Oil for KAMAZ axle. What and how many liters to fill.

Oil in the KamAZ axle is one of the most important conditions for long-term operation. For the correct and durable operation of the mechanisms, the volume of oil in the KamAZ axle must correspond to the established level.

The brand of oil used, as well as its timely replacement, is also decisive. How much oil to pour into the KAMAZ axle

How many liters of oil are poured into KamAZ axles? Design features establish different volumes of lubrication in the main gear housings. All-terrain vehicles produced by the Kama Automobile Plant are equipped with a front drive axle, which also requires lubrication. Its cavity holds 5.3 liters of oil. In addition, the steering knuckle assemblies need lubrication.

The presence of a center differential mechanism determines how much oil to pour into the middle KamAZ axle. Seven liters of lubricant must be placed in the gearbox. The center differential attached to it also needs an additional 750 grams of oil.

The plant has about 80 types of bridges, they all have a similar structure, but there are exceptions. Therefore, in any case, be guided by the level of the control holes.

In the middle part of the crankcase there is a control hole, which is used to determine how much oil to pour into the KamAZ rear axle. The control hole plug is unscrewed and oil is added to the filler hole until it appears in the control hole. The check should be carried out on a horizontal platform, you need to make sure that the wheels are at the same level: otherwise it is impossible to correctly determine the required level.

Do you need a KAMAZ bridge?

Which oil should you choose?

Drivers are not always responsible about what kind of oil should be poured into the KamAZ axle. However, the wrong choice of lubricant will lead to premature wear of moving parts and failure of the machine’s chassis components.

The most preferred oil for KamAZ axles is 75W-90 or 80W-90. You can also successfully fill domestic oil into the rear axle of a KamAZ TAD-17i brand. It provides good lubricating properties, but is unstable to low temperatures and tends to thicken in severe frosts, making it difficult for mechanisms to operate. However, most drivers use it due to its low cost.

It is better to use KamAZ axle oil from well-known foreign brands. Synthetic motor oils 75W-90 Shell Spirax S6 AXME and Castrol Syntrax Long Life have a long service life and perfectly protect the rubbing surfaces of gears, bearings and shafts. They also work excellently in temperatures of -40 degrees without losing their fluidity. The maximum ambient temperature for their use is 35 degrees.

Gearbox oil of the KamAZ middle axle 80W-90 is also used. They are used in temperate climates, since its operating temperature range is from + 35 to -25 degrees Celsius. One of the best in this category is Mobilube HD. It perfectly lubricates components subjected to heavy loads. For adherents of semi-synthetic oils, Esso Gear Oil GX, also 80W-90, is suitable.

In climate zones where high temperatures prevail, the best choice is 85W-90 oil. It retains its thickness in 45-degree heat. The minimum thermometer reading for this category is -12° C.

Change of oil

The first check of the oil level is carried out after 1000 km. mileage, the second - after another 4000 kilometers. Subsequent monitoring and topping up must be carried out every 8,000 kilometers, and after 50,000 km. A complete oil change must be performed in KamAZ axles. To do this, the gearbox is warmed up, allowing the car to run. Then unscrew the plugs of all three holes: filler, control and drain. After all the used lubricant has flowed out, the gearbox cavity is washed and the bottom plug is tightened. Then oil is poured into the KamAZ front axle through the upper hole until it appears in the control hole. Then the remaining plugs are tightened.

dvigatelkama.ru

Chemmotological map

The chemotological card applies to cars:

- KAMAZ-43501, -43502 (4x4 type);

- KAMAZ-5350, -53504, -43118 (6x6 type).

Engine lubrication system: ● KAMAZ 740.622-280 ● KAMAZ 740.652-260 ● KAMAZ 740.662-300 with oil sump: – 740.30-1009010 – 740.30-1009010 — 10

Engine lubrication system: ● Cummins ISB6.7 250 ● Cummins ISB6.7 275 ● Cummins ISB6.7 300 ● Cummins ISB6.7E5 250 ● Cummins ISB6.7E5 285 ● Cummins ISB6.7 E5 300

Engine lubrication system: ● Cummins ISB6.7E6 310 ● Cummins ISB6.7E6 250

Gearbox housing (Gearbox): ● KP-144 ● KP-154

Front axle housing: ● KAMAZ type 4x4 ● KAMAZ type 6x6

Middle axle housing: ● KAMAZ type 6x4 ● KAMAZ type 6x6

Rear axle housing: ● KAMAZ type 4x4 ● KAMAZ type 6x6

Change the oil Check the level Change the oil (at least once a year)

Transfer case: ● with power take-off (PTO) from the top hatch ● with side-mounted PTO, without PTO

Joints of cardan shafts of KAMAZ type 4x4: ● main ● front axle ● rear axle

KAMAZ cardan shaft joints type 6x6: ● main ● front axle ● middle axle ● rear axle

Pins: ● front springs ● rear springs (KAMAZ type 4x4)

Wheel hub bearings KAMAZ type 4x4: ● front axle ● rear axle

KAMAZ wheel hub bearings type 6x6: ● front axle ● middle axle ● rear axle

Adjusting levers of brake mechanisms: ● KAMAZ type 4x4 ● KAMAZ type 6x6

Expansion cam shaft bushings (front and rear bracket): ● KAMAZ type 4x4 ● KAMAZ type 6x6

Engine cooling system: ● Cummins ISB6.7 250 ● Cummins ISB6.7 275 ● Cummins ISB6.7 300 ● Cummins ISB6.7E5 250 ● Cummins ISB6.7 E5 285 ● Cummins ISB6.7 E5 300 with preheater 14TC , 15.8106

Engine cooling system: ● Cummins ISB6.7E6 310 ● Cummins ISB6.7E6 250

1) The oil level according to the standard indicator should be: top – at the top mark “B”; lower – not lower than 10 mm from mark “B”. 2) Volume of the entire oil system. The oil level should be between the “L” (lower level) and “H” (upper level) marks on the standard gauge. Mark “L” - 15.0 l; mark “H” - 17.5 l. 3) Volume of the entire oil system. The oil level should be between the marks “L” (lower level) and “H” (upper level) 4) For KAMAZ vehicles of Euro-5, 6 level during NTO (once every 3 months). 5) For KAMAZ vehicles of Euro-5, 6 level with 2 maintenance. 6) For KAMAZ vehicles of Euro-5, 6 level during maintenance. 7) For KAMAZ vehicles of Euro-5, 6 level with NTO. The tank volume is indicated. Fill the tank with neutralizing liquid no more than 90%.

lower – not lower than 10 mm from mark “B”. 2) Volume of the entire oil system. The oil level should be between the “L” (lower level) and “H” (upper level) marks on the standard gauge. Mark “L” - 15.0 l; mark “H” - 17.5 l. 3) Volume of the entire oil system. The oil level should be between the marks “L” (lower level) and “H” (upper level) 4) For KAMAZ vehicles of Euro-5, 6 level during NTO (once every 3 months). 5) For KAMAZ vehicles of Euro-5, 6 level with 2 maintenance. 6) For KAMAZ vehicles of Euro-5, 6 level during maintenance. 7) For KAMAZ vehicles of Euro-5, 6 level with NTO. The tank volume is indicated. Fill the tank with neutralizing liquid no more than 90%.

Which oil is suitable for the KAMAZ engine

Amount of oil to replace in the engine

The durability and reliability of the power unit of cars from the Kama Automobile Plant depends precisely on what kind of oil is poured into KAMAZ engines. They are known for their reliability, durability, unpretentiousness and extended service life. And the lubrication system of automobile engines played a significant role in this. Depending on the brand of the unit and its design, different lubricants are used.

Today there are a large number of different brands and types of oils on the market. And here the main thing is to make the right choice, because the main indicators of the engine’s performance will depend on this. Oil for the KAMAZ engine is selected in strict accordance with the engine specifications. And every owner of a truck of this brand must decide what oil to fill into the Kamaz engine, based on the manufacturer’s recommendations. Oil for KAMAZ engines should be used in group CD according to API classification or group D in accordance with GOST 17479.1. KAMAZ engine oils are most often used in accordance with international classifications from SAE 15W-40, for all seasons of use, to SAE 5W-40 or 5W-30, for areas with cold climates and severe operating conditions. KAMAZ engine oil for seasonal work or for maintenance in a temperate climate area can be used with SAE 20W.

What oil is better to pour into a Kamaz engine?

One of the most common oils for Kamaz diesel engines is KAMAZ SAE 15W40 API CI-4/SL K10-40.50 oil. What kind of oil to pour into the KAMAZ engine is chosen in each specific case by the mechanics themselves who service the vehicles. Sometimes, KAMAZ SAE 15W40 API CI-4/SL OPTIMUM KO15-40.50 engine oil is used for Kamaz engines, which has improved characteristics. Oil for the KamAZ 740 engine is selected based on the future operating conditions of the vehicle, most often it is Lukoil-Super (SAE 15W-40, CE/SG) or Lukoil-Super (SAE 15W-40, CF-4/SG). The brand of oil for the KAMAZ engine has a serious impact on the operation and performance of the engine. And its durability and reliability depend on what kind of oil is poured into the Kamaz engine. KAMAZ engine oil grades CES 20078, 20076 have improved friction properties and contribute to less wear of rubbing parts.

Modern engines of the Kama Automobile Plant, which meet modern environmental standards, require special lubrication. Oil in the Euro 3 KAMAZ engine is poured from Lukoil Super series with different viscosities, since the principle of operation of the power unit with supercharged air is fundamentally different in design from atmospheric. KAMAZ turbo engine oil Lubri-Loy15w40 API CJ-4/SN, CES 20081, Lubri-Loy API CI-4/SL Multi-Grade or CES 20072 contributes to the durability and reliability of power units.

List of motor oils for KAMAZ engines

LUKOIL-MZk factory break-in oilLUKOIL AVANTGARDE semi-synthetic SAE 10W-40, API CF-4/SGLUKOIL AVANTGARDE SAE 15W-40, API CF-4/SGCONSOL Titan Transit SAE 15W-40, API CF-4/SGRosneft Maximum Diesel SAE 10W -40, API CF-4/SGRosneft Optimum Diesel SAE 15W-40, API CF-4/SGRosneft Maximum Diesel SAE 15W-40, API CF-4/SGDiesel Extra SAE 10W-40, 15W-40, API CF-4/ CF/SGQUALITY 5z/14 (SAE 15W-40), type CF-4/SGEcoil Turbodiesel SAE 15W-40, 10W-40, API CF-4/SJTatneft Profi SAE 5W-30, 5W-40, 10W-30, 10W -40, 15W-40 API CF-4/SGTHK Revolux D1 15W-40, API CF-4, CF/SJTHK Revolux D2 10W-40, 15W-40, API CG-4, CF/SJNovoil Turbo Diesel SAE 10W-40 , 15W-40, API CF-4/SHSINTOIL SAE 10W-30, 10W-40, 15W-40, 20W-50, API CF-4/SJSelect Lubricants Magnum API CF-4/SG, SAE 10W-40, 15W- 40

Do you want to buy an engine?

Related materials:

dvigatelkama.ru

KamAZ-43118: multifunctional universal truck

The initiative to create KamAZ-43118 belonged to the Russian Ministry of Defense. The military needed a reliable multi-purpose off-road truck. As a result, in 1995, the first copies of the car rolled off the assembly line, which was distinguished by its unpretentiousness, ease of maintenance and operation. The truck was distinguished by a fairly modern, for that time, cabin and an enlarged cargo platform. Already in the first years of production, KamAZ-43118 was used not only as a truck, but also as a timber carrier, tank truck, dump truck, truck crane, and other hydraulic manipulators were installed on the chassis.

In 2010, a deep modernization of the model was carried out, a new modification of the vehicle appeared on the market - KamAZ 43118 46. The truck, as before, had a 6*6 wheel arrangement, but its appearance has undergone major changes. The cabin became more streamlined, the headlight, running lights and direction indicators were assembled into one unit, the manufacturer also installed a one-piece windshield and improved the rearview mirrors.

The truck's interior is equipped with two or three seats; the driver's seat has adjustment mechanisms in several planes. The latest modifications of KamAZ-43118 received a sleeping place, the presence of which was not initially provided for by the designers. The instrument panel is three-sectional, with anti-reflective coating. Thermal and sound insulation of the cabin has been improved, and fairly high-quality materials have been used to decorate the interior. The designers also worked on the cabin heating; the air circulation in the cabin was changed and a new, more powerful autonomous heater was installed.

Lubrication system in Cummins diesel engines

Do-it-yourself oil change in a VAZ-2114 engine

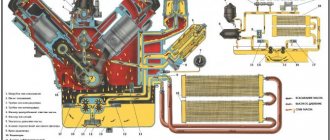

The main parts that make up the lubrication systems of all diesel engines are the oil pan, the oil cooler, and a system of channels that distribute oil to all moving mechanisms.

Sometimes units can be equipped with electric oil pumps, which drivers use to pre-lube the engine (before starting it) and increase the pressure to operating levels.

Oil pan

- This is an oil reservoir. The most common types of pans found in diesel engines are aluminum, cast iron or steel (stamped) pans. It is equipped with a rubber-metal oil dipstick for checking the oil level and an oil deflector that prevents oil from splashing onto the connecting rods. The walls of the pan remove heat from the oil, cooling it slightly. Oil sediment settles to the bottom of the pan.

Oil pump

– designed to take oil from the sump and supply it further to the oil cooler, as well as to maintain the required pressure in the lubrication system of a diesel engine. The drive is provided directly, via an intermediate shaft or a camshaft.

Diesel engines use gear and rotary pumps (externally geared, internally geared or planetary), while truck-type diesel engines use gear scavenge pumps. They ensure a constant supply of oil when the machine is operating on a slope.

Oil cooler

– designed for additional oil cooling. It becomes possible to reduce the size of the oil pan, resulting in much less oil coming into contact with hot engine parts during sudden changes in engine tilt. The oil cooler is a radiator - a system of copper tubes enclosed in a sealed housing.

Oil flows through the tubes, and coolant flows into the housing. Moreover, the directions of flow of oil and liquid are opposite. At the inlet of the oil cooler there is a pressure reducing valve designed to regulate pressure. The valve is set to a pressure of 414 kPa.

Oil filter

– installed at the outlet of the oil cooler. Modern diesel engines use full-flow and part-flow engines. The former completely allow the oil flow coming from the oil cooler to pass through them. The latter are only part of this flow.

The rest of the oil goes back into the pan. Thus, oil purification is ensured in several cycles. There is a bypass valve at the oil filter inlet.

The Cummins diesel engine duct system consists of the main oil duct and its branches, the oil supply duct and the turbocharger line. Oil is supplied to the turbocharger and drained back into the sump through flexible tubes made of neoprene rubber, nylon and other synthetic materials.

The main oil line supplies oil to all moving mechanisms - main and connecting rod bearings, crankshaft and camshaft, valve mechanism, piston and cylinder blocks, and others. Oil pressure in the lubrication system is maintained by holes of a given cross-section.

Disadvantages and typical breakdowns of power plants

Repairing KAMAZ engines does not bring much trouble to the owner if you strictly follow the maintenance regulations and carry them out in accordance with the passport recommendations. Thus, it is necessary to regularly, at established intervals, carry out maintenance of the main components, change working fluids, adjust thermal clearances, and change filters.

If serious damage could not be avoided, it is recommended that the KAMAZ engine be repaired by qualified specialists, since special equipment and stands are required to perform all the necessary work.

The main malfunctions of power plants include:

- The power plant does not start. There may be air in the fuel supply system. It is necessary to identify the cause of the air, bring the system into a sealed state and pump the fuel.

- The engine won't start. The fuel injection timing may be incorrect. The advance angle needs to be adjusted.

- The engine does not start at sub-zero temperatures. Water getting into the fuel pipes or onto the fuel intake grid and its subsequent freezing. It is necessary to warm up the fuel filters, tanks and pipes with hot water in order to melt the frozen liquid.

- Uneven operation of the power unit, the engine vibrates strongly, does not hold idle speed, power drops when the speed increases. A possible cause is clogged injectors. To eliminate the malfunction, it is necessary to wash the injectors on a special stand.

How much oil is required for a UAZ engine

Before draining the old one or filling in a new motor lubricant yourself, you need to familiarize yourself with the manufacturer’s advice on how much to fill when changing. Since all cars have different power, different modifications, engine size, this value will differ. Let's consider the parameters for engines of domestically produced cars, namely UAZ.

How many liters of oil are in a UAZ Patriot engine?

To change the lubricant for the UAZ engine of the Patriot model, seven liters are needed. In terms of viscosity, the most optimal options are 10W-40, 5W-30 or -40.

After how many kilometers, or what period of time, you can change the lubricant in the UAZ operating unit, you can find out from the operating instructions developed by the manufacturer. It states that after draining the old one, filling in the new one is done every 15,000 kilometers, at least once a year.

Specifications

All technical characteristics of the car are presented in Table 1.

Weight parameters and loads

Car load capacity, kg

Total weight, kg

A total of four variants of car No. 55111 were produced:

All modifications have the same diesel power unit. The engine is combined with a manual transmission: 152 with a gear ratio of 5.43 for 1 and 16 series. On modification 18, the gear ratio is 5.94. The chassis length and tire type are the same. The weight of each car was 9050 kg. Fuel tanks are designed for 250 liters of diesel fuel.

Body

Welded bucket-type platform, all-metal.

The tilt is directed towards the front side. The visor covers the free space between the body and the cabin. The bottom is heated by exhaust gases, which prevents bulk cargo from freezing to its base.

The maximum body tilt angle is 60 degrees. The platform volume is 6.6 cubic meters.

Body lift system

The platform is tilted using hydraulics. The machine is equipped with a three-stage telescopic hydraulic cylinder for these purposes. It is aggregated through a drive by a power take-off.

Cabin

Rectangular headlights were installed in front. The cabin is made of metal and is tilted forward in the direction of travel of the car. The cabin is designed for 3 people.

There is good noise and waterproofing inside the cabin. The entrance and exit are designed for two sides.

Engine

Diesel unit with turbocharging.

Develops power of 240 hp. at 2200 rpm. The maximum torque of 912 Nm is achieved at 1100 rpm. Engine V-shaped 8 cylinder. More details about the KamAZ 55111 engine and its components can be found in the repair and maintenance manual for KamAZ vehicles, starting from page 14.

Transmission

Ten-speed manual transmission in two variations:

- Without a 14.5-step divider, the distribution number is 7.22. 5 manual transmission.

- With 15.5 steps divider. Distribution number - 6.53. 10 manual transmission.

Diesel fuel consumption

The fuel consumption of KamAZ 55111 dump truck is 30 liters per 100 km. The KamAZ 55111 fuel tank capacity holds 250 liters of fuel and can cover a distance of 800 km without refueling. On special modifications of KamAZ 55111, the filling volumes have been increased. Models are equipped with a tank of 350 liters of diesel fuel, which makes it possible to travel a greater distance without additional refueling.

Brakes

The KamAZ 55111 brake system diagram is a symbiosis of small parts and components.

The KamAZ 55111 brake circuit is divided into main and auxiliary. The first controls the situation while driving. The second (parking) holds the truck during parking and stopping. Including downhill.

Figure 1 — Brake mechanism diagram

Explanation for Figure 1:

- Pad axis.

- Caliper.

- Shield.

- Axle nut.

- Pad axle lining.

- Block axle pin.

- Brake pad.

- Spring.

- Friction lining.

- Bracket for expansion knuckle.

- Roller axis.

- Expanding fist.

- Video clip.

- Adjustment lever.

Read more about the braking system in the KamAZ 55111 operating manual in the “Braking system” section on page 188.

Zil 4331: technical characteristics and its modification (video, price, reviews).

The KamAZ 4308 car is a worker of small and medium-sized businesses, description and characteristics are here.

A universal and economical KamAZ 65115 dump truck on this page.

Wiring diagram

Unfortunately, the KamAZ 55111 electrical wiring diagram has not undergone significant changes compared to the previous model 5511.

A description of the KamAZ 55111 electrical wiring diagram is in the “Electrical Equipment” section of the KamAZ 55111 operating instructions on page 213.

How much oil should be poured into a truck engine?

The engines of trucks, just like cars, require modern replacement of the lubricant. This procedure can be carried out independently, but you need to know how much lubricating fluid is required. Every car owner should clearly understand that the lifespan of the main unit of his car depends on timely oil changes, and change intervals should be monitored.

KAMAZ

What is the amount of lubricating fluid in the KAMAZ 740 and 5320 engine? According to the advice specified in the operating requirements, for stable operation of the engine, the required volume is 28 liters, and replacement should be made every 16,000 kilometers or after 250 engine hours.

Video of oil change in KAMAZ:

ZIL

Information on how many liters of oil are in the ZIL 130 engine is contained in the operating instructions developed by the manufacturer. This parameter is nine liters. The manufacturer also recommends that the lubricant should be changed every 6-10 thousand kilometers.

This measure, taken by the owner of the ZIL 130 car, will extend the life of an important unit

Gazelle

The manufacturer who created the operating instructions indicates the amount of lubricant in the Gazelle 405 and 406 engine. This value is 5.4 liters. This is the amount that should be adhered to when making a shift. The mileage that the machine travels from replacement to draining the old one and refilling the new one is 15,000, but you should focus on the load during operation. Service center employees servicing these cars recommend replacement every 7-8 thousand kilometers.

How much oil is in a Gazelle Cummins engine? This question worries many owners of the updated GAZelle model. Despite the fact that there is only one manufacturer, this modification has a more powerful engine. The amount of lubricant required is 5.7 liters. Recommendations for the period and kilometers traveled are similar.

GAS

Let's figure out how much lubricant to pour for stable operation of the gas 53 unit. For the GAZ-53, the displacement of the lubricant is eight, and replacement is carried out every 10,000 kilometers.

Advice! Sometimes, for prevention, you should fill in a mineral lubricant with additives and drive it for about 2,500 kilometers. It will help flush the engine. After this, refill with synthetic or semi-synthetic.

It is worth paying attention to the fact that manufacturers recommend draining the old lubricant and adding new lubricant every fifteen thousand kilometers. But be sure to take into account the fact that the cars are operated in city traffic jams, wear and tear occurs faster

Therefore, this gap should be reduced by at least half.

The Kamens engine lubrication system provides lubrication and cooling of the moving parts and mechanisms of the system - bearings, gears, and cylinders.

A lack of oil in the engine can lead to breakdown and failure of the entire system, so it is extremely important to promptly diagnose and lubricate the engine, as well as monitor the sufficient oil level. The volume in a Kamens engine (the capacity of the engine lubrication system) depends on several characteristics: the number of cylinders, engine displacement and type of oil pan.

The volume in a Kamens engine (the capacity of the engine lubrication system) depends on several characteristics: the number of cylinders, engine displacement and the type of oil pan.

Oil volume in a 4-cylinder Kamens engine (standard):

Small capacity tray – system capacity 10 l; pallet - 7.9 l.

- Hanging tray – system capacity 13 l; pallet – 11 l.

- Aluminum tray – system capacity 15 l; pallet – 13 l.

- Large capacity tray – system capacity 18 l; pallet – 16 l.

Oil volume in a 6-cylinder Kamens engine (standard):

- Small capacity tray – system capacity 13 l; pallet – 11 l.

- Hanging tray – system capacity 19.5 l; pallet - 17.5 l.

- Standard type tray – system capacity 16.7 l; pallet - 14.2 l.

- Hanging tray – system capacity 19.7 l; pallet - 17.5 l.

- Large capacity tray – system capacity 26.4 l; pallet - 23.9 l.

Kamens marine engine oil capacity is 15.1 liters (16 quarts).

If the type and capacity of the oil pan are unknown, you can:

- Contact your Cummins representative.

- Determine the oil pan volume using the engine serial number using the QuickServe OnLine system.

- Fill the pan with the minimum amount of oil specified for this engine type. Next, add 1 liter at a time to the top mark on the dipstick.

Transmission oils ZF

Attention! Operate ZF gearboxes strictly with oils approved by ZF. Complete information on oils (list, conditions of use and change periods) can be found at any ZF service center or on the website www.zf.com. The information on this site is updated every three months. Each subsequent edition cancels all previous versions. Table B.6 shows an incomplete list of oils from the most well-known manufacturers for the operation of ZF manual transmissions (list of lubricants TE-ML 02, version 01/01/2016). For the ZF 9S1310 gearbox, oils of the following classes are recommended: 02B, 02E, 02L. The frequency of changing oils in ZF gearboxes and the temperature range of their use are given in tables B.4, B.5.

Attention! It is allowed to mix different brands of oils only within the same class of the list of lubricants TE-ML 02.

Oil movement in the Kamens lubrication system

From the oil pan, oil enters the oil pump through the intake pipe. Next, the oil is supplied to the inlet of the oil cooler.

In case of increased pressure, excess oil flows back into the pump (3.9 L and 5.9 L engines) or into the sump (4.5 L and 6.7 L engines). Next, the oil enters the filter inlet, the bypass valve of which opens if the pressure drop across the filter is above 345 kPa.

After being cleaned in the filter, the oil enters the lubrication system - the main line, the injector channel and the turbocharger line. The main oil line passes through the cylinder block next to where the oil flows to the main bearings and crankshaft. From the main bearings there is a branch to the camshaft and piston cooling nozzles.

We list some possible reasons leading to a malfunction of the lubrication system:

High oil pressure. The pressure regulator valve is stuck in the closed position.

Low oil pressure. It is important to find out the conditions under which the pressure decreased. If after changing the oil, this may be due to its high level in the sump, since the connecting rods during operation are immersed in it and saturated with air, which leads to a decrease in pressure

Low oil levels can cause short-term loss of pressure when operating on slopes and turns. A clogged oil filter causes a gradual decrease in pressure by 69 kPa. Poor fastening of the intake tube leads to a decrease in pressure during startup. A decrease in pressure over a long period of time may indicate wear of the bearings or oil pump. Operation malfunction.

Presence of impurities in the oil (fuel, coolant). Mixing oil and coolant is usually caused by a leak in the oil cooler.

Description of the KamAZ-5320 (5320) model

SPECIFICATIONS

Maud.

KamAZ-740.10, diesel, V-o6p. (90°), 8-cylinder, 120×120 mm, 10.85 l, compression ratio 17, operating order 1-5-4-2-6-3-7-8, power 154 kW (210 hp .) at 2600 rpm, torque 637 N-m (65 kgf-m) at 1500-1800 rpm. Injectors are closed type, TNDV - V-type, 8-section, spool type, with a low-pressure fuel priming pump, a fuel injection advance clutch and an all-mode speed controller. The air filter is dry, with a replaceable cardboard filter element and a clogging indicator. The engine is equipped with an electric torch device (EFD) and (optional) a pre-heater PZD-30. Transmission

The clutch is a double-disc clutch with peripheral springs, the release drive is hydraulic with a pneumatic booster. Gearbox - 5-speed, with a front divider, total number of gears - ten forward and two reverse, gear. numbers: I-7.82 and 6.38; II-4.03 and 3.29; III-2.5 and 2.04; IV-1.53 and 1.25; V-1.0 and 0.815; ZX-7.38 and 6.02. Synchronizers - in II, III, IV and V gears. The divider is equipped with a synchronizer, the divider control is pneumomechanical, preselector. Cardan transmission - two cardan shafts. The main gear is double (conical and cylindrical), gear. number - 6.53 (ordered - 7.22; 5.94; 5.43); The middle axle is a straight axle, with a center differential locked using an electro-pneumatic or pneumatic drive.

Wheels and tires

Wheels - discless, rim 7.0-20, fastening with 5 studs. Tires - 9.00R20 (260R508), mod. I-N142B, front wheel tire pressure - 7.3; rear: KamAZ-5320 - 4.3; KamAZ-53212 - 5.3 kgf/cm 2; number of wheels 10+1.

Suspension

Dependent: front - on semi-elliptic springs with rear sliding ends, with shock absorbers; the rear is balanced, on semi-elliptical springs, with six reaction rods, the ends of the springs are sliding.

Brakes

The service brake system is with drum mechanisms (diameter 400 mm, lining width 140 mm, cam release), dual-circuit pneumatic drive. Brake chambers: front - type 24, bogies - 20/20 with spring energy accumulators. Parking brake - trolley brakes from spring energy accumulators, pneumatic drive. The spare brake is combined with the parking brake. The auxiliary brake is a motor retarder with a pneumatic drive. The trailer brake drive is combined (two- and single-drive). There is an alcohol fuse against condensate freezing.

Steering

The steering mechanism is a screw with a ball nut and a piston-rack that engages with the toothed sector of the bipod shaft, transmitting. number 20. The hydraulic booster is built-in, the oil pressure in the booster is 80-90 kgf/cm 2 .

Electrical equipment

Voltage 24 V, ac. battery 6ST-190TR or -190 TM (2 pcs.), generator set G-273 with voltage regulator YA120M, starter ST142-B.

Filling volumes and recommended operating materials Fuel tanks: for KamAZ-5320 - 175 or 250 l, for KamAZ-53212 - 250 l, diesel. fuel; cooling system (with heater) - 35 l, cool. liquid - antifreeze A-40; engine lubrication system - 26 l, summer M-10G (k) winter M-8G2 (k), all-season DV-ASZp-10V; power steering - 3.7 l, oil grade P; gearbox with divider - 12 l, TSP-15K; drive axle housings - 2×7 l, TSp-15K; hydraulic clutch release system - 0.28 l, Neva brake fluid; shock absorbers - 2×0.475 l, liquid AZh-12T; fuse against freezing of condensate in the brake drive - 0.2 l or 1.0 l, ethyl alcohol; windshield washer reservoir - 1.8 l, NIISS-4 liquid mixed with water.

Weight of units (in kg): Engine with clutch - 770, gearbox with divider - 320, driveshafts - 49 (59), front axle - 255, middle axle - 592, rear axle - 555, frame - 605 (738), body - 870 (1010), cabin assembled with equipment - 577 (603), wheel assembled with tire - 80, radiator - 25.

General information

Together with the listed indicators, the technical characteristics of the KamAZ-4308 medium-duty truck are as follows:

- international environmental safety class – Euro III;

- wheel formula – 2x4;

- layout – longitudinal engine located in front above the cabin;

- the car cabin is stamped, metal, with a sleeping place;

- number of places – 3;

- front axle load – from 4,300 to 4,350 kilograms;

- rear axle load – from 7,200 to 7,550 kilograms;

- wheelbase - from 4,200 to 4,800 centimeters;

- maximum permissible weight – 8,000 kilograms;

- as part of a road train - from 19,500 to 19,900 kilograms;

- power plants - 4ISBe and 6ISBe;

- cylinder volume – 3.9 dm2 and 6.7 dm2;

- number of cylinders – 4 and 6;

- compression ratio of the fuel mixture – 17.3;

- the car uses diesel fuel;

- gearboxes – 6J70T, ZF6S1000TO, KAMAZ-141;

- suspension type - spring on both axles, or spring on the front axle, and pneumatic on the rear axle with hydraulic shock absorbers;

- tire size – 245/70 R 19.5.

The technical characteristics of KamAZ-4308 justify its price - about 2 million rubles.

Cabin design KamAZ 4308

Medium-duty vehicles are equipped with the same cabins as those used in heavy-duty models. But still, they have undergone some changes and additions that add modernity and ease of use to them:

Cabin interior of KamAZ 4308

- a new method of applying paint is used that protects against corrosion;

- radiator grilles and side trims were replaced;

- Imported lift seats are installed;

- there are cabin options with and without a berth - for the city or long trips;

- plastic dashboard;

- handles and locks are unified with VAZ cars.

The interior cannot be called very modern, but it is comfortable for the driver to drive the truck and stay behind the wheel for a long time.

Video: Review of KAMAZ 4308 with trailer

Oil change Kamaz 740

Starting after valve adjustment and correct oil

in

the engine

for the mess, don’t blame everything.

A power unit with insufficient lubricant is much more susceptible to wear during operation and is more likely to fail. Using non-recommended oils and intermittently changing them increases wear on internal engine components.

Properties of oils and their differences

Modern motor oil

Made from mineral and synthetic base oils and additive packages. Thanks to this, engine oil differs in thermal-oxidative abilities, viscosity, temperature and performance characteristics. Choosing a brand of motor oil depends on your preferences and needs. It is worth highlighting the main characteristics of motor oils poured into the KamAZ 740 engine: Viscosity level. Diesel power units use oils with a high level of internal friction; - operational properties. For engines with a gas turbine system, special oils are used; Viscosity class.

With timely replacement and compliance with the required amount of oil poured into the engine

KAMAZ, you can achieve maximum engine life.

Reliability, problems and repair of KAMAZ 740

The production of engines for trucks at the Kama Automobile Plant began in 1975 and this was the first internal combustion engine for KamAZ vehicles. This engine has an 8-cylinder cast iron V-shaped cylinder block with a camber angle of 90° with a cylinder bank offset of 29.5 mm and with wet cast iron liners. The block is equipped with a steel crankshaft with a piston stroke of 120 mm, the diameter of the main journals is 95 mm, and the diameter of the connecting rods is 80 mm. The connecting rods are made of steel (225 mm long), the pistons are made of aluminum (their height is 75.7 mm), and they have a combustion chamber offset of 5 mm from the center. Piston pin diameter 45 mm. In turbo versions, the pistons are cooled using oil nozzles installed in the cylinder block. Oil pressure on KamAZ 740 is 4.0-5.5 kgf/cm2.

Separate cast iron heads are installed on top of the block for each cylinder separately, each cylinder head has 2 valves. The diameter of the intake valve plates is 51.6 mm, and the exhaust valves are 46.6 mm. The camshaft is located in the cylinder block and operates the valves through rods, pushrods and rocker arms. The camshaft drive is gear driven from the crankshaft. On the base Euro-0 engine, the camshaft characteristics are as follows: phase 242/256, lift 14.2/13.7 mm. Adjustment of valves on KamAZ 740 is required as necessary, valve clearances: inlet 0.3 mm, exhaust 0.4 mm. The valve adjustment order is: 1-5-4-2-6-3-7-8. For this internal combustion engine there was a YAZDA 33 pump and 33-03/10 injectors, later they were repeatedly changed to a variety of versions (see below for more details).

Euro-1 engines are distinguished by their crankshaft, pistons, piston pins, piston rings, modified head, turbocharging without intercooler, YAZDA 337 pump, 273 injectors. Euro-2 engines with a stroke of 120 mm use a crankshaft with a different flywheel mount, pistons from Euro-1, as well as an air intercooler. There are also Euro-2 engines with a piston stroke of 130 mm, which gives a displacement of 11.76 liters. There are pistons with a height of 70.7 mm, their liners, and the piston pins are still old. Diesels for Euro-3 are created on the basis of Euro-2 and have their own more durable heads, differ in crankshaft, piston rings, 274 injectors. Kamaz Euro-4 engines differ in pistons, piston pins, rings, heads with a Common rail injection system, the presence of SCR- catalyst. Versions without SCR are environmentally suitable for class 4 (Rules 96-02).

KamAZ 740 Euro-4 vehicles have a Bosch CP3.4 injection pump with an injection pressure of up to 1600 bar. These motors are controlled by a Bosch EDC7UC31 ECU.

These engines are equipped with two turbines TKR-700-01 and TKR-700-02 (their analogues: CZ K27-145, CZ K27-49, TKR 7S-6). For versions 7403 there were turbochargers TKR 7N1K-01 and TKR 7N1K-02.

Modifications of Kamaz-740 and their differences

1. KAMAZ-740.10 - naturally aspirated engine meeting Euro-0 standards with a power of 210 hp. at 2600 rpm, torque 667 Nm at 1600-1800 rpm. Found on KamAZ-4310, 43101, 54112, 5320, 53212, 5410, 54112, 55102, 55511; Ural-4320; ZIL-133; AGMS. Engine life - 400 thousand km.2. KAMAZ-740.10-20 - the same model, but with 271 injectors. The power is slightly higher - 220 hp. This internal combustion engine is installed on KamAZ-43101, 5320, 53213, 5410, 54112, 55102, 55111; Ural-4320; ZIL-133. 3. KAMAZ-7403.10 - a turbo engine based on 740.10, with pistons with a compression ratio of 16 (larger combustion chamber), with its own piston pins, with a different intake system, injection pump 334, injectors 271, as well as with TKR 7N1K turbines. The camshaft remains old. The motor complies with Euro-0 standards, and its service life is 400 thousand km. Power 260 hp at 2600 rpm, torque 834 Nm at 1600-1800 rpm. Installed on KAMAZ-43101, 43114, 43115, 43118, 54112, 5320, 53212, 5315, 53229, 5325, 5415, 5425; GAZ-5903; LiAZ-5256. 4. KAMAZ-740.11-240 - Euro-1 turbodiesel with YAZDA 337-40 fuel injection pump, 273-31 injectors, with a compression ratio of 16.5 and a power of 240 hp. at 2200 rpm, torque 834 Nm at 1400 rpm. The resource has been increased to 800 thousand km. The engine does not have an intercooler. This diesel engine is installed on KamAZ-4306, 43114, 43118, 43253, 4326, 43501, 4925, 53215, 54115, 55111; NefAZ-5297, 5299. 5. KAMAZ-740.13-260 - analogue of 740.11-240 with YAZDA 337-42 and injectors 273-20, power increased to 260 hp. Cars with this engine: KamAZ-43114, 43118, 53215, 54115, 65111, 65115. 6. KAMAZ-740.30-260 - model for Euro-2 standards. There are TKR 700 turbines with an intercooler, a YAZDA 337-20 pump and 273-20 injectors. Power 260 hp at 2200 rpm, torque 1079 Nm at 1300 rpm. Suitable for KamAZ-43118, 5350, 65112, 65115, 65116; NefAZ-5299. 7. KAMAZ-740.31-240 - analogous to 740.30, but the power is reduced to 240 hp. Installed on KamAZ-43114, 43118, 43253, 4326, 4350, 43501, 5297, 53215, 53228, 53229, 53605, 54115, 55111; NefAZ-5299; LiAZ-5256. 8. KAMAZ-740.35-400 - version with a crankshaft with a piston stroke of 130 mm, which made it possible to increase the working volume to 11.76 l, compression ratio 16.8. There are TKR 700 turbines with an intercooler, fuel injection pump 337-24, injectors 274-22, ELARA ECU 50.3763. Power is 400 hp. at 2200 rpm, torque 1570 Nm at 1400 rpm. Found on KamAZ-6560. 9. KAMAZ-740.37-400 - the same as 740.35, but it has a Bosch PE8P120A920/5RV pump, AZPI 216-02 injectors, a Bosch MS6.1 control unit, and the power reaches 400 hp. at 1900 rpm, torque 1766 Nm at 1300 rpm. This is a motor for KamAZ-5460, 65224, 65225. 10. KAMAZ-740.38-360 - analogous to 740.37, but the output is reduced to 360 hp. at 1900 rpm, torque 1569 Nm at 1200-1400 rpm. 11. KAMAZ-740.50-360 - Euro-2 engine with a YAZDA 337-20 pump, 273-20 injectors, TKR-700 turbines and an intercooler. Power 360 hp at 2200 rpm, torque 1472 Nm at 1400 rpm. The declared resource is 800 thousand km. You can find internal combustion engines on KamAZ-6350, 63501, 6460, 65115, 6520, 65201, 6522, 65221, 65225; NefAZ-5299. 12. KAMAZ-740.51-320 - the same option, but with 320 hp. at 2200 rpm, torque 1275 Nm at 1400 rpm./ This is a motor for KamAZ-6520 and 6522. 13. KAMAZ-740.52-260 - 260 hp version. 14. KAMAZ-740.53-290 - 290 hp model. 15. KAMAZ-740.55-300 - 300 hp modification. for KamAZ-43118. 16. KAMAZ-740.60-360 - Euro-3 modification with electronic injection pump YAZDA 337-23, injectors 274-20, turbochargers TKR-700 and ECU ELARA 50.3763. The engine began to develop 360 hp. at 1900 rpm, torque 1570 Nm at 1300 rpm. The resource is still 800 thousand km. Installed on KamAZ-6520 and 65201. 17. KAMAZ-740.61-320 - an analogue of the above-described engine with 320 hp. for KamAZ-6520. Pump 337-23.01 is used here. 18. KAMAZ-740.62-280 - 280 hp turbodiesel, which is distinguished by a 337-23.02 pump. You can find this internal combustion engine on KamAZ-5297, 53605, 65111, 65115, 65116, 6540; NefAZ-4208, 5299. 19. KAMAZ-740.63-400 - 400-horsepower Euro-3 version for KamAZ-6460, 6520 and 65225. There are AZPI 216 injectors and Bosch electronics (pump PE8P120A920/5RV, ECU MS 6.1). 20. KAMAZ-740.64-420 - Euro-3 model with 420 hp. for KamAZ-5460 and LiAZ-5256. 21. KAMAZ-740.65-240 - modification with 240 hp. for environmental class Euro-3. There is a YAZDA 337-23.03/04 pump, 274-40/41 injectors and an ELARA 50.3763 control unit. It is installed on KamAZ-5297 and NefAZ-5299. 22. KAMAZ-740.602-360 - model for environmental class 4 (rules 96-02) with Common rail injection. The internal combustion engine shows 360 hp, and its resource is indicated as 450 thousand km. 23. KAMAZ-740.612-320 - analogue of 740.602 with 320 hp. 24. KAMAZ-740.622-280 - 280 hp variation. for KamAZ-65111; NefAZ-4208, 5633, 6606. 25. KAMAZ-740.632-400 - 400 hp model. 26. KAMAZ-740.642-420 is the top model of this series, which develops 420 hp. 27. KAMAZ-740.652-260 - 260 hp version. for NefAZ-42111 and AC-3.0-40. 28. KAMAZ-740.662-300 - 300-horsepower model for NefAZ-5633 and 6606. 29. KAMAZ-740.70-280 - analogous to 740.602, but has an SCR catalyst and complies with Euro-4 standards. The resource has been increased to 1 million km. 30. KAMAZ-740.71-320 - the same diesel engine, but the power is increased to 320 hp. 31. KAMAZ-740.72-360 - an even more powerful model - 360 hp. 32. KAMAZ-740.73-400 - 400 hp version. for KamAZ-6460. 33. KAMAZ-740.74-420 - analogue with 420 hp. 34. KAMAZ-740.75-440 - the most powerful of the Euro-4 line - 440 hp. 35. KAMAZ-740.705-300 - Euro-5 version with a power of 300 hp. 36. KAMAZ-740.725-360 - the same version for the 5th environmental class with 360 hp. 37. KAMAZ-740.735-400 - 400 hp version. 38. KAMAZ-7409 - gas-diesel engine for KAMAZ-5320.

KamAZ-740 malfunctions

1. Cracked heads in the injector area. A popular problem on Euro-2 engines, which happens even on new engines (up to 100 thousand km) due to the characteristics of the cylinder head. The problem was solved using Euro-3 heads. 2. Wear of liners. Another problem is Euro-3 engines, which need to be checked every 50-100 thousand km and replaced if necessary. Sometimes it turns over even before 100 thousand km. 3. It gets warm. Look for the reasons in the radiator, which needs cleaning from time to time, as well as in thermostats, fluid coupling, perhaps a problem in the ignition, in the liners or in the heads. Overheating can lead to cracks in the liners. 4. Smokes: - white smoke

— there is water in the tank or coolant enters the cylinders.

- blue smoke

- oil enters the cylinders.

— black smoke

— a fuel problem, look at how the pump is configured. 5. Knock. The reasons should be sought in injectors, unregulated valves, ignition, liners, crankshaft, perhaps the problem is in incorrectly selected pistons, in piston pins. 6. Troit. First of all, look at the pump, filters, pipes, nozzles, check the spark plugs, most often the dog is buried here. Engines with Euro-3 have an oil pump that runs for about 150 thousand km. Motors with Bosch electronics for Euro-2 do not like frosts and have difficulty starting when they occur. On Euro-2 and Euro-3 engines the crankshaft often bursts. ICEs under Euro-3 are characterized by increased wear of valve guides. In general, use good oil, change it regularly, maintain the car regularly, try not to overload it, and then the engine will work normally.

Engine number Kamaz-740

The designation is located on the block on the left along the direction, in front of the engine. For engines before 2007, the number is stamped in the area of the 4th cylinder.

Car cabin

The updated design of the cabin lining, which can now be seen on almost all restyled KamAZ trucks, was first used on the 4308 model.

The plastic panels of the bumper and radiator grille are produced by the Ivanovo company RIAT.

The front rectangular optics, also first tested on the KamAZ-4308 medium-duty truck, were manufactured by Hella.

Almost the entire torpedo of the 4308 model is made of plastic. Painted metal panels, familiar to consumers at the KamAZ plant, are no longer used.

The medium-duty vehicle is equipped with seats from the German company Grammer, which are also used by other leading truck manufacturers.

The plastic body kit manufactured by RIAT is shock-resistant and frost-resistant.

The car cabin is treated with cataphoretic priming, which almost completely eliminates corrosion. The cabin is installed using quarter-elliptic springs.

In general, the cabin of the medium-duty KamAZ is comfortable and well-designed. The torpedo “surrounds” the driver, access to all controls and instruments is extremely simplified.

Door locks and interior handles are completely unified with VAZ ones. Gremmer seats are equipped with pneumatic adjustable cushions.

Did you know that, created by a Swedish company, it is popular due to constant updates and improvements that improve its technical characteristics?

Useful little things from the manufacturer often exceed the price capabilities of the buyer. you will find a cheat sheet for creating a gearbox for a motor drill with your own hands, thanks to which you can significantly reduce the cost of technical equipment.

Especially for you, we have prepared an article about the features of making a homemade grass and branches chopper.

Thus, the KamAZ-4308 vehicle is a medium-tonnage truck with wide application.

The car's design uses components developed in collaboration with foreign manufacturers.

Despite the fact that KamAZ-4308 was developed in a short time, with partial unification of components, the design turned out to be quite reliable and competitive.

The use of new developments and products from joint ventures has made the car a universal vehicle for professional use.

The truck can be used as part of a road train and is suitable for intercity transportation of small quantities of goods from warehouses located within large cities.

The design of KamAZ-4308 is constantly being improved and modified, which makes it possible to produce a vehicle that meets international standards of environmental safety and reliability. You can verify this by watching the following video:

Time does not stand still and KAMAZ is constantly changing, offering not only new models, but also improving existing ones. The “restyled” KAMAZ-4308 offers its customers a modern, stylish cargo appearance with a basic cab without a berth or with an enlarged cab with a berth (the only available option for the flatbed version). In addition, the improved cab, mounted on a four-point air suspension, received a high roof and an increased amount of free space inside, which significantly improves comfort characteristics, making the restyled KAMAZ-4308 more suitable for long-distance cargo transportation.

Like the pre-restyling version, the new KAMAZ-4308 is available in chassis and on-board modifications.

The restyled KAMAZ-4308 chassis received three wheelbase lengths: 3500, 4200 and 4800 mm, resulting in the total length of the truck varying from 5970 to 8150 mm. The width of the KAMAZ-4308 chassis is 2480 mm, and the height at the top point of the cabin is correspondingly equal to 2615 mm. The front overhang of KAMAZ-4308 is 1270 mm. The curb weight of the KAMAZ-4308 chassis, depending on the length of the wheelbase, is 4825, 4925 or 4995 kg, the total weight of the truck should not exceed 11900 kg, while the maximum permissible load on the front axle is 4350 kg, and on the rear axle - 7550 kg. The chassis load capacity is 7000, 6900 and 6830 kg.

The onboard restyled KAMAZ-4308 has only one wheelbase length option - 4800 mm, while its total length is 8435 mm. The width of the onboard KAMAZ-4308 is 2480 mm, and the height to the top of the cabin is 2670 mm. Please note that when installing a cargo superstructure, the total height of the onboard KAMAZ-4308 should not exceed 3910 mm. The front overhang of the flatbed truck is also 1270 mm. The curb weight of the on-board modification is 6020 kg, and the total weight is 11900 kg (the maximum permissible load on the front axle is 4350 kg, on the rear axle - 7550 kg). The carrying capacity of the restyled flatbed KAMAZ-4308 does not exceed 5730 kg, which is slightly less than that of the pre-restyled vehicle. Let us add that the onboard KAMAZ-4308 is equipped with a cargo platform with dimensions of 6112x2470 mm, which is complemented by metal folding sides with a height of 730 mm. The loading height of the platform is 1255 mm.

Regardless of the version, it can pull a trailer with a maximum weight of 8000 kg.

After restyling, for each of the KAMAZ-4308 modifications, the manufacturer prepared its own power plant:

- The KAMAZ-4308 chassis received the same 4-cylinder in-line turbodiesel CUMMINS 4 ISBe 185 with a displacement of 4.5 liters and a charge air intercooling system. The engine complies with the Euro-3 environmental standard and develops up to 185 hp. rated power already at 2500 rpm, and is also capable of producing up to 636 Nm of peak torque at 1700 rpm, which allows a loaded KAMAZ-4308 to accelerate to 100 km/h. The engine is combined with a 6-speed manual transmission ZF 6S1000 or a 6-speed manual transmission ZF 6S700. Note that both gearboxes are equipped with a single-disc diaphragm push-type clutch “ZF&SACHS” with a hydraulic drive, supplemented by a pneumatic booster.

- The onboard KAMAZ-4308 received a 6-cylinder in-line turbodiesel CUMMINS 6ISBe 245 with a displacement of 6.7 liters. Its rated power is 245 hp. at 2500 rpm, and the peak torque falls at 905 Nm, available already at 1500 rpm. This diesel power unit is equipped with only one gearbox option - a 6-speed manual ZF 6S1000.

The restyled KAMAZ-4308 in all modifications is equipped with reinforced spring suspension at the front and rear, while the rear suspension can be replaced with an optional pneumatic one. The wheel formula of KAMAZ-4308 is 4x2. All wheels of the truck are equipped with Haldex disc brakes with pneumatic drive and an ABS system. The new product is equipped with a fuel tank with a capacity of 210 liters, a three-blade wiper, an adjustable steering column, an adjustable driver's seat and air suspension, a new instrument panel with anti-reflective coating and two batteries of 190 Ah each. As additional equipment, it is possible to install a power take-off, air conditioning, CD radio, electric windows, armrest and heated driver's seat, as well as a factory frame awning for on-board modification.

The price (for 2021) of the restyled KAMAZ-4308 in the “chassis” version is about 2.50 ~ 2.65 million rubles (depending on equipment), and the cost of a KAMAZ-4308 (R4) flatbed truck is from ~2 million 800 thousand rubles.

KamAZ 4308 is a medium-duty truck that has been produced since 2003 at the Kama Automobile Plant. This model is equipped with components from leading automobile companies: BOSH fuel system, Cummins engine, ZF transmission, Haldex brake system, etc. The well-thought-out design of the cabin ensures good ergonomics. The informative instrument panel is made of fiberglass.

KamAZ-55111: main operational and technical characteristics

Dimensions and load capacity

- Dump truck height: 2,995 millimeters;

- Length: 6,690 mm;

- Width excluding mirrors: 2,500 mm;

- Center distance: 2,840 – 3,190 mm;

- Ground clearance: 290 mm;

- Maximum outer turning radius: 9 meters;

- Platform volume: 6.6 cubes;

- Curb weight of the truck: 9,150 kilograms;

- Load capacity: 13,000 kg;

- Total loaded vehicle weight: 23,125 kg;

- Total weight of the road train: 35.1 tons;

- Maximum platform elevation angle: 60 0 ;

- Maximum climbing angle: 25%;

- Wheel type: disc

- Tire type: pneumatic, tube

- Tire size: 10.00 R20 (280 R508)11.00 R20 (300 R508)

- The highest speed of the truck: 90 km/h.

Power unit and fuel consumption of KamAZ-55111

The domestically produced diesel engine 740.51-240 was chosen as the main power unit for this model. This eight-cylinder diesel engine is distinguished by a V-shaped cylinder arrangement, it has a turbocharging function and a cooling system for the consumed air. The working volume of the power unit is 10.86 liters, it develops a rated power of 240 hp at a rotation speed of 2,200 rpm. The engine uses cooling technology in which the fan is driven through a special fluid coupling. Thus, a sharp change in the angular speed of the fan when the engine speed drops or increases is eliminated. The motor is not highly environmentally friendly; it complies with Euro 2 standards.

It should be mentioned that a small number of KamAZ-55111 dump trucks were equipped with a six-cylinder YaMZ-236 engine with a power of 180 hp.

The manufacturer's declared fuel consumption per 100 kilometers is 30 liters. However, this norm can only be achieved when driving on a good road, at a speed of 50-60 km/h. When the speed increases to 80-90 km/h, fuel consumption indicators increase sharply and can differ significantly from the norm. The KamAZ-55111 dump truck is equipped as standard with a 250-liter fuel tank. However, small batches of trucks left the factory, equipped with a tank with a volume of 350 liters, which significantly increased the vehicle’s mileage without refueling.

Transmission and power supply KamAZ-55111

The car is equipped with two manual gearboxes: a five-speed gearbox without a divider with a three-way shift mechanism, with a gear ratio of 7.22, and a ten-speed gearbox with a transfer number of 6.53. To transmit force from the engine to the gearbox, a double-disc diaphragm clutch equipped with a hydraulic drive with a pneumatic booster is used. The clutch and gearbox are controlled remotely from the driver's cabin.

The electrical systems of the KamAZ-55111 dump truck are powered by two 12-volt batteries with a total capacity of 380 A/hour. In addition, the truck is equipped with a voltage regulator and a two-kilowatt 28-volt generator.

Engines

Before the creation of the joint venture, KamAZ-4308 vehicles were equipped with American Cummins diesel engines, assembled at the Chinese Dongfeng factory under license.

Despite the Chinese assembly, the B series engine was distinguished by stable, low-noise operation in all modes.

Let's look at the main technical characteristics of the KamAZ-4308 C3 engine:

- dimensions – 102x120 millimeters;

- number of cylinders – 4;

- cylinder volume – 3.9 dm2;

- power – 140 horsepower at 2,800 rpm;

- KM - 502 Newtons per meter at rpm 1,500;

- environmental subclass – Euro II;

- fuel pump – Bosch, mechanical;

- number of valves – 8;

- turbocharging;

- intercooler

After the creation of the Cummins-Kama joint venture, KamAZ-4308 medium-duty trucks began to be equipped with 4ISBe and 6ISBe power units, assembled at the joint venture’s facilities in Naberezhnye Chelny.

It is possible to bring these engines to the Euro IV environmental safety level. Urea is used for this. If the vehicle is equipped with a Euro IV engine, a special urea container is installed.

The technical characteristics of these engines are different from the Chinese ones and are as follows:

4ISBe

6ISBe

- dimensions – 107x124 millimeters;

- number of cylinders – 6;

- power – 185 horsepower;

- maximum torque – 800 newtons per meter;

- cylinder volume – 6.7 dm2;

- location – in-line;

- piston stroke – 120 mm;

- environmental subclass – Euro III;

- fuel pump – Bosch;

- electronic control module - ECM.

For power units of these configurations, the cylinder block is made with increased wall thickness and without the use of liners, which makes it possible to bore the working areas and install piston repair kits during major repairs.

A metal plate is attached to the block tray using bolts to reduce vibration and noise levels.

KamAZ-55111: reliable “construction” dump truck

The KamAZ-55111 truck is designed taking into account the advantages and disadvantages of the earlier KamAZ 5511 model. The first copies of the new dump truck rolled off the plant’s assembly line in 1988, the last truck of this modification was released in 2012. On the basis of the platform, not only dump trucks with increased payload capacity (13 tons) were produced, but also a variety of army equipment was installed. The military model was attracted by its high maneuverability, ease of maintenance and operation. However, the main purpose of a dump truck is to transport construction materials over short distances.

Structurally, KamAZ-55111 is a frame truck with a front engine and a 6*4 wheel arrangement. The dump truck is distinguished by rear unloading; the body is equipped with a heating system, which is carried out using exhaust gases from the muffler. The vehicle is equipped with a tilting cabover all-metal standard Kamzovsky cab, in which two or three air-suspended seats are installed; a sleeping bag is not provided in most trucks. The driver's seat has a mechanism for adjusting height, distance to the steering column and backrest tilt.

Some models are equipped with electric windows, all cars are equipped with autonomous heaters and hydraulic power steering (power steering). In the latest modifications of the truck, solid windshields were installed, which significantly increased visibility from the cab. When finishing the interior, low-quality, easily soiled and hard materials are used, which causes dissatisfaction among drivers.

Due to the cessation of production, there is no opportunity to purchase a new KamAZ-55111 dump truck; trucks of the latest years of production (2009-2010) can be purchased at a price of 1.7 - 1.9 million rubles. There are still many advertisements on the Internet for the sale of cars from 1998-2003, the cost of such cars does not exceed 500,000 rubles. The ideal option would be to purchase a car removed from military storage. Such trucks have low mileage, but are often sold without a body, for the reason that military equipment is removed from them.

The cost of KamAZ-55111, removed from army storage, reaches 1 million rubles.