Hydraulic compensators work to eliminate gaps that form in the drive. When air, water or other types of contaminants enter them, a knocking sound occurs in the valves during operation of the power unit. To eliminate this unpleasant effect, it is necessary to wash it. We will tell you how to do this procedure later in this article.

Initially, make sure that it is the hydraulic compensators that are causing the interruptions and unpleasant noises. To do this, start the engine and listen. A noise should appear, which will only intensify with a change in the crankshaft speed.

Remember that if these signs are absent, the cause of the knocking is no longer in the engine.

Preparing for the process of washing hydraulic compensators

How to check and wash hydraulic compensators without turning to the help of qualified automotive service technicians? Especially if your car is quite old and the factory warranty has long expired, otherwise it will be considered an interference in the integral operation of the car’s power unit and then no compensation will be provided. Of course, you will have to tinker. But if you follow the step-by-step instructions and follow the advice, then this will become a completely doable task. So, let's begin?

This rather unpleasant effect can be completely eliminated by washing the hydraulic compensators in compliance with a clear procedure. Firstly, you need to make sure that the hydraulic compensators are the source of these unpleasant noises and frequent interruptions.

You just need to start the engine and listen to it. Immediately after you start the power unit, you can hear an increasing noise that occurs when the crankshaft speed changes.

If these signs are absent, then the cause of the knocking should not be looked for in the engine. If everything is confirmed, then open the hood, secure it and disconnect the air filter and cylinder block cover. In addition to all this, it is also necessary to remove the rocker arm axles, on which the hydraulic compensators that have failed are located. Carefully remove them from the nests in which they are located. Before you start flushing the hydraulic compensator yourself, you need to prepare three containers of the same volume, approximately holding about five liters.

Before carrying out such procedures, the car should be left in the garage for at least a day to allow all the oil to drain as much as possible from the hydraulic compensators.

It is better to carry out work indoors without wind and dust.

And, of course, follow safety precautions! Open the hood and lock it. If the fastening is weak, which is typical for cars that have been in use for a long time, an additional spacer-clamp will be required so that the hood lid does not fall at the most inopportune moment. De-energize the vehicle by disconnecting the ground from the battery.

Then get free access directly to the hydraulic compensators themselves. This is usually achieved in different ways on different brands and models, but you certainly won’t have to disassemble half the car.

The main thing is to remove the air filter and cylinder block cover. On some models, for example, you will need to remove the alternator belt and turn the alternator towards the radiator to gain access to the mounting bolt. also need to dismantle and put aside everything that interferes with access: wires and supply hoses.

Before you start flushing hydraulic compensators, you need to make sure they are working. Otherwise, you will have to wash the non-functioning spare part, and then replace it with a new one. It just turns out to be extra double work. Checking hydraulic compensators is carried out quite simply, using the traditional method. Each hydraulic compensator should be pressed with a certain force. If it slides in easily with minimal effort, then it is most likely broken. This means that there is no need to wash it, but you should simply replace it with a new one. You can wash all the rest with a clear conscience.

The process of washing hydraulic compensators

1)

Remove the rocker shafts.

2)

Remove the hydraulic compensators from their sockets as carefully as possible.

3)

Prepare containers for immersing compensators. They must be deep enough so that the expansion joints are completely immersed in the filler.

4)

What should you use to wash them with? Many do this with regular 92 gasoline, diesel fuel or kerosene. The quality of the washing itself plays an important role here. Fill the prepared containers.

5)

Dip each hydraulic compensator into the first container of gasoline and clean it.

We recommend: What to do if the instrument panel on a VAZ 2109 does not light up

6)

Next, dip into the flushing liquid, but not completely, press the valve ball. Move the plunger until its movement is light enough.

7)

Repeat the entire procedure described above in container number two, finally rinsing the hydraulic compensator in a more transparent washing liquid.

In the last container, fill the washed hydraulic compensator with gasoline or any other flushing liquid, holding the valve ball in the pressed position.

9)

Remove the part and check the plunger.

10)

Carry out this procedure with all hydraulic compensators, thoroughly washing and checking them, but the plungers must remain stationary. Then reassemble everything in reverse order. Tighten and connect power, hoses and wires.

11)

Start the engine and let it idle for a while.

Tools for washing hydraulic compensators

To carry out the process of washing hydraulic compensators, you will need: a desiccant, tweezers, as well as three containers for flushing fuel with a capacity of approximately 5 liters each, a piece of hardened wire with a diameter of 0.5 mm and a length of approximately 10 cm.

At this point, our article on how to check and wash hydraulic compensators with your own hands can be considered complete. What should happen after you have performed this procedure? Firstly, this unpleasant knocking sound must go away when the power unit operates during a cold start. Secondly, washed and properly functioning hydraulic compensators, the valves themselves and the engine will be able to breathe in fresh air, and the car will operate more stably and evenly.

Subscribe to our feeds on social networks such as Facebook, Vkontakte, Instagram, Pinterest, Yandex Zen, Twitter and Telegram: all the most interesting automotive events collected in one place.

Increased engine noise may indicate the presence of serious malfunctions, which can lead to complete inoperability of the unit.

The knocking of hydraulic compensators when cold does not belong to this category, but if this part is not adjusted, the engine will consume more fuel, develop less power and the comfort of driving the car will sharply decrease. The wear of the piston group will also increase due to incorrectly selected gaps in the gas distribution system.

This article will tell you in detail how to eliminate the knocking of hydraulic compensators, as well as how to do this work efficiently and with minimal time and financial costs.

How to detect faulty hydraulic lifters

Checking hydraulic compensators for functionality begins with determining the correct operation of the engine by ear. Hydraulics may not knock on a cold engine, so you can check by ear when the engine is warming up. Next, an experienced mechanic or mechanic determines the malfunction of the hydraulic compensators by pressing them with his fingers. Serviceable hydraulic pushers are not so easy to push through, and faulty ones easily fall through without effort. A failing hydraulic compensator must be replaced.

Main types of faults

We answer the question of how to check hydraulic compensators for functionality. It can be noted that there are four reasons for the occurrence of malfunctions:

- Increasing the size of the gaps in the areas indicated by the arrows in the photo below. Gaps are formed between the plunger and the plunger bushing. The result will be increased oil leakage. The compensator simply will not have time to “select” the thermal gap;

- In rare cases, the check valve does not close tightly. Which, at a minimum, makes it impossible to create sufficient pressure generated between the sleeve and the plunger;

- The bushing should move freely relative to the plunger. In the areas indicated in photo 3, a blockage may appear, and then the plunger pair jams;

- Clogged engine oil passages are another reason why compensators stop working.

Points 1-3 are illustrated in the photo:

The first failure always occurs as a result of abrasive wear. If you use low-quality oil, you will get the appropriate result. The second malfunction is the result of wear or clogging. The latter, by the way, is more common. Well, jamming can occur due to gradual coking or due to the appearance of deposits.

Testing process from start to finish

Let's consider the answer to the question of how to check the serviceability of hydraulic compensators in practice. You need to open the hood, start the engine and listen:

- Let's say that immediately after starting the engine increased noise appears, and after 5-6 seconds it disappears. Conclusion: the compensators are working properly, oil just leaked out of their cavity;

- At idle there is an intermittent noise. As the speed increases, the noise disappears completely. Conclusion: there is a malfunction, but it is due to the second or third reason (see above);

- When a warm engine is idling, a continuous noise may occur. As the rotation speed increases, the noise goes away. Conclusion: the cause of the malfunction that occurs is indicated under number 1;

- Similar symptoms were mentioned above. But the engine may behave differently: noise appears at high speeds and disappears at low speeds. This means that the cause of the malfunction is oil foaming;

- Let's say there is a characteristic noise from one or more valves. The effect does not depend on the rotation speed. Be aware that this malfunction can be caused by any of the reasons listed in “Chapter 2”;

- Sometimes you can hear noise in idle mode, which increases with increasing frequency up to 1500-2000 rpm, but no more. This effect is not related to the operation of hydraulic compensators.

Now we just have to figure out what causes the oil to foam. In fact, both a lack and an excess of engine oil leads to the effect. Advice: you need to add consumable fluid to the MIN mark or get rid of its excess.

From all that has been said, a simple conclusion is drawn: you should park your car on a slope only when necessary. All experienced car owners know about this.

Hydraulic compensators knock when hot

If hydraulic compensators knock only when the engine is hot, this may be caused by the following reasons:

- Dirty oil (due to infrequent changes or low-quality oil purchased). The solution is to check the oil, if it is dirty, then drain it, rinse it and fill it with new one.

- The valves are clogged. This problem is solved by washing and filling with good motor oil.

- The oil filter does not cope with its functions. A clogged oil filter does not create the required operating pressure in the oil system, which is why the oil does not reach the hydraulic compensators and an air lock is created. If the engine oil is clean, then simply replace the oil filter.

- The oil level on the dipstick is higher or lower than the specified norm. The solution is to drain or add oil.

- The oil pump is not working properly. The pump may be set to operate at less than full capacity. The solution is to investigate and adjust the pump's operation.

- The hydraulic compensator socket is enlarged when the engine is cooled down, and when the engine is warm it increases even more. The solution is to contact the service to create the required size for the compensator fit.

- There can be reasons for both the hydraulic part and the mechanical part. Without the appropriate skills, you may not be able to repair them yourself. The solution is to contact the service or invite a knowledgeable person.

System health check

How to check automatic transmission solenoids for functionality?

After all the parts are already installed, clean the valve cover from dirt, dust and oil leaks. Using a small brush, remove the remaining sealant and old gasket from both surfaces of the base; this can also be done with the back of a penknife. We apply sealant to the perimeter of the supporting cover and install the purchased gasket, making sure that it does not extend beyond the edges of the upholstery. We apply exactly the same layer on the opposite surface and fix it with light pressure. If you still have questions about repairs, you can watch a video on replacing hydraulic compensators in two parts.

Video: How to change hydraulic compensators on a Chevrolet Niva with your own hands

Now, when driving, the knocking in the car should completely stop, but if this does not happen and you hear an annoying sound, then you should contact the nearest car service center for a full diagnosis and subsequent repairs.

Hydraulic compensators knock when cold

Below is a list of reasons typical for hydraulic compensators knocking on a cold engine:

- The hydraulic compensator itself has become unusable. To eliminate this cause with your own hands, you should dismantle them, wash them and disassemble them. Check for mechanical damage. Dirt may have gotten into the plunger system. The solution is to replace or repair if acceptable.

- The engine oil has become dirty and has coked solids. The solution is to flush the oil system and add new oil.

- The hydraulic valve does not work, so when the engine is just turned off, the oil flows down and an air lock is created instead of oil. Further, if you start the car, knocking noises will be heard at first, but as the engine warms up, the characteristic knocking noises will stop. The solution is to bleed the hydraulic compensator and replace the valve.

- The intake hole is clogged, which prevents the necessary oil circulation. The solution is to clean the hole.

- The engine oil is filled with oil, which becomes too thick at sub-zero temperatures. The solution is to fill in high-quality oil that retains its properties at different temperatures.

- The oil filter is clogged. The solution is if the engine oil itself in the engine is clean and transparent, then simply replace the filter.

How to check hydraulic valve compensators for functionality with your own hands

Good day to all! Repairing a car yourself is a pleasure for many people. There are a number of car owners who like to tinker with their own car. And they are unlikely to have problems with how to check hydraulic compensators.

If you don’t know what it is, where these expansion joints are located and why they are needed at all, I don’t advise you to do the repairs yourself. Too many risks.

Although in reality, testing for functionality does not involve any complex procedures. You can check it yourself, but repairs should be entrusted to specialists.

I suggest you discuss this topic with me. I will tell you what I managed to find out, and if you wish, you can add, comment or correct me if you suddenly find an error somewhere. No one is safe from them.

Typical faults

Before examining the removed hydraulic compensator, you need to identify the non-functioning element. Compensators are located on the valves, so their number is equal to the number of valves provided on the engine.

The check can be done without removing the camshaft. But first you need to understand why even new elements fail. There are 4 main faults.

- The gap provided between the plunger itself and its bushing increases. As a result, oil will begin to leak. The compensator will not be able, so to speak, to select thermal gaps;

- The valve does not close properly. This happens rarely, but it should not be ruled out. Because of this, the required pressure cannot be created between the plunger and the bushing;

- Jamming of the plunger pair. The way the sleeve works is that it should move freely relative to the installed plunger. If this freedom is not there, hello jamming;

- Blockages. Oil channels become dirty. Therefore, hydraulic compensators (HC) cannot work.

There is a fairly extensive list of video and photo guides that you can use to check.

It is important for the motorist to tell which of the existing main engines is knocking in order to repair it, replace it and restore normal engine operation.

It is worth noting that some cars do not have hydraulic compensators. So a slightly different technology is provided.

Most often, motorists ask such questions as owners of the following cars:

- Gazelle;

- Chevrolet Lanos;

- Volkswagen Polo;

- Lada Priora 16 valves;

- Daewoo Nexia 8 valves;

- Chevrolet Niva;

- VAZ 2110;

- Lada Kalina;

- Nissan Almera, etc.

It doesn't matter what kind of car or engine you have. You may have a ZMZ 406 motor at your disposal, or the malfunction has occurred on a VAZ 2112. Despite the slight difference in designs, the main engines are checked and repaired in approximately the same way. There are no significant differences.

When starting work, first make sure that you know where the compensators are located and what to do if a faulty element is identified.

Verification methods

Now the motorist is faced with the task of finding out whether the expansion joints on his car are working or not. What is the best thing to do in such a situation?

There are two verification options.

- The first option involves removing the valve cover. The method is more visual and allows you to almost certainly guarantee the correct diagnosis. But implementation is more difficult due to dismantling work;

- The second option does not require the elements to be dismantled. But here you need good hearing. To improve it, it is better to use a phonendoscope. By listening to the operation of the main engine in different modes, you can find the source of the problems.

Which option should I choose? It's up to you to decide.

Both verification methods have their strengths and weaknesses. For a beginner in such matters, I would recommend starting by listening to the hydraulic compensators. If wiretapping does not yield anything, then open the valve cover and more clearly examine the condition of the elements.

Wiretap check

The preparation for the procedure is extremely simple. You need to place the car on a flat surface, open the hood, start the engine and listen.

Even perfect hearing does not always allow one to clearly recognize a non-working compensator. It is better to take an auxiliary medical instrument to help. It's not difficult to find.

And here we will consider several situations. Depending on the result of the check, we will draw appropriate conclusions.

- After starting the engine, the noise appeared at first, but disappeared after a few seconds. Everything is fine with compensators. Lubricant just temporarily leaked out of the cavities of the main body. The engine turned over and filled them;

- The speed is idle, and the noise from the compensators is intermittent. As soon as you raise the speed, the noise goes away. There is a problem. It lies in the bushing or blockages;

- The engine is warm, the speed is idling, the noise is continuous. By increasing the speed, the noise disappears. This means that the gap has increased;

- The symptoms are similar to the previous point, only at low speeds there is no noise, but at high speeds there is. Here you are faced with foaming of the oil;

- One or several knocking noises occur at once, regardless of engine speed. Any of the above malfunctions are possible here.

By applying the wiretapping tool one by one to the area where each of the compensators is located, you can understand where exactly the problem is.

If the noise of one HA differs from the others, you have found the source of trouble. All that remains is to figure out the reasons and eliminate the malfunctions.

Disassembly check

To check these elements for their functionality, you can remove the valve cover. Next, you will have to rely on your own feelings when checking elasticity.

You will have to turn the crankshaft using the center nut to do this. This will set the shaft in motion.

When the pusher cam is directed in the direction opposite to the main body, check the elements one by one for their elasticity, whether there is free play.

You can use your hands or available tools. When the compensator is loose and moves too softly, it is faulty. Needs renovation.

A little about the reasons

Let's start with the knocking sounds of compensators that occur when operating incorrectly. Then the necessary pressure does not form in the system. There are several reasons for this:

- the plunger pair is worn out;

- the compensator is jammed, and this happened due to oil deposits;

- the element is contaminated with scale or scale;

- the contamination came from flakes of burnt lubricant;

- there are foreign objects in the compensator or oil channel;

- There was a foreign body under the ball valve.

It is also impossible to ignore the difference in the causes of knocking on a cold and hot engine.

If you hear knocking noises when the engine is cold, but there are no knocks when the power unit is warm, there are reasons for this.

Hydraulic compensators are knocking, is it possible to drive?

When there are knocking noises from the hydraulic lifters, you can drive, but this can lead to more expensive repairs than finding and eliminating the cause of the knocking.

Operating a vehicle with knocking hydraulic compensators will be accompanied by the following consequences:

- Reducing engine power.

- Uncomfortable driving in general. (Driving when something is knocking in the structure of the vehicle is not entirely pleasant for those who take care of their car).

- Increased level of environmental pollution.

- Excessive fuel consumption.

- Increased vibration.

Many people say that you can drive with tapping hydraulic compensators, but you need to understand that these parts are part of the engine design. And engine overhauls are much more expensive in both time and finances.

Manufacturers of hydraulic compensators

Using original spare parts for a specific make and model of a car is, of course, better. But this is not always possible due to the availability of auto parts in stores or due to the high price.

There are such manufacturers of HA:

- INA hydraulic compensators;

- FEBI Group of Companies;

- SWAG brand group;

- AE hydraulic compensators;

- AJUSA hydraulic compensators.

INA Group of Companies is produced in the German city of Schierheid. The word “German” already says a lot, because we are accustomed to the fact that products made in Germany are of much higher quality.

FEBI GCs were also initially manufactured in Germany. Now they are manufactured in Germany and in other countries thanks to the licenses they purchased.

SWAG hydraulic compensators are also German. But a percentage of such products are revealed to be of low quality, possibly defective.

GCs from the European company AE are also common due to their quality and inexpensive price.

AJUSA hydraulic compensators from Spain. According to reviews from car enthusiasts, Spanish hydraulic compensators are cheaper, but they are not of high quality (they start knocking faster).

The video shows the process of checking compensators with your own hands.

0

Author of the publication

offline 1 week

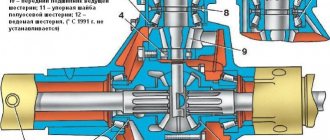

Design and principle of operation of hydraulic compensators

The device of a standard hydraulic compensator is represented by a housing with a movable plunger pair inside, which includes a spring-loaded plunger with a ball valve and a bushing. The housing can be a part of the cylinder head, a cylindrical pusher, or elements of valve drive levers.

The operation of the hydraulic compensator largely depends on the plunger pair. Thanks to a gap of 5 - 8 microns between the plunger and the bushing, on one side the connection is completely sealed, and on the other side the parts move freely relative to each other.

A check ball valve closes the hole in the bottom of the plunger, and a spring of the required stiffness is installed between the plunger and the bushing.

The operating principle of hydraulic valve compensators is discussed in more detail below:

- The thermal gap remains between the camshaft and the housing at the moment when the camshaft cam is positioned with its back side towards the pusher.

- Through the oil channel, oil enters the plunger from the lubrication system, and at the same time a spring acts on the plunger and lifts it, compensating for the gap. Oil also enters the cavity under the plunger.

- As the shaft turns, pressure is exerted on the follower from the cam side, causing it to move downward.

- The check ball valve closes, and the plunger pair takes on the role of a rigid element, transmitting force to the valve.

- A little oil is squeezed out from under the plunger because there is a gap between it and the bushing, but since the oil comes from the lubrication system, the leakage is compensated.

- The length of the hydraulic compensator changes slightly because the parts heat up when the engine is running, but the gap is automatically compensated by changing the volume of the oil portion.

This is interesting: Shelters for L200 and UAZ 3303 pickups