When do you need to undergo a technical inspection?

Each car must have a diagnostic card - it is received after passing a technical inspection. The document has an expiration date. When it ends, the driver needs to undergo MOT again.

- Category B cars, motor vehicles, trailers and semi-trailers undergo maintenance 3, 5, 7 years after release. After seven years - every year.

- Category C vehicles, training vehicles and vehicles equipped with special signals undergo technical condition checks annually.

- Buses and vehicles for transporting people and dangerous goods - once every six months.

If you bought a used car with a valid diagnostic card, you do not need to undergo an MOT, even if you changed the numbers.

Important information about diagnostics and personnel training

To carry out high-quality car repairs, there are now a lot of modern diagnostic and measuring instruments, a large amount of high-tech equipment for literally all occasions.

Without this equipment it is no longer possible to carry out high-quality repairs of the engine, gearbox, electrical equipment or car body.

And this is not surprising, because developers of modern equipment and tools for car repair are constantly trying to keep up with the times, constantly creating something new in accordance with the car repair requirements that are necessary in our real life.

However, this equipment and tools require a more professional approach. Masters must have the necessary knowledge and skills, and for this they even have to undergo special training courses. This is the main difference between modern car repairs of the 21st century and repairs carried out at the end of the 20th century.

Advanced technologies, new methods of approach to repair, training and subsequent ongoing training of highly qualified personnel are what underpin modern car repair.

What happens if you don’t pass MOT?

There are no fines for driving a car without a technical inspection, but without a valid diagnostic card you cannot obtain compulsory motor vehicle liability insurance. For the absence of an insurance policy, the driver will be fined 800 rubles. If a motorist without compulsory motor insurance causes an accident, he will have to pay for the damage himself.

Even if the driver has a valid MTPL policy, but the diagnostic inspection card has expired, there will be difficulties with payment: the insurance company may demand a refund of the money, citing the technical condition of the car.

Repair system for cars and their components

The main policy in the field of ensuring vehicle performance is a planned preventive maintenance and repair system.

The planned nature of the system includes scheduled maintenance, which ensures the prevention of unexpected (emergency) failure of the vehicle and regular receipt of information about its technical condition, and also assumes the planned operating time of units and vehicles before they are taken out for repair, as well as the volume of work during repairs, which helps to increase the rhythm of work of repair enterprises and optimize the conditions for their provision with materials, spare parts and other types of resources.

The preventive nature of the system lies in the fact that it allows repairs to be carried out on components and the vehicle as a whole before the period of forced wear of the basic and main parts begins. Further use of basic and main parts that have reached this stage of wear is directly related to the risk of accidents and inevitably leads to an increase in the volume, complexity and cost of repairs.

The vehicle repair system is a set of interacting repair tools, performers, strategy, technology and regulatory and technical documentation that ensure the operational condition of the rolling stock.

Repair facilities combine the production and technical base (buildings, structures, equipment) located at motor transport and specialized enterprises for the repair of rolling stock. Repair means are determined by the production and organizational structures of repair enterprises. The production structure of repair facilities as a system of automobile repair enterprises (ARE) reflects their functions, size, specialization and production relations with consumers of products and among themselves. The production structure of an enterprise, taken separately and not as a complex, reflects the nature, functions, size and relationships of production and warehouse divisions. The organizational structure of repair facilities provides for the interaction of enterprises and production units in accordance with the functions assigned to them, methods for assessing the performance of functions and rights that ensure the possibility of their implementation.

Performers are divided into main production and auxiliary workers, engineering and technical workers, accounting and office personnel, junior service personnel and fire guards.

A repair strategy is a system of rules that strictly determine the choice of decisions about the content, place and time of repair work or the method of writing off a car or its component.

Repair technology is all methods of changing the technical condition of cars and their components during the repair process.

Regulatory and technical documentation - contains principles, definitions, methods and standards designed to most effectively solve the problems of maintaining the performance of rolling stock of road transport.

There are two main types of repair strategies:

- by operating time, when the volume of disassembly of a product and defect detection of its components is determined uniformly for a fleet of similar products, depending on the operating time from the beginning of operation or after a major (medium) repair, and a list of restoration operations is developed taking into account the results of defect detection of the component parts of the product;

- by technical condition, when a list of operations, including disassembly, is developed based on the results of diagnosing the product before repair (pre-repair diagnostics), as well as based on data on the reliability of this product and similar products.

The experience of car repair shows that replacing their elements according to operating time does not provide high reliability and minimal costs for maintaining the operability of rolling stock due to the large variation in the operating time of elements before failure. Replacement based on operating hours, depending on the designated replacement frequency, can lead either to a significant underutilization of the element’s resource or to its unexpected failure. The repair strategy based on technical condition allows you to avoid this.

According to the purpose, nature and volume of work, current, medium and major repairs are distinguished.

Current repair (TP) is designed to ensure the working condition of the rolling stock with the repair or replacement of its individual units, components and parts (except for basic ones) that are in a limiting state. TP ensures trouble-free operation of repaired units, assemblies and parts over a mileage no less than to the nearest TO-2. Reducing vehicle downtime is achieved through the use of an aggregate repair method, in which faulty or in need of major repair units and assemblies are replaced with serviceable ones taken from the working capital. The revolving fund of car components can be created both directly at the ATP and at exchange offices, at regional central workshops and repair plants.

Average repair (CP) of cars is most often used when they are used in difficult road conditions; carried out at intervals of more than one year. During CP, the following repair work is performed: replacing an engine that has reached its limit state and requiring major repairs, troubleshooting other units with the replacement or repair of parts, painting the body and other work that would create the conditions for restoring the vehicle to good condition.

Major repairs (CR) of automobiles, assemblies and components are used to ensure a certain service life of the vehicle and its components by restoring their performance and close to full (at least 80% of pre-repair) restoration of the resource and ensuring other standardized properties. During a major overhaul, any components and parts, including basic ones, can be restored or replaced. Vehicles and units can, as a rule, be delivered no more than once for major repairs.

We used such a concept as “base part”. It is worth remembering that this concept is not the same for different vehicles. So, for example, the basic part of a car and bus is the body, of a truck is the frame. But we can also talk about “basic parts of units,” which are also individual for each car unit. The basic parts of the units include: in the engine - the cylinder block; in the gearbox, rear axle, steering mechanism - crankcase; in the front axle - a front axle beam or an independent suspension cross member; in the body or cabin - the body; There are longitudinal beams in the frame.

Overhaul of complete trucks, carried out centrally in a specialized auto repair enterprise, turns out to be insufficiently effective due to the fact that due to insignificant production programs and the universal nature of production, transport costs for the delivery of repair stock and products that have already undergone repairs increase significantly, vehicles to leave the field of exploitation for a long time. In this regard, the CR of complete vehicles should be produced mainly for those of them that operate in the most difficult road conditions with intensive and intense operation. At the same time, the CD and CP of cars should be as close as possible to the ATP and made using ready-made units, components and parts supplied to the auto repair shop from the corresponding repair plants that are in a cooperative relationship with this workshop.

There are situations when major repairs are not necessary. If the base part does not require repairs during the designated service life of the vehicle (unit) before write-off, then the resource is provided by replacing sets of faulty units and components with serviceable ones at the expense of the working capital.

There are planned and unscheduled repairs. This division arises from the nature of the repair.

Planned - repairs, which are carried out in accordance with the requirements of regulatory and technical documentation.

Unscheduled - repairs that are carried out without prior appointment. The need for unscheduled repairs arises in order to eliminate the consequences of failures.

According to the level of regulation of repairs, the following types of repairs are provided: regulated and according to technical condition.

Scheduled repairs are planned repairs carried out at intervals and to the extent specified in the operational documentation, without specific dependence on the technical condition of the product at the time of repair. Repair based on technical condition is a planned repair in which monitoring of the technical condition is carried out with the frequency and volume specified in the regulatory and technical documentation, and the volume and time of commencement of work are regulated by the technical condition of the product.

The repair method, based on the preservation of the belonging of the components to the product being repaired, can be non-impersonal and impersonal.

Non-impersonal method - with this method, the mutual wear-in of the parts, their original relationship is preserved, since this is a repair method in which the belonging of the restored components to a specific instance is preserved, i.e. to the instance to which they belonged before the repair. Thanks to this, the quality of repair is higher than with the impersonal method. The disadvantages of the non-impersonal repair method are that it significantly complicates the organization of repair work and, as a result, increases the time the product is under repair.

Anonymized method - with this repair method, the belonging of the restored components to a specific instance is not preserved. Units and components removed from vehicles are replaced, and faulty units and units are repaired and used to complete the working capital. Thus, the organization of repair work is simplified and the length of time vehicles and their components are under repair is significantly reduced. Due to the fact that repair objects do not wait until the units and components removed from them are repaired, time savings are achieved.

The aggregate method is a variant of the impersonal method of current repair. Failed units are replaced with new ones or pre-repaired ones. Replacement of units is possible after product failure or according to plan.

Other related articles:

- Car repair. General theoretical approach

- Reliability. Elements that determine reliability

- Basic concept of production, technological process and its elements

- Fighting noise in the car interior

- Electric sharpener from a generator

- Car body maintenance

- Spark plug. Part 2

- Installing an additional repair part

- Disadvantages of chrome coatings

- What is a marketplace and what are its advantages?

What documents are needed for maintenance?

To pass the technical inspection you will need:

- passport or driver's license;

- power of attorney for a representative if the owner of the car is not present at the maintenance;

- registration certificate, if not available - PTS.

The service station operator cannot require other documents from the driver.

After passing the technical inspection, a representative of the operating company signs and issues a diagnostic card to the driver. It will contain information about the condition of the vehicle.

What determines the service life of a car?

Unfortunately, a perpetual motion machine has not yet been developed. The only thing that the world leaders in car production can now offer is a longer service life of their products, of course, with timely maintenance and proper operation.

And the quality of the car and how you use it determine how long the time for its first repair will be delayed. And it doesn’t matter whether it’s a foreign car or a domestic car.

But foreign cars are still more durable than our cars. Galvanized bodies, metal quality, million-dollar engines, build quality, reducing the influence of the human factor on the assembly process, all this ultimately leads to one result, a high-quality, reliable car.

Repair of cars of this class is carried out very rarely and, as a rule, with the complete replacement of failed components and assemblies, which, unfortunately, cannot yet be said about our cars.

However, there is still one advantage: repairing domestically produced cars is much cheaper.

Let's figure out what types of repairs exist and give them a brief definition.

What is checked during a technical inspection?

Brakes and brake pads.

The operation of the brake system will be checked strictly according to the standards established by the Technical Regulations of the Customs Union. If there are any problems with the brake or brake pads, have them corrected immediately.

Lights and dimensions.

External lighting devices must be intact and clean. Headlights with improper bulbs, tinting, film and paint are considered a violation.

Power steering.

It shouldn't leak.

Wipers and glass washers.

All wipers and injectors should work. If a part for cleaning glass is indicated in the documents, the driver does not have the right to remove it. If the wipers are broken, they must be repaired before undergoing maintenance.

Studded tires.

If your car has studded tires, they must be on all wheels. You cannot put winter tires only on the front axle.

Engine.

A car will not pass inspection if there are oil, battery fluid or antifreeze leaks.

First aid kit and fire extinguisher.

The trunk should have a warning triangle, a first aid kit and a fire extinguisher. Medicines should not be past their expiration date.

List of car repairs - from current to major

With the introduction of mandatory maintenance for all cars, it has become much easier to identify current breakdowns that are not obvious, but affect the operation of the car and lead to serious breakdowns.

Maintenance

This is a type of repair that involves eliminating damage due to natural wear and tear or improper driving habits. So for the engine this could be tightening the bearings, changing the water pump, fan belt, liners. The transmission may require partial reassembly. In the rear axle, the hinge and keys have been replaced, and the bearings have been adjusted.

Medium renovation

This is an on-demand repair. This may include assembling and disassembling the clutch with replacing parts, washing components and parts of the rear axle or cardan drive. If the frame breaks, it may be necessary to reattach the brackets to it, change the bushings and pins of the springs, hinges, and footrests. But the most popular type of medium repair is engine repair.

The list of work to repair a car engine includes its removal and installation, while work at a car service center can cost a decent amount. This list also includes assembly and disassembly, pressing and boring of the cylinder block, grinding the crankshaft, replacing cylinder head valves and restoring the pressure plane, lapping it, replacing the pressure group and all consumables - engine gaskets, oil, spark plugs, belts.

How to change the steering cardan

Major car repairs - list of works

Major repairs are carried out as needed, during which it is necessary to disassemble all parts and components, identify unusable ones and replace them with new ones in all parts of the car. There are specifications, no earlier than the mileage at which the car may require major repairs. So for internal combustion engines the threshold is set at 250,000 km. The list of capital works may include the following list.

Car repair: list of works

- Engine repair

- Manual transmission repair

- Suspension repair

- Timing belt replacement

- Replacing brake pads

If any part or part of the car cannot be repaired, it must be written off. In a car service, each written-off part must be accompanied by a report that contains data about the car and a list of defects for write-off for car repairs. It is advisable to indicate the reasons and nature of the breakdowns so that write-off is justified for the owner. Opposite the defects, measures to eliminate them are indicated, as well as the estimated time frame with the signature of the repairman. A defective certificate must be issued for any major repair; do not forget to ask for it at car services.

Service Checklist

If you want to do basic maintenance on your car, here is a list of components that you should check:

Change of oil

Raise the car with a jack, unscrew the engine oil pan plug, make sure you remove the oil pan cap and place a suitable drain pan underneath to catch the used oil.

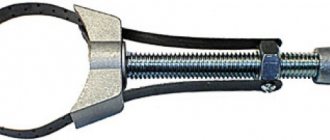

Then remove the oil filter using a special puller and wait until all the oil has drained. After this, insert the new filter in place of the old one, lightly moistening the rubber seal with oil to seal it.

Reinstall the pan plug, not forgetting to first update the washer around the plug. Then, using a funnel, you need to slowly pour in new oil, while checking with a dipstick so as not to overfill.

Run the engine for 10 minutes to allow the oil to circulate, then check that the filter and pan plug are not leaking. Stop the engine and wait until the oil level stabilizes. Then, using the dipstick, make sure the oil level is at its maximum.

Tire pressure

Incorrect tire pressure can result in loss of performance, tire wear and poor handling. Therefore, correct pressure is an important part of basic maintenance.

Also, you should definitely check the condition of the tires, making sure that they are not too worn, and that the tread depth meets the requirements of the rules.

Replacing Automotive Fluids

In addition to changing the engine oil, during basic maintenance you should check the levels of all other fluids:

- brake fluid;

- engine coolant;

- power steering fluid;

- windshield washer

Replacing spark plugs

Some manufacturers recommend replacing spark plugs every 30,000 miles, but keep in mind that there are other recommendations depending on engine type or manufacturer, so consult the service literature for your vehicle.

If your car won't start or vibrates a lot, you most likely need to replace the spark plugs.

First, the tip of the high voltage wire is removed. Before you start unscrewing the old spark plugs, you need to thoroughly clean the spark plug wells of dirt so that debris does not get into the cylinders. Insert the new spark plugs into the socket and tighten first by hand, and then tighten the threads with a torque wrench to the torque specified in the technical documentation.