It is unlikely that any motorist will be happy with the fact that the Check Engine light comes on on the dashboard. Often this does not bode well.

Yes, sometimes false alarms occur, and in reality there is no malfunction. But in most cases there are problems. They can be determined by the characteristic behavior of the car, as well as by reading error codes recorded and stored in the memory of the control unit.

It is enough to connect to the ECU with a diagnostic scanner or use a smartphone to connect to the unit. A universal error coding scheme allows you to understand what kind of malfunction we are talking about or at least in which of the many systems to look for it.

One of the unpleasant errors is considered to be code P0300. The motorist should know what it means, what caused it and how to fix it.

What does error P0300 mean?

The code in question is directly related to malfunctions on the part of the ignition system.

Error P0300 indicates the presence of misfires in the ignition system, that is, the ignition order is disrupted.

Also, such a malfunction can be described as random multiple misfires that were detected in the ignition system. This is if we take the translation of the English message as a basis. A literal translation yields a similar explanation. This problem is expressed in the form of code P0300 when scanning the memory of the control unit.

If multiple random leaks are detected in the system, the air-fuel mixture ignition system will not be able to function normally. The P0300 error that appears indicates this, helping the driver roughly understand what to look for and in which area to look for a fault.

Error P0300 on some cars varies from 0300 to 0312.

This is due to the fact that certain electronic control units can independently detect in which specific cylinder misfires are recorded. Depending on the final digit in the error code, the motorist understands which cylinder should be entered.

For example, if the engine has 6 cylinders, then the error will vary from 0300 to 0306. If code 0305 appears, then the problem is, accordingly, in the fifth cylinder.

But keep in mind that not all computers determine the exact location of the malfunction, and therefore the diagnostic scanner screen may simply display code P0300. Then, through additional checks, you will have to determine which of the cylinders has leaks.

avtoexperts.ru

Low prices and the ubiquity of OBD scanners have led to the fact that many car owners have them today. It seems like a great idea, connect the device and diagnose the car yourself, it will show everything itself. True, novice diagnosticians often encounter a problem. The car shows errors in non-obvious codes and it is not clear what to do with the received data. Error P0300 is one of the most common (and for some car models it is even a traditional “sore”). It’s easy to find its decoding on the Internet: “random multiple omissions across cylinders.” But not everyone can imagine what to do in practice if they see the combination P0300 on the scanner screen. Let's try to tell you briefly.

Car diagnostics

Where does it come from?

Identifying the problem that leads to the P0300 error code usually does not create difficulties - on the vast majority of cars the check light comes on. Sometimes this does not happen (depending on the ECU settings), but then something is wrong by the car’s behavior: loss of power, shaking at idle, uncertain start.

It is generally accepted that if there is “misfire on the cylinders,” then the problem is necessarily in the ignition system. But this is not entirely true - the ignition may be one of the reasons, but the problem may be elsewhere. If it was not possible to ignite the air-fuel mixture in a certain cylinder, it means either there is nothing to ignite, or there is nothing to ignite, or the conditions in the cylinder are unsuitable for ignition. There are a huge number of potential problems that can lead to this. We will disappoint those who want to get the result right away - not a single scanner will show the reason for the omission, you will have to look for it yourself.

Error P0300

The only way the device can help is to localize the problem by cylinder. If misfires occur in all cylinders, then the device will show error P0300, and if in just one, then instead of the last digit there will be a cylinder number, namely P0301, P0302, P0303 and so on. This makes further search for the problem somewhat easier.

Misfire in the first cylinder

What to check

It’s worth starting with the ignition system, namely the spark plugs. The easiest way to diagnose is to install a known-good set (this is where old, but definitely serviceable spark plugs come in handy, which are wise not to throw away after replacement). If nothing has changed with the other spark plugs, you need to dig further - to the coils and high-voltage wires. You can inspect them visually and try to look for current leaks or breakdowns, which will be clearly visible by sparking in the dark. It is convenient if there is information about which cylinder the problem is, because in this case there is no need to check all of them.

Old and new spark plugs

If everything is fine with the ignition, then the next step is checking the fuel system. The easiest way to start is with the fuel pump - check with a pressure gauge whether it creates the required pressure. On cars with a separate fuel filter, you can check it or even replace it - if it is very clogged, it can restrict the flow of gasoline. Another potential problem area is the fuel injectors. They may also be heavily soiled, but this is difficult to determine by eye. You can either wash and clean them preventively, or try to look for injectors for temporary installation and testing.

Checking the fuel pump with a pressure gauge

Another group of reasons are difficulties with the motor itself. Here you won’t be able to do without serious diagnostics and disassembly, because the problem could be stuck or incorrectly functioning valves, a clogged catalyst, timing belt jump, air leaks, or even low compression. It is no coincidence that we mentioned this only as the third point - it is worth delving into such “depths” only when simpler and more obvious options have already been excluded.

Valve burnout

Finally, you should not discount glitches of the ECU itself, as well as any of its sensors. There may either be no problem at all (the control unit is simply glitchy), or an incorrect signal may come from the crankshaft position, mass air flow sensor, detonation and other sensors, which the “brain” incorrectly interprets. To eliminate this problem, you need to arm yourself with a multimeter and check manually.

Cases from practice

Several interesting examples from practice related to error P0300.

The Lada Largus suddenly began to jerk sharply during acceleration. The incident happened on the highway; the driver did not have a scanner with him, but an LPG system was installed. Switching from gasoline to gas and back showed that the car behaves the same on both types of fuel, which means the problem is something else. As we have already said, the owner of the car did not have a scanner with him, but he had an old set of spark plugs, which he installed. The car drove smoothly and without failures. It’s interesting that before replacing the spark plugs, when the car was twitching, the “check” did not light up, but after the replacement it came on and did not go out until the error was reset by the scanner. The error was precisely P0304.

At one point, the Chevrolet Lacetti's "check" started to light up continuously. The scanner inexorably showed P0300, after resetting the error appeared again. Despite the fact that the appearance of the error did not particularly affect the behavior of the car, the owner turned out to be a passionate person and set himself the goal of getting to the bottom of the truth. He changed spark plugs, coils, high-voltage wires and even the battery, then flushed and cleaned the fuel line. But the error still appeared.

Ignition coil Chevrolet Lacetti 1.8

Finally, one auto mechanic advised him to drive several tens of kilometers in low gear with an engine speed of 5000 per minute. After which the check went out and the error no longer appeared. With a high degree of probability, the valves on this car were heavily coked, working at high speeds helped burn off excess carbon, the engine breathed more calmly and the ignition process began to proceed as normal.

These are just two stories, but there can be as many of them as possible with error P0300, because its very appearance is an excellent illustration of the thesis that even the presence of a scanner does not free you from manually searching for problems when you need to connect a multimeter, tools for assembly and disassembly, and most importantly - logic and common sense.

Conditions for generating an error

In order for error P0300 to be ultimately recorded by the control unit and stored in memory, certain conditions must be met.

- The system must detect the presence of misfires simultaneously in several working cylinders of the engine.

- When idling, the error is recorded in the memory 210 seconds after the engine starts.

- If the speed is 2000 rpm and higher, then the error will persist after 60 seconds.

- To fix P0300 in the ECU memory, it is required that the omission be more than 3.25% of the number of flashes that occur per 1 thousand crankshaft revolutions.

When misfires occur in the engine, the exhaust toxicity in the exhaust system pipe increases significantly.

This problem can cause an increase in the temperature of the catalyst and its further damage in the form of melting of the honeycomb. And replacing a catalyst is very expensive, even on budget cars.

On some cars, in order to reduce fuel burnout in the catalyst and reduce toxicity, the ECU monitors misfires based on data from the camshaft and crankshaft. In addition to registering an error and the appearance of the Check Engine indicator on the instrument panel, the electronics can turn off some injectors in the cylinders where misfires are observed.

When error P0300 occurs

The P0300 code appears when the problem is related to the ignition. The error code can be determined in the range P0300-P0312. The code values directly depend on the number of cylinders and the malfunction in each of them. For example, error code 0301 indicates a misfire in the first cylinder, and so on. When checking with a scanner, it will display a warning message about random multiple misfires on the cylinders. If the error is indicated as 0300, the problem is general sparking.

Error code on display

Nevertheless, it is the 300th code that is recorded by the scanner only when there is a failure in sparking in several cylinders at once. The failure is not stored in memory instantly, but only 210 seconds after the next operation at idle; at medium speeds, the error rate should be no less than once every 75 seconds. In this case, an ignition error in several cylinders is indexed only when more than 3.25% of all flashes are missed. If a specific cylinder is to blame, then we will see another version of this code - 0301, 0302 or 0303, if we are dealing with a three-cylinder Daewoo Matiz engine.

Interesting on the topic: History of the Citroen 2CV Sahara 4×4. Little king of the big desert

Characteristic symptoms

Even inexperienced motorists can predict in advance the display of error code P0300 on the scanner, based on changes in the behavior of their vehicle.

There are several signs characteristic of such an error:

- at idle speed the engine vibrates noticeably;

- similar shaking occurs at low speeds;

- when picking up speed, the car can jerk and throw to the sides;

- fuel consumption increases significantly;

- problems in the form of difficulty starting the engine cannot be ruled out;

- traction drops, dynamics deteriorate, the car fails to accelerate normally.

All this is accompanied by a lit Check Engine light on the dashboard.

Having noticed such signs, it is almost certain that there is a misfire. That is, when connected to the computer with a diagnostic scanner, the code P0300 will be displayed in the memory.

Rare cases of error p0300

On some vehicles of the VAZ family with an electronic on-board computer of the M74 series, errors p0300, p0301, p0302 may appear due to problems in the fuse connector. The connector body itself may appear completely sealed and show no external deformation when its contents fail. It is necessary to replace the connector with a new one to eliminate errors.

On older foreign cars, misfires in the cylinders may occur when the power unit is first started at a temperature below -10 degrees Celsius (or when the temperature of antifreeze/antifreeze in the expansion tank is below -10 degrees Celsius). This is due to the lack of adaptation of cars to Russian operating conditions. However, after the engine warms up, the error disappears.

Thus, the appearance of error code p0300 does not always indicate serious problems in the car’s ignition system. In each specific case, it is necessary to consider all possible options for the occurrence of an error. As stated above, engine misfire is considered one of the most serious problems, so it is necessary to quickly take action to accurately diagnose and eliminate the problem.

Causes

Error P0300 does not appear by itself. There must be appropriate reasons for this.

Misfires are possible in situations where it is not possible to ignite the air-fuel mixture or there is simply nothing to ignite.

Based on this, there are several main reasons for the occurrence of error P0300.

- Faulty power system. The point is that low quality fuel is supplied to the cylinders or there is not enough fuel for normal operation. This is usually due to a dirty filter, low pressure in the fuel line, carbon deposits and contamination on the injectors.

- Problems on the ignition side. There are many elements here that could potentially fail. These are all those components that take part in the processes of igniting the mixture of fuel and air. But most often, a broken high-voltage wire, a dirty or faulty spark plug, a broken coil or ignition module are discovered. Additionally, you can suspect faulty contacts or a violation of the integrity of the wiring.

- Damage to the intake and exhaust system. If error P0300 appears precisely because of problems in this system, then first check the catalyst for clogging. In the vast majority of cases, he is to blame. But it is also possible that there may be air leaks, valve malfunction, low compression, or problems with the timing (gas distribution mechanism).

- Failure of electronic components. There are several sensors, in the absence of signals from which error P0300 can appear. These include crankshaft, knock, camshaft and intake air temperature sensors. The last thing you can suspect is a faulty control unit. But the ECU fails extremely rarely, and its repair is carried out only with professional intervention.

If the scanner shows errors in a specific cylinder, that is, a code like P0301, P0302 or P0304 is displayed, for example, then the reason should be looked for in the ignition system.

When the ECU cannot report problems in a specific cylinder and simply generates an error code P0300, then a more in-depth diagnosis will be required, eliminating all potential causes of its occurrence.

What does error P0300 mean?

P0300 – misfire in one or more cylinders . It is the phrase “misfire” that is completely incorrect and sometimes leads in a completely wrong direction when trying to find the cause of this problem. Indeed, for many, “misfires” are a direct indication to look for a problem in the ignition.

In fact, error P0300 means that the piston stroke did not occur in some cylinder. In other words, one of the cylinders did not do useful work and did not give its impetus to rotate the crankshaft.

But this can happen not only due to problems in the ignition system, but also due to the fault of the fuel system, due to the fault of electrical equipment, due to the fault of the engine iron, due to a violation of the synchronization of processes, etc.

Therefore, it would be more correct to describe this error as follows: misfire in one or more cylinders. Because the mixture in the cylinder did not ignite for some reason, and this reason is not always a misfire!

For ignition to occur in the combustion chamber, all systems and components must fulfill their functions:

- the intake system and power system must provide the necessary air-fuel mixture

- the ignition system must ensure a reliable discharge between the spark plug electrodes

- The timing belt and cylinder-piston group must provide the required compression ratio

- the exhaust system must ensure complete removal of exhaust gases from the previous cycle

- the electrical equipment system must ensure the transmission of power and control pulses with minimal losses

- and all this must be strictly synchronized in time

As you can see, the field for activity in searching for the cause of error P0300 is not very small. Therefore, it is necessary to look for the reason! Search and search again! It’s just that no one will ever tell you the exact culprit of this problem.

To fully understand the meaning of error P0300, I strongly recommend reading the article about the rough road sensor. This will allow you to take a more creative approach to finding the true cause of P0300.

Exactly creative! After all, any diagnosis is the ability to fantasize and think through your thoughts three or four steps ahead. This will help save wasted money and irretrievably lost nerve cells. Because most people immediately rush to extremes and start changing everything - spark plugs, high voltage wires, coils, etc. And very often this does not give the desired result.

On more modern and expensive cars, the life of a diagnostician is greatly simplified, because if there are problems in some specific cylinders, errors P0301, P0302, P0303, P0304 are issued. The last digit in the error code indicates nothing more than the number of the cylinder in which the misfire occurred. Agree that this narrows the search for the culprit of the problem significantly.

We most often have to observe a dry and uninformative error P0300, which, apart from information about misfires somewhere and sometime, does not carry any benefit.

The leaders in the occurrence of error P0300 are VAZ and Chevrolet cars. Whatever you do, you have to take it for granted and periodically struggle with it.

Diagnostics and repair

By carrying out diagnostic measures, you can detect malfunctions and understand why exactly the P0300 error code appeared.

Experts advise adhering to this sequence.

- Check the condition of high-voltage wires. You will need a multimeter set to resistance measurement mode. If the insulation is intact, the resistance will be from 4 to 10 kOhm.

- Check the ignition module or coils. A stand or multimeter will help here. The easiest way to test is by mounting the coil on a properly functioning cylinder. After this, the engine starts and the code is read into the ECU again. If the code has not changed, then the coil is working. We are looking for the reason further.

- Test the spark plugs. They should be dismantled and inspected for carbon deposits and damage. If necessary, cleaning is performed and the gap is set. If the spark plug fails, it should be replaced.

- Compression in cylinders. If it is low or there is no compression, this provokes difficulties with ignition. If compression is normal, move on.

- Injector condition. You can’t do without a diagnostic stand here. One of the options without involving a service station would be to refuel with high-octane gasoline. You need to drive it for 10-20 km at high speeds, and then check the error again.

- Check the fuel filter. This is a consumable that changes periodically. If the filter is dirty or bad fuel is used, the injectors become clogged and misfires occur. Hence P0300.

- Inspect the condition of the gasket on the intake manifold. Sometimes, due to its wear, gaps form and the error in question appears. The gasket should be replaced.

- It would be a good idea to check the EGR valve. It can jam, which leads to the problems in question. To do this, long-term fuel correction is checked in specific suspect cylinders. Differences from optimal indicators should be no more than 1-3%. You can easily find out about the reference values from the manual. With deviations of more than 7%, excess air intake occurs. The valve should be repaired or replaced.

Not all problems can be solved on our own. But it is absolutely impossible to ignore the symptoms that appear with P0300.

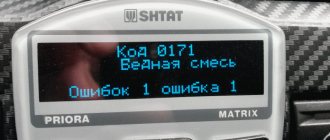

content .. 151 152 153 154 ..Lada Priora (2013+). Cause of P0300

P0300 - Ignition System Misfire (Random/Multiple Cylinder Misfires)

The P0300 code is set in the system when the computer detects a misfire in at least one engine cylinder. In the event of a misfire, excess unburned fuel can enter the exhaust system, which can cause the catalytic converter to overheat.

Causes of error (code) P0300:

- Worn or damaged spark plugs - Worn or damaged spark plug wires and/or ignition coils - Damaged distributor cap (if equipped) - Worn or damaged distributor runner (if equipped) - Damaged fuel injector - Clogged EGR pipes or valve - Incorrect ignition timing - Vacuum leak - Low fuel pressure - Damaged cylinder head gasket - Worn distributor cap - Malfunction of camshaft position sensor - Malfunction of crankshaft position sensor - Malfunction of air flow sensor - Malfunction of oxygen sensor - Malfunction of throttle position sensor - Malfunction of the catalytic converter - Malfunction of the PCM

Symptoms of error P0300

-Check Engine light comes on or flashes -Problems with starting the car engine (the car may take a long time to start or may not start at all) -Stalling engine when the car is stopped -Rough idling of the engine -Unstable engine operation when accelerating the car -Decreased engine power -Increased fuel consumption

Diagnostics when error code P0300 occurs:

-Read all data and error codes stored in the PCM memory using an OBD-II scanner -Clear error codes from the PCM memory and test drive the vehicle to see if the P0300 error appears again -Determine which cylinders are misfiring -Check the wires connecting the ignition coils to the spark plugs for wear and damage -Check the spark plugs for wear and damage -Check the ignition coils, as well as wires and connectors for corrosion and damage -If necessary, replace the spark plugs and coils - If the P0300 code appears again after replacing the above components, check the fuel injector and fuel delivery system - Check the ignition distributor cap and slider for wear and damage - If other codes remain in the PCM memory along with the P0300 code error codes, resolve any errors present, and test drive the vehicle again to see if the P0300 error appears again. -If error P0300 appears again, check the compression in the cylinders. -If the P0300 code persists, the problem may be a faulty PCM. In this case, the module may need to be replaced or reprogrammed.

Repair when error code P0300 occurs:

-Replace faulty spark plugs -Replace worn or damaged spark plug wires and/or ignition coils -Repair or replace clogged EGR pipes and/or valve -Repair vacuum leaks -Repair or replace damaged head gasket -Replace faulty position sensor camshaft -Replacement of a faulty crankshaft position sensor -Replacement of a faulty air flow sensor -Replacement of a faulty oxygen sensor -Replacement of a faulty throttle position sensor -Replacement of a faulty fuel injector -Replacement of a faulty catalytic converter -Elimination of all present errors -Replacement of the ignition distributor cap and slider ( if equipped), as well as wires, spark plugs and ignition coils - If necessary, repair faulty internal engine components - Replace the engine (if the cylinder is damaged) - Replace the faulty PCM

content .. 151 152 153 154 ..

How to Diagnose DTC P0300?

Once a P0300 code is detected, a professional auto mechanic will perform the following steps. You can do the same thing yourself.

Connect your car charger

The charger is extremely important when diagnosing the P0300 code. Because troubleshooting requires that the ignition remain on, and this can lead to battery discharge. As a result, additional error codes will appear, which will complicate the search. A car charger will help preserve battery charge.

Connect OBD2 scanner

An OBD2 scanner is required to scan and resolve the P0300 code. With the help of it, you can track the issues related to the error and also troubleshoot them easily.

For cars manufactured before 1996, an OBD1 scanner is used. If the car was manufactured after 1996, use an OBD2 scanner.

Check wiring

Before replacing any part, first make sure all wires and connections are in good condition. Visually inspect the wiring, check for corrosion and correct if necessary.

Check the spark plugs

Spark plugs do not wear out quickly. But if a cylinder is misfiring, it's a good idea to check the spark plugs and notice any signs of trouble.

If the spark plug appears to be faulty, replace it. As part of regular maintenance, you should change the spark plugs every 30,000 km. You should also check the ignition coils!

Inspect the distributor cap

If you replaced the spark plugs, but the problem persists, check the fuel injectors for defects. If you have an old car, check the ignition distributor cap.

Check other error codes

If the OBD2 scanner detects more than one fault code, take the necessary measures to diagnose and resolve them. After doing this, check if the P0300 code returns.

Replace engine control unit

If you have checked everything above, but the error does not go away, there is a possibility that the problem is related to the control unit (PCM). It may need to be re-flashed or replaced.

Error p0300 UAZ

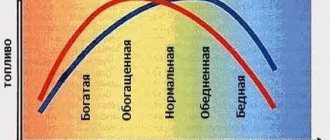

An important condition for the performance of the neutralizer is the correct composition of the working mixture in the cylinders. This mixture should be as close to stoichiometric as possible.

A rich mixture for the neutralizer is not so dangerous, because the fuel that gets into it must burn, and for this you need oxygen, which is not enough in the exhaust gases. It is quite difficult to clog the pores of the neutralizer with soot.

How does the controller “catch” misfires? He does not know the cause of the malfunction, but only records increased uneven rotation of the crankshaft, relying on the readings of the crankshaft position sensor - DPKV. How? Let's say an engine with a firing order in cylinders of 1-3-4-2 is operating in steady state, with the first and third cylinders in order, and the fourth not igniting. The half-turn time of the first and third cylinders is the same, but for the fourth it is longer - the crankshaft has slowed down. Then the second cylinder will speed it up again. The controller detects a malfunction in the engine and marks it as a pass.

The self-diagnosis system in the Euro III configuration closely monitors meter readings. If their sum exceeds 2.5%, a malfunction will be detected and error code P0300 will be recorded. Codes P0301, P0302, P0303, P0304 indicate a specific cylinder failure.

In some cases, self-diagnosis may be wrong for objective reasons. Thus, driving a car on an uneven surface means uneven rotation of the wheels, and with them the crankshaft. To prevent the controller from counting a push of a wheel in a hole as a misfire, a “rough road sensor” is installed in the engine compartment of some cars that meet Euro III standards (including the Kalina VAZ-1118) near the top support of the strut. This is simply a vibration sensor, the signals of which are also calculated by the controller. The controller analyzes strong shocks that affect the uniformity of rotation of the crankshaft and distinguishes them from misfires.

But the role of the second oxygen sensor does not end there - it also participates in fine-tuning the composition of the air-fuel mixture, compensating for the error of the first sensor, which must be taken into account as it ages. Controllers from some companies, comparing the readings of both sensors, calculate the aging coefficient of the converter, on the basis of which diagnostic specialists base their forecasts.

Modern catalytic converter for exhaust gases. The housing 6 contains a ceramic or steel carrier 5; it is permeated with numerous small honeycombs, creating a maximum contact surface with the exhaust gases. Their composition is controlled by oxygen sensor 1. The carrier is fixed in the housing by parts 2 and 3. The honeycombs are coated with aluminum oxide 4, on top of which a thin layer of catalysts is applied - platinum and rhodium. The purpose of these rare metals is to accelerate the oxidation of hydrocarbons and carbon monoxide to carbon dioxide, and reduce toxic nitrogen oxides to nitrogen. The neutralizer starts working after heating to 300°C. The optimal operating temperature range is from 400 to 800°C. The closer the neutralizer is to the engine, the faster it warms up to operating temperature. Therefore, the barrels under the bottom of the body were replaced by neutralizers combined with the exhaust pipe - catalytic collectors. The carrier in them is metal or ceramic. The film of noble metals is thin, but during normal operation of the neutralizer they are not consumed, and therefore they cope with their task for a long time and successfully. True, provided that the temperature regime was not exceeded, and the composition of the air-fuel mixture in the cylinders was maintained as close to stoichiometric as possible.

Troubleshooting

Usually, with P0300 codes on the dashboard, drivers go to car service centers. Our specialists have all the necessary diagnostic and repair equipment to quickly identify the problem and fix it. If the car is equipped with modern “electronic brains”, then identifying the exact location of the problem will not be difficult using the latest devices. The autoscanner connects to the diagnostic connector of the computer and immediately reads all errors in the computer memory.

But if the car has been in operation for over 10 years and no longer corresponds to modern ideas about the operation of an on-board computer, you will have to look for the root cause and eliminate the error at random. Typically, car service specialists begin searching for problems with the ignition system, smoothly switching to adjacent components.

If you have experience working with cars and electronic systems, you can eliminate errors yourself.

Step one

The first step is to check the ignition module itself (that is, the coil and high-voltage wires). Most often, it is because of broken wiring insulation or because the coil is heavily oiled that ignition problems arise. The normal resistance of the wires in the ignition system is 4-10 ohms. There is only one way to identify problems in individual coil units: swap them with the working elements.

All elements of the ignition system must be inspected for wear. It is quite possible that due to natural wear, all the problems with misfires in the cylinders arose.

It is necessary to understand that the work is carried out directly in a system that has high voltage. Therefore, compliance with all safety regulations is necessary!

Step two

After diagnosing the system, they usually move on to spark plugs. The following factors can affect the correct operation of each spark plug:

- gap increased during operation;

- strong oil deposits on the surface of the spark plug;

- electrode damage;

- broken insulator;

- low compression in the cylinder.

These factors should be taken into account when checking spark plugs. When measuring compression, low or absent compression indicates a low proportion of compression and, accordingly, problems with ignition of the air-fuel mixture. If spark plugs have been used within the last 30,000 kilometers, they must be replaced with new ones.

It wouldn’t hurt to check the condition of the valves.

Step three

If the problem has not been solved after diagnosing the ignition system and spark plugs, you need to carefully check the operation of the injectors. However, this cannot be done without a stand. Only a service center can identify clogged fuel injectors and clean them.

Step four

If error code p0300 is still displayed on the dashboard, then you will need to check the operation of the fuel filter, pump, and valves. In addition, it won’t hurt to change the fuel in the gas tank - due to low-quality fuel, deviations in the operation of the engine’s dosing systems are possible.

It is often these mechanisms, not directly related to the ignition system, that cause problems in the operation of the cylinders.