The modern automotive world has gone several steps forward. And this is not surprising, because this is the only way to stay afloat and make a good profit. This is especially true for power plants that are installed on cars. You've probably heard the phrase “injection engine”. In fact, this is a well-known carburetor, only slightly modified.

The process of fuel combustion and power release also occurs in it. The only difference in the injector is the new injection system for supplying the air-fuel mixture.

Story

Many people know that the first system for forming a fuel-air mixture was called a carburetor.

It allows fuel to be supplied directly to each cylinder of the car and set it in motion. As for the location, initially the carburetor was installed in front of the intake manifold and prepared a high-quality mixture.

Over time, the needs of modern drivers and designers have increased several times. Because of this, the system could not produce the desired result that everyone wanted to see. This is especially true for shipbuilding and aircraft construction. The fact is that these industries require enormous power and high efficiency.

As a result of this, the designers came up with an entirely new system that looked a little like a diesel engine, but had standard spark plugs. All this happened in the early 40s, it was at this time that the first injection engines were designed.

This leap made it possible to obtain the desired result in terms of power, but was slightly less suitable for environmental safety. As a result, development had to be stopped for a while until the early 70s. It was at this time that American designers decided to revive the supply of fuel directly to the engine cylinders and make a more advanced system.

The injector and its history of formation

What is an injector? An injector is needed in a gasoline internal combustion engine to form a fuel-air mixture and supply it directly to the combustion chambers or to the intake manifold.

This process is controlled electronically, which makes it possible to maintain a strict dosage of fuel, calculated depending on the operating mode of the engine and the load on it, which, unfortunately, carburetors cannot do.

It was this nuance that became decisive in the fate of the latter and sent them to the bench forever.

In order for you to get a complete picture of what an injector is, you need a short excursion into the history of gasoline units.

It all started a long time ago, in 1951. Specialists from the well-known Bosch concern equipped a small coupe of the forgotten Goliath brand with this innovative injection system by the standards of that time.

The idea was immediately picked up by Mercedes, but the electronics that were necessary for the operation of the injector were as exotic in those years as space flight, so such systems did not receive mass distribution, and the Bosh team shelved their invention until better ones times

And such times came 20 years later, when electronics became more accessible and cheaper. Since the 70s, the injector began its victorious march through the automobile industry, completely displacing the old, wasteful carburetors from under the hoods of cars.

Device

In modern injection engines, fuel is not supplied by gravity, but using a small system called an injector.

Its work is based on reading various sensors that are located in the engine. Thanks to this, the air-fuel mixture is dosed in small portions and supplied exactly at the moment when it is needed.

As for the control itself, everything rests on a simple control unit, the so-called computer. It is he who issues small commands to each injector.

The injection system has the following components:

- Fuel burner;

- Fuel rail;

- Pump;

- The control unit itself;

- And a small sensor system.

More details about each component:

- The fuel injector is the main component, which is called the injector. It allows fuel to be supplied in a timely manner and sprayed directly into each cylinder. The nozzle is based on a simple body and an electromagnetic valve, which carries out the process of opening and closing the nozzle. As for the spraying itself, it occurs through a special hole controlled by a valve.

- A fuel rail can be found in any modern injection engine. Its main purpose is to supply fuel to all injectors. To put it simply, it connects all the nozzles into a single whole.

- As for the fuel pump, it simply supplies the air-fuel mixture under pressure comparable to a pressure of several atmospheres. Without it, fuel would simply be supplied by gravity, as in a carburetor engine.

- The brain of the system is the control unit, which gives commands to all injectors. Essentially, it is a small microcontroller connected to a large number of sensors, injectors, fuel pump, ignition system, idle air control and other systems. Its main task is to collect all information on the condition of the engine and fuel distribution.

- Sensors are responsible for measuring the main parameters of the power plant in real time. These are mainly air flow, crankshaft location, the formation of detonation in the cylinders, temperature, vehicle speed, and more. You can also find sensors that determine whether the air conditioner is on, whether the road is smooth, and how the camshaft is positioned.

The secret - what is the injector, revealed

It is quite logical that you have the following question: how does the injector work and how is it designed?

First of all, I would like to clarify that an injector is understood as a unit that injects fuel into the combustion chamber or intake manifold.

This is partly true, but it is much more correct to call it a nozzle, and extend the concept of an injector to the entire system. And it consists of the following main parts:

- electronic control unit;

- gasoline pump;

- all kinds of sensors;

- injector nozzles;

- pressure regulators.

The key element, one might even say the brain of the entire system, is, of course, the control unit, stuffed with smart electronics.

The answer to the question – how the injector works – depends on it. Based on data received from a scattering of sensors (air flow sensor, throttle position, crankshaft speed, lambda probe, etc.) it calculates how much fuel the engine needs at a particular moment in time.

Having determined the value, it sends commands to the fuel pump, pressure regulators in the fuel system and, of course, to the injectors. This happens in a matter of seconds and at precisely controlled moments.

Principle of operation

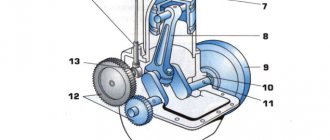

- In the power unit, the fuel mixture is prepared outside the combustion chamber using a special device. As a result of the downward movement of the piston, a certain amount of fuel is sucked into the combustion chamber.

- Next comes the main process, the so-called working stroke. At this time, the fuel is compressed and ignited using a spark.

- As a result, all the fuel burns and a huge amount of heat is released, which is used to power the injection engine.

- At the end of the stroke, the piston moves up and the exhaust valve opens, which removes the exhaust gases. Next, the intake valve opens slightly and a new portion of fuel enters the cylinder.

This process occurs over a long period of time while the engine is running. Experts call this gas exchange four-stroke. That is, all this happens in four clock cycles:

- Inlet;

- Compression;

- Combustion;

- Release.

To complete one such cycle, two revolutions of the crankshaft are required. To keep power losses to a minimum, designers came up with multi-cylinder systems. They allow you to produce huge amounts of heat and power.

In the modern world, the four-stroke injection engine has become very popular, which is not surprising. The fact is that it differs not only in technical characteristics, but also in the dimensions themselves. The basis of this system is the order of operation of the cylinders.

Operating modes

Now you can find eight operating modes of the power unit:

- During a cold start, the fuel mixture becomes very lean. This happens because the fuel mixes very poorly with air. As a result, the evaporation that is needed does not occur. This way of operating the engine is very harmful to the parts. That is, a large amount of fuel settles on the walls of the cylinder and exhaust pipes;

- If you start the car at low temperatures, then at the initial stage a very rich mixture is required. To do this, you need to supply more fuel until the temperature in the combustion chamber rises to the desired value;

- After start-up, the injection engine warms up. You know that when starting in cold weather the mixture is very lean and a kind of fuel film forms in the exhaust pipe. It disappears only after reaching a very high temperature. In this regard, the fuel mixture must be very rich;

- At partial load, it is necessary to maintain a certain composition of the air-fuel mixture. If the injection engine is not equipped with a neutralizer, then the enrichment should be in the range of 1.05 - 1.2;

- At full load the throttle valve is fully open. A large amount of air comes in, which is very good. In this mode, maximum power and torque are achieved;

- During acceleration, the valve opens and closes. As a result, the mixture becomes lean for a short time and the fuel supply is limited. To prevent this phenomenon, the enrichment should be less than 1;

- In idle mode, the car slows down and the car moves by inertia. In this case, the fuel supply is completely shut off;

- If there is an increase in altitude, the density of the air decreases. It follows from this that driving in the mountains is very difficult; the fuel mixture will be very rich. This can lead to difficult starting of the power unit and increased fuel consumption.

Advantages and disadvantages

The injector has gained immense popularity in the modern world. This is due to the following advantages:

- The operating mode changes automatically, without the use of the human factor;

- There is absolutely no need for manual configuration;

- The engine is very economical;

- Fully complies with all environmental standards;

- Very easy to start in any weather, no loss of power.

Of course, there are no shortcomings. They are also worth talking about:

- Quite high cost and maintenance;

- Many parts are beyond repair. That is, they will have to be completely thrown out and replaced with new ones;

- It is almost impossible to carry out repairs and maintenance at home. This requires special equipment and experience;

- The motor is very dependent on the mains voltage.

Types of injection system

Now you can find three types:

- Single point injection;

- Multipoint injection;

- Direct injection.

The first is the simplest and very common. It is not very packed with electronics, which leads to less effect. The big disadvantage of this system is that some of the fuel is lost during injection. That is, the fuel mixture is supplied through the nozzle to the intake manifold, where it is distributed among the cylinders.

Next comes multi-point injection, which allows fuel to be supplied individually to each cylinder. Thanks to this, you will not have the question: whether it is necessary to warm up the injection engine. As for the distribution itself, it is more powerful and more economical. According to numerous tests, it can be seen that power increases by 7 percent. The main advantages include automatic fuel supply adjustment and injection close to the valve.

Direct injection is used in many modern cars. Its peculiarity is that fuel is supplied directly to each cylinder. Not a single drop of the mixture will be wasted. If you have a question about whether you need to warm up the engine, the answer is very simple. It depends on the manufacturer himself and his recommendations. Some recommend warming up the power unit not for very long, so as not to harm all the parts. Everyone must answer the question of whether they need to warm up the engine by studying the recommendations for their car.

VAZ 2107 car engine

The engine is the heart of any car.

It’s not for nothing that the word “car” means “self-propelled” when translated from Latin. It is the power unit that distinguishes any bicycle from a car. The engines of the VAZ classic family, to which the VAZ 2107 belongs, were for their time advanced in their class - quite quiet, economical, and unpretentious. The weight of the power unit and the weight of the car are 10% and 90%, which is not bad for the development of traction. Let's talk more about the engine. All engines of the classic family, including the VAZ 2107, are gasoline, four-stroke. All units have four cylinders, four pistons, which are arranged in a row, and a carburetor is installed. The unit is eight-valve, two valves for each cylinder. The camshaft (or timing mechanism, gas distribution) is located on top. At the top is the supply of the mixture of fuel and air, which is supplied by the carburetor.

Initially, the VAZ 2107 was equipped with a carburetor, a “six” engine, like the VAZ 2106, its volume was 1.6 liters. In the future, we will keep in mind this particular carburetor engine.

You can also install the 21067 engine, its volume is 1.6 liters. The mass of these two types of engines is almost the same

In addition to this standard, the old VAZ 2107 models were equipped with power units 2103 and 2104, with a different cylinder size, which was not 79 mm, but 76. Accordingly, the engine power was slightly less.

In all power units, the cylinder operating order is 1-3-4-2.

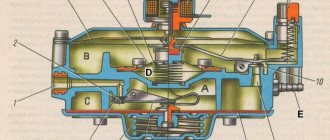

Power unit, section in the frontal plane

The power of the units installed on the VAZ 2107, and most of all in the VAZ 2106, is 54.8 kW, or 74.5 hp. There is a direct relationship: the larger the cylinder volume, the higher the engine power. A carburetor adds more reliability to the engine, compared to an injection engine, in case of engine failure, the ability to give it a “light”, etc.

The assembled engine weighs about 120 kg, so it is not recommended to try to remove the power unit without having an electric hoist or overhead crane at hand.

The engine structure is as follows:

In this diagram, without going into detail, you can see special channels and cavities in cast parts, the so-called lubrication passages and cavities for the circulation of coolant in the cylinder block.

It should be noted that the power of the unit cannot be maximum or close to it for a long time, without an adequate cooling and lubrication system.

In conclusion, it is worth noting that if you choose whether to choose a carburetor or an injector, then we can say that the first option is simpler and more reliable to repair, but the second is more modern and economical.

Source