The quality of the fuel system is influenced by many factors. As a result, this affects the performance characteristics of the vehicle as a whole, including power, consumption, and stability of the internal combustion engine.

One of the monitored parameters is the pressure in the fuel rail.

Timely diagnostic and test operations can be carried out independently using hand tools.

What does the fuel rail look like?

This is what the fuel rail looks like

To begin with, it should be noted that measuring the pressure in the fuel rail must be done when you are diagnosing the fuel supply and power supply system of the vehicle. Simply put, the procedure in question is necessary in order to determine the presence of breakdowns in the fuel supply to the injectors.

In what cases is it necessary to check pressure?

The pressure in the fuel rail should be checked if certain problems arise with the fuel system. The main signs of a malfunction include the following factors:

- Increased fuel consumption;

- Unstable engine operation at idle speed;

- Engine tripping occurs;

- An increased CO content is observed in the exhaust gases.

Sometimes the problems listed above may indicate a problem with the electronic control unit. Therefore, before starting to check the pressure in the fuel rail, the driver is recommended to make sure that the ECU is working properly.

The fuel pump does not pump: reasons

If the fuel pressure is below the permissible level and the pump stops working, you need to figure out the reasons why the fuel pump is not pumping fuel.

If there is no noise from the pump, that is, it does not turn on when the ignition is turned on:

- You need to check the 12 Volt power supply, the ground on the fuel pump chip. If the relay does not operate, add the electronic control unit “brains”. If there is no voltage, find and eliminate the cause in the vehicle's electrical circuit.

- Next, if there is voltage and ground, check the integrity of the wires inside the pump; to do this, you need to remove it from the tank and disassemble it. A common occurrence on VAZ modules is burnout of the chip in the fuel pump housing. Then you have to change both the chip and the top connector on the module body.

- If everything is in order here, but the engine does not start, connect 12 volts from the battery to the module and check the noise of the pump. If the fuel pump doesn't work, it's dying. Replace the fuel pump motor.

If the fuel pump works but does not pump gasoline, check:

- Rail fuel pressure

- Clogged pipelines, fine and coarse filters.

- Fuel pressure regulator for performance. It is located on the ramp or in the fuel pump module in the tank.

It is common for water in the tank to turn into ice in winter. Accordingly, the pump works, but does not produce the required pressure.

If the electric fuel pump works, then it doesn’t work:

- Disassemble the pump module

- Check the chip for contact burnout, as shown above.

- Check the relay and contacts on the brains.

There are times when the fuel pump stops working while driving. This is a very unpleasant situation, especially in the city, in traffic and traffic jams.

When the fuel pump is replaced and it burns out again, you need to check the fuel system completely.

What should the fuel rail pressure be?

Unlike the internal combustion engine cycle of a Diesel with a Common Rail injection system, in the fuel rail of a gasoline engine with distributor injection the pressure on the valves rarely exceeds 5 Atm. A working fuel pump is capable of delivering up to 7 Atm., but the RTD will dump excess gasoline back into the tank.

There is no single normal pressure value that is suitable for all types of power systems. Therefore, before checking, you should definitely refer to the repair and operation manual for your car.

What does too low fuel pressure in the rail indicate?

- The fuel pump needs to be replaced. On VAZ cars with a power supply system without return, it is possible to measure the pressure before the RTD. Therefore, when checking, you can eliminate the possibility of a regulator malfunction. The pump can also be checked after removal. It is enough to connect the device to the outlet fitting, place the housing in a tank with gasoline, and then supply power to the pump from the battery.

- Clogged fine fuel filter or fuel inlet mesh in the tank. In winter, there is a risk of water freezing in the fuel tank. Due to the reduced capacity of the filter element, after turning on the ignition, the pressure will increase slowly. In some design options, it is impossible to replace the coarse fuel filter separately, so you will have to change the fuel pump module assembly.

If, after turning off the ignition, the pressure gauge needle begins to drop quickly, the system is leaking. Most often, the cause is a faulty pressure regulator, which, after stopping the engine, should prevent gasoline from quickly draining into the tank. Also leading to a rapid drop are leaky injectors, which begin to leak fuel into the cylinders, and a faulty fuel pump fuel return valve.

You need to monitor the operation of your car regularly. This also applies to such an event as measuring the pressure in the fuel rail. Today we will talk about why this procedure is needed, as well as how to measure the pressure in the fuel rail.

Signs of Problems

In addition to the diagnostic reasons for resorting to this procedure, the pressure is also measured when you observe some problems in the operation of your car. These include unstable engine operation with characteristic knocking, jolting and jerking. Also, you need to think about it when the idling speed of your car has become insufficiently even and smooth.

In some cases, you may notice that the car begins to “trouble” when some of the cylinders seem to refuse to work normally. It is quite possible that your car’s fuel consumption will increase significantly, which is noticeable even without special devices. And, in the most difficult cases, the engine may even begin to stall while it is idling - this indicates that the engine is running on a lean mixture.

If you go to a service station, they can also measure the CO content in the exhaust gases. If this parameter is too high, then this may indicate the problems described above.

So, we have figured out the reasons, so we can proceed to direct measurements in the fuel rail. This procedure is not much different from measuring the air pressure in the tires.

Engine won't start

This is the main symptom of a faulty fuel pump. In the summer heat, a dying fuel pump may appear. The junction of the impeller with the rotor axis expands, and it rotates. You should check the fuel pressure from the rail and from the pump directly.

The service life of the fuel pump is determined by the owner's use of the vehicle. What is required for the fuel pump to last longer and not fail:

- Check the presence of water in the tank. For prevention, pour any pure alcohol into the tank. It mixes with water and burns out through the exhaust. There is a moisture displacer available in stores. Contains isopropyl alcohol.

- When purchasing other displacers or desiccants, carefully read the ingredients, as there may not be alcohol, but other chemical compounds may be present that will clean the tank and clog the injectors.

- It is advisable to have a fuel level of at least half the tank. This minimizes the water-gasoline ratio and the pump cools better.

- Change the fuel pump mesh every 30,000 km, and the fine filter (barrel) every 15,000 km. It is in this filter that all sediments and water accumulate. Causes of pump failure due to compressed water mesh are a common occurrence.

This is interesting: Possible reasons why the car does not engage in gear

The fuel pump is humming

The fuel pump may hum or squeak for a variety of reasons. The fuel pump may hum due to the nature of the system design. If there is a suspicion of a malfunction of the electric fuel pump, you need to check the fuel system completely.

If the fuel pump makes noise at high ambient temperatures, you need to check whether the gas tank is breathing. Check the gasoline vapor pipe and absorber valve. If you cannot find the cause, drill a hole in the filler cap.

After replacement, the new fuel pump may make short-term noise. Wait about 5 minutes, if the pump continues to hum, carry out the procedures above.

The car does not accelerate well

Loss of traction when the fuel pump fails is a fairly common symptom number two. The cylinders begin to work poorly, there is no normal injection by the nozzle, and ignition of the mixture becomes ineffective. The injector produces an uneven spray, and the flow rate of the mixture into the combustion chamber drops. Thus, if the electric fuel pump fails, the engine power is reduced.

If there is a loss of traction, the fuel pump does not necessarily break down. You need to check the filter, fuel line, and fuel pressure regulator for blockages.

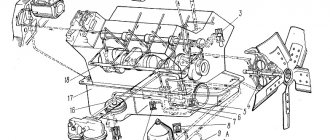

Fuel system filter

The fuel system filters of an injection engine are used to protect against damage to the main elements of the fuel system.

Fine filter

The fine filter is installed outside the car tank. On Lada cars with injection engines, a fine filter is installed under the bottom in the rear part in the area of the beam, secured with a clamp. This filter prepares fuel for the injectors. Differences between fine filters depending on the engine.

In 1.5 liter versions of the engine, the filter is connected to the fuel system via a metal threaded fitting.

In 1.6 liter versions of the engine, the filter is connected to the fuel system using quick-release plastic fittings.

Coarse filter

This type of filter is installed in the car tank. The coarse filter is connected directly to the fuel pump and secured in the glass of the fuel pump. Serves for coarse fuel cleaning and preparing fuel for a fine filter.

How to measure?

Of course, a special set with fittings, hoses and a pressure gauge is the ideal choice. But, if one is not available, then the kit can be assembled from improvised means.

The central unit of the measuring equipment is the pressure gauge. During measurements, the maximum pressure will fluctuate within 6 atmospheres, so the device must be designed for at least 7-8 atmospheres. As for the graduation of the scale, it is more convenient for it to be in atmospheres.

Valuable practical advice is to use a pressure gauge to measure tire pressure: the scale is convenient, and the nominal bore of the tube is 8 mm. It is worth noting that a gas pressure gauge is also suitable for similar purposes. However, the diameter of the outlet fitting is usually larger. For example, for a 1.0 MPa device this value is already 9 mm.

Attention! 0.1 MPa is approximately 1 atmosphere.

In addition to the pressure gauge, you need a rubber hose and a pair of clamps. This is the minimum kit. If you need to turn off the fuel pressure regulator on systems without a “return” or measure the pressure at the inlet to the fuel rail, you will need a plug and an adapter fitting, respectively. Since the design of the switching unit between the fuel line and the ramp can be different, the adapter must be selected locally. As a first approximation, it is worth noting that there are threaded and quick-release designs.

Making a pressure gauge for testing yourself

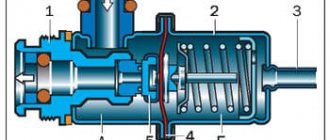

Device design for measuring pressure in the fuel system:

- mechanical pressure gauge with a measuring scale up to 6 kgf/cm2. Even a pressure gauge for checking tire pressure is suitable for express measurements;

- a hose with a suitable internal diameter and adapters for connecting hoses and connecting to fuel line fittings. The necessary parts can be purchased at refrigeration supply stores. Please note that the design of fuel lines on modern cars uses specific quick-release fasteners.

The type of measuring device will depend on the characteristics of the fuel line design of a particular vehicle. For example, a fitting is standardly installed in the fuel rail (feed system with return) on VAZ cars, through which measurements can be made. To check the pressure in the fuel rail, just unscrew the spool valve and secure the hose connected to the pressure gauge to the fitting using a clamp and FUM tape.

On sale you can find ready-made kits for measuring fuel pressure in the rail. The pressure gauge will come with a set of fittings for connecting to the most common types of fuel supply systems. Before purchasing a device, be sure to check whether the kit includes an adapter suitable for measuring the pressure in the rack of your car.

Fuel pressure test kits

Fuel pressure is an important parameter of injection and diesel power systems, which a carburetor engine does not have. Without pressure, gasoline and diesel will not overcome the resistance of the injector, and with low pressure the engine is prone to failures, malfunctions, non-functioning cylinders and lack of idling.

If you want to check the health of your car's fuel system and prevent future breakdowns, you'll need a fuel pressure tester. A fuel pressure gauge allows you to check the condition of your vehicle's fuel system. It shows what pressure the fuel system has.

It is worth measuring the fuel pressure when the engine is lacking full power. The tool performs the following diagnostics:

- Degree of brush wear;

- Precision operation of the dosing valve;

- Fuel pump performance;

An increase in fuel consumption and a decrease in engine power sometimes depends not only on the injectors, but also on changes in the optimal pressure in the fuel system. Accordingly, testing of the fuel pump and pressure regulator is required. Digital pressure testers (smc 1002) provide maximum measurement accuracy than analogue ones.

Reasons for measuring

- After idle time, the engine must be turned with the starter for a long time to start. A clear sign that the fuel pressure in the ramp is too low when cranking.

- The engine does not start, but the fuel pump in the tank turns on. The reason may be a drop in pump performance, as a result of which sufficient pressure is not created in the ramp to start the engine.

- The car idles due to the mixture being too rich or lean. In this case, the Check Engine light will most likely light up on the dashboard.

During the diagnostic process, you should not make hasty conclusions, since a mixture that is too lean or rich can be caused by a malfunction of the injectors, mass air flow sensor, air pressure sensor, IAC, lambda probe, or air leaks into the intake manifold/exhaust system.

- The engine does not develop speed, stalls when you sharply press the gas, the car jerks during acceleration.

- After warming up, the car loses power and stalls. Most likely, the deviation in the fuel system from the nominal values is due to overheating of the fuel pump.

Effect on engine operation

To understand the purpose of measuring fuel pressure in the rail, it is enough to know the principle of dosing a portion of fuel on engines with an injection system. The amount of gasoline supplied to the cylinders is controlled by the duration of opening of the injectors. The opening time is calculated by the ECU based on the values at each operating point of the engine (load, amount of incoming air and other parameters).

Accordingly, if the pressure in the fuel rail is two times lower than required, then for an equal time of opening the injectors, half as much fuel will enter the cylinders.

The fuel rail is just a storage tank for gasoline. Therefore, pressure measurement is primarily used when diagnosing the fuel pump and checking the fuel pressure regulator. The RTD is designed to maintain constant pressure in the rail. It can be installed in the tank (power system without return) or built into the fuel rail (excess gasoline enters the tank through the return hose).

Measuring process

Fuel pressure must be measured in 4 operating modes, that is, 4 different measurements will be required.

With the ignition on

When the ignition is turned on, the fuel pump must supply the system with the fuel needed to start the engine. Therefore, we simply turn on the ignition and look at the readings. The pressure must be above 3 atmospheres.

This is interesting: How to check the ignition coil with a multimeter

Idling

Just start the engine and look at the pressure gauge readings. Normal pressure is 2.5-2.7 atmospheres.

When the return line is turned off

Almost all modern cars have a fuel pressure regulator. It is aimed at preventing excessive pressure from being created in the system. When the limits are reached, it resets the pressure to normal. We clamp the return pipe and get the result on the pressure gauge.

It should be about 7 atmospheres. If you have a 6 atmosphere pressure gauge, the needle should be “filled up”.

Under loads

And one more stage of measurement is the measurement of pressure drops under loads. Just apply the throttle (you can just “tug” the throttle cable if you have a mechanical one) and observe the changes.

During recharging, the pressure should be about 3 atmospheres, and then drop to the idle value - that is, up to 2.5 atmospheres.

Diagnostic instructions

The first step is to free access to the ramp and fitting installed at the end of the manifold. Remove elements that interfere with measurements - air duct, filter housing, crankcase ventilation pipe, etc. (the list of parts depends on the car model). Proceed to measuring, following the instructions:

- Unscrew the protective plastic cap from the diagnostic fitting on the ramp.

- Place a cut-off plastic container and use a cap to unscrew the spool valves to release the pressure previously pumped up by the pump. You can press the valve or turn the spool 2-3 turns.

- Place one end of the gasoline hose onto the pressure gauge fitting and secure with a clamp. Unscrew the spool from the manifold, pull the second end of the hose onto the pipe.

- Turn on the ignition, and the electric fuel pump will pump fuel into the system. Make sure there are no leaks at the joints of the diagnostic tool.

- Start the engine and record the fuel pressure in the rail using the pressure gauge.

Advice. It is better to take readings from the device twice - after turning on the ignition and starting the engine. If you notice a difference, you need to additionally check the regulator and fuel pump.

The pressure level in the fuel supply circuit depends on the design of the system. In cars where the RTD and the discharge tube - “return” - are located in the engine compartment, the pressure gauge should show 2.7 Bar. The upper and lower permissible limit is 2.7–3.0 Bar. If the measured values are outside the specified range, you should continue the diagnosis and find the cause of the problem.

On many cars, including VAZ, the pressure regulator and the fuel return hose are located next to the fuel pump. The normal manifold pressure for such machines is 3.8 Bar, the maximum value is 4 Bar.

If during the measurement process periodic pressure surges within 0.2 bar are observed, the primary strainer needs to be cleaned or replaced. Typically, it is installed in the gas tank along with an electric pump.

Self-diagnosis

The pressure level that the pump produces is 6 atmospheres. Therefore, it is important to achieve tight connections.

To seal, you will need fum tape and a pipe with a diameter of 9 millimeters. So, how to check the fuel pump pressure yourself? Open the hood and look for a ramp with injectors. It is usually covered with a plastic casing. We remove it and see the cap in the form of a wheel nipple. Unscrew part of the ramp. Be careful - gasoline may spill out under high pressure. How to relieve pressure? To do this, remove the fuse for the fuel pump and start the engine. After a few seconds of operation it will stall. There will be no more fuel in the system from the pump to the injectors. You can safely unscrew the ramp that goes to the fuel pump. How to check further? We put on the hose with our pressure gauge, seal it with fum tape and secure it with a metal clamp for reliability.

Next, the assistant turns on the ignition. At this moment you are looking at the pressure gauge readings. If the obtained values are below five atmospheres, it means that the element is not able to generate the required pressure.

How to choose or make your own fuel pressure gauge?

One of the conditions for the safe operation of a car with an internal combustion engine is the proper operation of the fuel system. Pressure gauges are used to monitor its condition and find problems. How they work and work, what types exist, is described in the article, as well as recommendations for selection and instructions for making the device yourself.

Description of the fuel pressure gauge

Design and principle of operation

Features of setting up the pressure gauge

Instructions for making the device yourself

Tools and materials

Video “Do-it-yourself fuel meter for a car with an injector”

What about the injectors?

An alarm bell indicating that the entrance to the fuel rail will still have to be opened is detected even at the stage of diagnosing the fuel pressure regulator. At the moment the return line is compressed, the pressure rises slightly. It is also noteworthy that at this moment the injectors begin to actively overflow, causing the engine to operate unstably. The same thing is observed in a system without “return”, when the output from the RTD is muffled.

The final diagnosis is made based on measuring the pressure upstream of the ramp (the inlet chip/nut is disconnected and a pressure gauge is connected to it). In this case, we exclude clogging of the fuel line in the fuel pump-fuel rail section. If the pressure is restored to the passport 5-6 atmospheres, then the problem is with the injectors.

In conclusion, I would like to note that the pressure in the ramp is 2.5-2.7 atm. and 5-6 atm. at the pump outlet are diagnosed under different conditions: with the engine running and in ignition mode, respectively.

Troubleshooting

No pressure in the fuel rail? Causes:

- Clogged fuel filter;

- Clogged fuel pump filter;

- Fuel pump malfunction;

- Malfunction of the fuel pressure regulator (FPR). And with high blood pressure too.

If the pressure in the fuel rail gradually drops, the cause may be:

- leaking fuel pump connections;

- leaking injectors;

- fuel pump malfunction.

Let's check it like this. We clamp the leading rubber hose of the fuel rail:

- the pressure has become stable - the fuel module is leaking or the pump is faulty;

- the pressure drops - the injector(s) are leaking.

Checking the RTD. Connect the pressure gauge hose to the outlet fitting of the fuel pump and turn on the ignition:

- the pressure is low but stable - this means the RTD is faulty and is releasing pressure too intensely.

If the pressure in the fuel rail is within normal limits, we look for the causes of engine malfunctions elsewhere.

Keywords: power system Lada Granta | power supply system for Lada Kalina | power supply system for Lada Priora | power supply system for Lada Largus | 4x4 power system | power supply system for Lada Vesta | power system lada xray | Lada Granta engine | Lada Kalina engine | Lada Priora engine | Lada Largus engine | 4x4 engine | Lada Vesta engine | lada xray engine | Niva power system | Niva engine | universal article

13

4

AvtoVAZ began shipping the new LADA XRAY Cross Black and Granta Cross Quest to dealers

Video presentation of LADA XRAY from Steve Mattin

Reference information for undergoing maintenance of Lada Largus (articles and refueling volumes)

All about rear fender liners (lockers) Lada XRAY

Car won't start after DIY replacement

This is a fairly common problem. It must be said that the car should not start immediately after replacing the pump. The pump first needs to create operating pressure in the system. To do this, you need to turn on the ignition for a short time (a few seconds). The key must be inserted into the lock, but not turned. The lights on the dashboard should light up. Then you can rotate the engine with the starter for five to ten seconds. If nothing works out, then you should take a break for half a minute and repeat your actions.

If the engine does not start even after several cranks with the starter, this indicates that shortcomings were made during assembly and connection of the fuel pump. Another reason could be a malfunction of the new pump. There is also a possibility of a planned blocking or failure of the car’s security system.

When a car owner installs and connects a new unit, various failures may occur: sticking of valves on the pump, breakage of contacts, terminals and connectors. When such problems arise, you need to try to determine their nature. Did the breakdown occur in the mechanical or electrical part of the fuel pump? The easiest way to find out is if there is a problem with the power supply. You also need to remember that the fuel filter may become clogged.

In order to accurately determine the causes of the problems, you need to make sure that the fuel rail does not contain gasoline. After this, you need to re-remove and connect the pump directly from the battery or dimensions. This method of connecting the pump is the best for quickly checking it.

This is interesting: Air filters for cars: how to change them yourself

A car owner must take care of every part of the car. It is best to gain knowledge about its structure and repair yourself. It is important to acquire skills in diagnosing and solving problems in the operation of individual machine systems. This also applies to the functioning of the fuel pump.

Many drivers encounter breakdowns on the road, far from cities and service points. In such a situation, you can only rely on your own experience. Knowledge about the signs and causes of malfunctions in the fuel pump will help solve problems at the initial stage of their occurrence. It will also save effort, time and a significant part of personal funds.

How to check relay operation

What is a fuel pump relay? This is a special device that ensures the supply and termination of electrical power to the fuel pump at the command of the electronic control unit (ECU). On vehicles equipped with an automatic transmission system, a relay will be activated when the heavy acceleration mode needs to be activated.

Where is it located? The location of the relay depends on the model and make of the machine. On some vehicles it is located close to the injection control unit. On others, it's under the dashboard near the fuse box. There are other options.

Signs of problems at work

The fuel pump is controlled using a relay as follows: the key inserted into the lock is turned, thus turning on the ignition; After this, the fuel pump runs for about two to three seconds. This is enough to build up pressure in the fuel rail. A click should then be heard, indicating that the relay turns off the mechanism. After this, the pump will operate if two conditions are met: the engine is rotated by the starter at startup and the motor subsequently operates independently. When the ignition is turned off and the engine stops, the relay immediately or after one second turns off the fuel pump.

There are models where the relay limits the speed of the internal combustion engine if its number approaches the maximum. Fuel stops flowing to the engine and the speed drops. The power supply to the pump is then restored.

There are fuel systems in which the fuel pump starts working not when the ignition key is turned, but when the car owner opens the door. This helps to start the engine and create the required pressure inside the fuel system in advance.

Due to malfunctions in the relay, the device is deprived of the necessary power. It may buzz or hum for a very long time. It does not stop working a few moments after reaching the required pressure level in the fuel system. If there is a malfunction in the relay, the engine may not start at all because the pump does not pump fuel. When the car constantly hums or hums, the relay gets stuck and the battery energy is wasted to continuously rotate the pump motor.

How to check it yourself

First of all, you need to find the fuel pump fuse and its relay to check their operation. The relay may become hot and operate untimely or not operate at all due to problems with the fuse.

Checking the fuel pump relay yourself

The simplest test method is to install a working device. Another way is to connect a control light in place of the relay. When the ignition key is turned, the light should light up.

Even during the test, you can install a jumper on the terminals. If after turning the ignition key the pump starts to work, this indicates problems in the operation of the fuel pump control device.

Another method of testing a relay can be considered using the example of the VAZ 2110. The fuel system pump relay in this car is located near the fuse. For diagnostics, you need to take a multimeter or test lamp with a current not exceeding 0.25 A.

After this, you need to measure the current voltage at the terminals of the device one by one. At the same time, it is important to fix the contact going to the mass. This way you can definitely find out whether the relay needs to be replaced. If the light does not light, then the fuse is fine. In this case, you need to examine the wiring leading from the relay to the electronic control unit.

It should not be ruled out that there may be malfunctions in the motor control unit. In addition, you need to know that the relay may malfunction; it may not function normally or become stuck due to malfunction or poor installation of the alarm. The reason for this is that the security and anti-theft interlock devices stop the power supply to the fuel pump.

Video: Disassembling and ringing the fuel pump relay

Recommendations for selection

In order to be able to periodically and as necessary monitor the operation of the fuel system and its condition, you cannot do without pressure gauges for measuring fuel pressure. It is enough for a motorist to have one such device at his disposal. You just need to determine in advance which one is needed and which one is suitable for completing the planned tasks. To ensure that the pressure gauge for checking the pressure in the fuel supply system gives accurate measurement parameters, it is recommended to choose a high-quality device. If you contact the sellers, you will find a huge variety of models and manufacturers. But the main role will be played by the design and technical characteristics of the device. All of them are divided into 2 large groups.

- Analog. They're mechanical. Presented in the form of an arrow and a measuring scale. With their help, the user sees what pressure is currently in the fuel rail. The design of analog devices is as simple as possible, which gives such an obvious advantage as reliability. If you correctly understand the nuances of the application, the displayed parameters will correspond as closely as possible to the actual pressure in the system, that is, the error will be insignificant. But mechanical devices have one drawback. This is a fairly large error range. It is especially pronounced when it is in the hands of an inexperienced motorist. But the demand for analog pressure gauges is still high. This can largely be explained by the low cost.

- Digital. An alternative to mechanical meters and a more modern version of a pressure gauge is a digital device. It is characterized by more accurate results, as well as minimal error. For such pleasure you will have to pay a little more than for the analog version. All measurement data is displayed on the display. At the same time, the user has the opportunity to choose between different units of measurement, which makes the digital device more functional and versatile. The accuracy of the measurement directly depends on the accuracy class. Here it is important to wisely choose a device that is suitable specifically for measuring pressure in an automobile fuel rail.

Some actively use a tire pressure gauge, that is, a device designed to monitor the pressure in the tires of a vehicle. There is nothing surprising here, since devices for measuring tire, oil and fuel pressure operate on an identical principle. But there are certain features that you should definitely be aware of before buying such a supposedly multifunctional device. To measure the pressure in the fuel system rail of a car, the limit values should be at the level of 5-7 atmospheres. If air pressure is measured, then the interval varies from 16 to 20 units. If you take an air pressure gauge and connect it to the fuel rail, the error will be very high. The device will not be able to show the correct parameters. But even tenths play a role here.

When choosing an analog-type measuring device, be sure to make sure that the proposed scale will be convenient for reading information. Sometimes the font is very small, or the scale is divided in a way that is not entirely clear and easy to read. In this case, the measurement limit should be 5-6 atm. If you have decided on the model, then finally check the tightness of all connections. This is extremely important because you will be working with fuel. As for digital devices, everyone decides for themselves whether they are worth buying or not. Their cost is noticeably higher than mechanical or analog pressure gauges. And such costs are not always justified. If your financial condition allows it, and you don’t mind spending this money on a pressure gauge, feel free to buy it. Moreover, it is better to choose devices from famous brands with a high level of accuracy.

Sources

- https://LifanoVod.ru/kak-izmerit-davlenie-v-toplivnoj-rampe-kogda-neobxodimo-ego-proveryat/

- https://diagnozbibike.ru/kak-proverit-benzonasos/

- https://autobann.su/kak-proverit-davlenie-v-toplivnoi-rampe.html

- https://www.autoscaners.ru/catalogue/?catalogue_id=testers_fuel_pressure

- https://zen.yandex.ru/media/id/5beafefd84edee00aa843c51/kak-samostoiatelno-izmerit-davlenie-v-toplivnoi-rampe-avtomobilia-i-zachem-eto-nujno—5c195ae994ee4e00aadf0242

- https://studiofiring.ru/heating-system/check-of-pressure-in-a-fuel-stage-on-cars-of-vases-and-a-fret-with-an-injector-engine/

- https://avto-idea.ru/remont/kak-proverit-toplivnyy-nasos-v-avtomobile-svoimi-rukami/

- https://DriverTip.ru/zhizn/kak-vybrat-izgotovit-manometr-davleniya-topliva.html

[collapse]

Do-it-yourself diagnostics and testing of the fuel system

Fuel system diagnostics can be done at almost any service station, but who wants to overpay for such a trivial matter? So let's figure out how to diagnose it yourself. It is necessary to begin diagnosing the fuel system by measuring the fuel pressure in the fuel rail. Based on the measurement results, a diagnosis will be made and the culprit identified.

Checking fuel pressure yourself

What you need to check fuel pressure:

- Pressure gauge with scale up to 10 atm.

- Hose with a diameter of 10 mm.

- Two 20 mm clamps.

We need to assemble a device for checking fuel pressure with our own hands. We put the hose on the pressure gauge fitting and secure it with a clamp so that the hose sits tightly on the fitting and does not fly off when pressure appears.

Checking fuel pressure is carried out in several modes:

- When the ignition is turned on.

- When idling.

- When changing gas.

So, let's proceed directly to the verification.

Before checking the fuel pressure in the rail, it is necessary to relieve the residual pressure in the rail.

Relieving fuel pressure in the fuel rail, methods:

First way:

Remove the power plug from the fuel pump cup (located under the rear seat). Start the car with the plug removed and let it run until the car stalls.

Second way:

Remove the fuel pump fuse (located under the center panel F3 (15A) ). Start the car with the fuse removed and let it run until the car stalls.

After the pressure in the fuel rail has been released, you can begin measuring the fuel pressure.

For safety, you should cover the generator with a thick cloth to prevent fuel from getting on the generator and possibly catching fire.

- Measuring fuel pressure begins by twisting the plastic cap of the ramp fitting.

- By unscrewing the spool valve from the ramp.

- We connect the device for measuring fuel pressure to the ramp fitting and securely tighten the hose with a clamp.

- We turn on the ignition of the car and wait until the gas pump pumps fuel. The pressure gauge should show a pressure of at least 3.6 bar (for a 1.5 liter engine, at least 2.8 bar).

- We start the engine, the pressure gauge readings should remain at the same level or increase.

- We re-gas the engine, the pressure gauge readings should stay in place or increase.

- We stop the engine, the pressure gauge readings should drop slightly or remain unchanged, and a slight drop in pressure in the rail is also allowed. The pressure in a working fuel system completely disappears within a few hours.

The fuel pressure measurement is completed; to quickly relieve pressure and install the spool valve in place, you can use the tips for relieving fuel pressure in the rail.