How does it all work?

Ignition of the fuel-air mixture in the cylinders of a diesel engine occurs at temperatures of 800–850 °C. When the engine is warmed up, such indicators, at the moment of the compression stroke, are achieved instantly and the diesel engine starts without failure.

But when the car is not warmed up, it is difficult to achieve such a temperature only by compressing the mixture, especially in cold weather - starting the engine is problematic.

To solve this problem, glow plugs were installed in diesel engines, the task of which is to very quickly warm up the air in the cylinders to 75 degrees and thereby ensure the desired temperature at the moment of the compression stroke.

Inside the products, two spirals are structurally provided - heating and regulating.

The first one has a heating function. The second, due to floating electrical resistance, protects the glow plug from overheating.

The spark plugs will work until the coolant temperature goes above 60°C, this is about 3 minutes. Then the motor will be able to work without them.

Before starting the car, you must turn on the ignition and pay attention to the instrument panel. The glowing spiral indicator indicates that the glow plugs are heating up

As soon as the light goes out, you can start the car.

In modern cars, the spiral lamp may not light up. This will happen if the engine is already warmed up, which means there is no need for glow plugs. All this is achieved thanks to modern electronics that monitor the temperature indicators of the motor.

There are also glow plugs that maintain the temperature for a long time after warming up, and therefore turn off immediately after the starter is turned off and heat the air in the diesel cylinders due to residual heat.

The devices are very energy-consuming; heating one glow plug to 850-1350°C in half a minute can take an average of 8-16A (96-192 W), sometimes 40A. The amount of voltage and the time it is supplied are controlled by an electronic unit and a thermal relay (switch).

The latter, if necessary, only closes and opens the circuit, thereby setting the desired air temperature in the cylinders. And the ECU regulates the entire heating process by sending signals to the relay. It takes the necessary information from the crankshaft and coolant sensors.

The first sign indicating that one of the glow plugs has failed will be the re-ignition of the indicator in the form of a spiral after starting the engine and its prolonged burning (about 50 seconds).

If after the specified time, after warming up the car, the indicator does not go off, then the time relay (thermal switch) has failed.

It is important to replace the device immediately, otherwise the glow plugs will fail due to burnout of their heat pin

If it is still relatively warm outside (above +5°C), then you are unlikely to notice the output of one or two products; the car will still start.

Otherwise, when the thermometer scale approaches zero and below, even with one faulty spark plug, starting the car when cold is problematic. This can only be done if it is heated to 60°C or more.

Glow plug control

The heating rod is cooled by the flow of the fuel-air mixture on the supply stroke and the air flow on the compression stroke. A decrease in temperature occurs with increasing speed, and an increase occurs with stable engine operation. To compensate and regulate these processes, modern cars use an electronic engine control unit (ECU), which supplies the spark plug with a voltage that optimally matches the current operating mode of the engine.

In addition, the ECU can carry out extreme heating of the glow plug (in the shortest possible time intervals of up to 2 seconds). The most advanced systems provide the ability to independently control each spark plug using semiconductor elements, which also simplifies the process of diagnosing their condition.

Useful tips

- Before the onset of the cold season, the glow elements should be checked regardless of whether the diesel engine starts well or poorly.

- Checking on a diesel engine by assessing the spark is recommended only for older cars. You should not test heating solutions in this way on a “fresh” model, which is equipped with a complex electronic engine control system.

- If a malfunction is detected, it is optimal to replace the entire set, rather than one or two failed elements.

- Try to purchase products from well-known manufacturers, since cheap solutions have a noticeably shorter service life and often demonstrate low efficiency of the heating element.

Finally, we would like to add that in order to reliably start a diesel engine in winter, it is necessary to correctly select, charge and maintain a diesel battery, refill high-quality diesel fuel according to the season, and use anti-gels if necessary. Also, in the case of diesel engines, it is advisable to install a diesel fuel pre-heater or a Webasto-type engine pre-heating system.

Signs of a non-working cylinder (tribbing and vibration) of a diesel engine. Troubleshooting: compression, diesel injectors, glow plugs, injection pump and others.

How to replace glow plugs on a diesel engine yourself. Necessary tools, features of removing spark plugs, important tips and recommendations.

Independent implementation of diesel fuel heating: fuel intake, coarse and fine filters. Installation of heating elements. Flow heating.

Choice of spark plugs between NGK and Denso manufacturers. How to choose candles and which brand to choose. Features and nuances during selection.

What you need to know when selecting spark plugs according to your car model: size, heat rating, interchangeability. Choosing candles by design, useful tips.

Purpose and design of spark plugs for a gasoline engine. Design features, types of spark plugs. Heat number, spark gap.

Glow plugs for diesel engines in Yekaterinburg

Glow plugs for a diesel engine are significantly different from spark plugs for gasoline, as they operate according to completely different patterns. The glow plug for a diesel engine is not used to ignite the mixture of air and fuel, as happens in a gasoline unit; the mixture will ignite due to compression. When diesel fuel enters the chamber, the sucked air mass, due to compression, heats up to 900 degrees. Which starts the combustion process. But! Such an engine is very sensitive to frost, while the “winter period” begins at quite warm +5. It is because of this factor that there is a need for a source that will help the mixture ignite at low temperatures. If we remember about spark plugs for a gasoline engine, then everything is simple. Depending on the characteristics of the engine, different “warmth” and heat ratings are required. A diesel engine has 2 types of glow elements:

How to check glow plugs on a diesel engine at home?

In winter, owners of diesel cars rely on glow plugs, which help start a cool engine. But situations often occur when even these “assistants” do NOT cope with the task assigned to them, and starting a cool engine on a frosty winter morning becomes simply impossible. Now I will talk about why this happens, how to deal with it, and also the most important thing. how to check glow plugs on a diesel engine at home, using 3 different methods.

As you understand, glow plugs. are very important for a diesel engine, especially when the temperature drops below 0 ° C. This invention makes heating the combustion chamber essential, so ignition of the fuel mixture in the cylinders becomes possible even at very low temperatures.

Modern diesel engines have more advanced heating systems, which cannot be said about old diesel engines. Once upon a time, diesel engines used glow plugs almost every time they started, despite the fact that there was no particular need for this, especially in the summer. For example, modern diesel engines start successfully even without glow plugs.

The glow plugs must be turned on at a certain temperature, and the corresponding indicator lights up on the device panel. What to do when this doesn't happen? Of course, inspect what's going on. How to check glow plugs.

The principle of operation of glow plugs in a diesel engine

The glow plugs in a diesel engine start automatically when the key is turned in the ignition switch. The duration of operation of the glow plugs is determined by the engine temperature sensor. As soon as the turbodiesel is completely warmed up, the glow plugs are turned off.

The table below shows the algorithm for the operation of glow plugs in a diesel power unit.

| Action | Description |

| Turning the starter key | Electric current is supplied to the glow plug |

| The glow plug status indicator light on the instrument panel lights up | In the winter season, it is necessary to hold the key in the ignition switch to ground; the glow plugs have heated the combustion chamber. While the control lamp is on, the glow plugs heat up; as soon as the control lamp goes out, this means that you can start the engine with the starter. |

| Starting the engine with the starter | After 15-30 seconds of glow plugs working, we can start the turbodiesel. |

| Glow plugs run for three minutes after starting the engine | After starting the engine with the starter, the glow plugs operate for three minutes to ensure uninterrupted operation until the engine is completely warmed up. |

Test methods (diagnostics)

Many diesel car owners will say that the weak link in their car is the glow plugs. And this is not far from the truth.

These products really often fail, and the breakdown could have occurred in the summer, but it would appear in the winter, when the car stopped starting in cold weather.

Before diagnosing a malfunction, it is important to understand the principle by which diesel heating works in your car. At the moment there are two of them:

At the moment there are two of them:

- Turning on the glow plugs every time you start the engine is typical for older diesel engines.

- Periodic activation of heating elements depending on the temperature of the engine and the air supplied to the system.

It is also important to understand what types of glow plugs are installed, rod or ceramic. If your car meets environmental standards up to Euro 4, then most likely the diesel engine has rod heating elements

If Euro 5, 6 - ceramic

If your car meets environmental standards up to Euro 4, then most likely the diesel engine has rod heating elements. If Euro 5, 6 - ceramic.

The latter have many additional features, the main ones:

- Intermediate glow function, with which the DPF particulate filter is regenerated.

- Pre- and post-start heating – ensures that the fuel burns out in a cold engine.

To check glow plugs, for example, on Renault Megane 2 station wagon 1.5 86 hp, Ford Mondeo 2 1.8 90 hp, Ford Transit 2.2, Renault Laguna 3 or other cars with diesel engines, you can use several methods. Moreover, the approach to checking will be the same regardless of whether they are removed from the engine or standing still.

Verification methods:

- BY VISUAL INSPECTION. The integrity and condition of the relay and wiring are checked, and after removal, the product itself is checked;

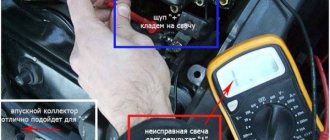

- USING A TESTER (MULTIMETER). The winding resistance or its breakage is checked.

- SPARKING. It is not used on new diesel engines with an ECU, since the latter may fail.

- USING A 12V BULB. A simple way to check for a broken spiral.

For quick diagnostics, provided you have access to the glow plugs and a multimeter, you can measure their resistance. You need to check it when it is cold. The advantage is the presence of a non-contact ammeter (induction type). Indicators should vary from 0.6 to 4.0 Ohms. A new spark plug may have 0.7-1.8 ohms.

If your tester does not show such a low resistance, then you can check for a break in the spiral - readings to infinity (1) will indicate this.

Also, many multimeters support the sound signal function when the wiring is ringing - there is a sound, which means the spiral is intact.

Despite the results obtained, an external inspection of the spark plugs is recommended, especially if the car’s mileage has exceeded 50 thousand km. The presence of tip deformation, melting, and soot deposits are unacceptable.

If the results of preliminary diagnostics are disastrous for all glow plugs at once, then most likely, a complete diagnostic of the electrical equipment included in the heating system will be required, since the simultaneous failure of all products indicates a global malfunction.

To check glow plugs on a diesel engine, in addition to visual inspection, you must use all the methods described below.

Each of them will require the presence of certain instruments and knowledge in electrics, but if you repair electrical wiring yourself at home at a household level, you will figure it out here too.

Also read how to diagnose a car using a laptop.

Design features of various types of candles

These structures can be made of either closed ceramics or open metal. The heating element is made in the form of a spiral.

Metal pin structures have spirals: heating and adjustment. Thanks to the first, rapid heating occurs, the second serves to protect the structure from overheating.

The composition of ceramic parts is more complex:

- Metal body.

- Heating tube.

- Connecting bolt and nut.

- Adjustment spiral.

- Ceramic filling.

- Central electrode.

- Threaded part.

Ceramic parts are preferred due to their ability to produce heat quickly and provide very high temperatures.

Under the influence of electric current, the coil heats up. The high temperature in the motor prevents the element from heating above 850°C; heating lasts for a short time: from 4 seconds to 2 minutes. The duration of heating is monitored by an electronic control unit, which monitors the temperature of the coolant through special sensors.

While heating continues, the control light located on the instrument panel lights up. Turning off the lamp indicates that the engine is completely ready to start.

The glow plugs continue to work after the engine is turned on, continuing to warm up and ensuring the most complete combustion of the air-fuel mixture, reducing harmful emissions.

Glow plug connection diagram and signs of malfunction

In principle, they can be compared to an electric heater. The spark plug rod is located in the pre-chamber in such a way that its tip is located directly on the border of the vortex of the working mixture created by the nozzle. The glow plug connection circuit provides automatic supply of electric current immediately after turning the ignition key to the operating position. They heat up themselves to a very high temperature and, accordingly, warm up the combustion chamber, as well as the air entering it.

The glow plug control unit is responsible for their proper functioning. The algorithm for its operation is as follows: after turning the key, the spark plugs are connected directly to the battery, at the same time the corresponding light on the instrument panel lights up, after some preheating time this light goes out, which indicates that the engine is completely ready to start.

The first sign that there is a failure in the electric heating system is a non-working indicator. This may indicate a failed fuse or temperature sensor. If the indicator burns for a long time, it indicates the need to replace the thermal switch, and if this is ignored, the thermal pin may burn out, and then the glow plugs will need to be replaced. True, the indicator sometimes may not signal a possible breakdown.

How do glow plugs work?

To find out how to check the glow plugs in a diesel engine without removing them, you need to familiarize yourself with the operating principle of these elements. And they, unlike their analogues for gasoline engines, function somewhat differently. The same can be said about their appearance - nothing in common. And if in units running on gasoline, a spark from a spark plug ignites the working mixture, then in diesel engines the fuel ignites due to pressure.

But there is also one nuance here: if it’s cold outside, the engine will not start, which is facilitated by cold air entering the working chamber. In this case, starting is difficult and the car needs to be warmed up. On older cars, the glow plugs come on every time the engine is started. In modern models they are not always activated, but only at negative temperatures.

The maximum temperature of the spark plug tip is 1350°C. There are two spirals inside it:

- heating;

- regulating.

With the first, everything is clear - it provides heating. The function of the latter is protective in nature, since it protects the spark plug from overheating as the temperature rises. This is done by increasing electrical resistance.

Glow plug design

Anyone who has held a boiler or heating element from a water heater in their hands will immediately understand the principle of operation of a diesel glow plug. By the way, the first glow candles had an open spiral and actually looked like a mini-boiler. The heating coil of modern candles is covered with a durable rod body (usually steel, sometimes ceramic) filled with magnesium oxide - magnesia. When an electric current passes, the spiral heats up, giving off heat to the rod, which transfers heat to the air in the combustion chamber and the fuel-air mixture, helping it ignite. The tip of the rod is located exactly in the place of the combustion chamber where turbulence of the mixture is formed when fuel is injected by the nozzle.

Plug with open heating element and modern rod glow plug

The warm-up time for the first glow plugs in the 1920s was an endless 180 seconds - a full 3 minutes for the driver to wait for the plugs to reach operating temperature to start the engine! Modern candles with a steel rod heat up completely in less than 10 seconds (record holders - in 4 seconds), and the temperature of the rod reaches 800–1000 °C.

Candles with ceramic rods are even more effective: warm-up in 2 seconds and a maximum temperature of 1350 °C. Such spark plugs are used in highly accelerated diesel engines that meet the most stringent environmental requirements. But the cost of ceramic candles in comparison with classic steel ones is noticeably higher.

Disconnect the terminals

In fact, the first step in the replacement itself assumes that you disconnect the negative terminal from the battery. This will require unscrewing several small nuts that secure the tips of the high-voltage wires to the contact rods of the glow plugs. The wire is connected to the spark plug from above. The nut unscrews instantly: all you need is a wrench; It is recommended to move the wire itself a little, since otherwise it will interfere with further work.

Design features of various types of candles

These structures can be made of either closed ceramics or open metal. The heating element is made in the form of a spiral.

Metal pin structures have spirals: heating and adjustment. Thanks to the first, rapid heating occurs, the second serves to protect the structure from overheating.

The composition of ceramic parts is more complex:

- Metal body.

- Heating tube.

- Connecting bolt and nut.

- Adjustment spiral.

- Ceramic filling.

- Central electrode.

- Threaded part.

Ceramic parts are preferred due to their ability to produce heat quickly and provide very high temperatures.

Under the influence of electric current, the coil heats up. The high temperature in the motor prevents the element from heating above 850°C; heating lasts for a short time: from 4 seconds to 2 minutes. The duration of heating is monitored by an electronic control unit, which monitors the temperature of the coolant through special sensors.

While heating continues, the control light located on the instrument panel lights up. Turning off the lamp indicates that the engine is completely ready to start.

The glow plugs continue to work after the engine is turned on, continuing to warm up and ensuring the most complete combustion of the air-fuel mixture, reducing harmful emissions.

Features of the operating principle

The standard glow plug is an immersion-type electric heating element with a spiral resistor. The core part of the spark plug is located inside the combustion chamber, and its end is located at the boundary of the working fuel mixture. When you turn the key and turn on the starter, the glow plug is connected automatically, and the indicator light on the instrument panel lights up. In the process of heating the glow plug to high temperatures, the combustion chamber and incoming air masses are heated.

Five seconds of glow from a candle, in an unheated state, is enough solely to independently warm up the element, and the problem of heating the air in this case is caused by cold air masses coming from outside. The main purpose of heating a glow plug is to heat the fuel to the optimum levels required for compression ignition. As soon as the temperature rises to a predetermined level, the indicator light on the panel immediately goes out, but the voltage supply to the spark plug remains.

At the moment of engine start-up, the fuel injected through the injectors becomes very hot and, in the process of mixing with air masses, easily evaporates, and compression allows the fuel-air mixture to self-ignite. A malfunction of the spark plug elements is accompanied by a lack of such ignition, so the diesel engine does not start immediately, or may not start at all. When the engine is running, glow plugs play a secondary role as an element of the fuel atomization system and improve the prepared working mixture.

IMPORTANT: A glow plug is a solid body characterized by very good thermal conductivity, and the design features and material of such a diesel element directly depend on the typical characteristics of the engine, voltage and resistance parameters, heating level and some other important criteria.

How to check glow plugs on a diesel engine? There's an answer!

Glow plugs are a very useful and necessary invention for owners of diesel engines.

Thanks to these heating devices, starting a diesel engine in winter occurs without any problems. However, even this, at first glance, “frost-resistant” invention often malfunctions or breaks down. Today in the “Useful Tips” section - glow plugs. In this article you will learn how to test glow plugs in three different ways.

Glow or glow plugs, or glow plugs, whichever suits you, are, as I already said, a very important invention. Thanks to these “miracle spark plugs”, starting a diesel engine in winter occurs without much difficulty, so to speak, “with a bang”

The task of the candles is quite banal and simple - heating the combustion chamber to facilitate the first start of the engine. Modern glow plugs are significantly different from their “ancestors”. The first glow plugs were activated every time the engine was started; modern analogues are able to analyze the ambient temperature and do not turn on unnecessarily (in summer, for example). Before checking the glow plugs, you need to clearly know the principle of operation of the spark plugs in your car, so that God forbid, working plugs are not “recorded” as non-working. As a rule, the inclusion of glow plugs is signaled by a special indicator in the form of a spiral on the instrument panel.

Methods for checking glow plugs1. Checking glow plugs using the battery.

This test method allows you to understand the cause of the malfunction of the heating elements. The principle is as follows: each glow plug is unscrewed and checked separately, and its external technical condition is analyzed, as well as its performance. The disadvantages include the need to unscrew the glow plugs; for some car models this is quite a big problem.

So, to check you will need a battery and a piece of wire half a meter long.

We take the glow plug, turn it over with the heating element facing up, then connect the central electrode of the spark plug to the “+” battery, and connect a piece of wire to the body of the spark plug and the “-” battery. If at the same time you see that the candle heats up quite quickly and evenly by more than half, you can conclude that the glow plug is in order. If the spark plug heats up slowly, or only the tip heats up, the spark plug is most likely faulty.

Video - how to check glow plugs on a diesel engine

https://youtube.com/watch?v=ixLCDINEwj0

2. The second method will require a multimeter or ohmmeter.

Turn on the device in the resistance testing position (ohmmeter). Disconnect the power supply to the glow plug. We connect the positive electrode of the multimeter to the central electrode of the glow plug, and connect the second negative electrode to the body of the glow plug. Let's look at what the device shows: if the needle moves and has not deviated from the zero mark by a single division, most likely there is a breakdown in the heating element. Such a breakdown can be treated by replacing the glow plug. The disadvantage of this testing method is that it allows you to detect only a completely “dead” glow plug; it will not be possible to detect a weak glow of the heating element using this method.

3. The third method is to check the “spark” of the glow plug or check for spark formation.

Yes, that’s not a typo, these spark plugs are also tested for spark. The method is old, but very effective, because it allows you to check the degree of sparking of glow plugs. To check, you need to have a piece of wire (half a meter to a meter), the ends of which will be stripped on both sides (remove 2-3 cm of insulation on each side). We remove the glow plugs and turn off the power. After this, we connect one end of the wire to the “+” of the battery, and with the other end we quickly make a tangential movement along the central electrode of the glow plug. In short, touch should be similar to striking matches on a matchbox. During the test, a working heating element should exhibit a strong spark. If the spark is weak, the glow plug heats up slightly and may soon fail completely. A completely “dead” glow plug will not produce any spark at all. The disadvantage of this test is that on new cars “stuffed” with electronics, this method can damage the ECU. Therefore, before checking the glow plugs for a spark, make sure that this method will not harm your car.

Video - how to check glow plugs for spark

https://youtube.com/watch?v=PP4aCPuPg44

Replacement

to take on the task of replacing glow plugs in diesel engines that have not been removed from their seat for more than three years. There are reasons for this. The thread sticks to the wells, thereby creating a strong connection. Added to everything is the length and thinness of the rod. It’s unlikely that you’ll be able to immediately take the key and unscrew it. It will be necessary to treat the threads with penetrating lubricants and solvents. Therefore, you need to do everything carefully and without haste.

Post Views: 880

Checking JMC glow plugs

For a diesel engine, winter begins when the thermometer drops to + 5 °C. Only up to this air temperature is it possible to somehow start a diesel engine with non-working glow plugs. At lower temperatures this is impossible, even if only one spark plug is acting up.

So, jmc glow plugs must provide the temperature in the combustion chamber necessary for normal mixture formation and self-ignition. It must be said that the spark plugs cope with their task quite effectively, especially on vortex and pre-chamber diesel engines.

The operation of the JMC glow plugs is “signaled” by an indicator on the instrument panel, which should light up and go out after a while, as if indicating that the air in the combustion chamber is ready to receive a portion of diesel fuel. Experience shows that you should not trust this indicator. It can light up even if the fuse has blown and the spark plug control unit relay has not activated.

You can check the jmc spark plug without removing it from the engine using a conventional tester: to do this, you need to set the tester to resistance measurement mode; Connect one terminal of the tester to the vehicle ground, the second to the spark plug terminal. Lack of contact means the spark plug is faulty. It should be replaced.

Why do you need a spark plug for a compression ignition engine?

To help the engine start at temperatures around zero and below, you can preheat the air in the combustion chamber. To do this, electric heaters are placed in it in the form of an incandescent filament, protected by a fireproof housing, which heats up to a red-white glow. Despite the large volumes of cold air and the environment in the form of metal walls of the head and block with a low temperature, this method turned out to be quite effective. If you do not apply voltage to the spark plugs, the engine does not flash at all, but if you warm them up for a few seconds, it starts up confidently.

Checking the removed spark plug

Apply voltage from the battery positive to the spark plug terminal, and the spark plug body to ground. With a working spark plug, the glow tube heats up immediately. After 10 seconds it becomes hot and begins to glow, otherwise the candle should be replaced.

While glow plugs on passenger diesel engines are found everywhere, more efficient pre-heaters that are so necessary in winter are extremely rare. And this is understandable, because most diesel foreign cars are designed for the climate of Central Europe and are absolutely not adapted to our winters. Cars from Scandinavia, as well as German and French ones, aimed at our market, are much better prepared for operation in winter conditions and have a number of “highlights” in their design in this regard, including pre-heaters. Even if they are installed for an additional fee, but paired with a timer, such a heater works wonders - the car “comes to life”, as if an alarm clock is ringing. When the owner arrives, everything is ready for the trip: the engine is warm, the interior is warm, there is no need to scrape ice off the windows, etc.

Glow plug design

Heaters have different designs and are made of different materials, but their structure mainly consists of the following elements:

- Fastening the power wire to the central rod;

- Protective shell;

- Spiral electric heater (in some modifications there is also an adjustable spiral element);

- Thermally conductive filler;

- Retainer (thread allowing the element to be installed in the cylinder head).

Regardless of the design, their operating principle is similar. The adjusting spiral maintains the operating temperature in the cavity. The resistance in this element directly affects the heating of the tip - as the temperature in this circuit increases, the current flowing to the heating coil decreases. Thanks to this design, the glow plug does not fail due to overheating.