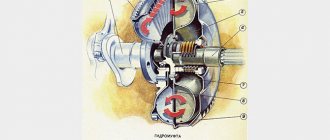

Valve block design, valve, sensor location

1.

The hydraulic unit, the second screw on the right, under the hexagon regulates the pressure. My pressure increased by 0.3 one full turn (in case the pressure does not rise after flushing). The optimal pressure is considered to be 3 bar at XX in D, in fact it can be in the range of 2.55-3.0, this is normal, but 2.55 is the lowest threshold! After washing, you can tighten it half a turn... During its operation (about five years), the spring has become a little weaker. If it still doesn’t reach the required pressure, then simply drain the oil again, remove the valve body cover and, without removing the valve body itself, tighten it further. But this MUST be done very carefully! Because I get a lot of complaints, I want to WARN you IN ADVANCE, if you twist this, then you should twist it a quarter, or even less. The reason is banal, twist it more, the pressure will be high, the standard pressure at XX is 2.8-3 bar, can you imagine what will happen to the box with 6.0 bar cranked up? Better not to know!

Pressure control and blocking valves

As you can see, mostly only one valve wears out. Photo 2.

Disassembled valve. So there is no need to disassemble the valve, just remove it, wash it and swap it. It is recommended to replace the O-ring art. 2578. 13 Photo 1.

Temperature sensor

The location of the temperature sensor, if this sensor is not working properly, then the automatic transmission may also go into emergency mode. Changes along with the scythe.2529 26 (but it’s better to look at the wine).

| Temperature sensor location |

Valve diagram

Swap valve 2, consisting of an o-ring (B) and valve (2), art. 2574.16

For Renault, the analogue is 77 01 208 174, the remaining valves numbered (A) are removed one at a time, washed, cleaned and replaced (so all in turn). The remaining adjusting screws should not be touched.

| Scheme |

How to repair a valve body

Do-it-yourself automatic transmission valve body repair is carried out in the following sequence:

- They stock up on materials, manuals, and diagrams for repairing their hydraulic stove. Buy new seals.

- Computer diagnostics are carried out and faults are identified using error codes.

- Drain the oil.

- Remove the pallet.

- Unscrew the hydraulic unit.

- Before disassembling and repairing, photographs are taken of the “before” condition. Prepare an “accordion” tray for the removed parts.

- Remove the solenoids, unscrew the bolts, separate the housing, throw out the old seals. The parts are arranged into an accordion in the order of dismantling.

- Remove the valves, check balls and springs. Serviceable valves move easily along the channel.

- Inspect the slab.

- Clean and rinse the housing from wear products and oil.

- Check the resistance of the solenoids.

- Reassemble in the reverse order with new gaskets and replacing faulty parts.

- Install the hydraulic unit and pan with a new gasket.

- Add fluid and check the level.

To overhaul and repair the valve body, repair kits are used:

- Sonnax;

- Masterkit;

- Precision;

- ATOC;

- Overalkit;

- Transtek.

How to flush the automatic transmission valve body and how to do it

First of all, before you start washing the hydraulic plate of the machine, you need to prepare the necessary materials and tools. As a rule, you need to have a new automatic transmission oil filter, you will also need oil pan gaskets, an O-ring for the filler plug, and an automatic transmission valve body gasket.

At the same time, you should prepare keys for removing the pan, containers for draining old oil, and clean rags. You also need to purchase transmission oil (8-10 liters), carburetor cleaning fluid (3-5 liters), a “Galosh” type cleaner, brushes (the bristles should be hard), prepare a container of water, stock up on rags (preferably lint-free ).

The place where the work will be performed must be clean, free from dust, drafts, etc. It is important to prevent dust, debris, particles, lint, etc. from getting on automatic transmission parts. Before you start cleaning the automatic transmission valve body, it is recommended to separately study the issue of removing the valve plate (valve block) on a specific automatic transmission model. Having figured out how to remove the valve body from the automatic transmission on a particular box, you can get to work

In general terms, you will need to unscrew the drain plug with a wrench, drain the old oil, then tighten the plug. After this, you need to remove the automatic transmission pan and disconnect the electrical connector plug. To do this, you need to turn the plastic lock, after which you can disconnect the connector itself

Having figured out how to remove the valve body from the automatic transmission on one or another box, you can get to work. In general terms, you will need to unscrew the drain plug with a wrench, drain the old oil, then tighten the plug. After this, you need to remove the automatic transmission pan and disconnect the electrical connector plug. To do this, you need to turn the plastic lock, after which you can disconnect the connector itself.

Then the connector adapter is removed, after which you can begin removing the block. First, you need to very carefully unscrew the bolts that secure the hydraulic unit. It should be remembered that the block is divided into two parts (front and rear), and when unscrewing and tightening the bolts, you need to follow the order (it is better to remember the position of the bolts).

Let us also add that disassembling the valve body is a complex operation. The block consists of 4 parts (plates) connected to each other by plates. Each such slab has paths that become clogged with deposits and wear products. However, it is impossible to wash them without disassembling the hydraulic unit.

First, the “large” (front) part of the block is unscrewed, then the remaining bolts are unscrewed, then the “small” (rear) part of the valve body is removed. Next, you should slowly lift the intermediate plate of the valve body (the remaining plates are removed in the same way).

In other words, we remove the first plate, and after unscrewing the last bolt, it is advisable to remove the plate along with a special spacer plate. If this is not done, certain elements may fall out and assembly problems may arise.

It turns out that when the time comes to remove the rods, the plates need to be unscrewed so that the springs between them are not accidentally lost. After removing the hydraulic unit, you can start washing it.

Cleaning and washing the valve body of the automatic transmission

After disassembly, you need to remove dirt from the parts using a hard-bristled brush. Then the parts are washed with an aerosol for cleaning carburetors

It is also important to thoroughly clean the solenoids with carbicleaner. After this, you can rinse the parts again with gasoline.

Also, in some cases, you can limit yourself to a partial replacement (transmission oil consumption is reduced), that is, fill the oil according to the level without expelling or replacing the waste in the gas turbine engine.

One way or another, after filling in the ATP fluid, you need to correctly set the oil level in the automatic transmission and check the operation of the unit while driving. After checking, you need to completely warm up the automatic transmission, then check the level again for “hot”, and then adjust the level if necessary.

Procedure for replacing the valve body

If the hydraulic plate is severely worn out, a decision is made to replace it with a new one or a rebuilt one – “rebuild”. The procedure is simple, but it requires updating all consumables and flushing the automatic transmission. Deposits and dirt inside the box will quickly clog the new valve body, so you need to get rid of them.

For mileages over 100,000 km, hardware cleaning is not recommended. High pressure will raise the accumulated suspended matter, which will further clog the filter and channels. To flush the automatic transmission, use the displacement method: alternately drain the old fluid from the cooling radiator pipe and fill in new one.

To replace the hydraulic plate, you will need a seal repair kit for this automatic transmission model, keys, fresh fluid, a drain container, a funnel with a hose, and a lint-free rag. General recommendations for work are similar to the repair procedure:

- Drain the old slurry.

- Unscrew the bolts and remove the pan. Wipe the seat with a rag.

- Wash the cover from adhering wear debris, clean the magnets from metal hedgehogs. Install a new gasket.

- Remove the old filter.

- Inspect the accessible parts of the automatic transmission and, if possible, replace the rubber bands.

- Disconnect the solenoid connectors. Disable sensors.

- Unscrew the hydraulic unit.

- Install a new hydraulic unit.

- Connect wiring, sensors.

- Install a new filter and a clean pan.

- Pour in new fluid in the same amount as drained.

- Flush the automatic transmission using the displacement method.

- Check oil level.

- Tighten the plugs with new O-rings.

Adaptive automatic transmissions require retraining when replacing fluid and components.

Symptoms of valve body malfunction

Symptoms

A characteristic sign of a faulty automatic transmission valve body is increased vibrations and grinding noises when changing gears. In some cases, a complete stop of the engine may occur when the selector is moved from Parking mode to Drive mode. Also, quite often the malfunction manifests itself in shocks, impacts and slipping between gears. Modern cars, equipped with numerous sensors, when they break down, display a message indicating that the gearbox is damaged. The exact cause of the breakdown can only be determined by connecting the computer to diagnostic equipment and carrying out the appropriate gearbox tests. In this case, you can install the failed element. However, it is impossible to say exactly the nature of the breakdown even after computer diagnostics. It is necessary to dismantle the hydraulic unit and disassemble it.

Photo of automatic transmission valve body

Self-repair – is it possible?

The valve body can be repaired in specialized workshops and service centers. Do-it-yourself automatic transmission valve body repair is only possible if you have practical experience working with such spare parts. You will need to dismantle (in some cases) the automatic transmission, open the housing and first check the valves. You most likely will not be able to clean them yourself, because... Professional equipment is used for this. Also be sure to check the valve body springs, which tend to wear out. Reassembling the valve body structure is of great importance; if you make a mistake, the consequences can be much worse than replacing just one assembly part. As you can see, repair work can only be carried out by an experienced specialist if he has the appropriate equipment.

Valve block diagram

The cost of repairing a hydraulic unit directly depends on the nature of the breakdown. For example, problems with springs, valves, and solenoid blocks are quite often noted. Many car service centers do not undertake repairs, citing the fact that it will be cheaper to replace it when assembled. This is not always the case, you can contact us and we will be happy to repair the valve body inexpensively and efficiently. Due to the fact that the design of the valve body is quite complex, consisting of a large number of parts, it requires a huge amount of knowledge and experience to carry out such repairs. The cost of such repairs can range from 10,000 rubles to several tens of thousands of rubles. There is also the problem of a clogged valve body, when the valve plate spools begin to stick. In some cases, it makes sense to replace a broken element rather than try to carry out an expensive and complex restoration procedure.

Automatic transmission valve body repair – Video

As a preventive measure to prevent hydraulic unit breakdowns, we recommend that you closely monitor the condition of the automatic transmission cooling system. It is the incorrect operation of the cooling system that is one of the most common causes of damage to this element.

Valve block repair – price in our service

Also, the car owner should properly operate his car and the automatic transmission in particular. Especially in winter, you should not start driving the car without first warming up the oil in the gearbox. This procedure takes only a few minutes and allows you to easily bring the oil temperature in the gearbox and valve body to the required temperature. This way you can ensure high-quality cooling and lubrication of moving elements.

To warm up the transmission, you need to move the selector to the Drive (D) position and hold the brake for one minute. Immediately after this you can start moving. You should also remember that after starting to drive in a cold car, it is not recommended to spin the engine above 3000 rpm. By following these simple rules, you can protect the gearbox and valve body from damage and extend the trouble-free life of your car.

Causes and signs of failure of hydraulic units of the 5HP19 series

I’ll tell you that the automatic transmission 5HP19 series is not afraid of frequent slipping and cold starts, which are the sin of new car enthusiasts. It can easily survive even overheating. My 5HP19 automatic transmission had 210 thousand kilometers before I started flushing the valve body.

But she doesn't like oil starvation. And the lack of lubricating fluid does not necessarily arise from the fact that the car owner forgets to top it up every 10 thousand km. Sometimes a negligent attitude towards the 5HP19 automatic transmission leads to the driver not changing the oil even after driving 100,000 kilometers. What happens next is:

- wear products, such as burnt paper from the clutches, clog the hydraulic plate valves. The oil cannot function as expected;

- faulty pressure regulator or EPC solenoid;

- dying torque converter. First of all, the pump wheel bushing breaks. Productivity decreases. Due to weak movement, the oil overheats, mechanical parts wear out faster because they are not lubricated in time

- Well, and the usual oversight of the oil level in the 5HP19 automatic transmission.

The driver feels shocks and jerks. These are the first signs that there are problems with the box. And some other signs of a dirty valve body:

- the automatic is warmed up, but when switching from 5 to 4 strong shocks are felt;

- jolts from neutral to the “Forward or Reverse” position;

- When braking, the 5HP19 stays in main gear for a long time.

All these symptoms indicate only one thing: the hydraulic plate is faulty. And the faster the driver disassembles the machine, washes it and reassembles it, the better for the driver and for the 5HP19. The first one will not spend money on major repairs, but will cost at most by replacing solenoids, the second one will serve the car owner for a long time.

Typical automatic transmission valve body malfunctions

According to many car mechanics, valve body repair is one of the most difficult areas of car maintenance, and at the same time the main component of an automatic transmission. This unit performs the extremely important function of directing the flow of transmission coolant. In addition, he is responsible for the process of switching speeds using an electronic unit. The hydraulic unit designs may be different, but the operating principle and its functions are always the same.

When driving a car with an automatic transmission, the valve body is subject to heavy loads, so failure to comply with the correct operating mode can lead to its breakdown.

For example, in the cold season, it is very important to warm up the transmission fluid before starting to drive. This is necessary for the normal operation of the valve body and the box as a whole.

What causes problems with the valve body?

Malfunctions of the automatic transmission valve body often arise as a result of problems in the cooling system if the owner does not regularly change the coolant. It should be noted that this is not only the most important, but also the most fragile element of the transmission. Due to constant loads, it wears out faster than other components. It is very difficult to fix the breakdown yourself, as well as to determine the cause of the malfunction, since the gearbox must be dismantled for diagnosis. An automatic transmission is technically much more complex than a mechanical one, so repairing or replacing its components will cost a lot of money. In this case, amateurish actions can cause more harm than the breakdown itself.

A malfunction of the hydraulic unit can be recognized by shocks and high levels of vibration. If the driver hears grinding and extraneous sounds when changing gears, this is a reason to contact a professional auto mechanic. If the automatic transmission valve body malfunctions, the symptoms are clearly visible when the car is moving. For example, switching the selector from one mode to another is accompanied by a complete stop of the engine. Also, do not ignore the readings of on-board sensors, which display a message on the display about a breakdown or incorrect operation of the gearbox. To eliminate the breakdown, it is necessary to find out the causes using a number of auto repair measures. Computer diagnostics will help identify which valve body element has failed. However, to determine the nature of the failure, it will need to be opened and disassembled.

Self-repair of the valve body - is it possible?

Some drivers who observed the work of the technician in the salon do not see any difficulties in independently repairing an automatic transmission. After removing and opening the transmission housing, checking the valves will most likely show that they need cleaning. But without special equipment it is almost impossible to do this. All that a driver can do at home, even with experience, is to replace the springs, which wear out quite quickly. Now you need to reassemble. As practice shows, making even a small mistake when assembling a gearbox is fraught with dire consequences.

Quite often, the cause of valve body failure lies in contamination of parts from the operation of the clutches. Sticking spools also cause jolts when shifting gears. Faulty operation of even one valve of the valve body leads to loss of pressure in the clutch, malfunction of the clutches, and loss of one of the speeds.

If malfunctions occur, the sooner the driver organizes a valve body overhaul, the less cost it will cost. During the overhaul process, the technician will completely overhaul the valve body, clean the valves, change springs and consumables. This procedure will give the unit several more years of life. Drivers who wait until the last minute with repairs are often forced to buy a new brain center of the box. In some cases, a complete replacement of the automatic transmission is required.

What is a valve body in an automatic transmission?

The hydraulic plate is called the “brains” of automatic transmissions, not only for the external resemblance of the complex channels to the convolutions of the brain. Before the advent of control electronics in the 1980s, the valve body decided which automatic transmission unit needed to be connected to operation. Now the valve plate is controlled by the computer, maintains pressure in the system and distributes fluid flows from the oil pump to the actuators: clutch packs and torque converter lock-up (GDT).

The hydraulic unit includes:

- a metal plate with a labyrinth of channels through which oil passes;

- solenoids;

- pressure regulators;

- spool valves;

- sensors;

- filters;

- hydraulic accumulators;

- wiring;

- separator plate, seals.

How to avoid the problem

The problems that arise can be divided into two groups:

1) The occurrence of physical wear and tear;

2) Incorrect operation of the transmission.

Many car enthusiasts ignore the instructions in the service book about the correct oil change. As a result of this, troubles arise; the gearbox works intermittently. And this is not surprising, because the lubricant becomes dirty and loses its fluidity. At one point, the box may simply jam, and you will have to spend a lot of money on replacement.

Experts also note that it is necessary to use only original oil, not fake oil or the like. Fortunately, in the service book the manufacturer writes which oil is best to purchase for an automatic transmission. If you use low-quality oil, the solenoids and other elements will fail. You'll have to spend a lot of money on replacement.

When operating at high loads, knocking and rapid burnout may occur. If you do nothing, the parts will fail, and you will have to spend a lot of time and money on restoration. To prevent this, you must follow the manufacturer's recommendations.

As for the diagnosis itself, there are several types:

1) Listen to the operation of the gearbox. This method is only suitable for specialists;

2) Touch the electrical wiring and other elements;

3) Disassemble the system to fully check the integrity.

Conclusion

An automatic transmission is very important for a modern car. It is necessary to carry out technical inspections regularly to prevent troubles. Fortunately, there are now a huge number of services; you just need to contact them and send them for diagnostics.

15.12.2017

Signs of hydraulic unit malfunction, symptoms

The first sign that indicates a malfunction of the hydraulic unit appears during operation of the automatic transmission. Symptoms of a malfunction are strong vibration and crackling noise when shifting gears. In severe cases, the power unit stops working when the box switches from mode to mode. As a rule, this happens when switching from Parking mode to Drive mode. Frequent confirmation of malfunction: shocks, impacts and slipping.

Modern vehicles are equipped with sensors that display information about a breakdown in the form of a code on the on-board computer screen. To make an accurate diagnosis and identify a breakdown, the car’s on-board computer is connected to a diagnostic stand designed to test the functionality of the valve bodies. Carrying out automatic transmission tests will identify the faulty element. Detailed information about the failure is obtained after removing and completely disassembling the valve plate.

Self-repair - is it possible?

Some owners, wanting to save money, try to repair the hydraulic unit themselves. Remember that an automatic transmission is a serious and complex device, the repair of which requires practice and skill. To perform the work properly, you must have at least an idea of how automatic transmission valve bodies are repaired. Mistakes made during self-repair will lead to irreparable consequences, as a result, more is lost.

Repair of the automatic transmission hydraulic unit includes the following steps:

- Diagnostics, determination of scope of work;

- Removing the valve plate from the box seat;

- Flushing the automatic transmission valve body;

- Inspection and determination of the performance of solenoid valves;

- Identification of parts to be replaced;

- Restoration of control valve block;

- Valve plate assembly and calibration;

- Installation of the slab on the workplace.

The correct decision to replace the solenoid valves is made by a specialist. Solenoids with slight contamination are restored, after which they are able to work for quite a long time. It is better to replace severely damaged solenoids, since restoring them will cost more than buying new ones.

Repairing a hydraulic unit is a difficult task for an inexperienced user, however, it is possible to dismantle it yourself for the purpose of replacement or cleaning. Moreover, the operation does not require complex manipulations and saves money.

Removing the hydraulic unit:

- Drain the transmission fluid from the box;

- Remove the battery;

- Disconnect the solenoid valve connectors;

- Unscrew the fastening bolts;

- Remove the hydraulic block.

Cleaning the automatic transmission valve body:

- Unscrew the hydraulic block bolts;

- Remove the hydraulic block cover;

- Remove the filter and solenoid valve of the hydraulic unit;

- Clean the hydraulic unit and parts;

- Reassemble the hydraulic unit in reverse order.

It is recommended to clean the mechanism with a special washing liquid or carburetor cleaner. Installation of the valve plate is carried out in the reverse order of dismantling. Before installation, it is recommended to change the sealing gasket; assembly is carried out carefully and carefully, followed by checking the correct gear shifting.

After installing the hydraulic unit in place, pour 4 liters of transmission fluid into the box, preheating it to 50-60°C. We start the car, set the automatic transmission to park mode and, with the power plant running, unscrew the fluid level check plug. If the oil flows in a thin stream, the order and level are acceptable. If it drips or does not flow, you need to fill in half a liter of lubricant and repeat the control procedure.

Why is diagnosis so important?

Diagnostics helps to identify unit malfunctions and determine the location of the breakdown. Without a complete diagnosis of the automatic transmission, no technician will be able to begin repairs. The survey begins with collecting information:

- about the age and mileage of the car;

- about the history of oil changes;

- about machine overhauls;

- about the symptoms of the problem “cold”, “hot”, in different modes.

Read

Automatic transmission reset, calibration and adaptation

At the next stage, the automatic transmission error codes are removed and deciphered in order to determine whether the valve body or other automatic transmission unit is faulty. Then check the level and quality of the transmission fluid and remove the pan for inspection.

For mild dullness, changing the oil, filter, and cleaning the solenoids solves gear shifting problems. Ignoring the symptoms leads to a general drop in pressure in the box, and then to wear of the torque converter lock-up clutch, abrasion of the clutches, and destruction of bushings and bearings. The longer the valve body valves operate in metal chips, the more the body wears out. Exceeding the wear tolerances entails replacing the entire plate.

Design and purpose of the automatic transmission valve body

What is an automatic transmission valve body - it is a distribution plate with many channels in which control valves, sensors, hydraulic accumulators, solenoids, and filters are installed. A complex device is determined by the tasks that the node performs:

- regulates pressure in the common line of the gearbox;

- directs fluid to cool connections;

- controls turning the torque converter lock on and off;

- directs oil flows to the brake system pistons to change gears;

- dampens increased pressure, ensuring soft, consistent operation of the automatic transmission.

Automatic transmission solenoids operate based on the TCM signal and come in different types:

- “On-Off” work in the open-closed position;

- PWM, VBS, VFS solenoids open gradually and can regulate fluid pressure.

The remaining valves are spool valves. The plunger opens the way for flow by moving under fluid pressure. After the pressure decreases, the valve returns to its original position due to the spring.

The most common valve body failures

Computer settings are optimized for fuel economy and fast acceleration. In 6- and 8-speed automatic transmissions, robots, and CVTs, the driver can squeeze the maximum out of the engine even in aggressive modes. But such freedom of choice is paid for by the rapid wear of the valve block and the entire automatic transmission.

This happens due to rapid wear of the torque converter lock-up clutch. Dust and adhesive resins spread throughout the box along with oil. The liquid loses its properties and does not have time to cool.

The valve body channels and valves become clogged with dirt. Springs do not return plungers to their original position. Solenoids cannot open a stuck valve. This is where jolts and jerks appear when changing gears. The metal abrasive wears out the separator plate and the channels of the plate, changing their geometry. Oil leaks appear.

Read

DIY automatic transmission repair Nissan x trail

Overheating causes wiring and board elements to melt as the temperature rises above 120℃. The solenoids fail. Sensors overheat. Finely tuned electronics block the operation of the faulty unit, and the automatic transmission can no longer engage a certain gear.

But even with timely oil changes and good cooling, you should not forget about consumables: paper gaskets, clogged filters, weakened springs, and hardened tires make themselves felt by 100,000 km. Replacing consumables often solves problems with shifting gears in older automatic transmissions.

Similar symptoms and typical faults are common in the DSG. Problems in the mechatronics unit are indicated by:

- shifting gears with jerks and impacts;

- vibrations due to sharp clutch of discs;

- oil leaks;

- transition to emergency mode.

The clutch engagement solenoids receive oil with friction dust and metal chips back from the drum. Long-term operation in this mode reduces the life of the valves.

Automatic transmission valve body: malfunctions, do-it-yourself repairs

One of the components of the transmission is the valve body. This device is necessary for directly switching speeds. The design features of this element on machines are different. The high-quality design of the hydraulic unit is distinguished by its reliability, as a result of which it perfectly tolerates all the loads placed on it during movement.

Where is the best place to repair the valve body?

Valve block diagram

The operating life of the valve body is influenced by the conditions in which the vehicle is operated and how often the vehicle is diagnosed. The repair and restoration work of this system should be entrusted to experienced professionals who work in auto centers. As a rule, there is the necessary professional working equipment, which allows you to accurately identify the nature of the breakdown.

Any unqualified intervention will be the reason why the transmission system is prematurely out of working order. Carrying out repairs on your own is possible if the owner of the car who has encountered a valve body failure has the necessary experience in this field.

Malfunctions of the automatic transmission valve body

There are several reasons why the automatic transmission valve body fails. First of all, this is the result of improper operation of the transmission system. In particular, you should start driving in winter with warm transmission fluid. It warms up quite quickly. Thanks to this, the motorist will ensure high-quality cooling of the system.

The coolant should be changed in a timely manner to minimize the risk of premature failure of the oil receiver, failure of the valve body, and gearbox.

It seems possible to determine exactly the nature of the malfunction by dismantling the gearbox and then disassembling it. In this case, it is necessary to check the condition of the valves; in some cases, they need to be cleaned. Sometimes worn springs that are related to the valve body can be the reason why the unit is not functioning properly.

The main sign of when you need to check the condition of the valve body is the appearance of vibrations and a characteristic grinding sound when a gear change occurs. There should be no shocks or impacts.

The fact that the automatic transmission valve body is broken may be indicated by the engine stopping when the “P” mode is activated to the “D” mode.

It should be noted that not every service center is ready to take on the task of restoring the operation of the automatic transmission or its individual components. This is explained by the fact that such an automatic transmission has a complex structure; repairing it is not a cheap undertaking. That is why some motorists decide to purchase a new gearbox, instead of replacing the automatic transmission valve body, to fix the problems that have arisen.

Need for repairs

The function of the valve body is to redistribute the flow and pressure of the transmission. In order to prevent premature failure of the valve body, the driver must monitor the condition of the cooling system in the box. The valve body includes a valve plate and an electronic control unit

It is necessary to pay attention to the working condition of the sensors if slippage begins to be observed. There may be poor contact between the valve body and them.

Inside the valve plate there are channels with control valves, sensors, and solenoids. These elements are responsible for the operation of the high-speed gearbox. The need to replace solenoids arises after 80,000 km. With careful driving, this figure is almost 2 times higher.

Failure to change the oil in a timely manner may result in the need for premature repair of the automatic transmission valve body. It is necessary to select fuel of such a class that it corresponds to the performance indicators of the automotive system.

Repairing an automatic transmission valve body with your own hands requires you to acquire a special repair kit, which includes materials such as rubber seals, for example, cuffs, clutches.

On a number of Volkswagen models that are equipped with an automatic transmission, restoration of the valve body can cost more than 40,000 rubles. To begin the repair, you should drain the fuel from the automatic transmission and remove the battery.

The cost of repairing this automatic transmission device depends on the existing malfunction.

Thus, a common source of all problems with the valve body is the use of dirty oil. A specialized station may offer a procedure such as cleaning the valve body. Also, they will help with solving problems of overheating and disruption of the performance characteristics of board elements. All signs of a malfunction at the station are quickly identified.

Features of washing the “machine”

How to flush an automatic transmission? It is recommended to carry out this procedure in specialized auto repair shops that have the necessary equipment and washing machines. Flushing the gearbox allows you to remove dirt deposits.

If the car owner decides to wash the automatic transmission with his own hands, he needs a new transmission, a set of wrenches, polygons, screwdrivers, and a washer. Also, rags and empty containers are needed.

Washing algorithm:

- The machine must be driven into the inspection hole, after which the liquid must first be drained into an empty container.

- Next, a device is connected to the box, through which new transmission oil will be added.

- The engine starts (for about 15 minutes).

- The device creates pressure, due to which the oil passes through the channels of the automatic transmission hydraulic system.

- The transmission is drained.

- The filter element and pan gasket need to be replaced.

- New oil is added.

Finally, the operation of the transmission system must be checked and the engine will start. In normal condition, there should be no extraneous noise during operation. The amount of fuel spent on this procedure depends on the gearbox model (approximately 10-15 liters).

Flushing the automatic transmission can be carried out simultaneously with a complete change of transmission oil. It should be noted that a number of car owners decide to wash the automatic transmission with diesel fuel.

Hydraulic unit care

With prolonged use of the vehicle, the transmission fluid gradually becomes contaminated. The result of this is the failure of the components of the gearbox.

When servicing the automatic transmission for the first time, it may be necessary to replace the solenoids and clean the automatic transmission valve body. This allows you to extend the service life of the transmission. The cost of repairing the hydraulic unit depends on the nature of the existing breakdown. Malfunctions of this device mainly occur as a result of overheating of the transmission and the use of dirty oil. Overheating of the gearbox leads to deformation of its parts, the valve body, the repair of which may involve replacing springs and valves.

What is dangerous about the presence of sediment in the form of metal shavings and combustion products in oil? The presence of these substances helps reduce the service life of the gearbox. In particular, filters and hydraulic system channels become clogged. The correct option in this situation is to flush the automatic transmission. Carrying out this procedure helps restore the stability of the transmission system.

In what other cases is flushing required? We list the main reasons for the need to clean the automatic transmission:

- gears are difficult to shift;

- the appearance of shocks during acceleration;

- instability of the functioning of the checkpoint.

If this procedure does not help solve the problem, it is advisable to order automatic transmission diagnostics, the results of which require disassembling the box and replacing worn parts.

Thus, the oil constantly circulates through the transmission channels; over time, wear products form in it, which clog the valve body channels. Because of this, the solenoids fail. As a result, the box begins to push when switching. A procedure such as flushing the gearbox can solve the problem.

Why and when is it necessary to flush the valve body of an automatic transmission?

Let's start with the fact that the most important element of the automatic transmission is the valve plate (valve block). Mechanics themselves often call this element the “brain” of the automatic transmission, since it is thanks to this device that they can achieve smooth and timely gear shifting in automatic mode.

In other words, the valve body is an actuator that controls the operation of the automatic transmission. The valve body itself (automatic transmission valve block) is a plate with channels through which transmission oil (ATF fluid) is supplied under pressure.

In fact, the oil activates the actuators, which “switch on” the desired gear. Also, the distribution of fluid flows is realized by installing special valves (automatic transmission solenoids) in the channels of the hydraulic plate. The valves open and close at the command of the ECU via the automatic transmission.

It is not difficult to guess that since the oil constantly circulates through the channels, over time wear products, small mechanical particles, deposits, etc. can clog the specified valve body channels or even damage them. The solenoids themselves also fail.

Such defects and malfunctions lead to the fact that the automatic transmission begins to push, jerks when switching, etc. At the same time, changing the oil in an automatic transmission is often not enough, especially if the oil is changed using a partial change. In other words, it may also be necessary to flush the valve body, as well as an understanding of how to flush the valve body of an automatic transmission. Let's figure it out.

How to flush the automatic transmission valve body and how to do it

First of all, before you start washing the hydraulic plate of the machine, you need to prepare the necessary materials and tools. As a rule, you need to have a new automatic transmission oil filter, you will also need oil pan gaskets, an O-ring for the filler plug, and an automatic transmission valve body gasket.

Torque converter repair

Buying a new torque converter is quite an expensive proposition. The situation is further complicated by the fact that it is often difficult to get a suitable donut for old used imported cars. Therefore, in most cases, car owners prefer to repair torque converters, especially since this unit is quite repairable.

The price of the simplest repair starts at about 4...5 thousand Russian rubles. However, here you need to add the cost of dismantling the transmission, performing troubleshooting, as well as the price of new replacement parts. Typically, torque converter repair consists of the following work:

- Dismantling and cutting. The torque converter housing is sealed in most cases. Accordingly, to get to its insides, it is necessary to cut the body.

- Washing internal parts. To do this, the transmission fluid is removed and the blades, channels and other parts of the donut are washed using cleaning agents.

- Troubleshooting. One of the most responsible processes. During its execution, all internal parts of the torque converter are checked. When damaged internal parts are identified, a decision is made to replace or repair them.

- Replacing parts. As a rule, when carrying out repair work, all rubber and plastic seals are replaced with new ones. Frequently, friction linings and hydraulic cylinders are also changed. Naturally, the listed spare parts need to be purchased additionally.

- After repairs are completed, the housing is reassembled and soldered.

- The torque converter is being balanced. It is needed for the normal operation of the node in the future.

When performing repairs, the professionalism of the performers is important. The fact is that the torque converter operates at high speeds and fluid pressures. Therefore, the accuracy of the unit settings is very important here, since the slightest misalignment or imbalance under significant loads can again damage the torque converter and even other elements of the automatic transmission, right down to the automatic transmission itself.