Where is the fuel pressure regulator located?

A diaphragm valve-regulator, which is subjected to fuel pressure on one side and spring force on the other, is used to more accurately dose fuel and maintain constant pressure in the system. A VAZ fuel pressure regulator of this type is installed in those systems that have a return line. In them it is located in the fuel rail. Less commonly, the part is installed in the fuel tank, but such systems do not have a return line. How the fuel pressure regulator works depending on its location is described below.

Measuring pressure: several ways

There are several ways to determine the pressure in the ramp. So, you can purchase special equipment that diagnoses fuel pressure. This is a kit that, in addition to the pressure gauge, includes an adapter and a drain. The price for such an assortment is only 1.5 thousand rubles, but there are so many benefits.

The second option is to go to a service station and ask the workers to measure the pressure. In Moscow, such diagnostics cost no more than 500 rubles.

The third option is to measure the pressure using a tire air pressure gauge. Its only drawback is that the initial values of the scale cannot be considered as accurate. As a rule, pressure gauges are equipped with a scale of up to 16-20 atm, and the measurement limit for fuel is only 5-7 atm. Measurements in this case may be inaccurate due to the error falling into the initial scale values. For this reason, it would be more correct to use a pressure gauge with a scale no higher than 7 atm.

Pressure is measured as follows:

- take a tire pressure gauge;

- a fuse is wound onto the nozzle and an oxygen tube with a diameter of 9 mm is inserted (securely secured with clamps);

- Be sure to protect the generator with something (a damp cloth) so as not to cause a fire hazard;

- provide access to the fuel frame fitting by unscrewing the internal nipple;

- To prevent gasoline from splashing out, it is recommended to relieve the pressure in the system in advance by removing the required fuse;

- Place the second end of the oxygen tube onto the ramp fitting and secure with a clamp;

- Start the engine and take pressure readings.

2.8-3.2 atm is normal.

There are other ways to measure pressure. Here's one of them.

- Provide access to the fuel pump module fitting. You will need to insert a tube with an internal diameter of 8 mm into the fitting;

- The other end of the hose is put on the pressure gauge.

- Take readings.

- Take a pressure gauge with a hose from the compressor.

- Unscrew the cap from the fitting to check the pressure in the fuel system.

- Unscrew the spool valve from the fitting, doing this carefully so that the fuel does not splash too much (you can initially release the pressure).

- Pull the pressure gauge hose with a clamp onto the fitting and tighten it with a screwdriver until it stops.

- Start the engine and, looking at the pressure gauge scale, take readings.

Location of the regulator in the fuel rail

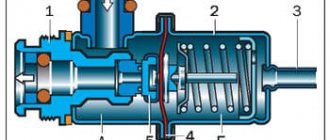

One of the most common placement schemes: the VAZ fuel pressure regulator is located on the fuel rail. The principle of operation of the element is to pump fuel through the line from the fuel tank using a fuel pump. The regulator is under pressure from the fuel. The RTD itself consists of two separate cavities-chambers, separated by a membrane: a fuel chamber and a spring chamber. Through special inlet holes, fuel enters the regulator, which puts pressure on the membrane on one side; on the other hand, a spring and the pressure of the intake manifold presses on it. If the fuel exerts greater pressure than the spring force and inlet pressure, then the regulator opens, due to which part of the fuel is discharged into the “return”. Excess fuel is sent back to the fuel tank via the return line.

Location of the regulator in the fuel tank

The RTD is placed directly in the fuel tank in systems that do not have a return line. The advantage of such a system is the absence of an additional pipeline. The required volume of fuel is supplied directly from the tank, that is, excess fuel does not accumulate in the engine compartment, and accordingly, there is no need to send it back to the tank. Thanks to this design, the fuel does not overheat and evaporates less, which is an additional advantage.

Electronic circuit for regulating fuel pressure

The fuel pressure in the system is adjusted using an electronic circuit, the design of which does not imply the presence of a mechanical regulator. The pressure in such systems is controlled by an electric fuel pump. The electronic control system installed in it records the voltage and regulates the volume of supplied fuel. The advantages of using a fuel pressure regulator sensor are maximum savings and reduced fuel heating.

Only a strictly limited amount of fuel is supplied to the engine injectors, necessary for the selected operating mode of the engine and the specific conditions of its operation. Excess pressure does not rise to a critical level due to the presence of a relief valve.

Some useful tips

To ensure that the fuel pressure regulator does not cause you trouble and works as long as possible, use these tips.

- When planning to replace an RTD, buy only a branded device recommended by the manufacturer.

- Fill your car tank with only high-quality fuel. Do not use fuel additives of unknown origin.

- Do not forget to promptly replace the fuel filter.

- At each maintenance check the fuel pressure in the system. If problems are identified, correct them promptly.

- If you find problems with the regulator, do not delay replacing it.

The fuel pressure regulator is an element of the injection engine power system, which allows you to maintain the required fuel pressure in the fuel injectors at different operating modes of the internal combustion engine. In other words, the overall performance of the injectors and the stability of the engine depend on the serviceability of the fuel pressure regulator (FPR).

Considering that the pressure regulator is actually a diaphragm valve, failure of this element can greatly affect the operation of the engine. In this article we will look at the principle of operation of the regulator, highlight the main signs of its malfunction, and also talk about how to check the fuel pressure regulator.

Read in this article

The main symptoms of fuel pressure regulator problems

When diagnosing the engine power system, it is necessary to take into account the signs of a malfunction of the fuel pressure regulator. The main symptoms associated with RTD problems are a decrease in engine power and its inability to reach the required speed. Signs of a malfunction of the fuel pressure regulator and, accordingly, the engine are as follows:

- The engine idles unsteadily and stalls.

- Fuel consumption increases, power decreases.

- The engine responds slowly to the accelerator pedal.

- When accelerating the car and when changing the throttle, jerks and dips appear.

- The car does not gain speed and does not accelerate.

RTD defects: spring

The main problem with the regulator is the weakening of the spring, which causes premature draining of fuel into the return line. This leads to starvation of the engine: it does not have enough fuel to operate at high speeds, when the accelerator pedal is pressed, or in transient modes. A faulty regulator spring causes low fuel pressure in the fuel rail, which leads to a decrease in engine power, problems with the ECU and unstable operation of the engine.

RTD contamination

Another malfunction of the regulator is its contamination and reduced throughput. In this case, the engine stalls regardless of which specific operating mode is selected. If the regulator is heavily contaminated, the pressure in the system increases sharply, and this can lead to fuel escaping through the sealing parts and joints. Vehicle manufacturers always consider the possibility that injector and fuel pump performance will deteriorate over time. This problem is solved by pumping more fuel into the fuel pump. Excess fuel increases pressure if it cannot return back to the return line.

Useful tips

These tips will come in handy when measuring blood pressure.

- If the pump is working, then it makes sense to check it for normal pressure supply. You can do this, as mentioned above, by connecting a pressure gauge, or you can use another method. For example, measure the current at the pump terminals. It must be equal to the voltage of the machine's on-board network. In other words, 12 V for cars and 24 V for trucks.

- It is always recommended to relieve the total system pressure before diagnosing pump or rail pressure. This helps release residual pressure, which improves accuracy. As mentioned above, it is reset by turning off the fuse and starting the engine for 3-5 minutes (this is enough for the pressure in the system to drop to 0).

- In some cases, the fitting on the fuel frame may be missing and then measuring the pressure becomes more difficult. But there is another way out - connect the pressure gauge to the fuel hose through an adapter.

- When measuring pressure, it is recommended to pay attention to the behavior of the pressure gauge needle when the internal combustion engine is operating in idle mode. The arrow should tremble a little, but not oscillate at full strength. The latter indicates a clogged coarse mesh or a malfunction of the DDT.

Regulator jammed

The pressure regulator located in the fuel rail may begin to jam at certain intervals. Symptoms of such a problem include pressure drops in the system and jerking of the car. Another sign of a faulty fuel pressure regulator, which is no less common, is the banal wear of all parts: in other words, over time the valve completely exhausts its life. The service life of this engine element depends on the quality of the fuel, the presence of various impurities in it, the operating mode of the vehicle itself and many other factors.

Fuel pressure regulator diagnostics

In terms of its symptoms, a malfunction of the RTD is in many ways similar to malfunctions of the fuel filter or fuel pump. It is worth noting right away that if, during diagnostics of the fuel system, faults were found in the RTD, then the optimal way out of the situation would be to replace the fuel pressure regulator. This is explained by the fact that replacing individual parts, washing and cleaning the device will not return it to full functionality. Considering that the cost of the RTD is very affordable and acceptable, repairing the fuel pressure regulator is simply impractical.

You can diagnose the RTD yourself in one of the simplest and most effective ways: check the fuel pressure in the fuel system. This is done using a pressure gauge. It is measured with the engine idling; The pressure gauge is connected in parallel with the vacuum hose between the fitting and the fuel hose.

The measurements taken show pressure fluctuations in the system. It should increase, while being in the range from 0.3 to 0.7 Bar. If such indicators were not detected, then it is necessary to reconnect the fuel pressure regulator hose and reuse the pressure gauge. The fitting plug is unscrewed to measure the fuel pressure at the end of the fuel rail. The plug has a special sealing ring: you need to check it for integrity - it should not be elastic. If there are still defects on it, then it is changed either separately or together with the plug.

The main causes of error P0087

- Malfunction of the fuel pressure sensor;

- The fuel pressure control valve is faulty;

- Poor performance of the fuel injector (does not hold pressure);

- The pusher is worn out (located in the injection pump).

In addition to these common faults, it may be time to replace the fuel filter or if the fuel pump located in the tank is unstable (sometimes there is simply a loose contact in the connector). Therefore, you should start by checking the pressure using a pressure gauge in the low and high pressure lines under different engine operating conditions.

Of course, there may be more serious reasons related to the fuel injection pump or control unit, but we do not take them into account, since the average driver is unlikely to be able to eliminate them on his own.

When looking for the cause of pressure loss in the fuel system in various cars, such as Audi, Citroen, Ford or Kia, in order not to rack your brains in vain, pay attention to the features of their fuel systems, since problems are often the most likely. based on the weaknesses of car brands. For some it is a connection on the pump in the tank, for others it is a pressure regulator on the fuel injection valve, and for some it is simply filling the injector in the reverse order.

Owners of diesel vehicles run the risk of experiencing a drop in pressure in the fuel line. The presence of this malfunction is indicated by a lit Check Engine light, as well as a number of symptoms. The best way to determine if your car has fuel line pressure problems is to run a scan tool, which will often prevent the unit from working properly again. Considering that the price of a fuel pressure regulator is quite affordable, any attempts to repair it are pointless.

Measurements should show system pressure fluctuations within the specified range. The fuel pressure should be between 0.3 - 0.7 bar. If this does not happen, you can first try replacing the vacuum hose and then repeat the measurements. To check the fuel pressure at the end of the rail, unscrew the connector plug. The plug also has a special O-ring. The said ring should be checked for integrity and the element should remain flexible. If any defects are found, the ring or the entire plug must be replaced immediately.

Fuel pressure regulator repair

After the diagnostics of the system is completed and the sealing ring is inspected, the umbrella is unscrewed from the fitting. You can unscrew it using the metal valve cap. The pressure gauge hose is then connected to the fitting, then the entire structure is secured using clamps. Pressure measurements are carried out only when the engine is running. Standard pressure readings should be 2.9-3.3 kg/cm2. Then the hose is carefully disconnected from the fuel pressure regulator, and the pressure gauge readings are recorded: the pressure should increase to 70 kPa from 20 kPa.

The fuel pressure regulator is changed if the readings remain too low or zero. Replacing this part is not difficult: you can do it yourself in a regular garage. Before starting the procedure, all pressure is released from the engine power system. To do this, unscrew the nut securing the fuel pipe, after which the bolts that secure the regulator itself to the fuel rail on most cars with injection engines are unscrewed.

Subsequently, the regulator fitting is carefully removed from the hole in the fuel rail, after which the RTD is completely dismantled. Before this, the fuel pipe is completely disconnected. The last stage is the installation of a new or working regulator into the ramp, after which the functionality and serviceability of the entire fuel system is checked using a pressure gauge.

Before installing a new fuel pressure regulator, experts recommend lubricating the O-rings with gasoline: this will make installation of the new part easier. A similar procedure is performed when replacing the o-rings themselves.

How to check fuel rail pressure

The procedure for taking pressure measurements is as follows. First, connect a fuel pressure gauge to one end of the hose and secure the connection with a clamp. We unscrew the cap on the fuel rail (on the side opposite to the one where the RTD is installed). We place a container under the fitting to collect fuel. Using the nipple cap, press the central protrusion, thus releasing the fuel pressure in the system. This process is required! Next, without removing the container, unscrew the locking nipple completely.

When the remaining fuel has drained into the container, put the other end of the hose on the fitting and secure it with a clamp. Turn on the ignition and wait until the gas pump pumps fuel into the system. We check the pressure and compare it with the recommended one.

After this, we start the engine and take measurements at idle. Checking the functionality of the fuel pressure regulator is carried out with the vacuum hose disconnected from it and with the power unit running. If the pressure has increased to 3.3 kg/cm2, the regulator can be considered operational. If it has not changed, the RTD has most likely become unusable.

Similarly, we measure pressure when the return hose is closed, as well as in the gas overflow mode.