Problems with the engine (troits, jerks, pulls poorly), causes

Does the car jerk at low speeds or when accelerating?

Is the engine running rough and the Check Engine light on? Has the car lost its dynamics and doesn’t drive like before? In this article we will tell you about all the possible causes of these malfunctions and how to solve the problem. It is worth noting that the causes of malfunctions are similar for all modern Lada cars (Kalina, Granta, Priora, Largus, Vesta, Niva or XRAY), because AvtoVAZ equips them with engines with identical characteristics.

It is recommended to start searching for a problem with diagnostics (reading errors). If this is not possible, then we first perform a test (or temporarily install a known working spare part/sensor), and only then replace the faulty parts.

If the engine idles or the car jerks when accelerating (driving), possible reasons:

Electronic control unit

According to the observations of experts, most often the phenomenon of floating speed at idle is inherent in injection-type engines, in which regulators “assigned” to it - electronic engine control units - are responsible for idling. They are designed to constantly analyze data on the functioning of the idle speed, and when failures occur, to give the appropriate mechanisms a command to correct the errors. Therefore, the cause of floating speed is often a breakdown in the electronics.

Having discovered the effect of floating speed in a car, the driver needs to take this seriously so that the situation does not worsen and does not lead to serious engine damage, and its large-scale repair, as we know, is always expensive. Therefore, it is better to conduct a thorough diagnosis of the car, and if in the process it is discovered which part or unit is faulty, replace it with new ones, after which the engine will work normally.

#Engine#RPM#Problem

OTHER ENGINE AND SYSTEMS FAULTS

- Compression in the engine cylinders is low.

- The cylinder head gasket is damaged.

- The engine control system is faulty.

- The valves of the gas distribution mechanism are burnt out and leaky.

- The exhaust system is leaking.

- The valve clearances are not adjusted (8-valve engines only).

- The hydraulic pushers are faulty.

- The engine air filter is dirty.

- Vacuum hose connections are leaking.

Have you encountered power failures or observed unstable engine operation? What was the reason?

Source

Problems with the engine (troits, jerks, pulls poorly), causes

Does the car jerk at low speeds or when accelerating? Is the engine running rough and the Check Engine light on? Has the car lost its dynamics and doesn’t drive like before? In this article we will tell you about all the possible causes of these malfunctions and how to solve the problem.

It is worth noting that the causes of malfunctions are similar for all modern Lada cars (Kalina, Granta, Priora, Largus, Vesta, Niva or XRAY), because AvtoVAZ equips them with engines with identical characteristics.

It is recommended to start searching for a problem with diagnostics (reading errors). If this is not possible, then we first perform a test (or temporarily install a known working spare part/sensor), and only then replace the faulty parts.

If the engine idles or the car jerks when accelerating (driving), possible reasons:

Other engine and system malfunctions

- Compression in the engine cylinders is low.

- The cylinder head gasket is damaged.

- The engine control system is faulty.

- The valves of the gas distribution mechanism are burnt out and leaky.

- The exhaust system is leaking.

- The valve clearances are not adjusted (8-valve engines only).

- The hydraulic pushers are faulty.

- The engine air filter is dirty.

- Vacuum hose connections are leaking.

Have you encountered power failures or observed unstable engine operation? What was the reason? We solve similar power unit problems in the comments or on the forum. Let us remind you that along with misfires, other engine malfunctions may appear, for example, floating speed.

Found an error? Select it and press Ctrl+Enter..

Source

The engine jerks at idle: the main reasons

The idle mode involves the operation of the internal combustion engine at the lowest speeds, when the gas pedal is not pressed and air is supplied to the cylinders bypassing the throttle valve. As a rule, in idle mode, the power unit does not transmit torque to the wheels of the car, since this mode is activated when the car is parked with the engine running, when coasting in neutral gear, as well as when the clutch is depressed to change gear, etc. .d.

Let's sum it up

As you can see, there are many reasons why engine speed fluctuates and fluctuates. Moreover, in some cases, unstable speeds can appear both on a cold and hot engine, in idle mode, in transient modes, under load, etc.

It is important to understand that if the engine speed fluctuates (hot, cold or constantly), this malfunction is quite serious and requires a quick solution to the problem. Otherwise, further operation of the engine may lead to breakdowns of the power unit and its expensive repairs.

Why do you need to clean the throttle valve periodically? How to clean the throttle valve, training and adaptation of the throttle valve after cleaning, useful tips.

At idle the speed “floats”: why does this happen? The main malfunctions associated with idle speed on gasoline and diesel engines.

Why the engine may have high idle speed. The main reasons for high idle speed on an injection engine and engines with a carburetor.

Why the speed drops and the engine stalls when the clutch is depressed: possible causes of the malfunction. Diagnosis of the problem, checking, replacing individual elements.

The engine stalls at idle: what to check. Possible causes of malfunction on engines with a carburetor, injector, and diesel power plants.

Floating engine idle speed when cold. Basic malfunctions, symptoms and identification of breakdowns. Unstable idling of the diesel engine.

Why does the engine jerk at low and idle speeds?

So, if the car jerks at idle, there may be several reasons for such a malfunction. Most often, problems affect the ignition system and power supply system; less often, elements of the engine control system or parts inside the internal combustion engine fail.

- First of all, damage to the engine mounts should be excluded, since increased vibrations from the internal combustion engine in this case often occur precisely at idle. If everything is normal with the airbags, then twitching of the power unit may occur due to malfunctions of one cylinder.

- The most common cause is spark plugs, as well as high-voltage armored wires. Often, the spark plug may be damaged, dirty from carbon deposits, etc., as a result of which there is a spark on it, but it is very weak or unstable, and is supplied at the wrong angle.

Damage to the insulation of high-voltage wires when a spark “breaks through” also leads to similar symptoms in the form of motor twitching. The ignition coil, switch, ignition module, and distributor also deserve additional attention. Depending on which ignition system is installed on a particular engine, all its elements must be checked one by one.

- After diagnosing the ignition system, you need to move on to the fuel and air supply systems. As a rule, injection nozzles may be faulty or dirty. Fuel filters are also checked, and fuel lines should be inspected for leaks.

- Let us also add that in cases where the engine jerks at idle, you need to make sure that not only the fuel filter, but also the air filter is in good condition.

The fact is that if the air filter is dirty, the engine may not have enough oxygen to prepare the correct fuel-air mixture. The same is true in cases where airing occurs in the power system or excess air is sucked in at the inlet.

In any case, the mixture may turn out to be too rich or lean, and the normal and timely combustion of such a charge in the cylinder does not occur. At the same time, in such a situation, the spark plugs become even more covered with soot, and sparking further deteriorates.

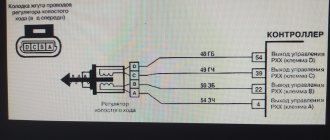

- On injection engines, the cause of twitching at idle in some cases is the electronic engine control system (ECM). In such a situation, it should be taken into account that this system includes a whole group of various electronic sensors and actuators that exchange data with the controller (ECU).

- Another possible cause of engine jerking at idle is problems with the throttle valve and problems with the IAC (idle air control). The idle air control itself is a stepper motor that closes the channel for supplying air bypassing the throttle valve.

In case of incorrect operation and malfunction of the regulator, as well as in the accumulation of a large amount of dirt and carbon deposits on the damper, the idle speed becomes unstable. In this case, the engine not only jerks, but the idle speed often fluctuates greatly.

Such “floating” of revolutions can appear on a cold engine and disappear as it warms up. Also, in some cases, the speed jumps and floats both cold and hot. To solve the problem, you need to clean the throttle and also check the IAC. It is also important to consider that on many cars, after cleaning, it is also necessary to train the throttle valve.

Carburetor and injector

In the first case, difficulties in operation are caused by a clogged nozzle, an incorrectly adjusted XX engine or a failed valve.

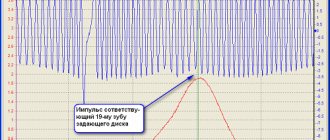

The speed on the injector fluctuates most often due to difficulties with electronic elements. Here, failures are possible not only in the throttle valve, but also in the location of the crankshaft. Failure of the EGR or heater, clogged filters, spent spark plugs, burnt electrodes, breakdown of wires.

Useful tips

Quite often, engine jerking at idle can occur precisely when the internal combustion engine is cold. In this case, you should pay special attention to the motor temperature sensor.

Failure or malfunctions in its operation often lead to the ECU receiving a premature signal to warm up the power unit, while the engine is still cold.

A similar situation can occur when air leaks appear or problems arise with the air flow sensor (MAF). In this case, the control unit incorrectly calculates the actual amount of air that enters the cylinders, as a result of which the correct ratio of fuel and air will be disrupted (disturbance of mixture formation).

First, let's find out why the speed on carburetor power systems may fluctuate.

Most often this happens due to the fact that there is an air leak in the carburetor.

The reason for this may be:

- brake booster hose,

- solenoid valve,

- carburetor gasket wear.

When excess air enters the carburetor, the mixture becomes lean. The dose of gasoline remains the same, but more air is supplied. This ratio of fuel to air makes it difficult to ignite in the cylinders, which leads to the fact that the engine may not start at all, and if it does, the idle will fluctuate.

To eliminate this problem, the carburetor must be completely checked. An effective way is to check whether foreign air is being sucked in. To do this, you need to remove the air filter, then start the car and shut off the air supply to the carburetor by closing the channels with your palm. If there are no suction, then the engine will begin to stall, but if this does not happen, then this indicates that there is a suction, because in this case the carburetor will look for places from which it can get air. If everything is in order and the problem is not in the carburetor, then you should look for another reason.

The reason may also be a stuck crankcase ventilation valve. In this case, the engine speed will change every 3 seconds. This happens despite the fact that the power system is disrupted, and the speed begins to float.

In diesel engines, the speed may fluctuate as a result of the fuel pump supply blades being jammed. This usually occurs due to rust that occurs when water gets into the fuel pump.

If you decide to leave your car for a long time, then before doing so, pour one liter of engine oil into the gas tank and remove this fuel. This is done so that all engine parts are covered with an oil film, thereby protecting the engine.

What's the result?

As you can see, at the initial stage of diagnosis, if the engine twitches at idle, you should start with the simplest:

- check spark plugs and high-voltage wires;

- assess the condition of the air and fuel filter;

- if the car has a carburetor, clean and adjust the carburetor;

- on the injector, check and wash the nozzles;

- perform computer diagnostics of the engine;

If the diesel engine jerks at idle, then problems with the injection pump should also be added to the general list of possible problems. The pump has many moving elements, damage to which or clogging can also lead to jerking or obvious tripping in the cylinders.

Electrical problem

The first thing you need to check when the speed on gas fluctuates is the electrical component of the car, namely: spark plugs, high-voltage wires, or switch.

We described in detail how to choose the right spark plugs for a car with a gas installation in this article.

Read about what high-voltage wires are and how to check their functionality here.

If the above-mentioned problems with the electrical equipment of the car are solved, and the reason that the speed is floating on gas has not been identified, you should pay attention to the components of the gas equipment.

When accelerating the car, the engine jerks: how to find the cause of the problem

Quite often, when operating an injection or carburetor car, you may encounter that the engine jerks during acceleration. In other words, after sharply pressing the gas pedal, there is no clear response from the power unit, a pause-failure occurs, the speed increases in jerks, etc.

As for failure, that is, when the engine “stubs” during acceleration, there is a noticeable delay in the reactions of the internal combustion engine after the driver sharply presses the gas to increase the speed. Moreover, in both cases, when you smoothly press the gas pedal, the speed increases without jerks or delays, that is, quite predictably.

It is quite obvious that operating a vehicle with such faults is not only difficult, but also dangerous. While driving, there is no opportunity to overtake, quickly change lanes, etc. To solve the problem, the engine requires in-depth diagnostics, since it is first necessary to clearly determine the cause of the breakdown.

Next, we will talk about why an injection engine or carburetor engine jerks during acceleration, as well as what methods can be used to identify and fix problems that have arisen.

Why the engine jerks during acceleration: the main reasons

Let's start with the fact that most of the reasons why such deviations occur in the operation of internal combustion engines are often associated with the following systems:

The culprit may be either the carburetor itself (dirty jets, incorrect settings, etc.) or the fuel pump. At the same time, we should not exclude the possibility that excess air is being sucked in somewhere, which causes the carburetor engine to jerk when accelerating the car.

As for modern injection engines, a number of common problems will be similar to engines with a carburetor. At the same time, problems that are unique to units with injection injection are also added to the list. Let's focus on the possible causes of dips and jerks.

- First of all, let's start with the ignition system. As a rule, if problems arise in this system, there is a loss of power and the unit consumes more fuel. Usually spark plugs, high-voltage armored wires, and ignition coils fail. We also note that on injection cars the problem may lie in a faulty camshaft position sensor (CPR).

If no breakdown is detected, you should unscrew the spark plugs and inspect them. The electrodes must be intact, excessive carbon deposits are not allowed, the insulator must not have cracks, etc. Checks may also require armored wires. In some cases, after replacing the spark plugs and spark plug wires, the engine stops jerking during intense acceleration.

However, it happens that these methods do not bring the desired result. In such a case, it is necessary to check the camshaft position sensor separately.

Let us also add that the ignition timing (ignition timing, ignition timing) also deserves special attention. If the car jerks when accelerating, the ignition may be too early. On carburetor internal combustion engines, it is necessary to manually set the specified angle. On the injection unit, adjustment occurs automatically. However, we should not forget that interference with the factory firmware of the ECU (especially on cars with gas equipment) or problems with sensors can lead to malfunctions of the ignition system.

To quickly check the ignition timing, you need to accelerate the car to a speed of about 50 km/h. After this, a higher gear is engaged (for example, 4th), and then you will need to sharply press the gas pedal. Detonation will immediately appear in the engine, which should not last more than a couple of seconds with a normally adjusted OZ.

- Now let's move on to the power system. At the very beginning, you should make sure that the fuel tank is filled with fuel suitable for the vehicle and meeting quality standards. Very often jerks and failures occur when low quality fuel was filled. In some cases, a “check” may also light up on the dashboard of fuel-injected cars.

What to do?

Excess air in the cylinders - check the hoses for leaks by blowing. It is also possible to detect cracks by applying WD-40 to the entire surface of the tubes and inspecting them. The solvent dries fastest near cracks. You can close the holes with electrical tape or change the hose.

Replacing the IAC . Measure the resistance with a multimeter. Indicators in the range of 40-80 Ohms indicate a poor condition of the regulator.

Cleaning the crankcase vent valve . Disassemble the crankcase, wash it in a special product to remove traces of oil. Dry and install in place - the issue is resolved.

Replacing the air flow sensor. Repair is often not possible, so replacement is the best solution.

Adjusting the engine idle speed. A suitable tool is a screwdriver.

Replacing the solenoid valve on the carburetor. Replace the used element with a new one.

The XX jet can be cleaned without dismantling. Pour in the product and wait five minutes. Remove any remaining dirt with compressed air.

Treatment of fuel injection pump blades from rust . All that is needed is that before refueling, an anti-corrosion agent is sprayed into the neck of the fuel tank. 0.2 liters of engine oil is added to the tank to create a protective layer on the blades.

Washing and correct position of the remote control .

Remove it (on a cold engine) by disconnecting the wires. Place the part in a container and treat it with a special product (use a brush if necessary). Dry the clean throttle body with a lint-free cloth and return it to its original place. The second method is carried out on a hot engine using the same cleaning aerosol. Disconnect the regulator and fill it with product. After a couple of minutes, start the engine and continue cleaning. Don't be afraid of white smoke - this is a sign of burning greasy pollution. Connect the part and configure it by programming the desired opening size.

Air leaks and sensors

As you know, the injection engine is equipped with an electronic engine control system (ECM), which completely controls the operation of the power unit. This system is actually multiple sensors and a controller (ECU). Based on sensor readings, the control unit adjusts the SOP, increases or decreases the amount of fuel supplied, prepares a fuel-air mixture that will be optimal for a particular engine operating mode, etc.

If the signal is incorrect, then fuel supply may not be implemented correctly. In this case, a failure appears, which the driver feels in the form of a delay in pressing the gas, that is, a failure. Note that such failures are especially relevant on those cars with an “electronic” gas pedal. In other words, there is no direct connection to the throttle body.

Let us also add that the throttle valve must be cleaned periodically, and also on many cars it is necessary to carry out the procedure for adapting the throttle valve after cleaning this element. To avoid problems, experienced drivers clean the throttle valve at least once a year. This procedure is performed for preventive purposes.

In garage conditions, when there is no diagnostic equipment, checking electronic sensors is carried out by elimination; a multimeter tester is used for diagnostics.

- As for air leaks, this phenomenon may well lead to jerks and failures during acceleration. If excess air is sucked in somewhere, then the ECU loses the ability to correctly determine the amount of air entering the engine.

As a result, the mixture of fuel and air will be prepared incorrectly; instead of a power-rich “rich” mixture, a lean working mixture will be supplied to the cylinders. The suction may occur at the intake, and problems in the fuel supply system are also possible. In any case, depressurization requires immediate detection of the problem area.

Gas injectors

If we are talking about 4th generation HBO, then one of the most likely problem areas in the system is the injectors. It often happens that when switching from gasoline to gas, the revolutions fluctuate for a couple of seconds, after which the car starts to work normally. The problem in this case should be sought in leaking injectors. Most often, the problem occurs during the first frost, when there is a sharp drop in ambient temperature. When you first switch to gas, its pressure in the fuel line is low, therefore there is not enough of it for all cylinders and the speed on gas begins to float.

The following malfunctions of gas injectors are distinguished:

- Natural wear and tear of internal elements.

- Dirty and stuck injectors.

- Incorrect operation due to malfunctions of the computer or failure to receive a signal from the control unit to the injectors.

- Air leaks often occur due to leaky connections or gaskets.

- Initial installation of injectors that are not suitable for your car.

- Incorrect setting and calibration of injectors to the engine parameters of your car.

In case of contamination or complete failure of the injectors, you should first assess the general condition of the internal elements of the injector by first disassembling it. If normal contamination occurs, you can get by by cleaning the elements and then calibrating the injectors. If you cannot limit yourself to cleaning, you should use a rem. kit or replace the injectors with new ones.