer case control lever using a syringe screwdriver (2 – arrows in the photo indicate the cover latches). Unscrew the screws that secure the rubber cover of the lever, and then lift the part along the lever (photo 3 shows the removed cover).

Loosen the terminal bolt at the transfer case shift lever (4) and remove the transfer case shift lever, opening the terminal connection (5) with a screwdriver. From the bottom side of the car, we disconnect the wires from the two sensors (6, 7).

If dismantling the transfer case is done for the purpose of further repairs, it is recommended to unscrew the nuts that secure the shafts, thus facilitating disassembly. Disconnect the handbrake cable (8). We unscrew the 2 bolts that attach the transfer case to the gearbox on the left side. We unscrew the fastening bolt from the top on the right side (10) and a similar one from the bottom. Then remove the transfer case together with the handbrake mechanism (11).

Installing the UAZ Patriot transfer case into place is done in the reverse order. Before doing this, apply sealant to the transfer case area adjacent to the gearbox.

Disassembling the device

Having removed the UAZ Patriot transfer case, we begin to disassemble it. First, unscrew the top cover (1 in diagram a). 2. With the lever set to the neutral position, unscrew the 4 bolts and remove the gear shift device (2 in diagram a). Unscrew 2 screws and remove the handbrake device. Having secured the rear axle shaft (3 on a) from turning, twist the nut (5 on a), after which you can remove the flange and washer. We dismantle the brake mechanism (9 in diagram a), attached to the transfer case with bolts (8 in a).

At the next stage, the front axle activation sensor (3 in diagram b) is unscrewed. Using a special tool, secure the flange in a stationary position (7 on b) to the flange of the front axle axle, and unscrew the nut (9 on b). Next, dismantle the cover (6 on b) with the gasket (10 on b) by unscrewing the three corresponding bolts. Along the perimeter of the unit, you need to remove the bolts (1 to b) and disconnect the crankcase so that the parts located inside continue to be on the cover. It is important to remember that it is not recommended to remove the plugs (2 and 4 on b) unless absolutely necessary.

Assessment of the technical condition of parts

After disassembling, thoroughly rinse all parts of the transfer case in kerosene, blow with compressed air and inspect. Please note the following:

Transfer case housing and its cover. By external inspection, identify cracks, chips, kinks, paying special attention to the mounting ears of the crankcase and cover, the condition of the threads in the holes, the absence of nicks and burrs on the sealing surfaces. Replace the crankcase and cover that have cracks, chips, or breaks. Eliminate minor defects. Keep in mind that the crankcase and transfer case cover are machined together and therefore are not interchangeable between different transfer cases.

Gears . There should be no chips or nicks on the teeth. The side surface of the teeth should not have any signs of chipping or crushing, and there should be no scoring on the end surfaces of the gears. The seating surfaces must not have any damage or wear that could interfere with the alignment of the parts. Replace worn gears.

Dispenser device

Transfer case and gearbox levers

The transfer case on an UAZ consists of the following main elements: drive shaft, differential, differential locking device, rear axle drive, gear transmission, reduction gear and front axle drive. The device is shown in Fig. 1. For the convenience of switching the transfer case, there are special levers inside the car that allow you to turn on or off the rear or front axles, or turn on both axles at the same time.

Through the holes of the support plate, a metal housing with a cover is attached to the rear wall of the gearbox. This crankcase is the main one in the design of the transfer case. Centering is carried out on a bearing, which has a ball structure.

The cover and crankcase are connected with small bolts and secured with two pins to prevent unexpected movement. Behind the transfer case there is a handbrake (parking brake) mechanism. The bearings inside the crankcase contain special shafts, which are drive and intermediate. There are also shafts that drive both axles simultaneously.

The UAZ Hunter transfer case is more advanced, which is due to a smaller module of gear teeth and, accordingly, a reduced gear ratio. But it can be completely replaced with the old model without losing its working properties.

Tuning details

It is possible to replace gears in order to change the torque of low and main gears, and modify the transfer case to eliminate noise. Downshift has self-shutdown properties. Tuning the transfer case can eliminate this problem. In addition, the design itself is not very reliable; sometimes it is necessary to strengthen the attachment to the body. Sometimes the transfer case is redesigned so that it completely disables the front axle.

New and old parts: the differences in the switching mechanism are obvious

The transfer case, like other vehicle mechanisms, requires care and scheduled maintenance in order to prevent malfunctions. Periodically, the oil in the transfer case should be changed and, if necessary, the seals should be inspected and replaced. The transfer case can be customized by the car owner independently to suit his needs and desires.

To prevent the filler plug from becoming stuck tightly over time, it must be periodically cleaned with degreasing agents. The same should be done with the threads on the gearbox. After cleaning, the plug threads are lubricated with a special lubricant to secure the threaded connections. The plug must be tightened tightly, but not overtightened.

It is not recommended to install used seals on the transfer case. Before installation, new parts must be lubricated with the oil with which they will work. The installation site, on the contrary, should be wiped with a degreaser. When installing oil seals, you must carefully monitor the correctness of the process, do everything smoothly and accurately, without distortions.

The transfer case breather on some UAZ vehicles requires minor modifications. It should be placed under the hood of the car so that liquid does not get into it. For these purposes, you can use brake hoses and tubes. To prevent dust from entering the bridge, filters are attached to the ends of all tubes. When a car enters a body of water more than expected, there is a risk of water getting into the bridge, so it is advisable to bend the ends of the tubes downwards.

Causes of device malfunction

Possible breakdowns of the UAZ transfer case:

These breakdowns can be caused by long trips with under- or over-inflated tires, or with incorrect tire pressure distribution. Also, the cause of the malfunction may be a front axle that is connected for a long time. It should be turned on only when necessary, and turned off when unnecessary. A poorly screwed transfer case becomes a source of extraneous noise. Malfunctions of the driveshaft can also affect the operation of the transfer case.

Low quality of components, especially bearings, is another problem with the transfer case. Poor quality bearings usually fail quickly. The use of low-quality oil also leads to rapid wear of all parts of the unit. A similar problem will also arise due to an insufficient amount of lubricant, which is why it is so important to monitor its level, top up and change the oxol on time.

Often, inexperienced craftsmen can perform poor tuning of the transfer case and set incorrect transmission ratios, which can cause problems with the transfer case in the future.

Checking the working condition

Before carrying out the inspection, it is necessary to thoroughly clean all elements with a brush and a special scraper. After removal, rinse the parts under running water and blow off with air. Particular attention should be paid to the bearings; they should be blown lightly, not quickly, to avoid damage.

How does a UAZ transfer case work?

The UAZ “Bukhanka” transfer case is controlled via a lever in the cabin. It is located between the driver and passenger seats and takes 2 or 3 positions. Some models of boxes provide the output of 2 levers (they are called double-lever).

How to turn on the transfer case on the UAZ “Bukhanka” (mechanical):

The new generation UAZ transfer case (two-stage) is controlled a little differently. Unlike the old box, this mechanism does not have a lever (changing the position of which requires considerable effort), but a switch. To ensure that its activation is not accidental, the manufacturer has provided special protection through an established launch algorithm. So, to redistribute the load in a two-stage transfer case, you need to:

If these steps are followed, the load will be transferred to the front axle.