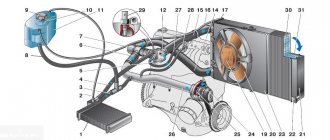

Cooling system diagram

The cooling system diagram for the 402 internal combustion engine is quite simple. So, the engine is cooled using a coolant, which can be water, antifreeze, and in rare cases even antifreeze. The fluid flow pattern is circular and looks like this: radiator - pipe - thermostat - water jacket - water pump - pipes - radiator.

Of course, in addition to the main elements through which the coolant moves, the system includes a fan, temperature sensor, and heater elements.

To understand more clearly, it is worth considering the direct coolant circulation scheme, as well as the elements that are included in it:

I - with one heater; II - with two heaters and an electric pump (for vans with two rows of seats and buses); 1 - expansion tank; 2 — thermostat; 3 — coolant temperature indicator sensor; 4 - radiator; 5 — radiator drain plug (cock); 6 - fan; 7 — fan drive belt; 8 — coolant pump drive belt; 9 — coolant pump; 10 — drain valve of the cylinder block; 12 — electric pump of the heating system; 11, 13 — heater valve; 14 — additional heater radiator; 15, 16 — main heater radiator; 17 — main thermostat valve; 18 - bypass valve.

Replacing the coolant of a Gazelle car with a ZMZ-406 engine

All work should be carried out only on a cold engine.

Unscrew the expansion tank cap and open the heater tap.

We put a hose of a suitable diameter on the drain tap pipe.

1. Having lowered the hose of the radiator drain valve into a container (volume of at least 10 liters), open the valve and drain the coolant.

2. Remove the hose from the radiator tap

By placing it on the tap located on the left side of the engine, we drain the remaining coolant from the cylinder block

4. Close the drain taps

We fill the system with water through the expansion tank.

We start the engine for a few minutes.

We drain the water and fill it with fresh water and flush the cooling system again.

To avoid spilling liquid, insert a funnel into the expansion tank and slowly, in a continuous stream, pour coolant into it.

Source

Device and elements

The ZMZ 402 motor cooling (cooling system) has a simple design and consists only of basic elements, which makes independent repair possible. Let's consider the main elements of the coolant system, as well as possible malfunctions and repairs.

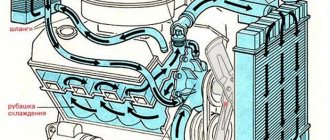

Thermostat

The most common problem is the thermostat. First of all, this is due to low-quality spare parts. The thermostat acts as a control valve that controls the flow of coolant circulation through the engine. As you know, the 402 engine has a large and small “coolant” circulation circle.

When starting the engine and warming it up, the coolant moves in a small circle, which makes it possible to quickly warm up. When the temperature reaches 60-70 degrees Celsius, the thermostat opens and the liquid begins to circulate in a large circle through the radiator.

The operating temperature of the motor is 87-103 degrees Celsius. If the engine does not heat up to this value, or exceeds it, this means that the thermostat has a malfunction. Often, as practice shows, this is a jamming of a part associated with wear or scale formation inside the housing.

Changing the part is quite easy yourself. To do this, it is necessary to drain the coolant to a level below the thermostat location. Then, you need to unscrew the supply pipe and remove the cover in which the product is located. We remove the old part and install a new thermostat, not forgetting to change the seal. Further operations are carried out in the reverse order from disassembly.

Water pump

The water pump plays a very important role. It circulates coolant throughout the entire system. In the ZMZ 402 engine, this process is constant and forced. The pump has several elements, and therefore it can be disassembled and rebuilt. The water pump is located in the front of the cylinder block and is driven by a belt.

The most common malfunctions are wear of the shaft bearings and wear of the impeller. These parts, as well as the shaft itself, can be found for sale on the car market. Replacing parts is quite simple.

To do this, you need to dismantle the part from the car, and then replace the worn parts with new ones.

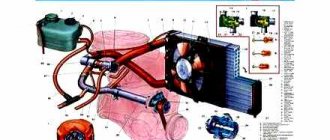

Radiator and fan

The radiator of the cooling system is installed from the factory with a copper 3-row, but many car enthusiasts during operation change it to a 3-row aluminum one. Thus, the motor cools much better, which ensures more stable operation and increases safety.

The part acts as a cooler, which is cooled using a counter flow of air and a fan. The cooling fan on the 402 engine has a forced system and only works when the crankshaft is spinning. Thus, it is very difficult to overheat the motor. The fan impeller is located on the crankshaft pulley and in close proximity to the rear of the radiator, which ensures a high degree of cooling of the part.

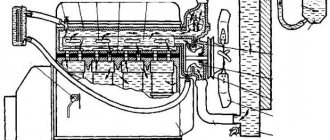

Pipes and water jacket

The pipes serve as connectors between different parts of the cooling system. When parts wear out, coolant leaks and will lead to a decrease in the fluid level. The consequence will be constant overheating of the motor, followed by deformation and deflection of the block head.

The water jacket acts as a heat absorber directly inside the cylinder block, after which everything is transferred to the radiator for subsequent cooling. Wear, or rather corrosion, of the water jacket will lead to leakage of the “coolant”, which can serve as a water hammer if the coolant gets into the cylinders.

GAZ 31 Eazy29 › Logbook › Modernization of the ZMZ 402 cooling system

At the same time, the cylinder head began to convert the cooling system from standard 402 to 402.5. The following articles served as theoretical material for modernization:

The first step was to install a 402.5 cylinder head gasket in order to increase the flow of coolant washing the cylinder liners and to solve the problem of overheating of the central cylinders and pulling out the studs in the center of the block. I couldn’t find the required gasket in stores, but I made it myself: I took a regular asbestos gasket, sample 24D, with triangular holes for the coolant channels (I always use the simplest gaskets without sealant, a la Soviet), put the original gasket, sample 402, on top of it, and noted the location of the two holes behind the fourth cylinder and the punch knocked them out. The result is a gasket like this:

The second stage was the installation of half-inch plumbing fittings for an 18mm hose on the pump and cylinder head tank. Comparison of the internal cross-section of new and old fittings gives an idea of the increase in coolant flow through the cooling system:

For this modernization, a tank model 402.5 without a fitting and with an internal thread is required. Mine also had a hole for the coolant temperature sensor, which I plugged, and screwed a half-inch fitting for the hose into the second hole. Having previously leveled the contact planes on the cylinder head and tank, I installed the latter without a gasket, using Renzosil sealant.

When purchasing plumbing fittings, you need to be careful; initially they gave me 16mm, instead of the required 18mm, I had to change the fittings on the already installed cylinder head and pump, which is not very convenient.

Then I modified the pump: I drilled out the hole for the fitting and cut a 1/2-inch conical thread. Using a drill, I selected the flash from the casting inside the pump body so that it would not block the hole for the coolant inlet. The pump I have is made by KENO, Chinese, but so far there are no complaints about it, the axle does not play, and the bearing does not make any sounds. I assembled it again without a gasket, using sealant, the processing of the planes of the body and cover was initially carried out at a high level, operation for 3.7 thousand kilometers has shown that no leaks have arisen.

The next step is to install the thermostat housing sample 402.5 with a throttled hole on a small circle. Fortunately, after disassembling/reassembling many engines, I had the right amount of such stuff. If you don’t have such a housing for the thermostat, you can throttle the hole using the old-fashioned method - by inserting a spring bushing into it, the main thing is to make sure that the inner hole does not compress less than the same 18mm.

I set the thermostat itself to 87 degrees, manufactured by Vernet (code 677987), after first checking its correct operation in boiling water. Such a “hot” thermostat significantly accelerated the warming up of the engine, and I did not receive any negative effects from installing it. The operating temperature of the engine has risen slightly; if previously the temperature gauge needle was at the very beginning of the scale, now it has moved two millimeters to the “warm” side. I note that for hermetically sealed installation of the thermostat in the housing of sample 402.5, a rubber ring-gasket is required. We install the air bypass valve in the thermostat upward to prevent the formation of air locks in the system.

At this stage, it is worth paying attention to the quality of manufacturing of the pump housings, thermostat and tee-connector between the thermostat and the pump. The fact is that the quality of ZMZ castings is very low; flash and seams from molds are normal. Internal casting flaws lead to a decrease in the flow of coolant passing through the parts, and external ones lead to poor sealing of the pipes and, as a result, to leaks. Therefore, the parts should be processed independently and all unnecessary things that we got after factory processing should be removed. Those. literally finish it with a file.

I will also note that very high-quality sets of gaskets for the entire engine produced by GAZ have appeared on sale. They are made of high-quality paronite of sufficient thickness and are made very carefully and efficiently. Our set costs only 70 rubles. What’s noteworthy is that the kit even includes a gasket for the cylinder head tank; it differs from others in thickness and material of manufacture.

Since we have converted the entire system to 18mm fittings, we will also need a heater radiator model 3110 with 18mm fittings. I compared aluminum radiators produced by three companies: Luzar, now the Chinese Pekar and Orenburg radiator. My favorite Luzar turned out to be the worst radiator of the entire sample - despite the outer diameter of the fittings being 18mm, inside they still have the same 16mm hole, as on the radiators of the 2410 model; things are a little better with Pekar, but the largest passage holes are on the radiator from Orenburg. The only thing is that you need to be careful when tightening the plastic fittings - they are very easy to overtighten and thereby damage.

The last step before assembling the entire cooling system was flushing the radiator. I washed it with a regular mini-wash under low pressure, both inside and outside. The radiator turned out to be very clean, not a lot of dirt leaked out.

Source

Modernization

Modernization of the ZMZ 402 engine cooling system is carried out with your own hands. For more efficient cooling, silicone pipes are installed on the engine. The thermostat changes from indoor to outdoor. As mentioned earlier, to improve the entire system it is necessary to install a 3-row aluminum radiator.

To completely upgrade the system, it is recommended to install and connect an electric fan with a cooling system sensor. You need to pour antifreeze into the system so that the system is less susceptible to corrosion.

Replacing the coolant of a Gazelle car with a ZMZ-406 engine

All work should be carried out only on a cold engine.

Unscrew the expansion tank cap and open the heater tap.

We put a hose of a suitable diameter on the drain tap pipe.

1. Having lowered the hose of the radiator drain valve into a container (volume of at least 10 liters), open the valve and drain the coolant.

2. Remove the hose from the radiator tap

By placing it on the tap located on the left side of the engine, we drain the remaining coolant from the cylinder block

How does the ZMZ 402 engine cooling system work?

Fig.1.

I – with one heater; II – with two heaters and an electric pump; 1 – expansion tank; 2 – thermostat; 3 – coolant temperature indicator sensor; 4 – radiator; 5 – radiator drain plug (cock); 6 – fan; 7 – fan drive belt; 8 – coolant pump drive belt; 9 – coolant pump; 10 – drain valve of the cylinder block; 12 – electric pump of the heating system; 11, 13 – heater valve; 14 – additional heater radiator; 15, 16 – main heater radiator; 17 – main thermostat valve; 18 – bypass valve.

The cooling system ZMZ-402 of the Gazelle GAZ-2705 car is liquid, closed type, with forced circulation. The pump provides a constant flow of fluid through the cooling jacket of the block and cylinder head, after which the fluid passes through the thermostat and radiator, releasing heat to the surrounding air. The cooling jacket, pump, thermostat and radiator form a “large circle” of circulation.

The cooling system includes a cab heater core, an auxiliary heater core (for vans with two rows of seats and buses), and an electric pump mounted on the heating system outlet hose (for cars with two rows of seats and buses). The amount of liquid passing through the heater radiator does not depend on the thermostat and is regulated only by the heater tap. The water pump of the ZMZ-402 engine of the Gazelle GAZ-2705 car is of a centrifugal type, located in the front part of the cylinder block, driven from the crankshaft pulley by a semi-V-belt or V-belt.

The redistribution of liquid flows is controlled by a thermostat with two valves: main and bypass. On a cold Gazelle GAZ-2705 engine, the main valve is closed, and all the liquid circulates in a “small circle”, returning directly to the cooling jacket, bypassing the radiator. This speeds up warming up of a cold engine. At a temperature of 80–84°C, the main valve begins to open, allowing part of the liquid to pass through a large circle, and the bypass valve closes. At a temperature of 94°C, the main valve opens completely, and the bypass valve closes and all the liquid circulates through the engine radiator.

The fan has a six-bladed plastic impeller. The fan axis rotates in two bearings. The bearings are installed in a special bracket, secured to the timing gear cover with three studs. The radiator of the Gazelle GAZ-2705 engine is tubular-tape, with side plastic tanks. The tanks are connected to the radiator frame through a rubber sealing gasket by crimping the support plate onto the tank flange. On the tanks and the top plate of the radiator frame there are brackets for attaching the radiator to the body. On the left side of the car in the lower part there is a plug or tap for draining the coolant.

Engine ZMZ 402 – modernization of the cooling system.

After boosting the engine, the problem of overheating arises, since the operating mode has changed dramatically. The ZMZ 402 engine installed on the Gazelle and Volga is not without such shortcomings. You can even say that in normal (not forced) mode, this engine is not characterized by a highly efficient cooling system. Therefore, many car enthusiasts, sooner or later, come to the conclusion that something needs to be done.

Boosting the ZMZ-402 engine leads not only to the modernization of the cooling system, but also to the improvement of lubrication, gas distribution, and ignition systems. In other words, simply boring the cylinders is not enough; for proper engine operation, almost everything will have to be redone. In addition, it would not hurt to improve the braking system, since engine power and maximum speed have increased.

Engine cooling upgrade.

First, you need to decide what exactly you are unhappy with, what do you expect to get after the alterations? First of all, of course, you will need to replace the crankshaft-driven impeller with an electric fan. The radiators provide space for installing a fan switch sensor, so there will be no problems with this.

The second thing to do is to provide manual activation of the fan, in case the sensor suddenly fails. A good idea is to turn on the fan smoothly. This can be implemented using a delay block. Thus, the load on the engine is reduced when the fan is turned on.

Third, replacing the radiator with a more advanced one. For example, copper will cost a little more. But it has a plus - heat transfer is higher. Consequently, the ZMZ-402 engine with such a radiator will be cooled much better and more efficiently.

Cooling system ZMZ-402.

The ZMZ-402 engine cooling system is liquid (although, of course, it would be more correct to call it combined, since the oncoming air flow cools the radiator). Sealed type - the coolant in the system is under pressure. Two cooling circles - large and small. To put it simply, the large circle is when the radiator is involved in the work, the small circle is without it.

The duty of the thermostat is to switch the circulation of coolant from a small circle to a large circle and vice versa. Most malfunctions of the engine cooling system lie precisely in this. Boiling of the ZMZ-402 engine is the first sign that the thermostat has failed. It only needs to be changed, since it is not collapsible and therefore cannot be repaired.

Technical characteristics of the engine 402 GAZelle cars

A number of cars are equipped with a 402 engine: Gazelle, Volga, transport from the Ulyanovsk Automobile Plant and minibuses from Latvia. ZMZ-402 - four-cylinder power units running on gasoline, produced at the Zavolzhsky Motor Plant. Gazelle is a Russian small-class truck. The first copies were produced with gearboxes and Volga engines.

Device and characteristics

The ZMZ-402 engine is the leader in the number of units produced in the Volga region. This is a 4-cylinder engine running on gasoline. The performance of the equipment depends on the installed mechanisms and power unit: the K-151 carburetor is better, providing greater speed.

Technical characteristics and description of the motor:

- aluminum block;

- cast iron sleeves;

- lower camshaft location;

- increased camshaft lift;

- upgraded oil pump and exhaust manifold;

- engine displacement - 2440 cm³;

- simple carburetor system;

- mechanical fuel pump;

- low power - 100 hp. With.;

- fuel consumption on a Gazelle with a 402 engine is 11.1 l;

- at 2500 rpm the torque is 182 Nm.

The timing system is equipped with 8 valves and a chain drive. The engine cylinder diameter and piston stroke are 92 mm. The technical parameters of the power unit are the reason for the high sensitivity of vehicles to the slightest overload. The manufacturer recommends changing the engine oil every 10,000 km.

Cooling system

The 402-power unit has a simple design of the engine cooling system in the form of a ring: with the help of a water pump, the coolant - antifreeze or antifreeze - is forced to move. Cooling system elements:

- The radiator is a copper 3-row part that plays the role of a cooler.

- The fan operates with a rotating crankshaft. Its location at the rear of the radiator ensures a high degree of cooling.

- Pipes are elements that connect the components of the cooling system.

- The thermostat is a control valve that controls the flow of fluid through the engine.

- The water jacket is a part that absorbs heat inside the cylinder block.

- The water pump is an element at the front of the block, responsible for the movement of liquid in a circle.

A simple cooling circuit allows car enthusiasts to independently repair and upgrade its elements.

Engine electrical equipment

If the car owner decides to install the engine of a new multi-valve version, at the same time the electrical wiring of the Gazelle can be replaced. A factory electrical diagram with color and symbols is an assistant in replacing old wires and a fuse box with new elements.

Features of the electrical circuit:

- The first level of protection is based on power fuses;

- two main electrical circuits;

- two mounting blocks under the hood.

The function of the fuse box is to protect vehicle elements from short circuits and high voltage values of the on-board network. It opens the circuit and prevents damage to electrical appliances. Additional stability of the operation of Gazelle equipment is provided by a two-level model.

Exhaust system

The exhaust system of a Gazelle with a 402 engine consists of the following elements:

- muffler;

- resonator;

- suspension;

- pipes.

The small cross-sectional diameter leads most car enthusiasts to the need to modernize the system.

Gas equipment

Gas equipment of the second and fourth generation is suitable for the Gazelle; the choice is determined by the modification of the power unit. For the 402 engine, some system upgrades will first be required:

- set the ignition one point earlier;

- recommended boring of the unit head is 4.5 mm;

- gaps - 0.45 mm.

Gas consumption in a truck is 20-30 liters.

Maintenance and repair

Having a diagram of the internal structure of the machine allows you to independently repair the engine in case of simple malfunctions. Increased fuel and oil consumption, coolant leakage, uncharacteristic noises and knocking in the mechanism are the first indications for repair. Maintenance and replacement of worn-out components helps prolong the functioning of parts and vehicles.

Why does it heat up and what to do

Engine overheating is a sign of problems in the cooling system. It is necessary to diagnose the functioning of the radiator, thermostat and water pump.

If there is no charge

Lack of charging can be caused by a number of reasons:

- Lost contact in the electrical wiring from the battery to the fuse box.

- The fuse in the car battery charging circuit has broken. Charging does not occur, there is voltage from the generator.

- Lost communication between the generator and the fuse box.

- Lack of contact between the second generator brush and the relay.

- Open circuit in the relay regulator.

- Lack of electrical contact in the brush mechanism and brush holder.

- Due to a break, the rotor winding does not function.

- Problems with the diodes of the rectifier unit.

If the spark is lost, diagnostics should begin by monitoring the operation of the fuel system and carburetor.

Why does the engine boil?

If the Gazelle engine regularly boils in the heat, the reason is the cylinder head gasket. Deaerating the cooling system and increasing the clearance for the tube will help correct the situation. After this, the electric fan will turn on and cool the mechanisms in time.

How to adjust the carburetor

Adjusting the carburetor on a Gazelle with a 402 engine ensures reliable engine operation. Sequence of work:

- warm up the car;

- remove the rotation limiter with a narrow screwdriver;

- determine the position of the screw with maximum rotation speed;

- set an increased rotation speed;

- With the engine idling, tighten the quality screw.

The adjustment ends when the rotation speed drops to 120 rpm.

Ignition settings

Ignition installation sequence:

- Combination of medium marks on the engine shaft on the cylinder head cover. The compression torque on cylinder 1 is determined by opening the cover.

- Installing the slider opposite the internal contact connected via a cable to the spark plug.

- Loosening the octane corrector bolt with a wrench

- Setting the scale to zero.

- Loosening the bolt securing the octane corrector plate.

- Rotate the distributor body until the marks are completely aligned.

- Tightening the bolts.

During repair work, knowledge and consideration of the features of the 402 engine will be required: tightening torque, valve clearance, torque and other technical characteristics.

Specifications

Before moving directly to the consideration of the characteristics of the ZMZ 402 cooling system, it is worth considering the main technical characteristics of the power unit. The Volgov engine was considered one of the most reliable in the Union. Despite the high consumption, the 402 engine was loved by many motorists. So, let's look at the main characteristics of the ZMZ 402 engine, as well as how it works:

| Name | Characteristic |

| Manufacturer | ZMZ |

| Model | ZMZ 24, ZMZ 24D |

| Modifications | ZMZ 4021, ZMZ 4022, ZMZ 4025, ZMZ 24S |

| Motor type | Petrol |

| Injection type | Carburetor |

| Configuration | 4-cylinder in-line longitudinal internal combustion engine |

| Engine power | 95 hp |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Piston diameter | 92 mm |

| Piston stroke | 92 mm |

| Cooling | Liquid |

| Block and head material | Aluminum |

| Resource | 300,000 km |

| Cylinder operating order | 1-2-4-3 |

| Ignition system | Contact or non-contact |

Resource

The 402 Gazelle engine will need repairs no sooner than after 200 thousand kilometers. For a commercial vehicle this is not a long time. The motor can be overhauled up to four times. And so that the Gazelle engine does not need repairs for a long time, you need to change the oil in it on time and not overheat the engine.

You should also set the correct ignition. On a Gazelle with a 402 engine, it is installed on the distributor. Adjusting the ignition timing will save the valves from burning out and increase the engine's throttle response.

Coolant system components

Both the ZMZ 402 internal combustion engine and the cooling system have a fairly simple design, which will allow vehicle owners to easily carry out repair and restoration operations with their own hands. Let's consider each element of the cooling unit separately, its characteristics and malfunctions.

Thermostat

Thermostat is a part of the cooling system that circulates coolant in a small or large circle. When the power unit warms up, the part is in a closed state, but when the coolant temperature reaches 50-60 degrees Celsius, the thermostat opens to a large circle that goes through the radiator, where cooling occurs.

The main problem that all motorists encounter is the thermostat being stuck closed. This is quite good during the winter period of vehicle operation, but not good when the car power unit begins to overheat. If jamming occurs in the open state, the motor will warm up for quite a long time. The only way out in this case is to replace the part with a new one.

Water pump

A water pump or water pump is an engine part that circulates coolant through the system. The ZMZ 402 water pump has a collapsible base, and in the event of a breakdown, some parts can be replaced separately. Usually, when carrying out a major overhaul of the engine, the water pump is disassembled and the following parts are changed: shaft with bearings, impeller, pulley and oil seal.

Radiator and fan

A 3-row copper radiator was installed on the Volga and Gazelle. Its resource is quite long, but since the cars are already 30 years old, the part cannot withstand it. It is in this element that the coolant is cooled. The main malfunction is metal corrosion, which leads to leakage.

The fan on the ZMZ 402 works forcedly, so the cooling is constant. The part is attached to the crankshaft pulley. This is not entirely convenient, since the engine takes a long time to heat up.

Heating elements

The elements of the interior heater include a heater radiator, a heater fan and pipes. With the help of hot coolant that flows through the radiator, the interior of the car is heated. This system operates in the winter, but in the summer the liquid supply is shut off.

Pipes and water jacket

The cooling water jacket is located directly in the cylinder block and head. Thus, the fluid flowing through the water channels of the motor absorbs heat and is discharged to be cooled in the radiator. There are two types of malfunction of this system - clogging of the channels with foreign objects and corrosion when operating on water or low-quality antifreeze.

The worst thing that can happen in this case is coolant getting into the engine cylinders, which can lead to water hammer. Corrosion of the water jacket is detected during a major overhaul of the power unit.

Modernization of the coolant circulation circuit in the cylinder head

Currently the power limiter on my 402 is detonation. That is, when the shoe hits the floor, detonation begins in one of the cylinders. Detonation occurs primarily due to overheating, meaning some cylinders are hotter than others. The hot mixture must be ignited a little later, that is, after the introduction of the MPSZ with an individual OZ for each cylinder, the problem will partly decrease, but why not try to solve the problem with “improvised” means? After introducing constant circulation through the stove (improving coolant circulation in the 4th cylinder), the sound of detonation noticeably changed and became duller, that is, it moved to the 2nd or 3rd cylinders. This is also confirmed by the burnout shape of the cylinder head gasket. And, in general, this is a well-known fact - due to the proximity of the exhaust channels of the 2nd and 3rd cylinders, the cylinder head in this place heats up more. And then, in my spare time, an idea came to me, as simple as it is ingenious - what if I made an antifreeze drain from the hole intended for the EGR thermal switch.

I bought a new thermal switch. I planned to gut it and weld/fit a fitting onto the thread there, but fortunately it had a standard 1/2 plumbing thread:

The thread of the thermal switch is conical, but this can be treated with fum tape/sealant. Thus, I only had to purchase an angle for 1/2 nut/fitting and a fitting for 16-18 mm. I also needed a metal tee for 16, inside the central outlet covered almost half of the cross-section, I had to work with a file and remove the excess:

This is what happened:

The installation is ridiculously simple. Unscrew the old thermal switch:

We plant a corner on the fum tape. Of course, it would be more convenient to do this with the cylinder head removed; I had to unscrew and slightly move the valve cover:

Then we also screw the fitting onto the fum tape. At the same time, make sure that the fitting does not cover the cylinder head mounting nut:

In the previous version with a branch from the tank, the hose was too close to the exhaust manifold, so it was not in vain that I replaced it - it was already cracked in just a couple of months:

In general, ideally, you will need to get a silicone hose for 16, since now the coolant temperature can be above 100 degrees - its intake now comes from the hottest places. The assembled system looks like this, the antifreeze intake comes from the hole of the thermal switch and the tank, then they converge at the tee and then go to the stove:

The gap to the exhaust manifold has increased significantly:

I don’t see any downsides to the design, except perhaps for the increased number of possible places for air jams to occur. On the plus side, I expect a significant reduction in detonation. In addition, I previously noticed that even after heating the antifreeze to 90 degrees, the stove turned on at maximum after a few minutes. Perhaps this is due to the fact that colder antifreeze from the block got into the tank and the stove reached its maximum only after the engine temperature as a whole had equalized. It may be necessary to make some adjustments to the system in order to change the proportions of the cross-section of the outgoing hoses. For example, it turns out that the temperature of the 2nd and 3rd cylinders will be lower than the 4th - then the cross-section of the hose from the thermal switch will need to be reduced and vice versa. The temperature of the cylinders can be judged by the OZ - the earlier it is, the colder the cylinder, but this will be clear from the MPSZ.